Multipurpose high weather resistant acrylic acid electrophoretic paint and preparation method thereof

A high-weather-resistant acrylic and electrophoretic coating technology, used in electrophoretic coatings, coatings, etc., can solve the problem of not meeting the weather resistance requirements of topcoats, only reaching 250 hours, etc., achieving good bath stability, convenient painting, decoration good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

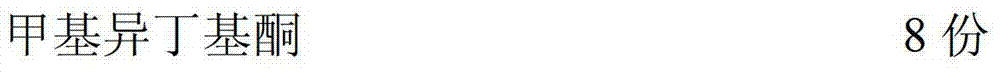

[0038] 1) The formula of the fluorine-containing cationic acrylic modified resin:

[0039]

[0040]

[0041] Glycidyl methacrylate, hydroxypropyl methacrylate, methyl methacrylate, n-butyl acrylate, trifluorooctyl methacrylate, dodecafluoroheptyl methacrylate, benzene peroxide The formyl is mixed uniformly and is called mixed solution a; the formula amount of azobisisobutyronitrile and butyl acetate is mixed evenly and is called mixed solution b. Add methyl isobutyl ketone and n-butanol into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen gas, raise the temperature to 95°C, start to add the mixed solution a dropwise, keep the temperature for half an hour after 4 hours of dripping, Then add the mixed solution b dropwise, drop it for half an hour, then keep it warm for 1 hour, then add diethanolamine dropwise according to the formula, drop it for half an hour, then raise the temperature to 110°C, aminate for 4 hours, then cool ...

Embodiment 2

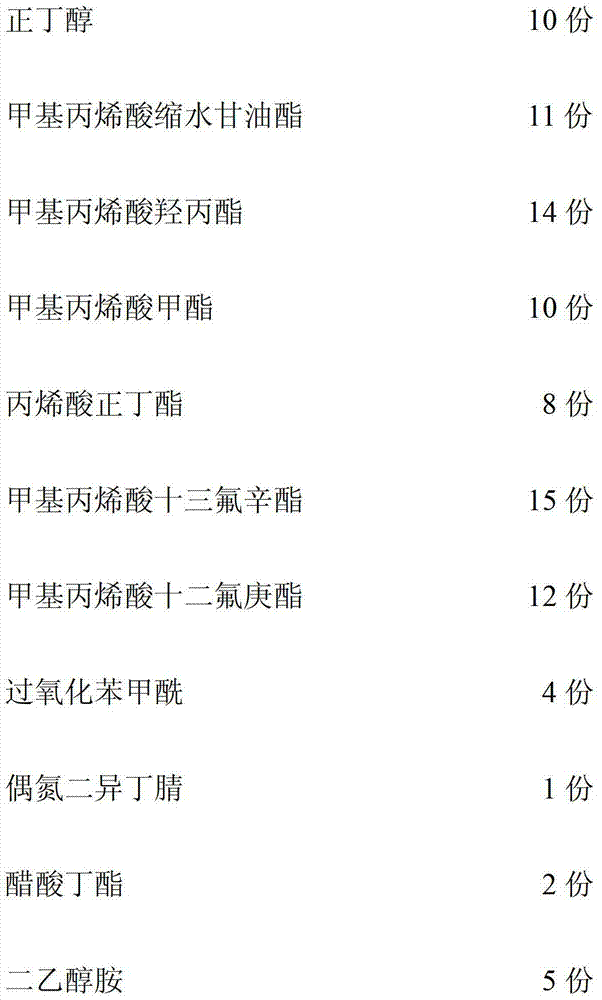

[0057] 1) The formula of the fluorine-containing cationic acrylic modified resin:

[0058]

[0059]

[0060] Glycidyl methacrylate, hydroxypropyl methacrylate, methyl methacrylate, n-butyl acrylate, trifluorooctyl methacrylate, dodecafluoroheptyl methacrylate, benzene peroxide The formyl is mixed uniformly and is called mixed solution a; the formula amount of azobisisobutyronitrile and butyl acetate is mixed evenly and is called mixed solution b. Add methyl isobutyl ketone and n-butanol into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen gas, raise the temperature to 95°C, start to add the mixed solution a dropwise, keep the temperature for half an hour after 4 hours of dripping, Then add the mixed solution b dropwise, drop it for half an hour, then keep it warm for 1 hour, then add diethanolamine dropwise according to the formula, drop it for half an hour, then raise the temperature to 110°C, aminate for 4 hours, then coo...

Embodiment 3

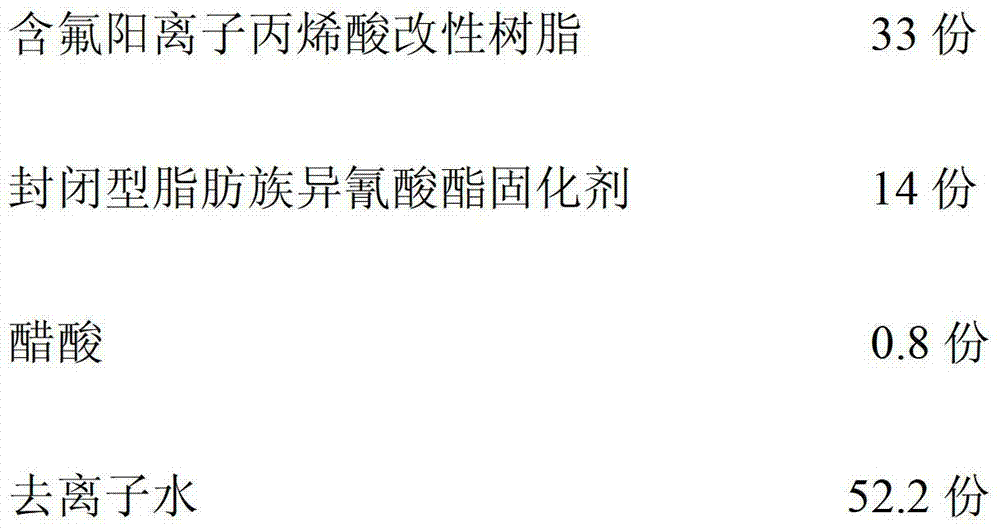

[0076] 1) The formula of the fluorine-containing cationic acrylic modified resin:

[0077]

[0078] Glycidyl methacrylate, hydroxypropyl methacrylate, methyl methacrylate, n-butyl acrylate, trifluorooctyl methacrylate, dodecafluoroheptyl methacrylate, benzene peroxide The formyl is mixed uniformly and is called mixed solution a; the formula amount of azobisisobutyronitrile and butyl acetate is mixed evenly and is called mixed solution b. Add methyl isobutyl ketone and n-butanol into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen gas, raise the temperature to 95°C, start to add the mixed solution a dropwise, keep the temperature for half an hour after 4 hours of dripping, Then add the mixed solution b dropwise, drop it for half an hour, then keep it warm for 1 hour, then add diethanolamine dropwise according to the formula, drop it for half an hour, then raise the temperature to 110°C, aminate for 4 hours, then cool down to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com