Solvent-free epoxy heavy anti-corrosion paint extruded and coated to inner wall of crude oil gathering pipeline

A solvent-free technology for gathering and transportation pipelines, applied in the field of coatings, can solve the problems of expensive pipeline manufacturing, laying and updating, high pipeline replacement costs, corrosion of pipeline inner walls, etc., achieve good corrosion resistance and physical properties, and reduce economic costs , The effect of reducing the number of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

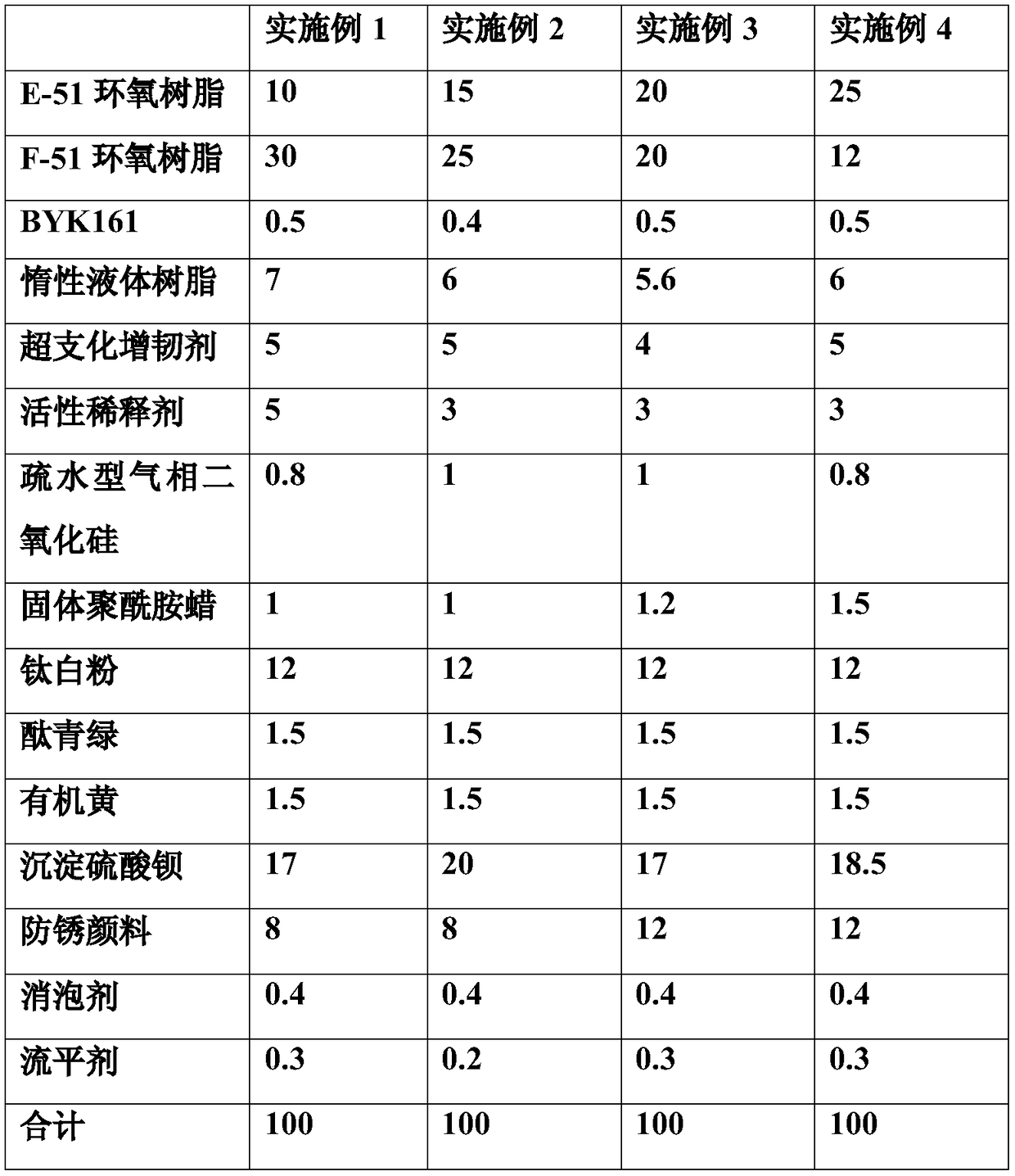

[0032] The weight composition of component A of the solvent-free epoxy heavy-duty anti-corrosion coating on the inner wall of the crude oil gathering and transportation pipeline is shown in the following table:

[0033]

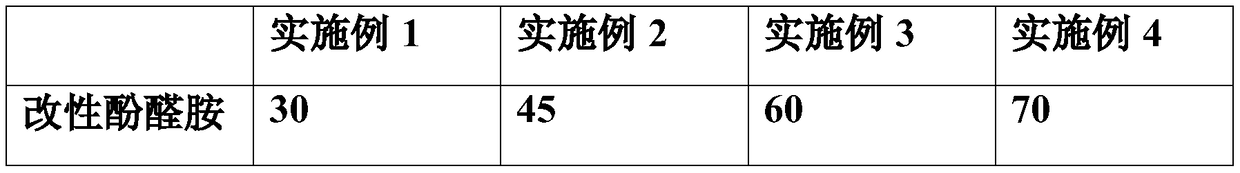

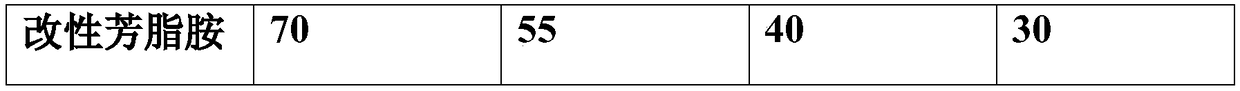

[0034] The weight composition of component B of the solvent-free epoxy heavy-duty anti-corrosion coating on the inner wall of the crude oil gathering and transportation pipeline is shown in the following table:

[0035]

[0036]

[0037] The preparation process of extrusion coating solvent-free epoxy heavy-duty anti-corrosion coating on the inner wall of the crude oil gathering and transportation pipeline is implemented according to the following steps:

[0038] A component:

[0039] Step a, E-51 epoxy resin, F-51 epoxy resin, inert liquid resin, hyperbranched toughening agent, wetting and dispersing agent, titanium dioxide, phthalocyanine green, organic yellow, thixotropic additive, antirust pigment , The precipitated barium sulfate is mixed accord...

Embodiment 1

[0046] The mass ratio of component A and component B in Example 1 is 5:1

Embodiment 2

[0047] The mass ratio of component A and component B in Example 2 is 5:1

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com