A Solid Cone Bubble Atomizing Nozzle Suitable for High Viscosity Non-Newtonian Fluids

A non-Newtonian fluid, atomizing nozzle technology, applied in liquid spraying devices, spraying devices, etc., can solve the problems of poor atomization effect, high atomization gas consumption rate, large average particle size of droplets, etc., and achieves convenient processing and manufacturing. , The effect of high atomization and low gas consumption rate

Active Publication Date: 2016-07-06

NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

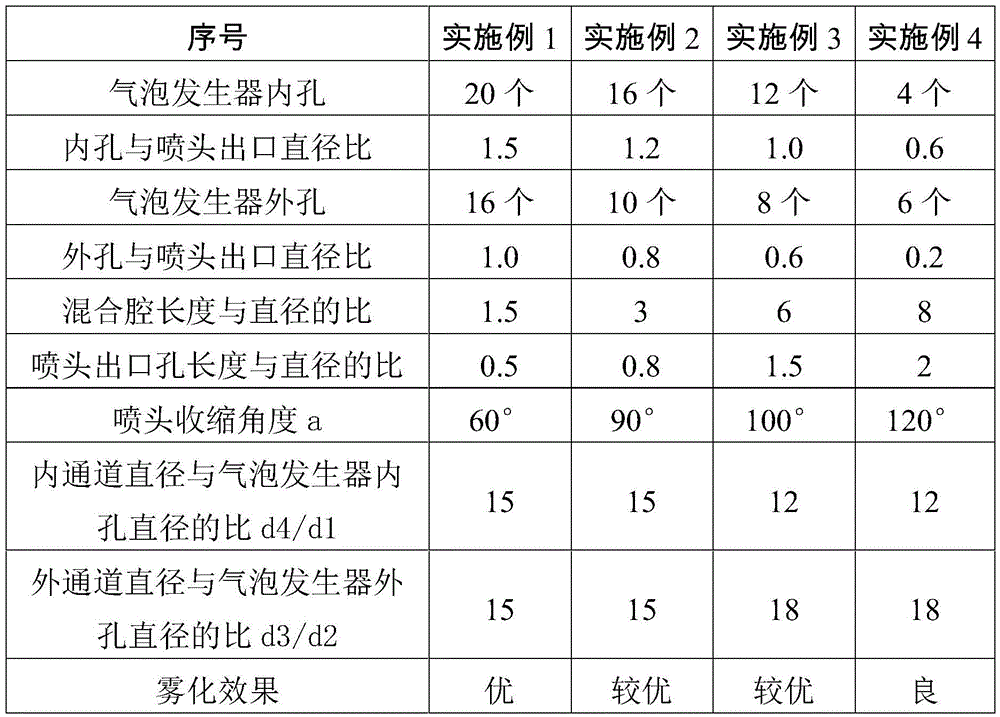

[0003] In order to solve the technical problems of poor nozzle atomization effect, high atomization gas consumption rate and large average droplet size of existing high-viscosity non-Newtonian fluids, the present invention provides a solid bubble atomization nozzle suitable for high-viscosity non-Newtonian fluids. The nozzle has good atomization quality in a wide range of flow adjustment, and the average particle size of droplets is greatly reduced at a small gas consumption rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

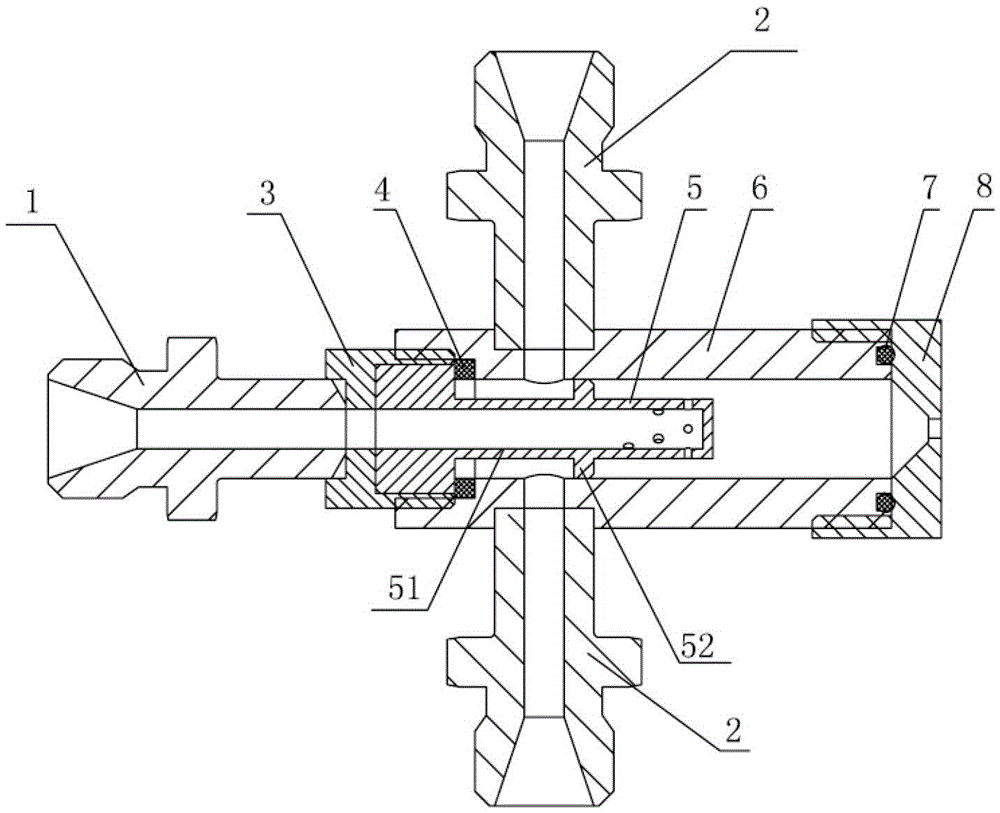

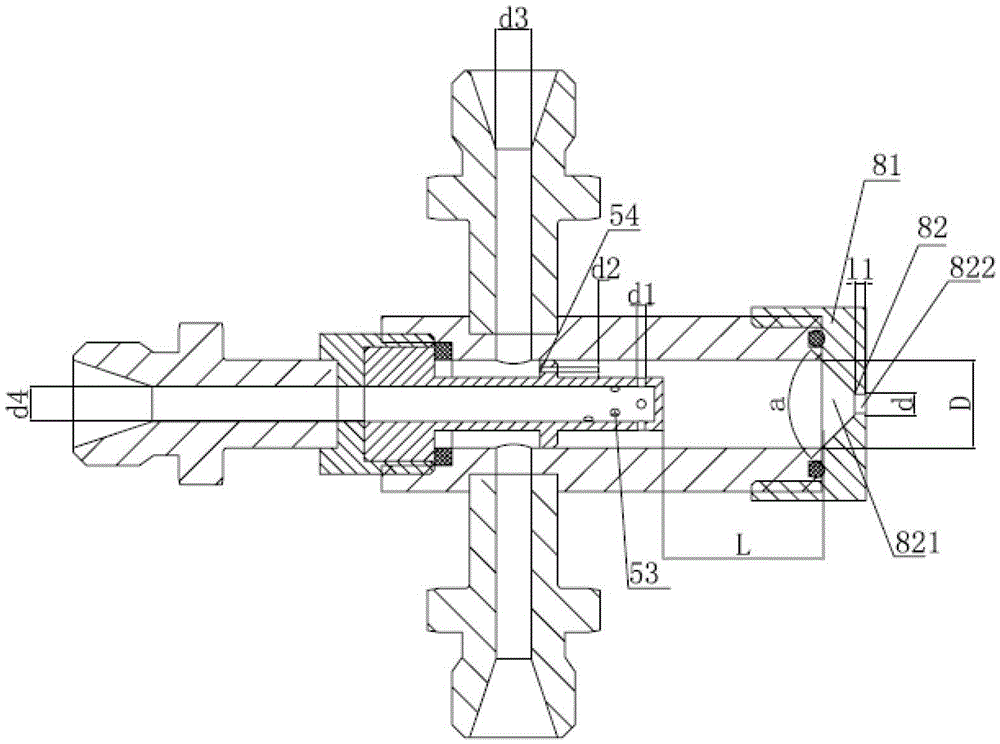

The invention relates to a solid cone-shaped bubble atomizing nozzle suitable for high-viscosity non-Newtonian fluids, which includes an inner interface, an outer interface, a sleeve, a bubble generator, a mixer and a spray head, and the inner interface is fixed on the side of the mixer through the sleeve. One end, the nozzle is fixed on the other end of the mixer, the external interface is fixed on the mixer, and the bubble generator is set in the mixer; the bubble generator includes a guide tube and a guide plate fixed on the guide tube, and the guide plate The inner cavity of the mixer is divided into the outer flow channel and the mixing chamber. One end of the guide tube is connected to the inner interface through the sleeve, and the outer flow channel is connected to the outer interface. There are multiple outer guide holes evenly distributed on the circumference of the guide plate, which are located in the mixing chamber. One end of the indoor guide tube is provided with a plurality of inner guide holes. The invention solves the technical problems of poor nozzle atomization effect, high atomization gas consumption rate and large average droplet size of the existing high-viscosity non-Newtonian fluid. quality.

Description

technical field [0001] The invention relates to a solid-cone bubble atomizing nozzle capable of atomizing non-Newtonian fluids, in particular to high-efficiency atomization of non-Newtonian fluids with high viscosity and complex rheological properties, capable of forming a solid-cone spray field, and can be applied here Atomization and combustion devices for similar fluids. Background technique [0002] Gel propellant motor has the advantages of high specific impulse of liquid rocket motor, adjustable thrust, multiple starts and solid rocket motor, which are easy to store and transport, and easy to use and maintain. It is one of the research and development directions of missile weapons and space vehicle power systems. However, gel propellants are non-Newtonian fluids, and their high viscosity makes flow and atomization difficult. How to achieve efficient flow atomization has become the key technology for the application of gel propellants. Contents of the invention [00...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B05B7/04

Inventor 王延涛李龙飞陈炜杨伟东洪流

Owner NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com