Gas phase auxiliary atomizing nozzle with built-in magnetization structure and atomizing method

A gas-phase assisted, atomizing nozzle technology, applied in the direction of chemical instruments and methods, spraying devices, liquid spraying devices, etc., can solve the problems of large-scale application, large gas consumption of pneumatic atomizing nozzles, high air pressure of bubble atomizing nozzles, etc. problem, to achieve the effect of shortening the magnetization length, easy to meet the gas phase conditions, and small atomized particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in combination with specific embodiments.

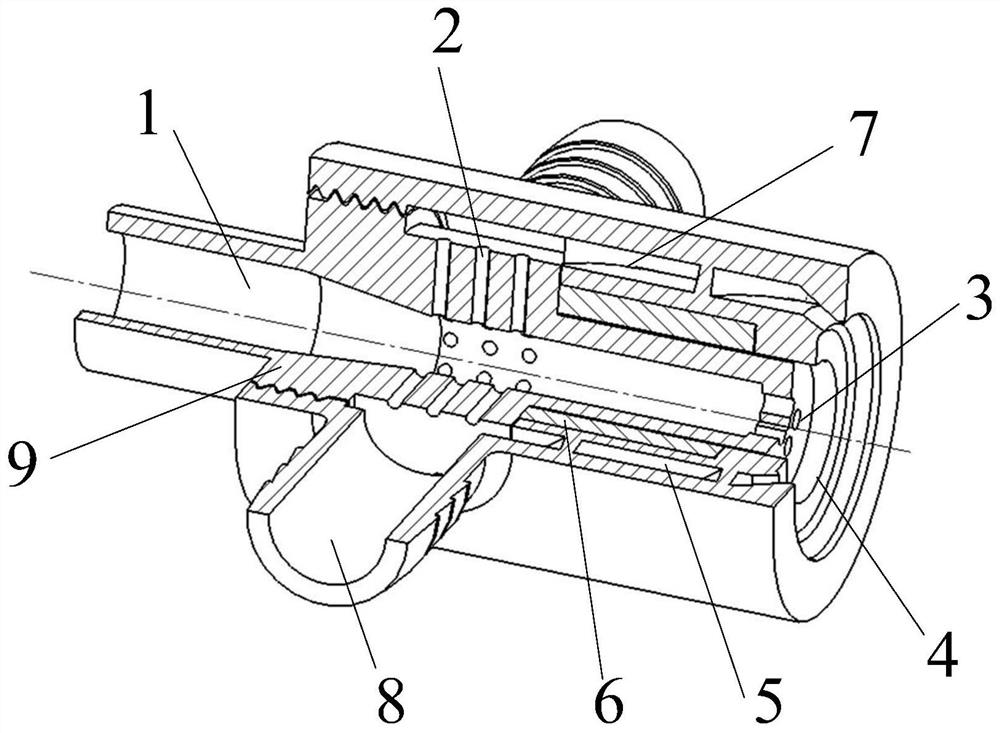

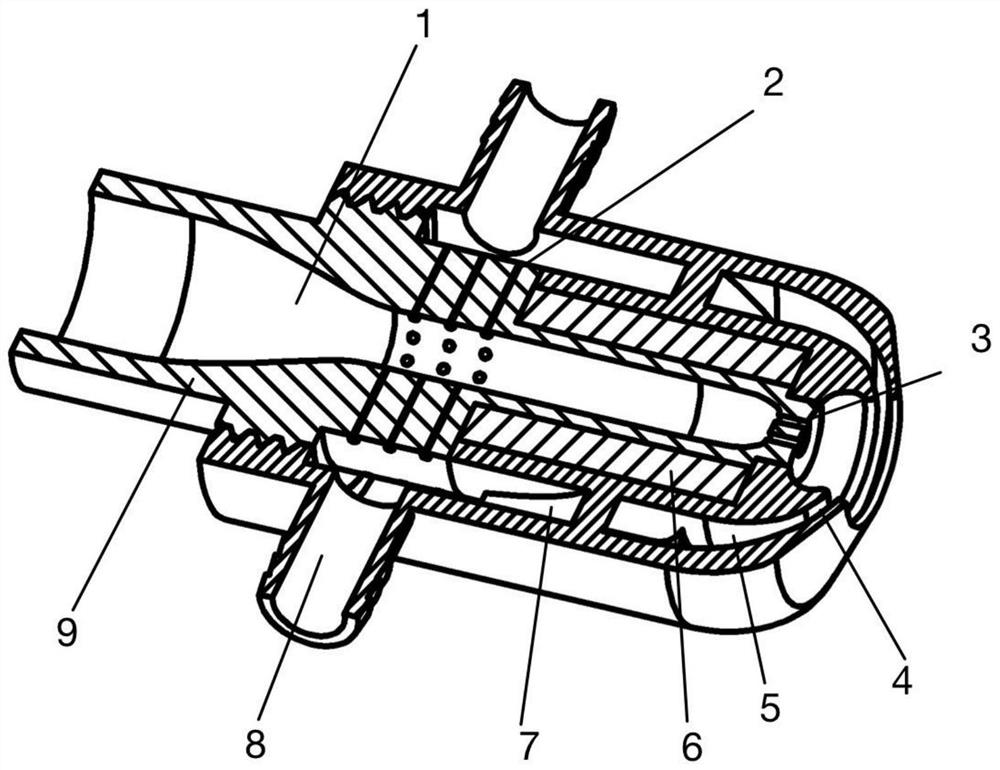

[0027] see figure 1 and figure 2 , the gas-phase assisted atomizing nozzle with built-in magnetization structure is a bubble atomizing nozzle, a pneumatic atomizing nozzle or a combined nozzle of bubble atomization and pneumatic atomization, including a cylindrical shell, a liquid inlet 9, and a tapered inner flow channel 1 , air inlet 8, aeration hole 2, magnetization device 2 and magnetization ring 6, swirl sheet 7, tapered air passage 5, bubble-shaped outlet 3 and cyclone outlet 4. Among them, one end of the housing is provided with a liquid inlet 9, and the other end is provided with a cyclone outlet 4; the magnetization device 2 composed of a magnetization ring 6 is embedded inside the housing; a number of air inlets 8 are provided in the middle of the side wall of the housing. A tapered inner flow channel 1 is provided. One end of the tapered inner flow channel 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com