High-stability sand-in-water multicolor paint and preparation method thereof

A high-stability, multi-color paint technology, applied in the field of paint, can solve the problems affecting the overall board, color point color development, hardening and brittleness, etc., to achieve the effect of enhanced compatibility and improved tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

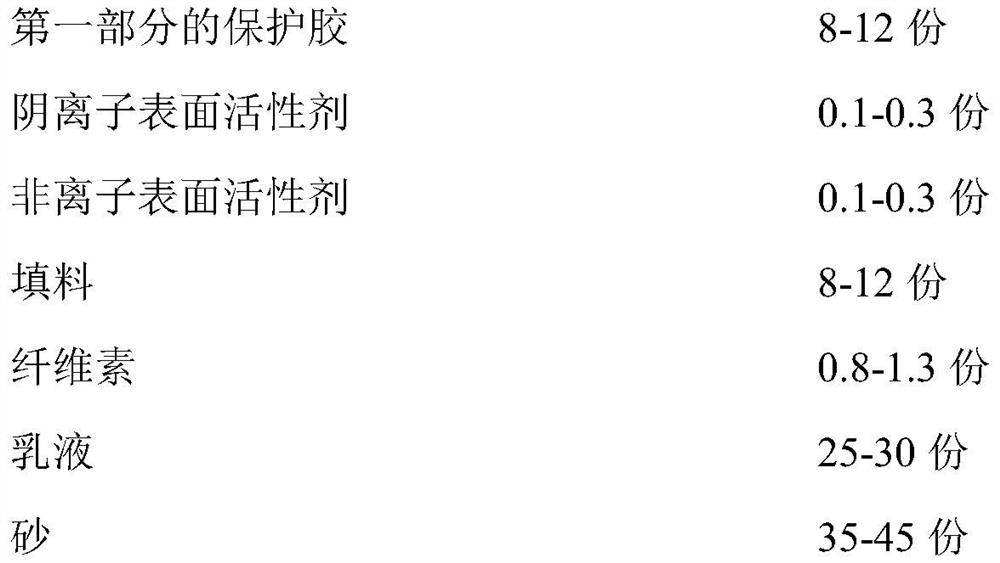

[0041] A sand-in-water colorful paint with high stability, comprising the following components in parts by mass:

[0042] 60 parts of sand base paint;

[0043] 20 parts of continuous phase emulsion;

[0044] The second part of the protective glue 20 copies;

[0045] Wherein, the sand-containing base paint includes the following components in parts by mass:

[0046]

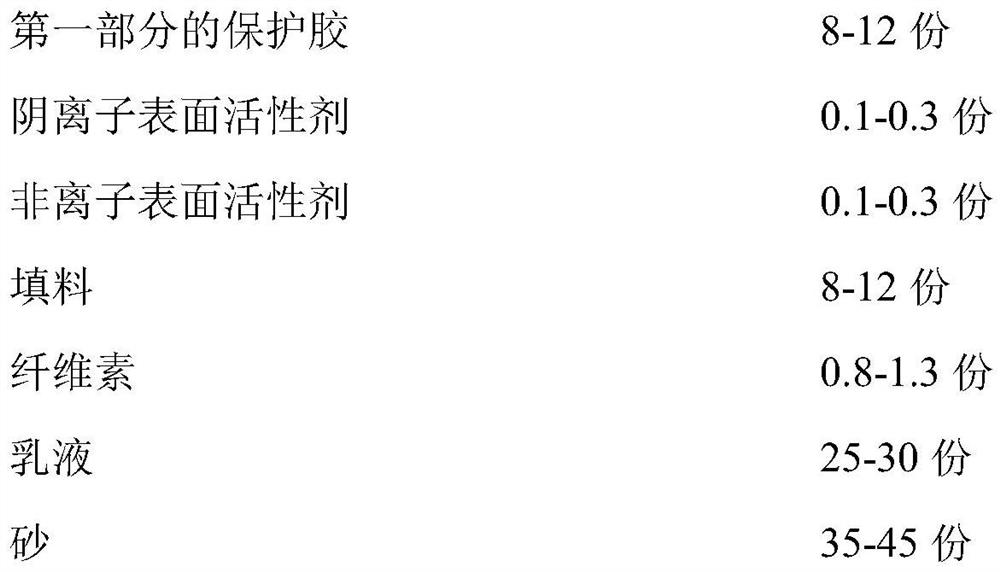

[0047] The continuous phase emulsion includes the following components in parts by mass:

[0048]

[0049]

[0050] The first part of the protective glue and the second part of the protective glue are both 10 wt % aqueous solution of magnesium lithium silicate.

[0051] The preparation method of the above-mentioned sand-in-water colorful paint is:

[0052] According to the above-mentioned parts by mass, the protective glue is divided into two parts, namely the first part of the protective glue and the second part of the protective glue;

[0053] Preparation of sand base paint:

[0054] According to ...

Embodiment 2

[0060] A sand-in-water colorful paint with high stability, comprising the following components in parts by mass:

[0061] 45 parts of sand base paint;

[0062] 25 parts of continuous phase emulsion;

[0063] The second part of the protective glue 25 copies;

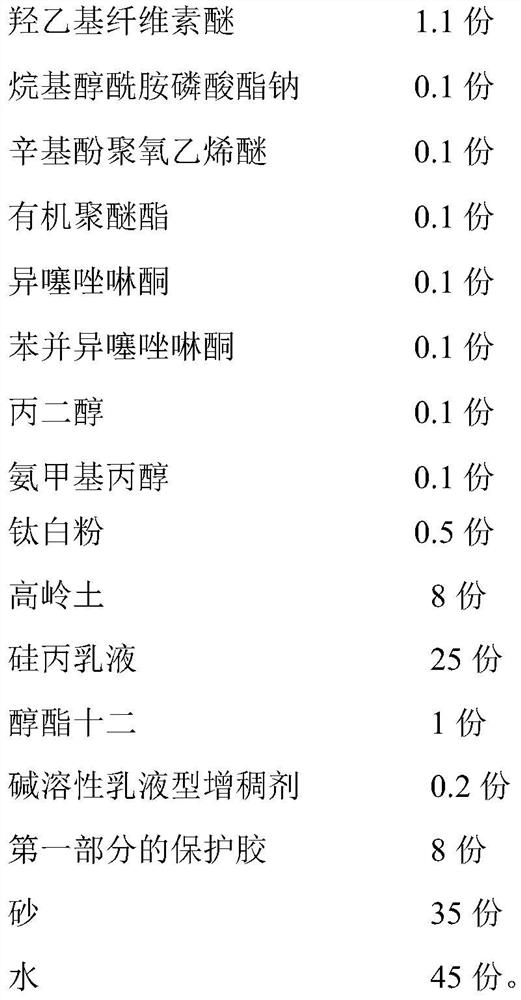

[0064] Wherein, the non-sand base paint includes the following ingredients in parts by mass:

[0065]

[0066]

[0067] The first part of the protective glue and the second part of the protective glue are both 10 wt % aqueous solution of magnesium lithium silicate.

[0068] The continuous phase emulsion includes the following components in parts by mass:

[0069]

[0070] The preparation method of the above-mentioned sand-in-water colorful paint is the same as that in Example 1.

Embodiment 3

[0072] A sand-in-water colorful paint with high stability, comprising the following components in parts by mass:

[0073] 50 parts of sand base paint;

[0074] 22 parts of continuous phase emulsion;

[0075] The second part of the protective glue 22 copies;

[0076] Wherein, the non-sand base paint includes the following ingredients in parts by mass:

[0077]

[0078]

[0079] The first part of the protective glue and the second part of the protective glue are both 8 wt % modified aqueous solution of magnesium lithium silicate.

[0080] The continuous phase emulsion includes the following components in parts by mass:

[0081]

[0082] The preparation method of the above-mentioned sand-in-water colorful paint is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com