UV-LED two-piece can high-flexibility offset printing ink and preparation method thereof

A UV-LED, 1.UV-LED technology, used in inks, household appliances, applications, etc., can solve the problems of poor acid and alkali resistance, poor adhesion and flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

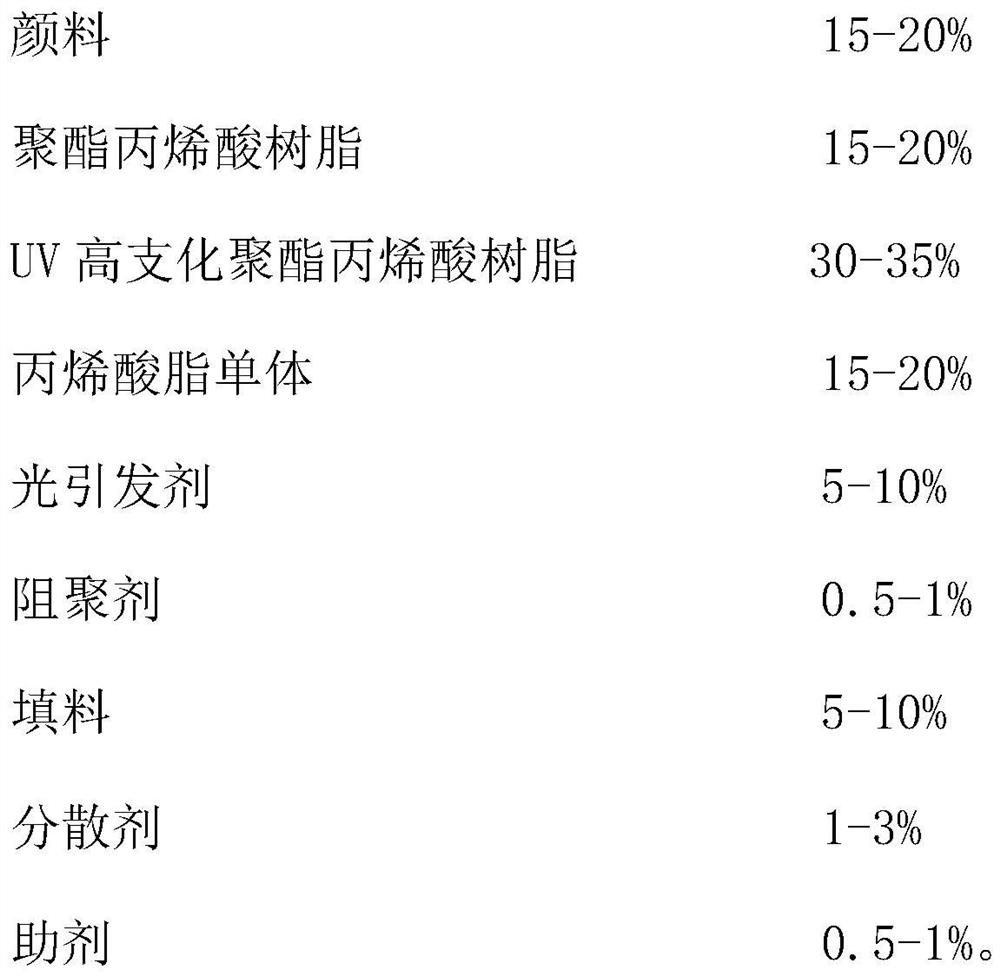

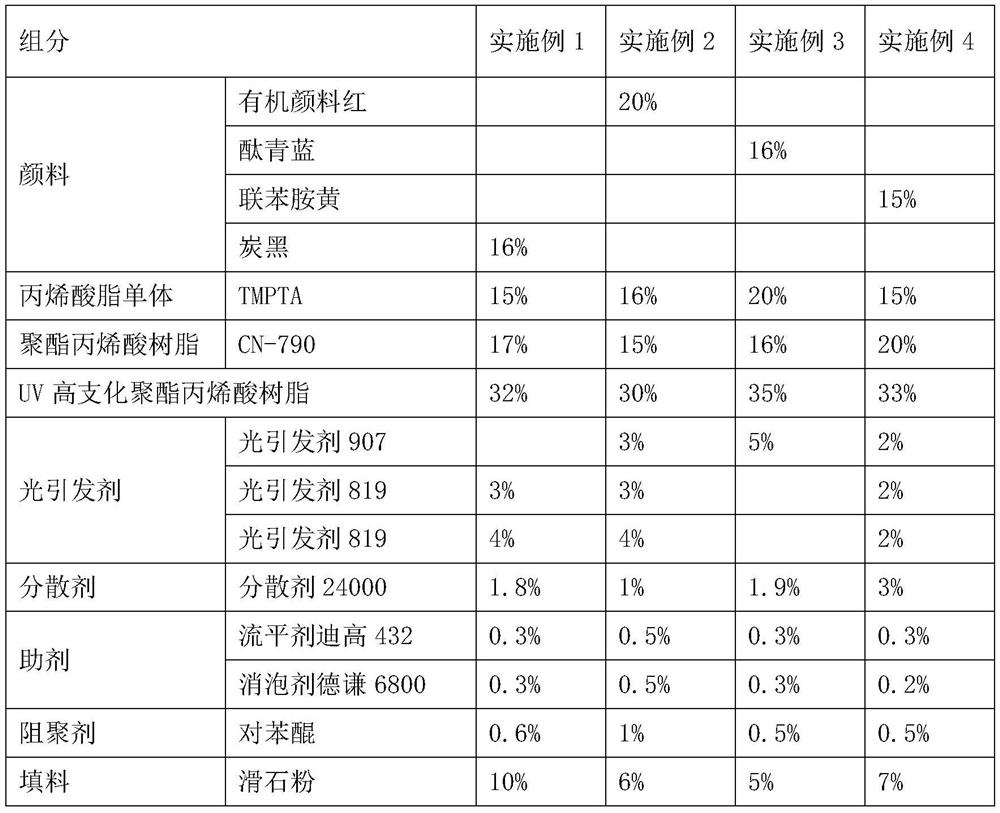

[0026] Below in conjunction with specific embodiment 1-4 and comparative example illustrate the concrete technical scheme of the present invention:

[0027] The offset printing ink of embodiment 1-4 adopts following preparation method, comprises the following steps:

[0028] Prepare each raw material according to the weight percentage in Table 1, first mix polyester propylene resin, UV hyperbranched polyester acrylate, acrylate monomer, polymerization inhibitor, dispersant, auxiliary agent, photoinitiator, and disperse through a high-speed mixer Until it is completely dissolved, then add pigments and fillers, stir well until it is preliminarily dispersed, and then grind it fully on a three-roller machine until the ink reaches the specified fineness.

[0029] Table 1: The weight ratio of offset printing ink in Examples 1-4

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com