Water-based paint for multifunctional fiber textile and preparation method thereof

A multi-functional, fiber technology, applied in the field of coatings, can solve the problems of rough surface of fabrics, affecting comfort, affecting aesthetics, etc., to achieve the effect of fluffy volume, easy dispersion, convenient and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

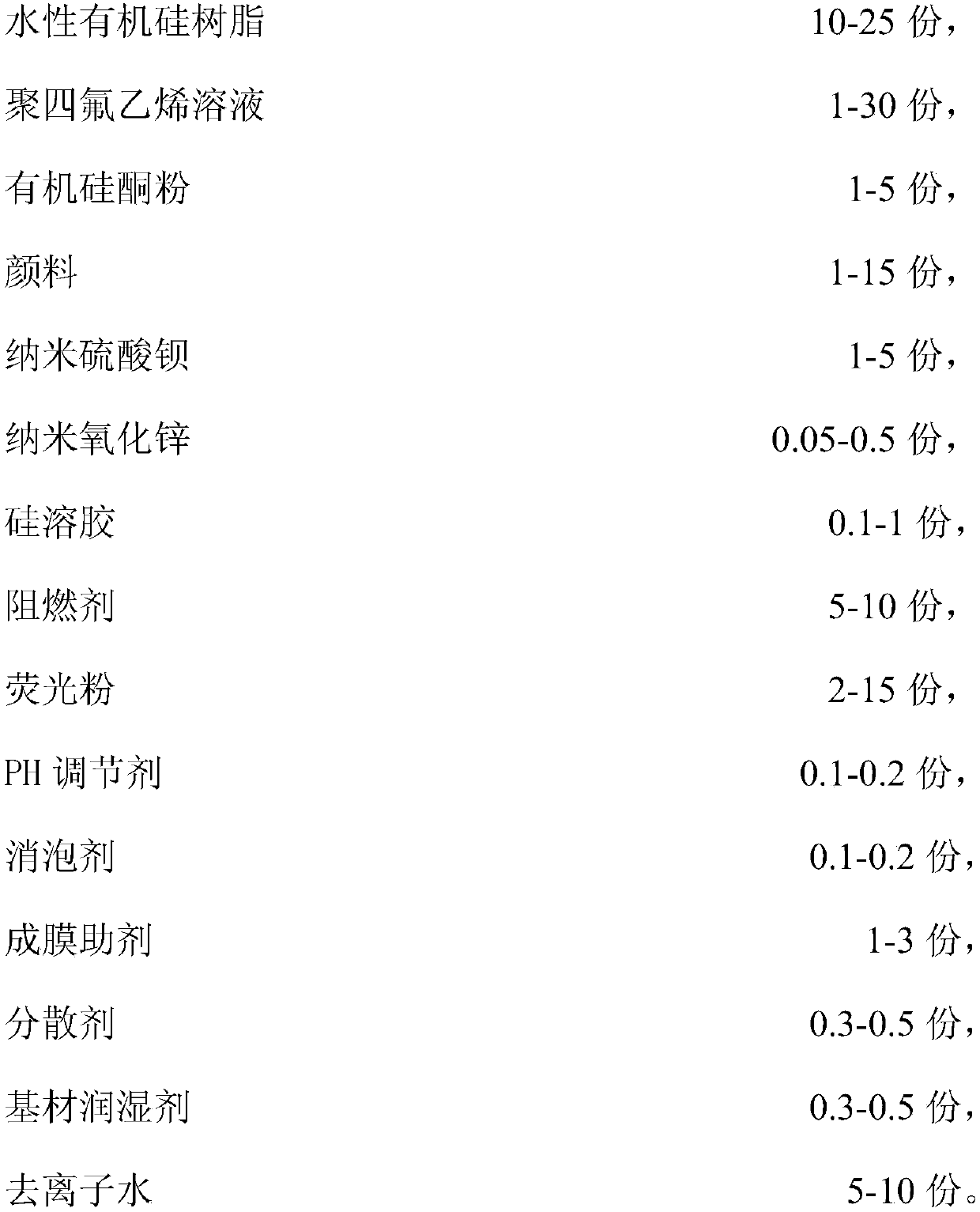

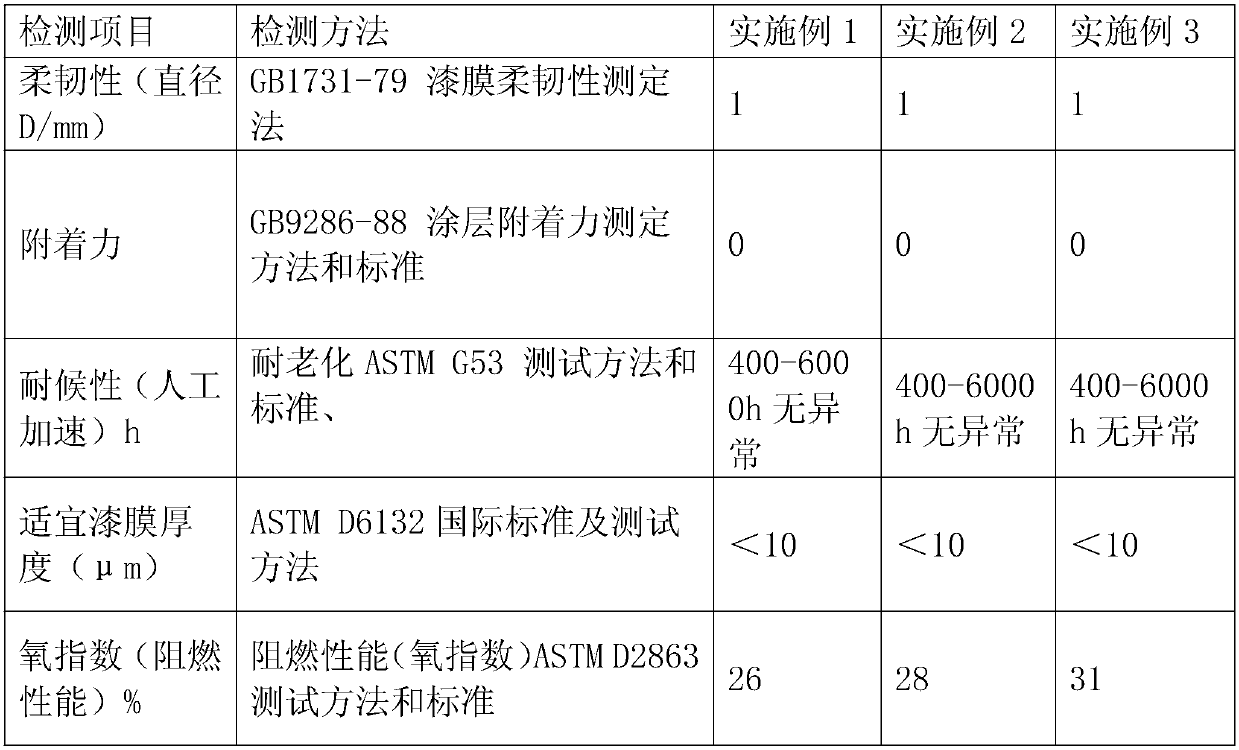

[0050] A water-based paint for multifunctional fiber textiles, which comprises the following raw material components in parts by mass: 10 parts of water-based silicone resin, 1 part of polytetrafluoroethylene solution, 1 part of organic silicone powder, 1 part of pigment, and nanometer sulfuric acid 1 part of barium, 0.05 part of nano-zinc oxide, 0.1 part of silica sol, 5 parts of flame retardant, 2 parts of fluorescent powder, 0.1 part of pH regulator, 0.1 part of defoamer, 1 part of film-forming aid, 0.3 part of dispersant, 0.3 parts of substrate wetting agent, 5 parts of deionized water.

[0051] Wherein, in this embodiment, the polytetrafluoroethylene solution is American DuPont DISP 30 polytetrafluoroethylene emulsion; the water-based silicone resin is JY8742 water-based silicone resin of Dongguan Junyi Chemical Technology Co., Ltd.; organic silicone powder It is BT-9273 silicone powder from Guangzhou Batai Chemical Co., Ltd.; the pigment is superfine pigment from Suzhou ...

Embodiment 2

[0056] A water-based paint for multifunctional fiber textiles, which comprises the following raw material components in parts by mass: 15 parts of polytetrafluoroethylene solution, 20 parts of water-based silicone resin, 3 parts of organic silicone powder, 8 parts of pigment, nanometer sulfuric acid 3 parts of barium, 0.3 parts of nano-zinc oxide, 0.5 parts of silica sol, 7 parts of flame retardant, 10 parts of fluorescent powder, 0.2 parts of pH regulator, 0.1 part of defoamer, 2 parts of film-forming aid, 0.4 part of dispersant, Substrate wetting agent 0.4 parts, deionized water 5 parts.

[0057] Wherein, in the present embodiment, the polytetrafluoroethylene solution is U.S. DuPont DISP 30 polytetrafluoroethylene emulsion; the pH regulator is the multifunctional auxiliary agent AMP-95 of Dow Chemical Industry in the United States; 941PL and silicone defoamer (BAK company) BYK's defoaming additive BYK024, the two types of defoamers are mixed at a ratio of 1:1.1; the substrat...

Embodiment 3

[0062] A water-based paint for multifunctional fiber textiles, which comprises the following raw material components in parts by mass: 30 parts of polytetrafluoroethylene solution, 25 parts of water-based silicone resin, 5 parts of organic silicone powder, 15 parts of pigment, nanometer sulfuric acid 5 parts of barium, 0.5 parts of nano-zinc oxide, 1 part of silica sol, 10 parts of flame retardant, 15 parts of phosphor, 0.2 parts of pH regulator, 0.2 parts of defoamer, 3 parts of film-forming aid, 0.5 part of dispersant, Substrate wetting agent 0.5 parts, deionized water 10 parts.

[0063] Wherein, in the present embodiment, the polytetrafluoroethylene solution is U.S. DuPont DISP 30 polytetrafluoroethylene emulsion; the pH regulator is dimethylethanolamine from BASF of Germany and the multifunctional additive AMP- 95; The defoamer is 941PL from MOUSSEX company and BYK-028, the defoaming agent of BYK, a silicone defoamer (BAK company). The two types of defoamers are used in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com