A Diesel Engine SCR Atomizer Used in Air-Assisted Mode

An air-assisted, diesel engine technology, applied in the direction of machines/engines, exhaust devices, mechanical equipment, etc., can solve the problems of unsatisfactory atomization effect of urea aqueous solution, affecting NOx conversion efficiency, damage to urea electromagnetic nozzle, etc., to improve conversion efficiency , Simple structure, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

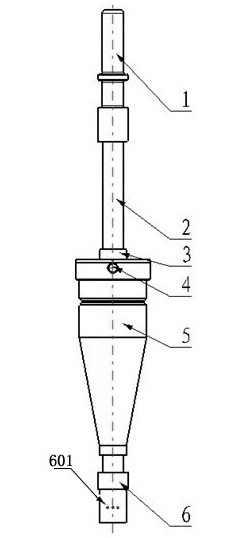

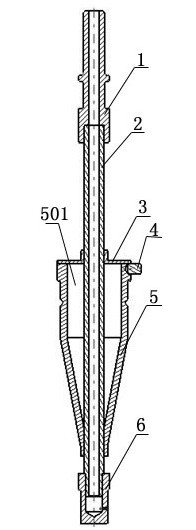

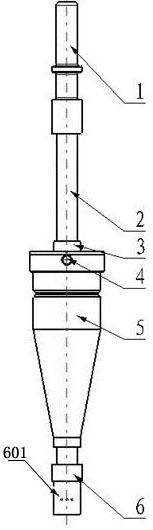

[0016] As shown in the figure, an air-assisted SCR atomizer for diesel engines includes a hollow pipe 2, and the top of the pipe 2 is fixedly connected to a pipe joint 1. The pipe joint 1 complies with the SAE J2044-2002 standard and can be connected with a quick joint Quick connection for easy connection of the nebulizer with external devices. The tail end of the pipeline 2 is fixedly connected with the nozzle 6. A group of nozzle holes 601 are arranged on the side of the nozzle 6, and the diameter of the nozzle holes 601 is 0.3-0.7mm, in order to achieve the atomization effect and improve the NO x In the most preferred way for the conversion efficiency, three spray holes 601 are arranged on the side of the spray head 6, and the diameter of the spray holes 601 is 0.5 mm.

[0017] The pipe body of the pipeline 2 is socketed with a heat insulating shell 5 for heat ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com