Large-yield efficient gas atomization powder manufacturing apparatus

A pulverizing equipment and gas atomization technology, which is applied in the field of powder metallurgy, can solve the problems of burning spray plates, high production costs, and limiting production efficiency, etc., and achieve the effects of saving costs, increasing smelting volume, and reducing the risk of shutdown maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

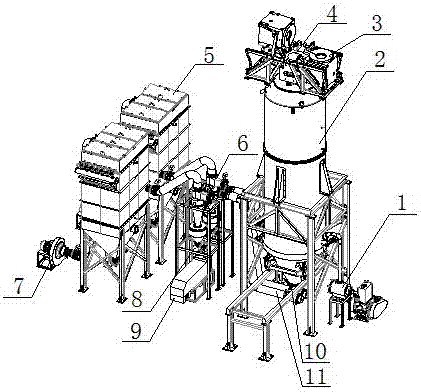

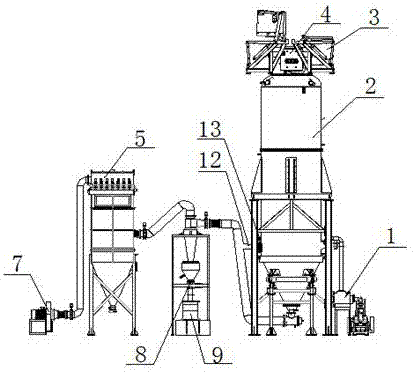

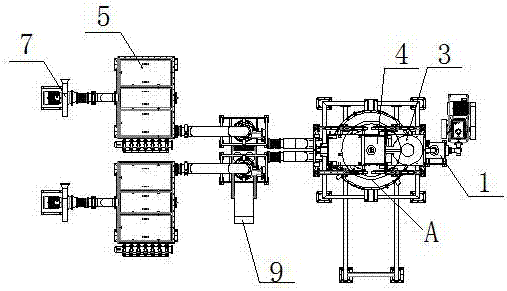

[0027] Such as Figure 1-4 As shown, a large-capacity and high-efficiency gas atomization powder making equipment includes a smelting system, an atomization system, a vacuum system 1, a powder feeding system, a dust removal system and a screening system.

[0028] The smelting system includes two melting furnaces 3, which are arranged opposite to each other.

[0029] The atomization system includes an atomization tower 2 and a double leak hole transition material bag 4, and the vacuum system 1 is connected with the atomization tower 2.

[0030] The powder feeding system includes a herringbone connector 10, two air ducts 11 and two air duct branches 12, the inlet of the herringbone connector is connected to the atomization tower, and the outlet of the herringbone connector is respectively connected to the two air ducts. The connection of the first air duct, the other end of which is connected to the dust removal system. One end of the air pipe branch is connected to the atomiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com