Patents

Literature

48results about How to "Realize automatic screening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

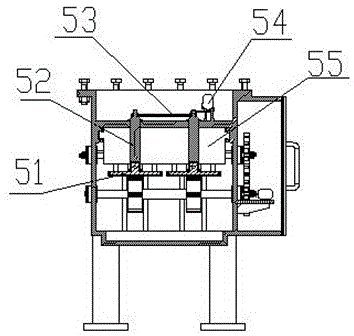

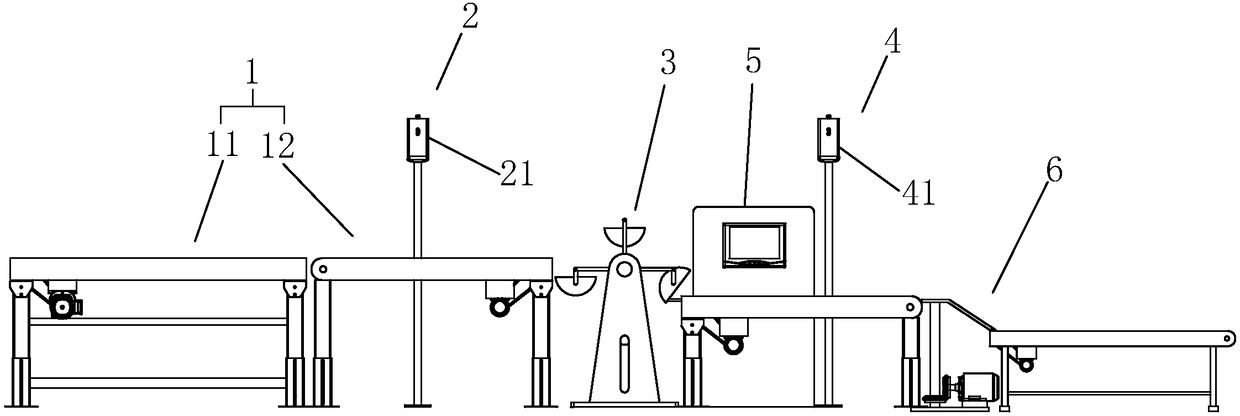

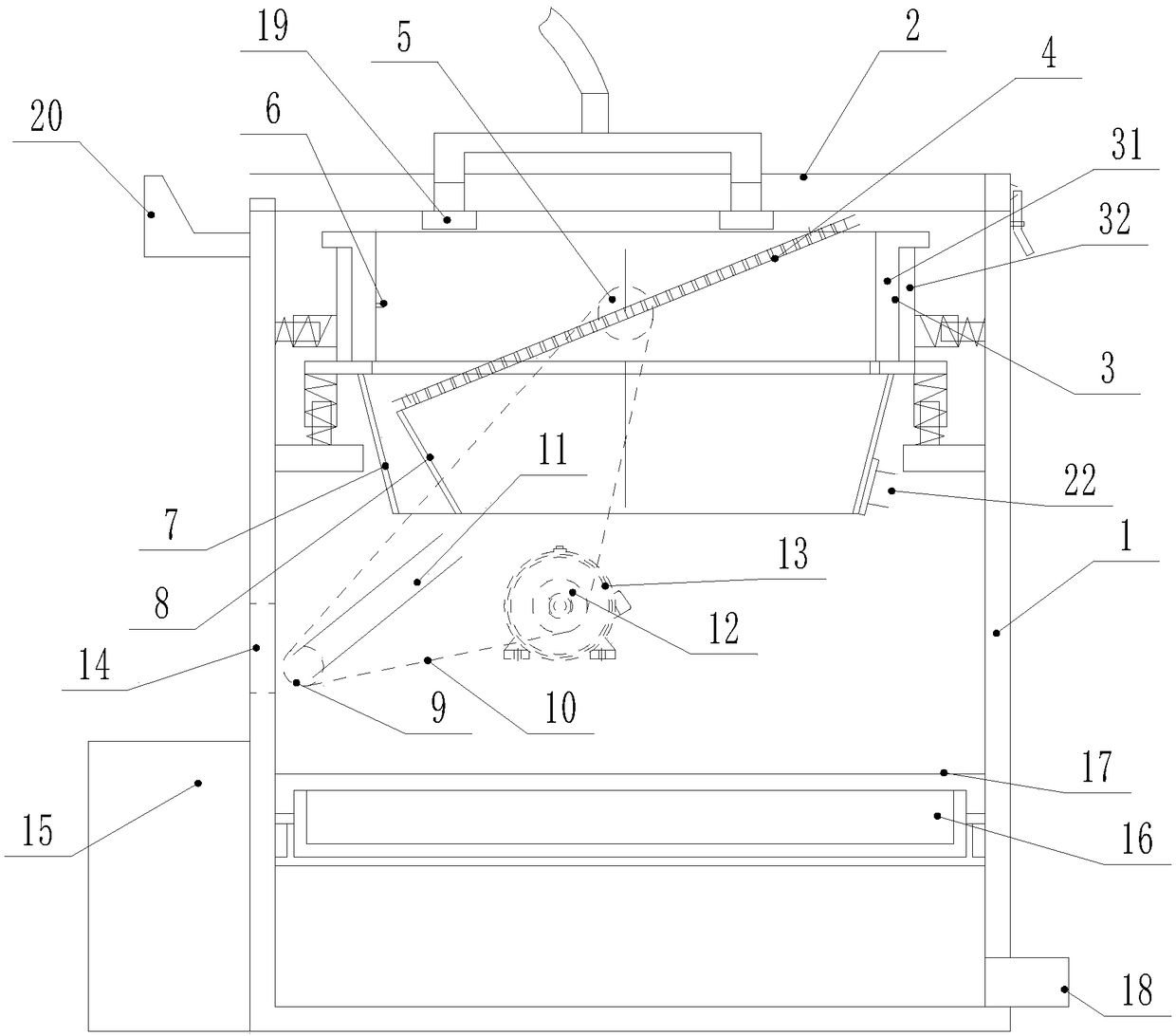

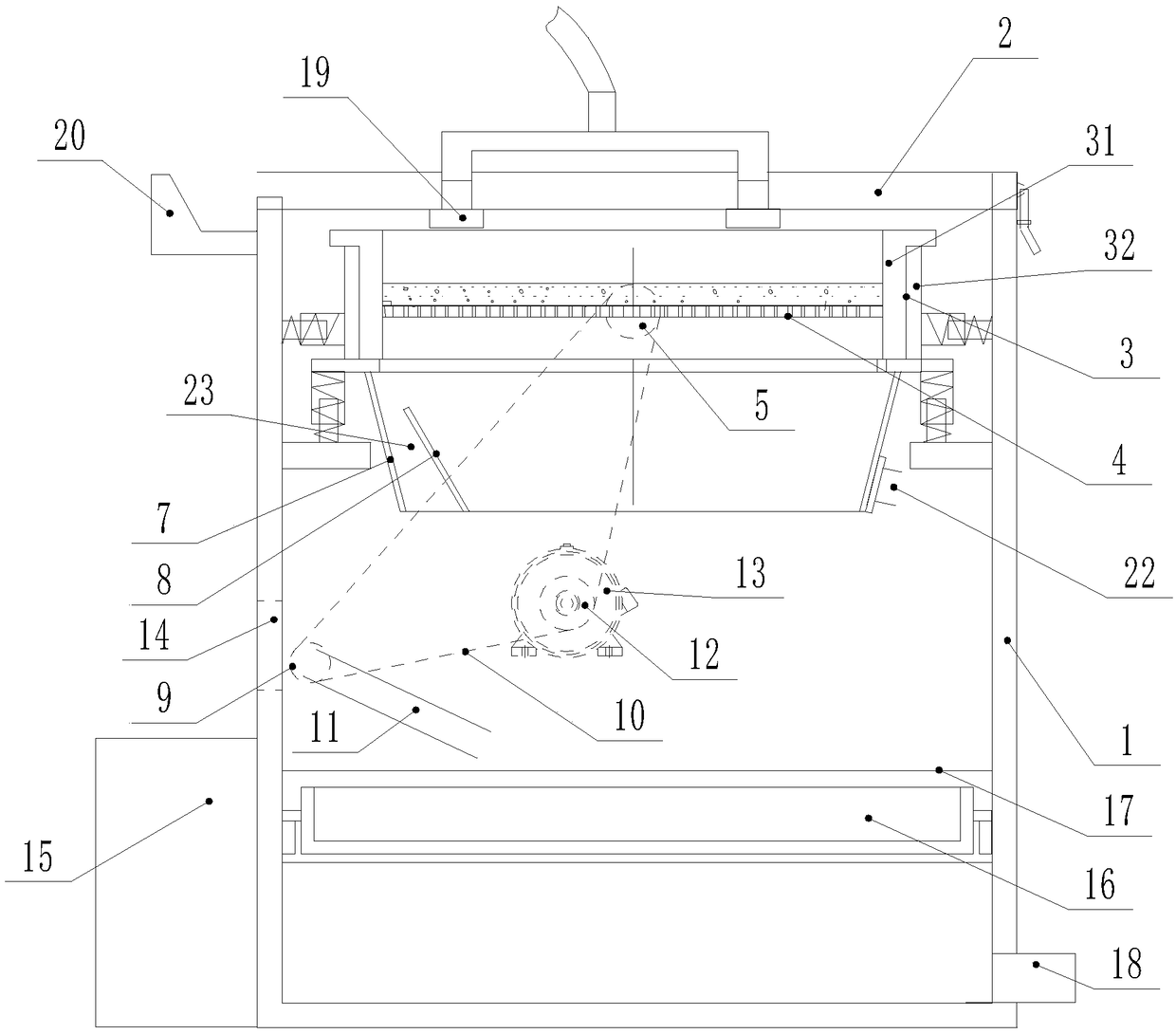

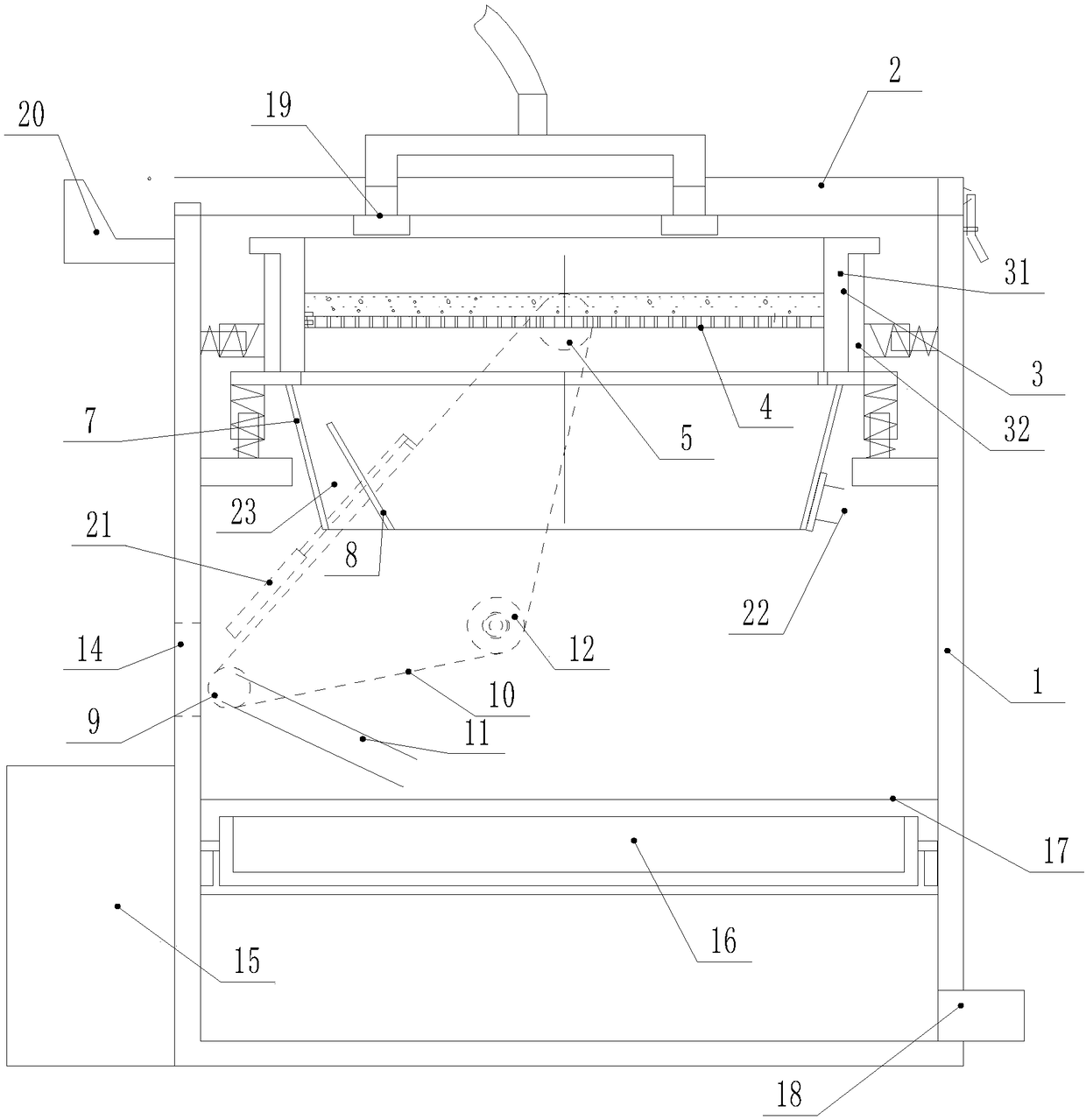

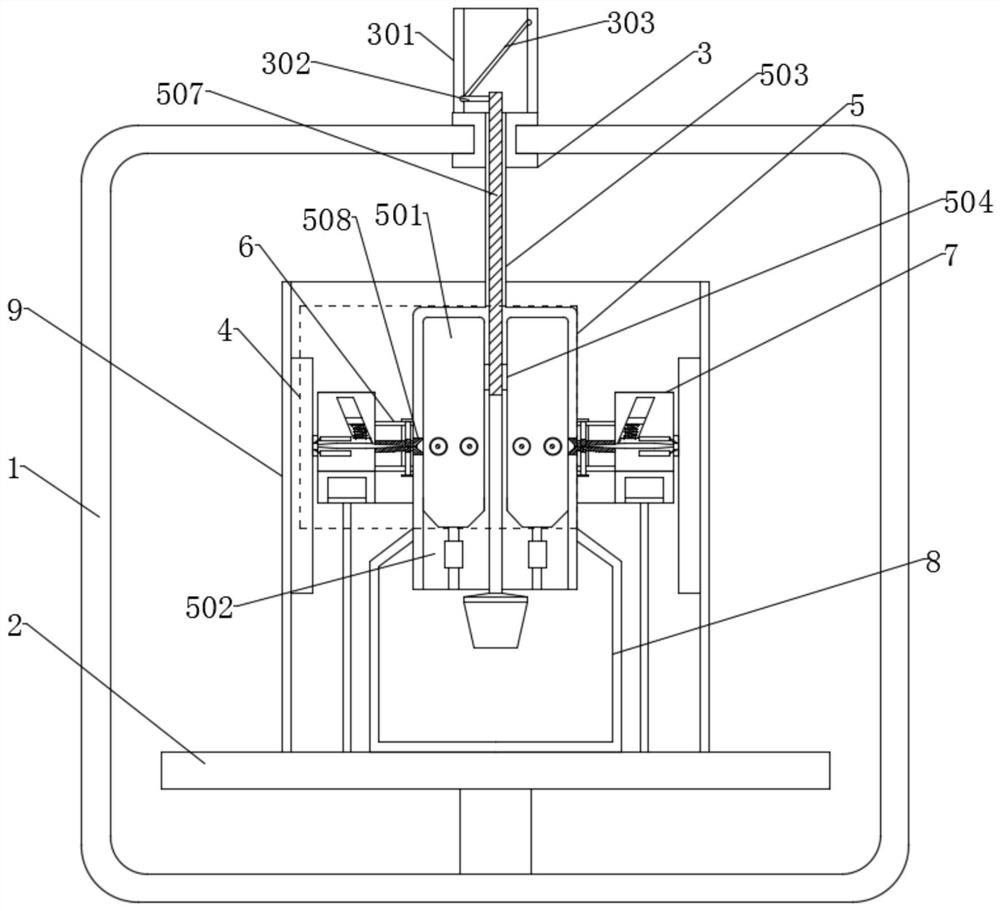

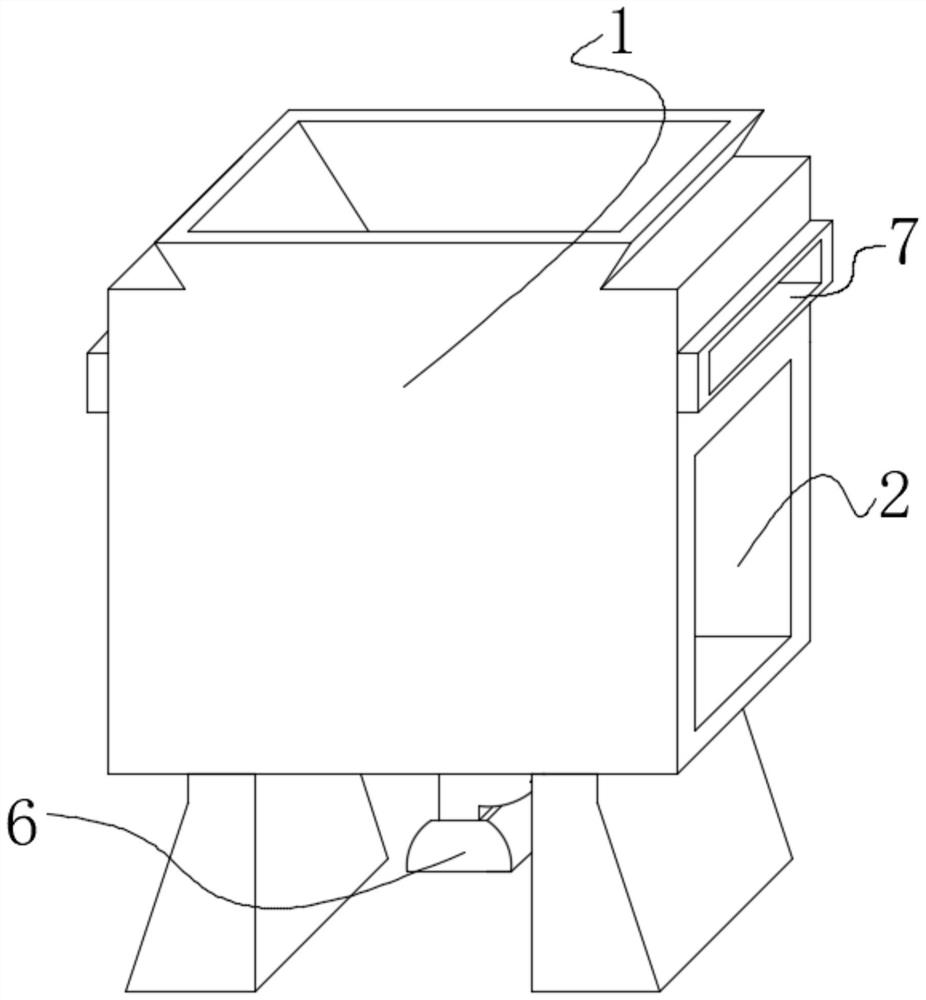

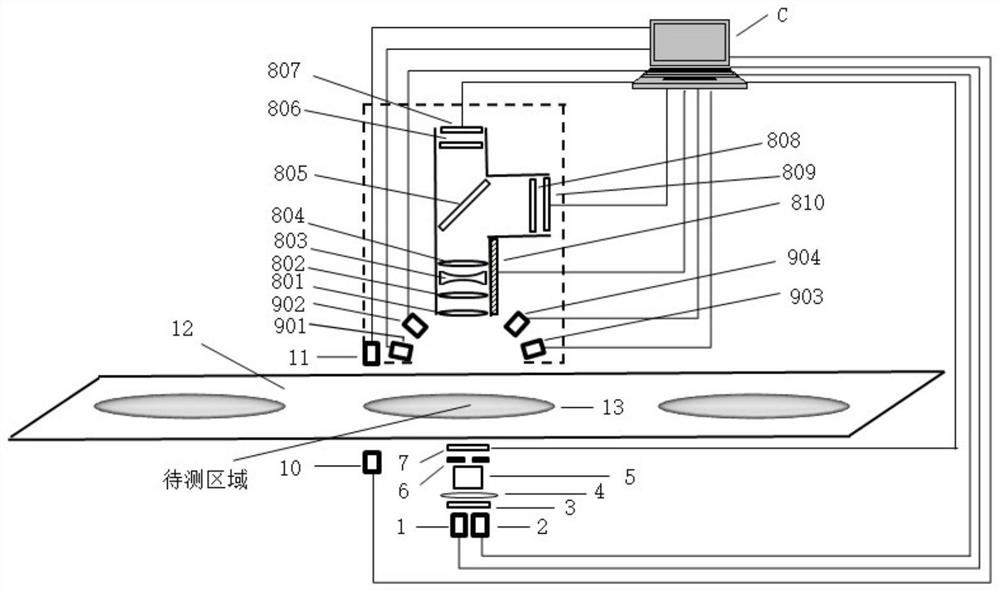

Digitalized paddy rice seed testing machine

ActiveCN101905215AEvenly dispersedSolve adhesionGas current separationIndividual particle analysisAgricultural scienceRice grain

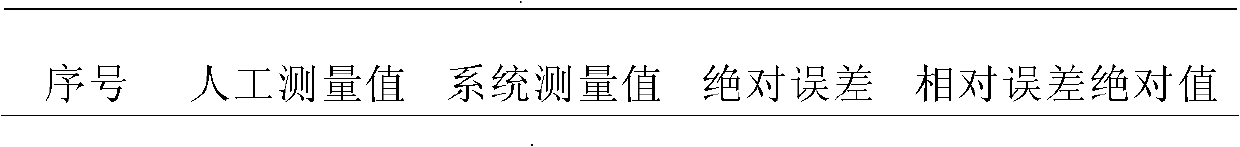

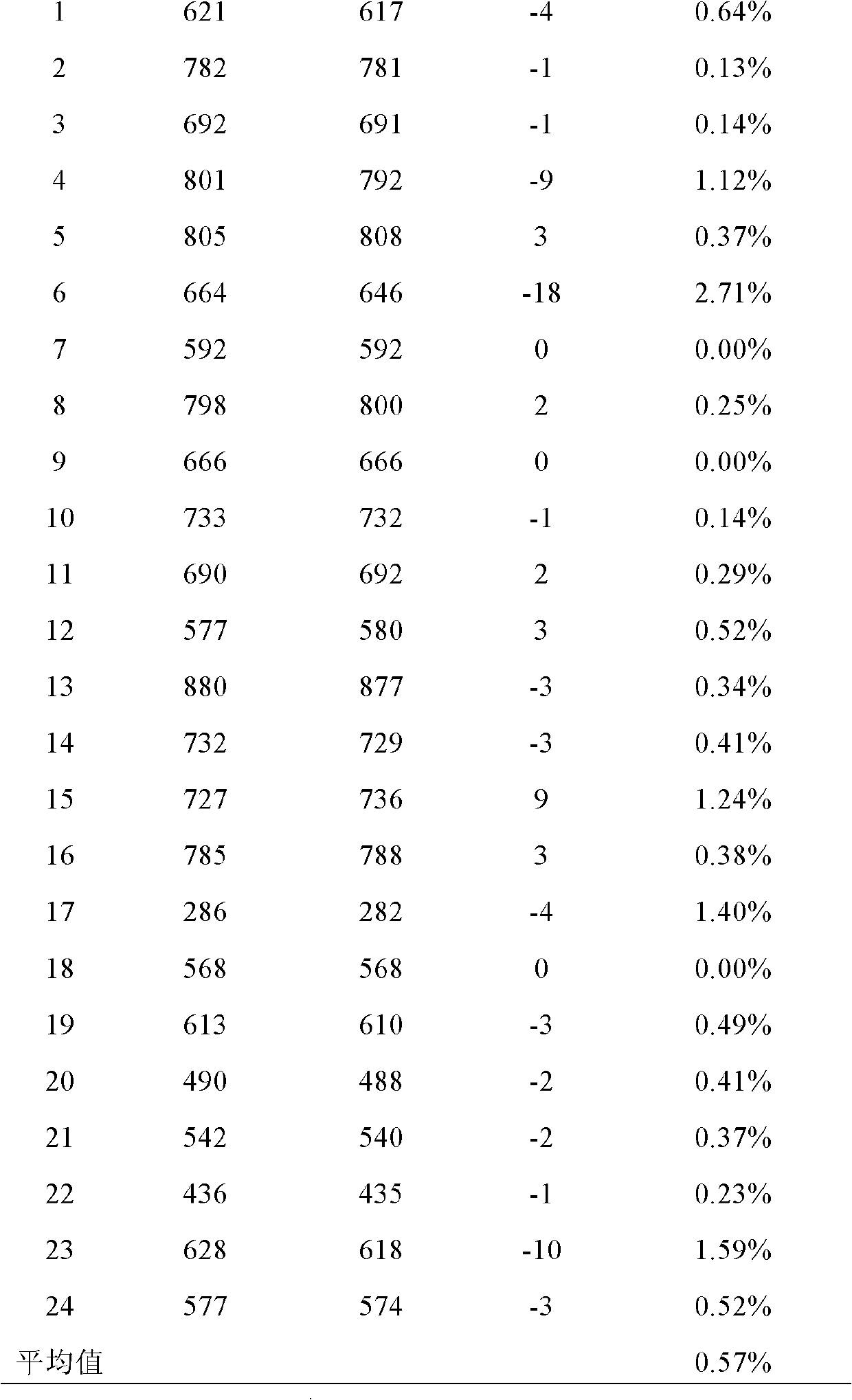

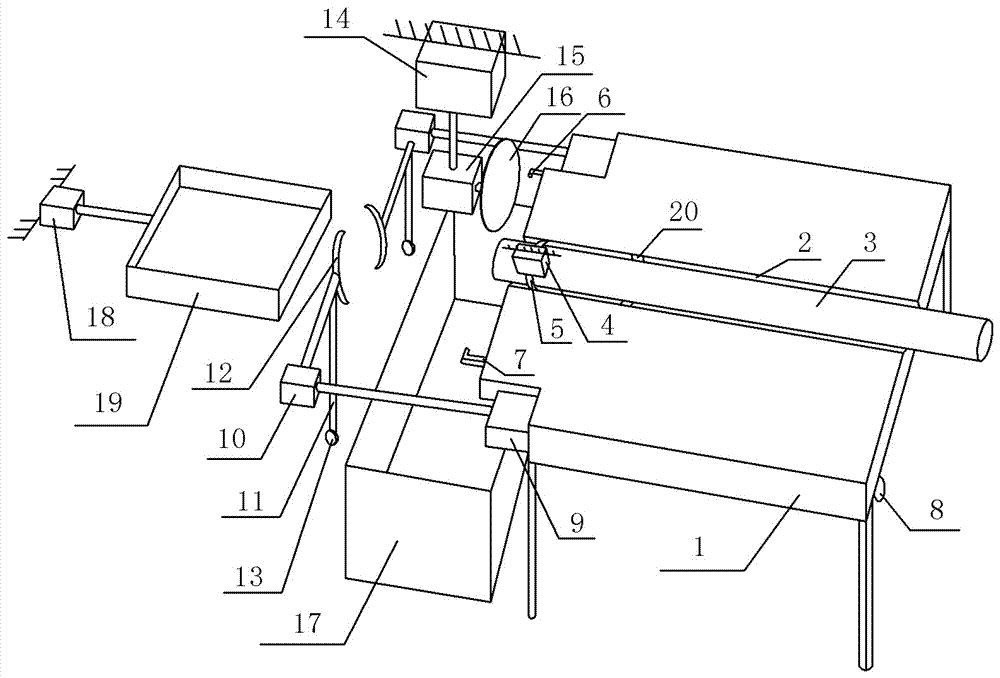

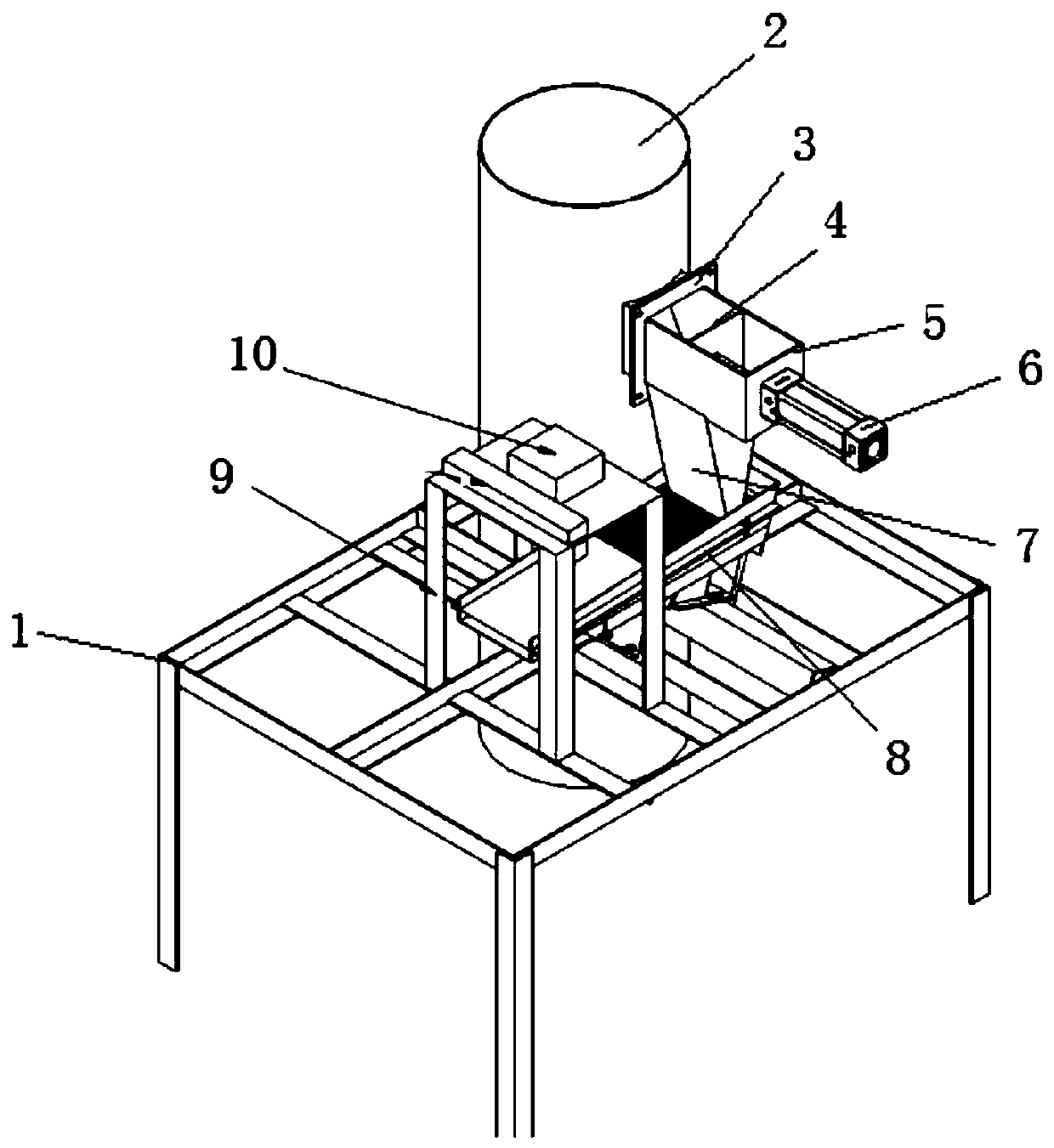

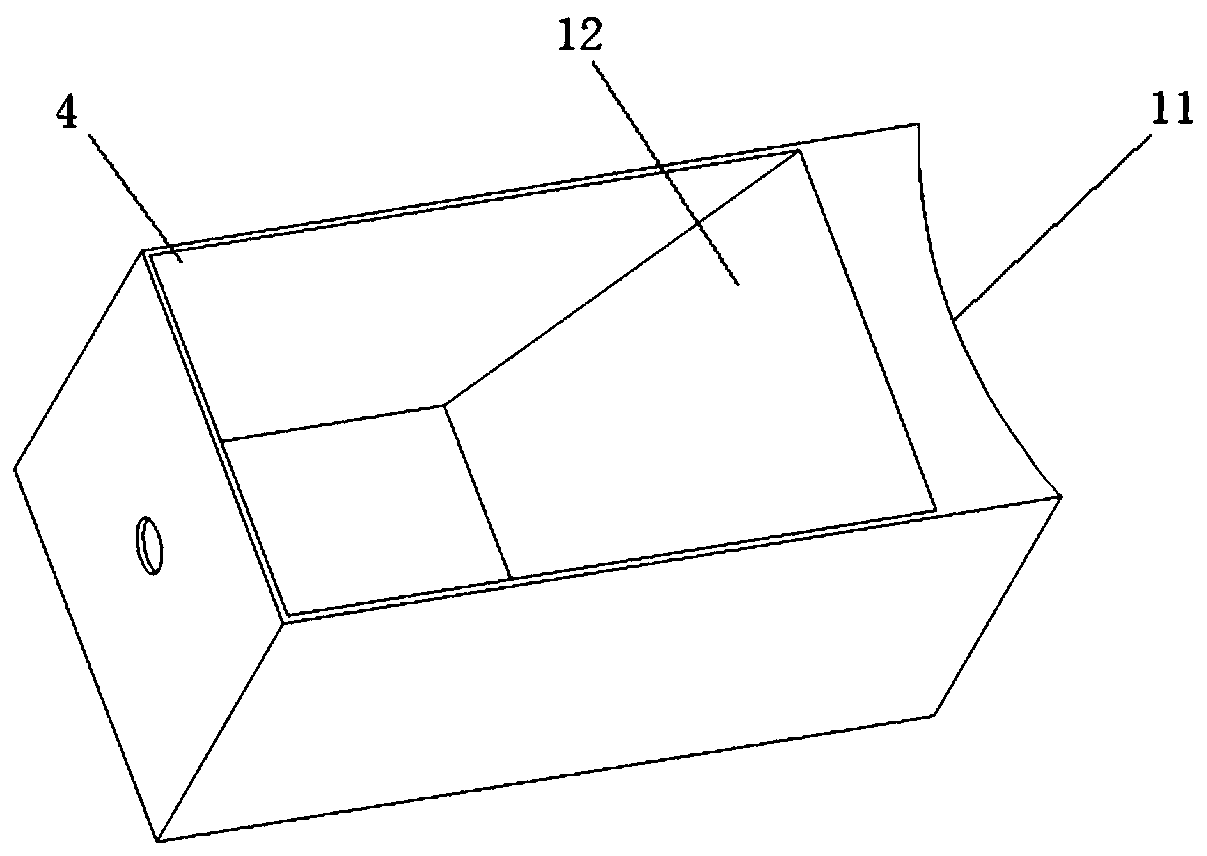

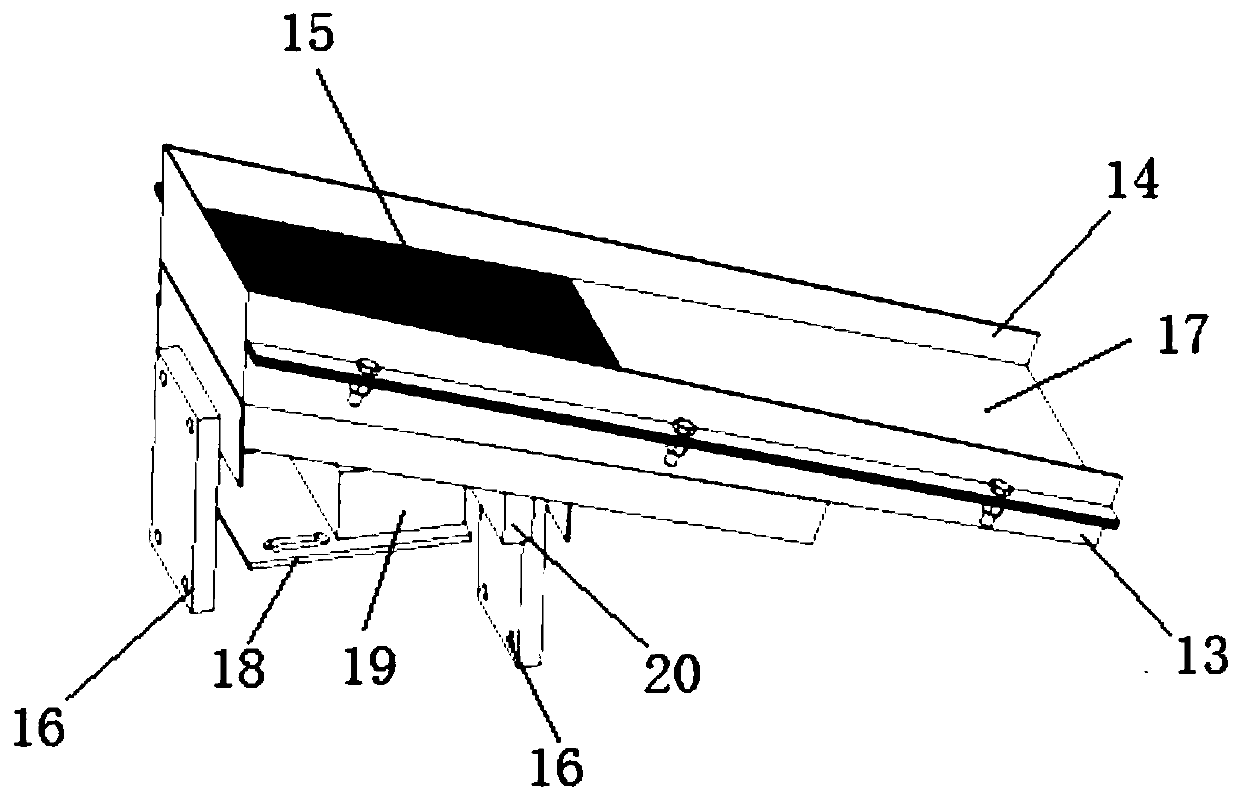

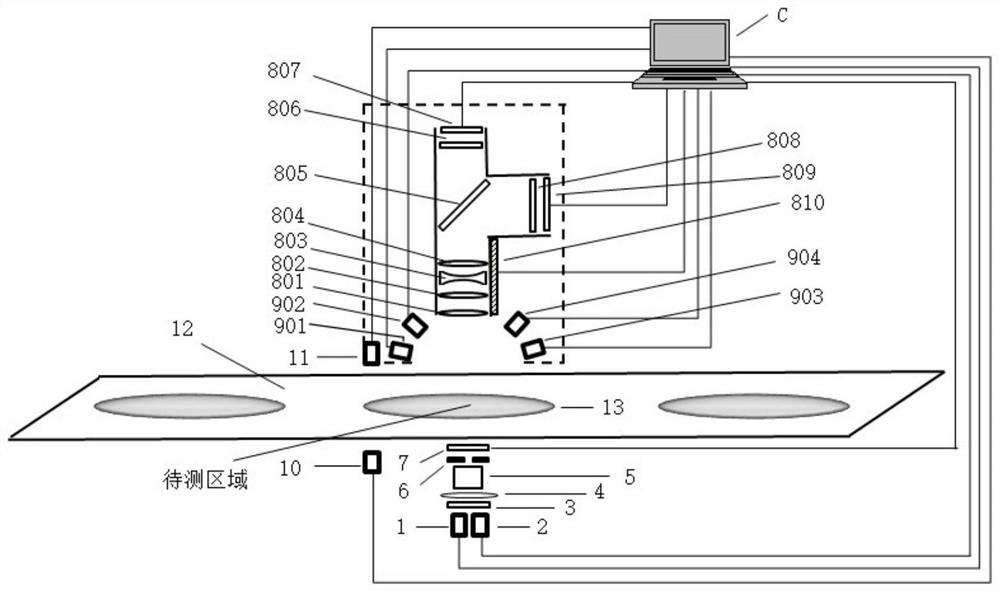

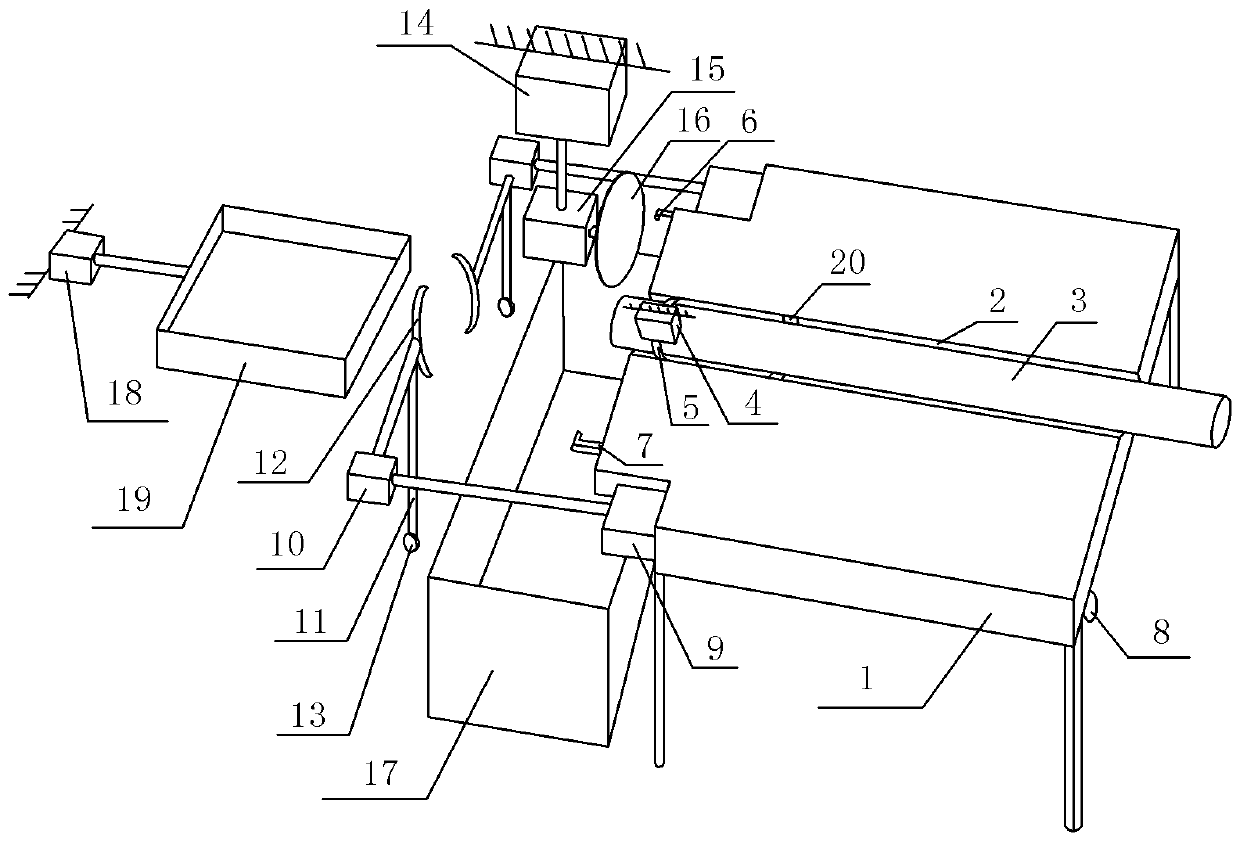

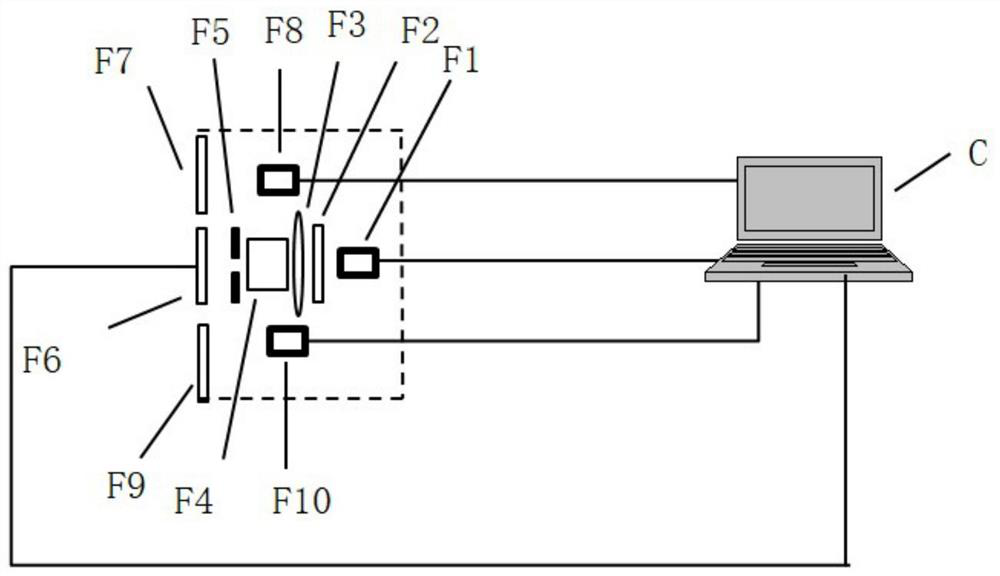

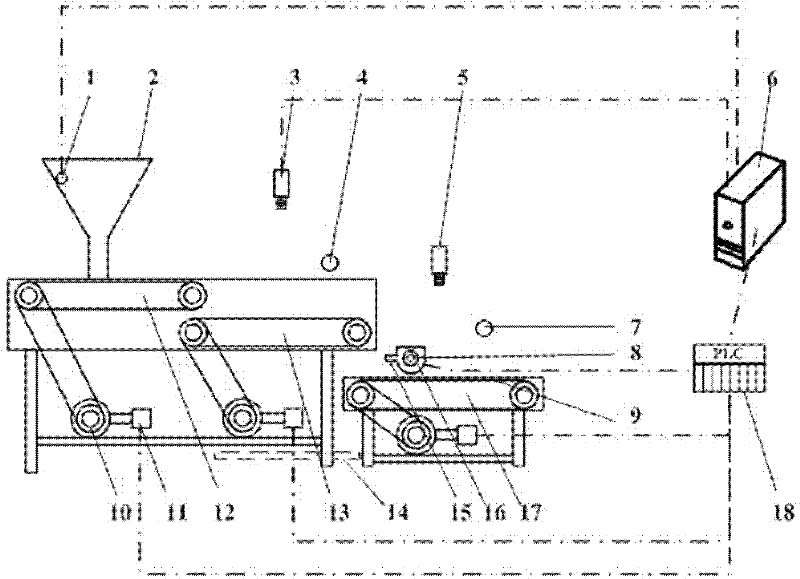

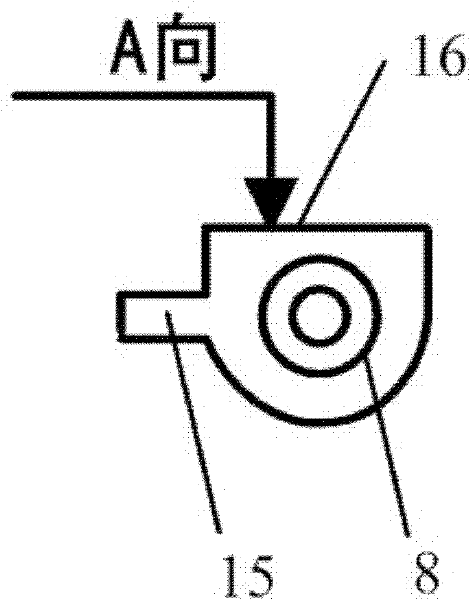

The invention relates to an online non-destructive testing method which is suitable for automatically measuring and recording the total grain number, the filled grain number, the maturing rate, the grain lengths, the grain widths and the length-width ratio of a single plant or single-batch paddy rice in the paddy rice seed testing process for agricultural scientific research personnel. The digitalized paddy rice seed testing machine mainly comprises six functional modules of a bar code recognizer, a grain transfer device, an air separation device, an image acquisition device, a PLC (Programmable Logic Controller) and a computer system. The digitalized paddy rice seed testing machine can be used for separating filled grains and empty and shriveled grains by utilizing the air separation device, dynamically acquiring grain parameters by utilizing a machine vision technology and simultaneously measuring the total grain number and the filled grain number of the paddy rice, thereby overcoming a bottleneck that the traditional testing measure can not simultaneously acquire the total grain number and the filled grain number and realizing the detection to the grain-size parameters of the paddy rice at the same time of calculating the paddy rice grain number. The invention can be also widely applied to the seed testing work of other grain crops.

Owner:HUAZHONG UNIV OF SCI & TECH

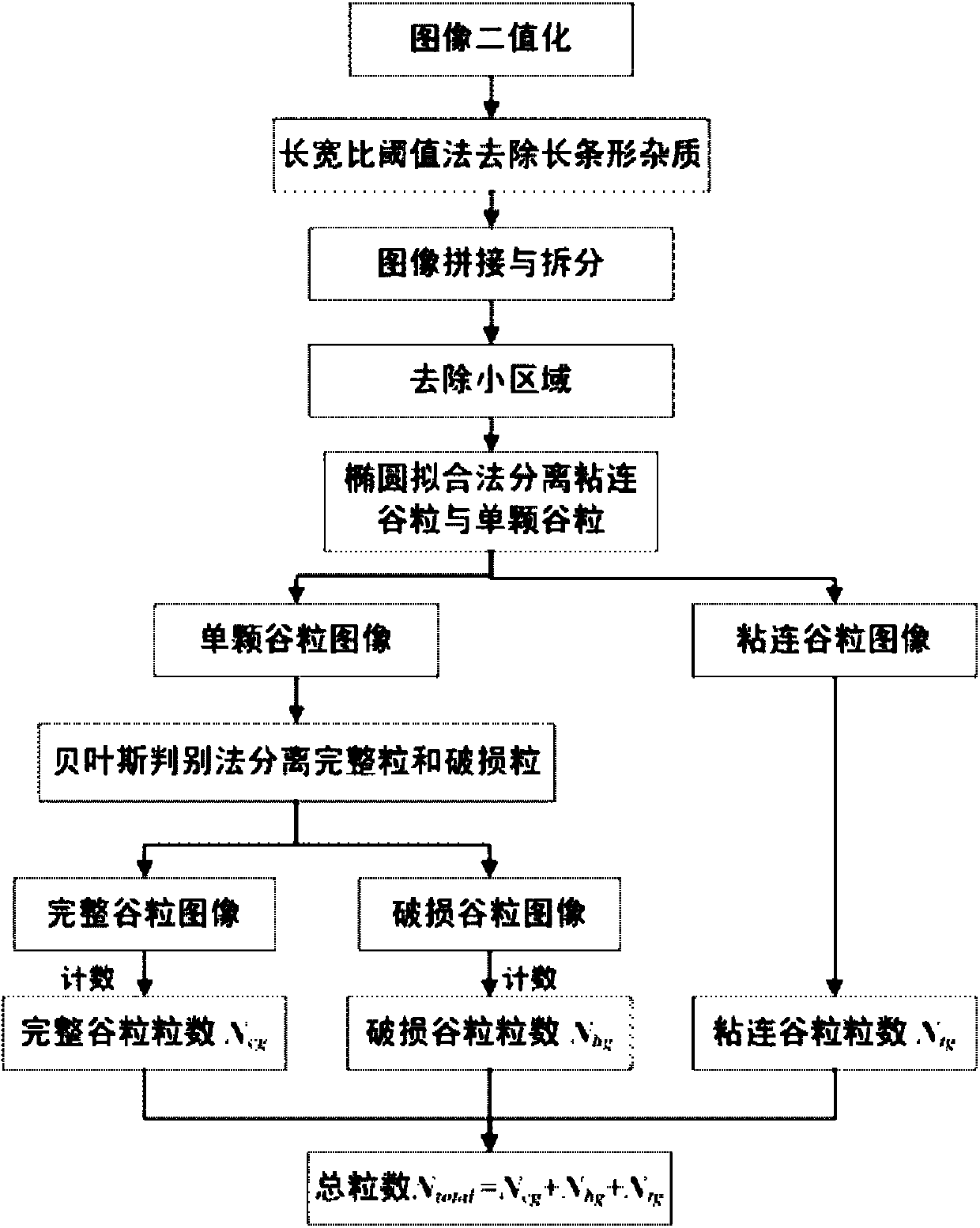

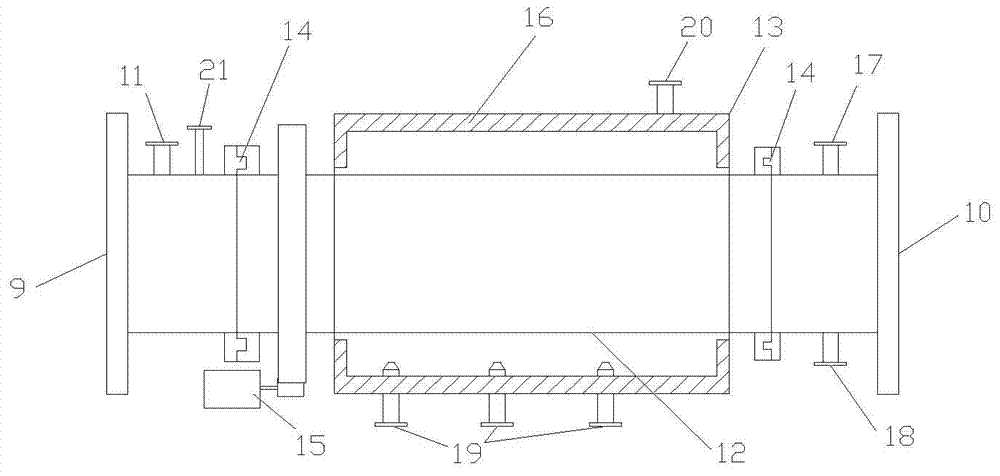

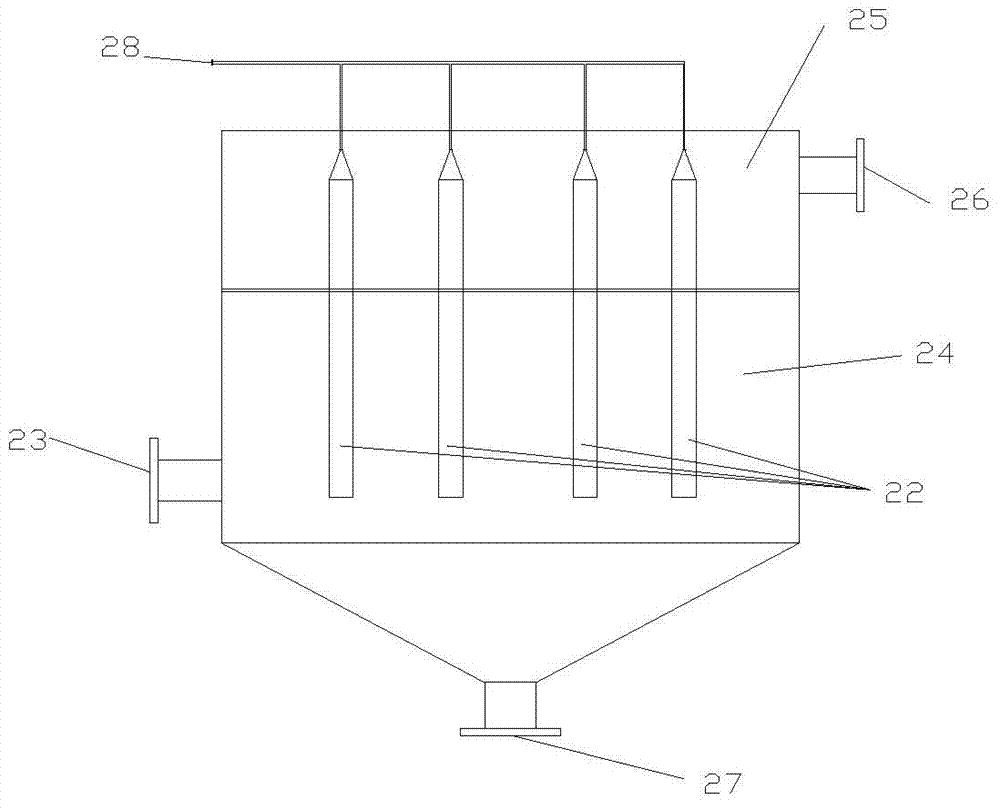

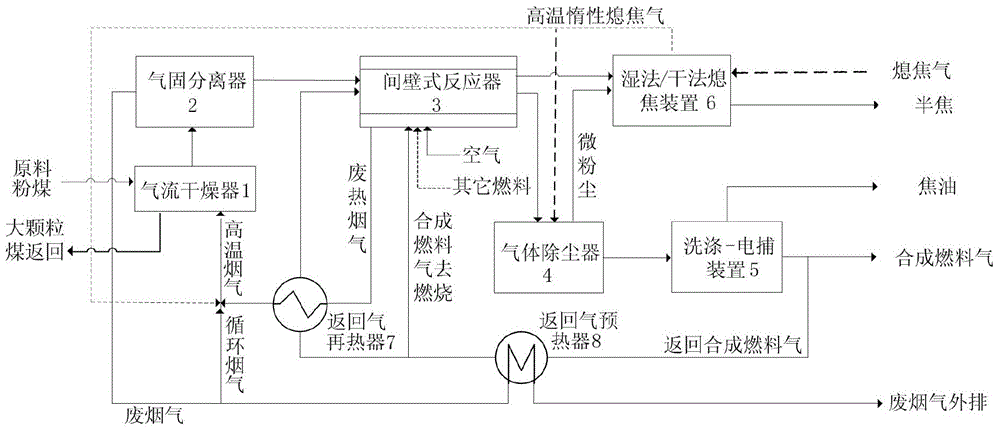

Method for producing tar, semi-coke and synthetic fuel gas by low-degree of coalification powdered coal

ActiveCN103497784AReliable waySafe wayLiquid hydrocarbon mixture productionSpecial form destructive distillationCoal conversionPollution

The invention relates to a method for producing tar, semi-coke and synthetic fuel gas by low-degree of coalification powdered coal. The method comprises the steps of low-degree of coalification powdered coal pre-drying, dry powdered coal separation, low-degree of coalification powdered coal conversion, light gaseous product dedusting, light gaseous product separation and collection, pyrolysis product semi-coke recovery and the like. The method provided by the invention provides a safe and reliable way for realizing efficient utilization of the powdered coal. The method provided by the invention is high in throughput and high in heat exchange efficiency, and can automatically sieve raw material grains, so that load on a coal preparation system is reduced, and yield of a light product is increased. Compared with the prior art, the method provided by the invention has the advantages that inert component content and tar dustiness in the synthetic fuel gas are effectively reduced, heat transfer efficiency and conversion reaction speed are effectively improved, and yield of tar and synthetic fuel gas products is increased, wherein the tar dustiness is less than 0.1mg / kg. The method has the characteristics of low energy consumption and low environment pollution, thereby having very important economic significance and social significance and having a great application prospect.

Owner:THE NORTHWEST RES INST OF CHEM IND

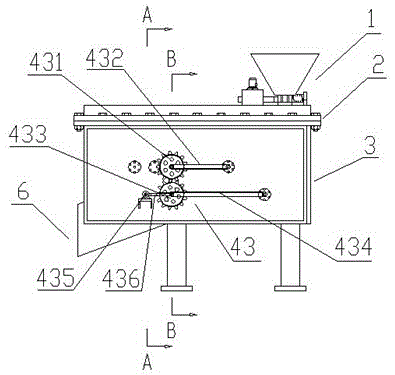

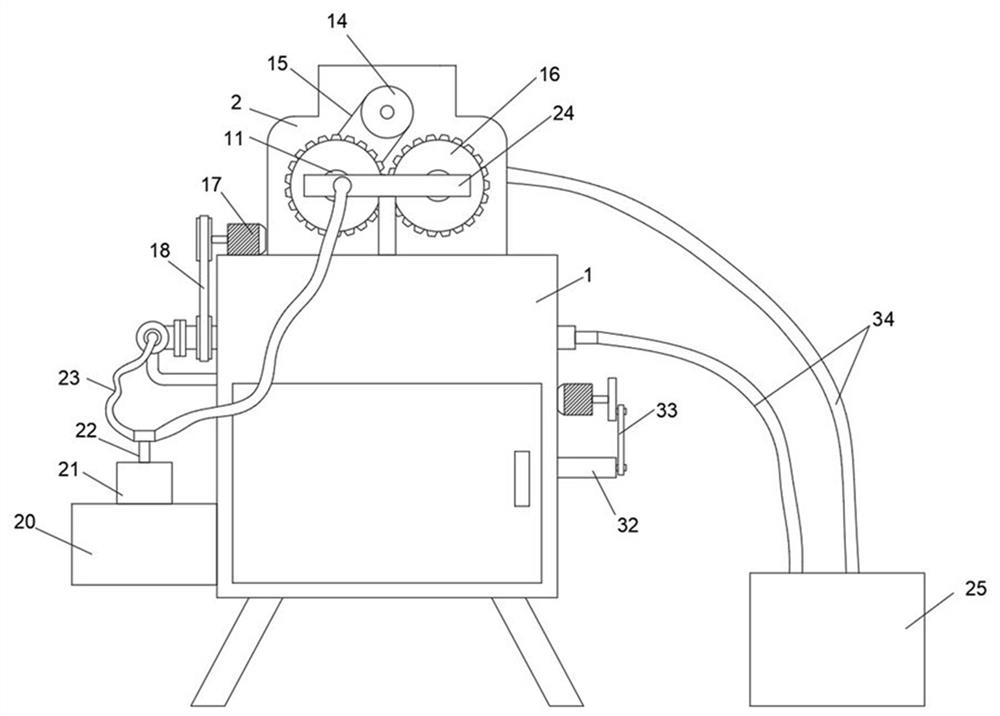

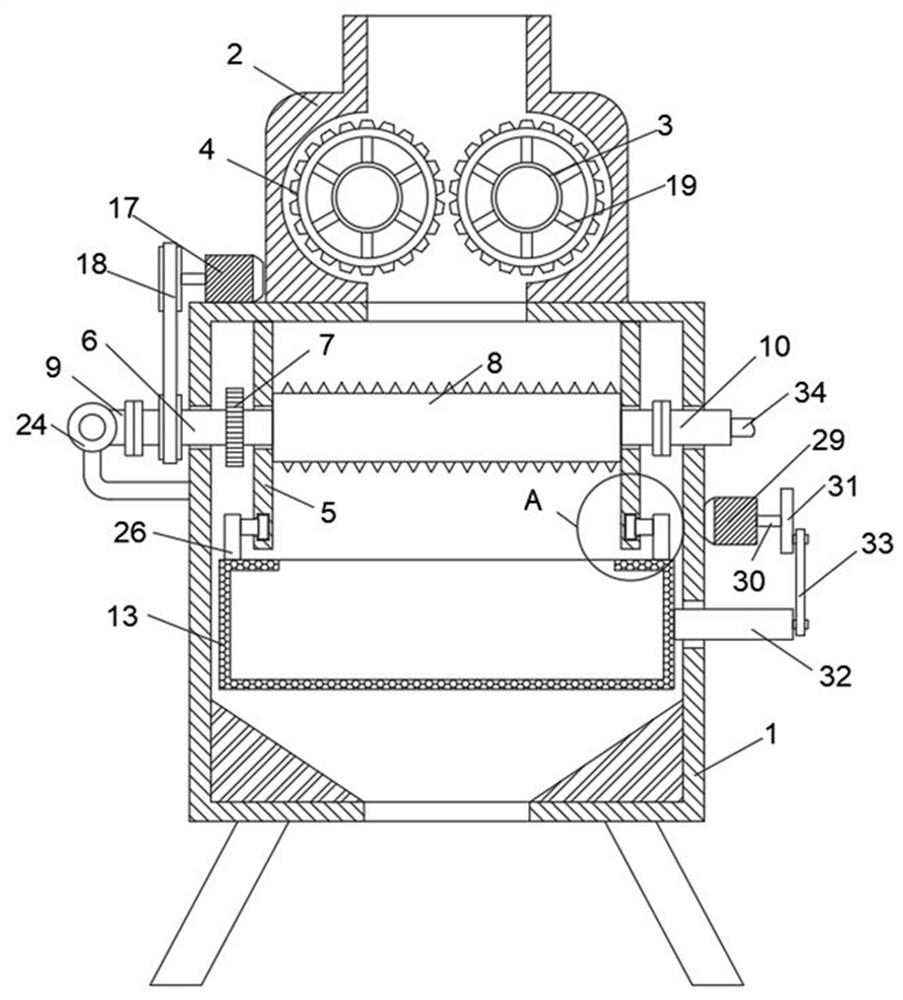

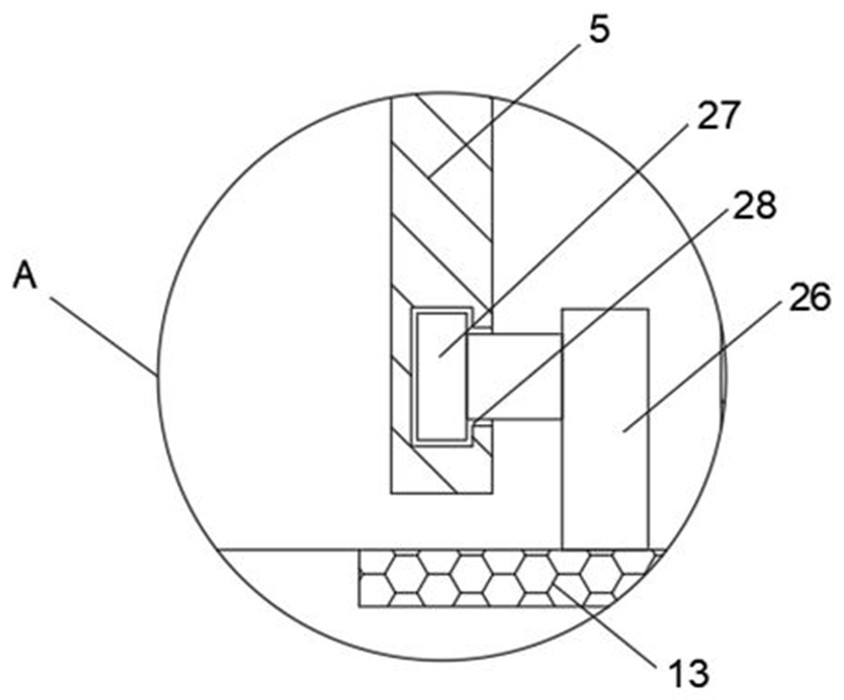

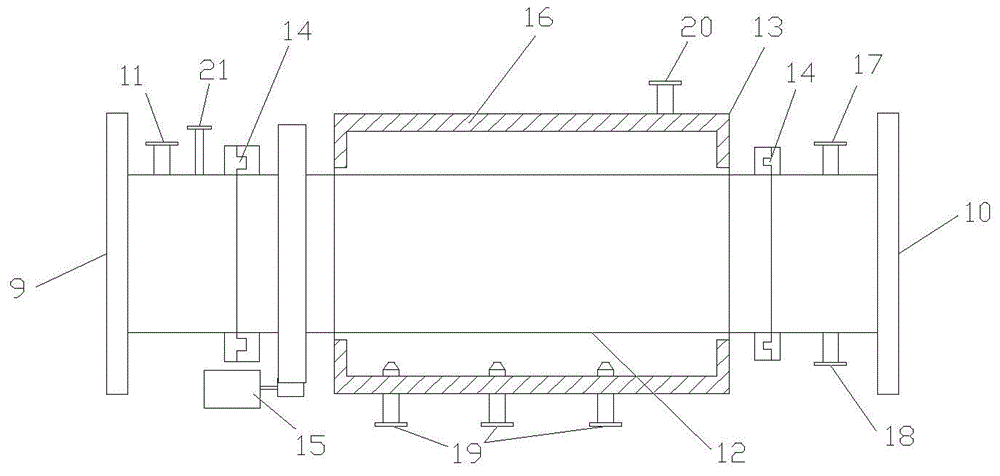

Apricot pit opening machine

ActiveCN105077526ARealize automatic screeningRealize automatic cuttingConveyorsHuskingDrive shaftEngineering

The invention discloses an apricot pit opening machine. The apricot pit opening machine comprises a feeding device, an upper cover plate, a box body, a conveying device, a cutting device and a discharge port. The feeding device is arranged on the upper cover plate. The conveying device and the cutting device are fixedly arranged in the box body. The cutting device is arranged at the discharge end of the conveying device. The conveying device comprises an upper transferring device, a lower transferring device, a transmission shaft and a conveying power device. The upper transferring device comprises an upper transferring belt and an upper pressing plate device. The lower transferring device comprises a lower transferring belt and a lower pressing plate device. The conveying power device is connected with the transmission shaft. The upper pressing plate device and the lower pressing plate device are correspondingly arranged. The apricot pit opening machine has the advantages that apricot pits can be automatically screened and cut, production efficiency is improved, and production cost is reduced; the automation degree is high; overall equipment is low in weight, small in size and convenient to carry; apricot pits which are different in size and middle height can be clamped and cut, and the application range is wide.

Owner:徐州淳康生物科技有限公司

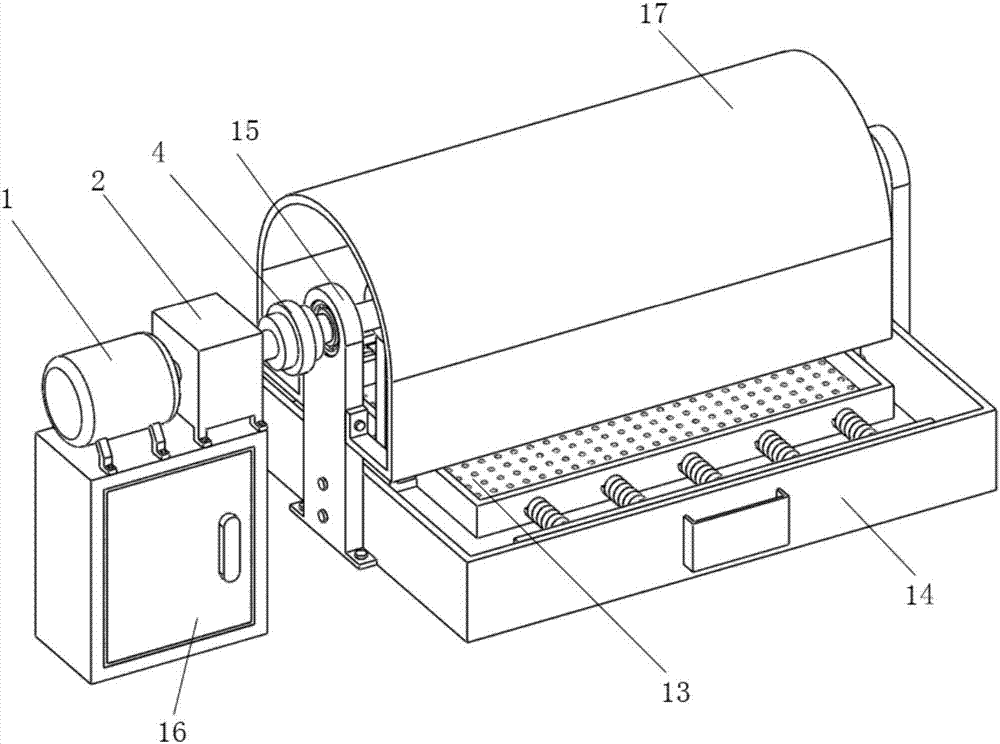

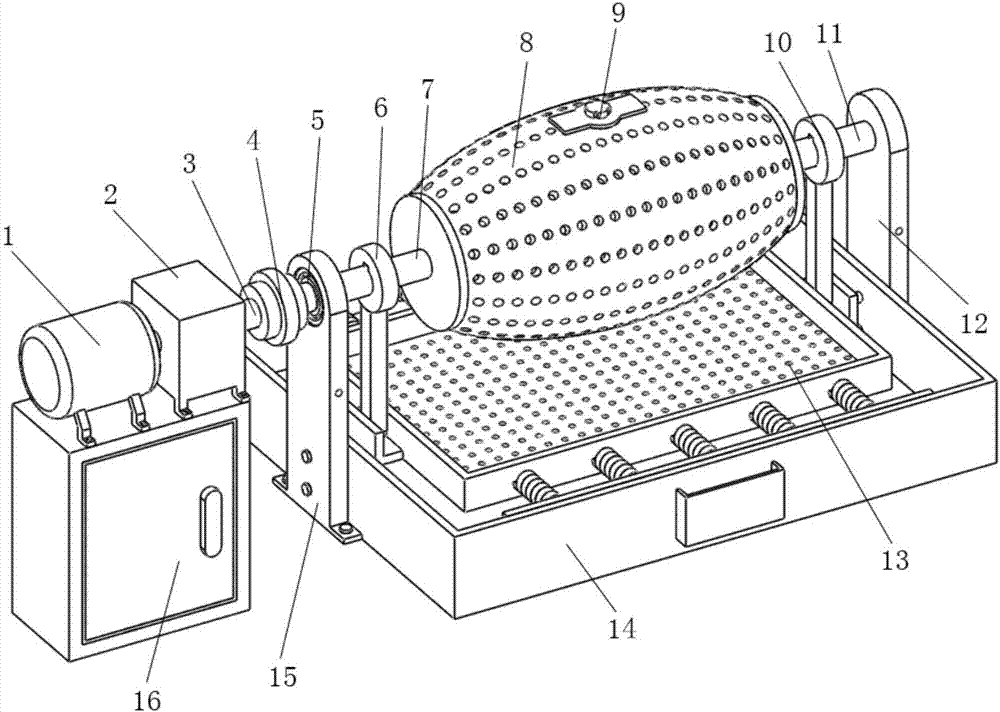

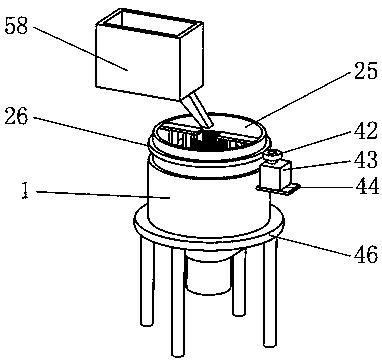

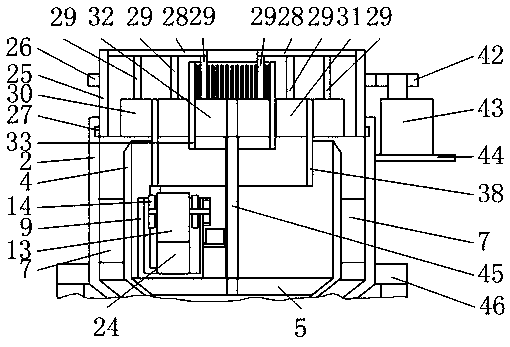

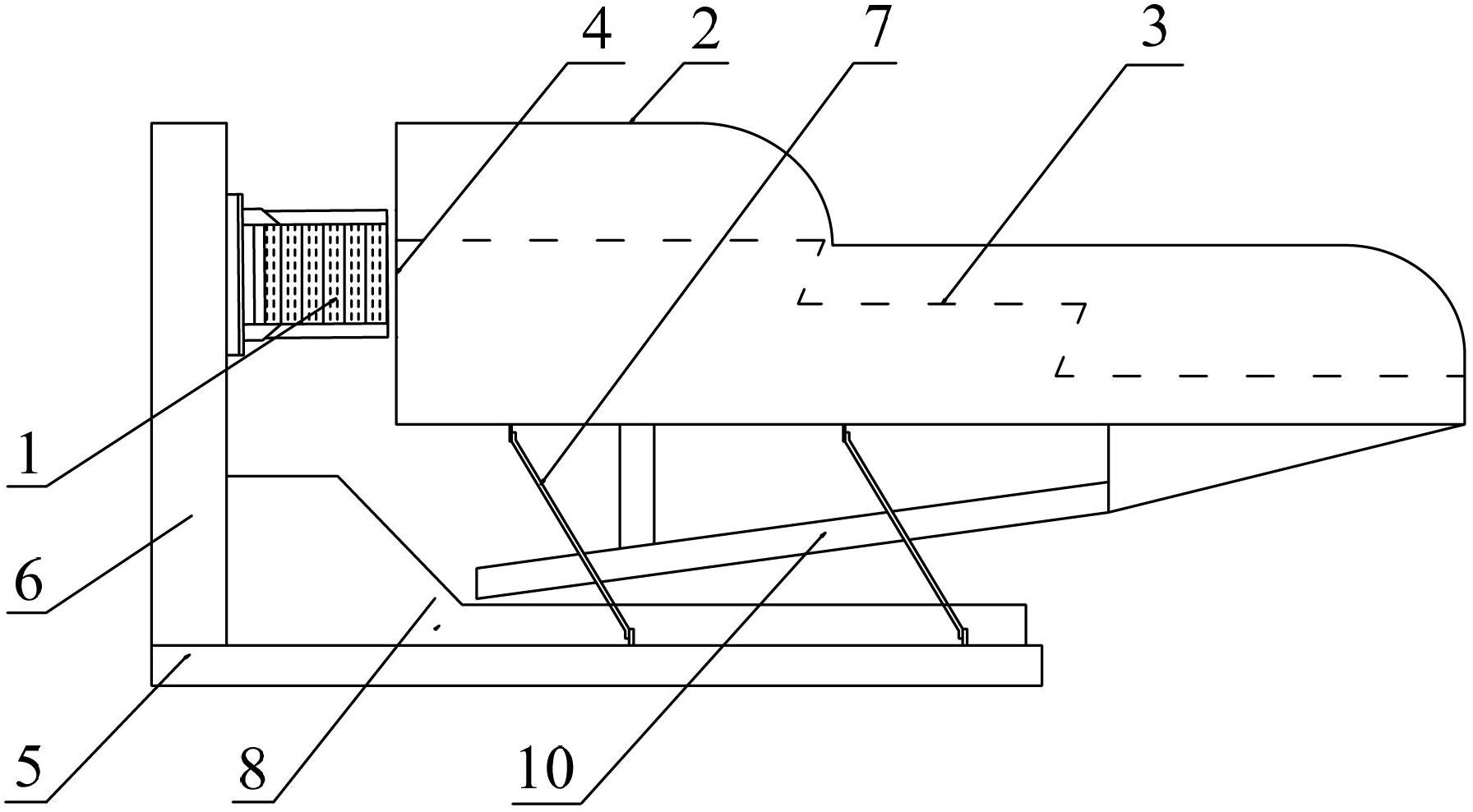

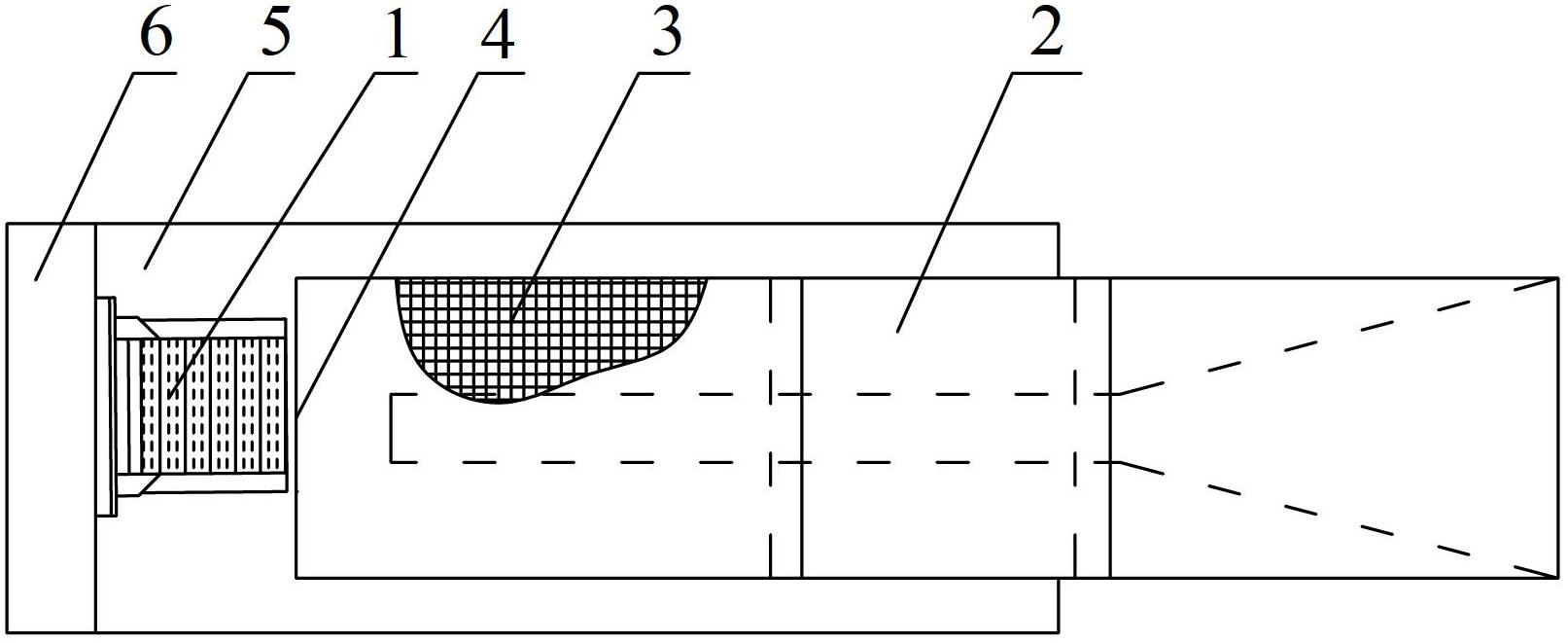

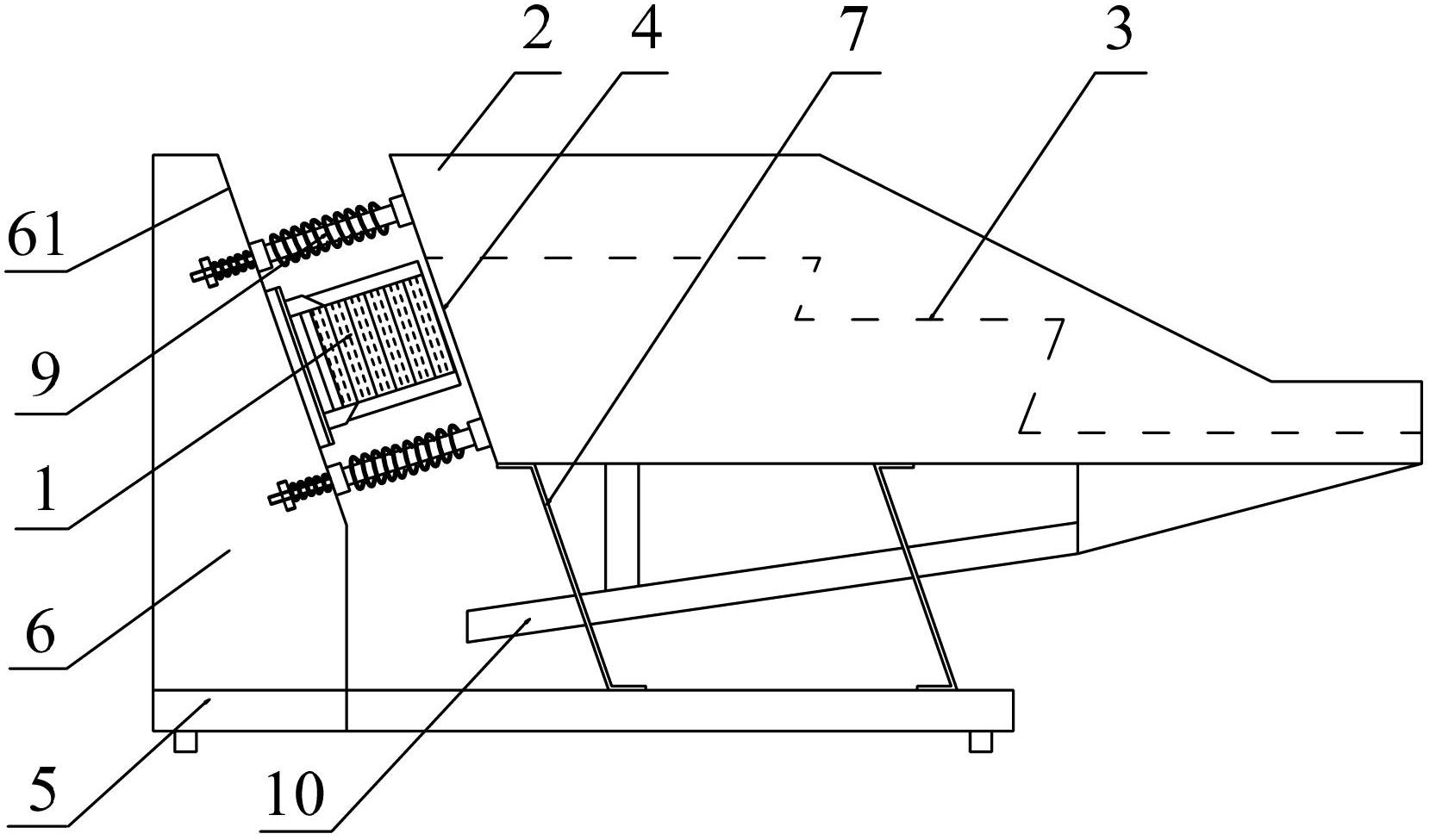

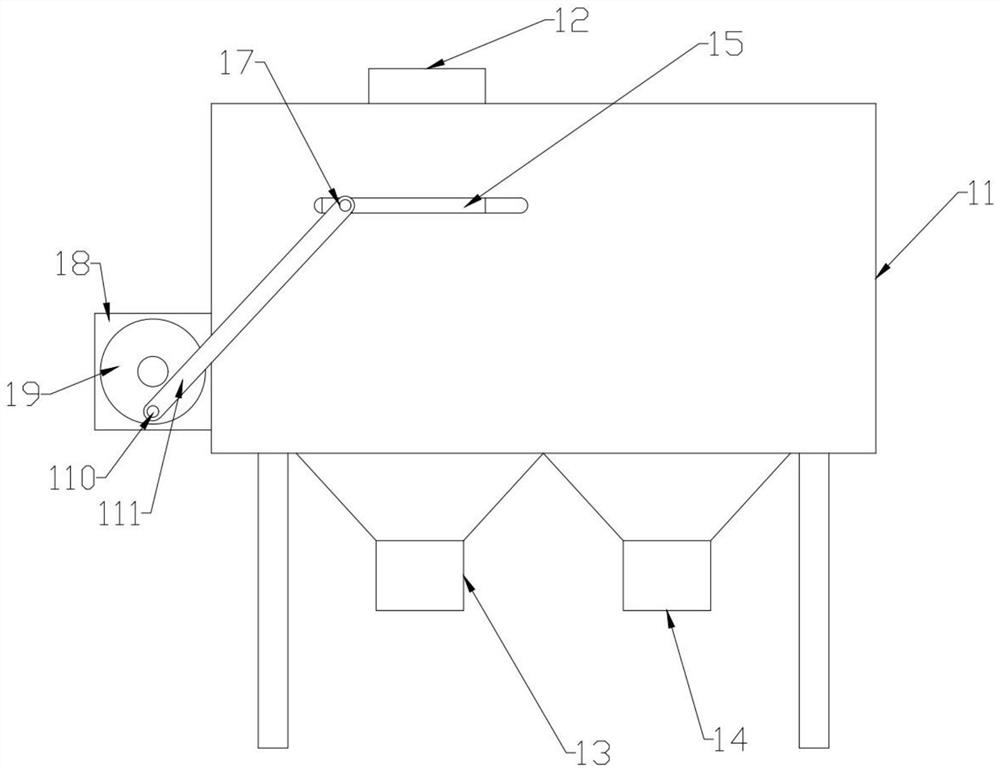

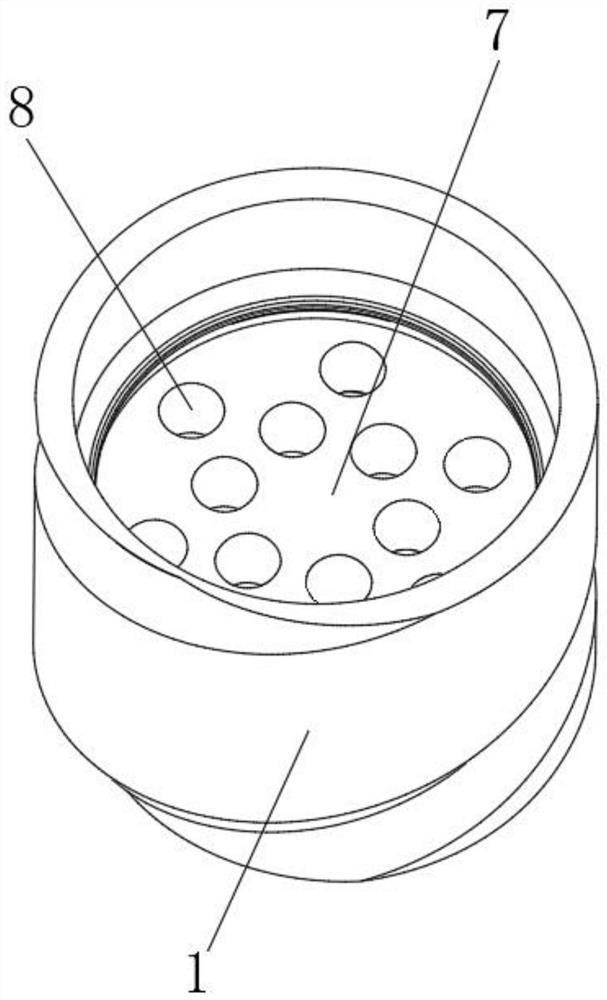

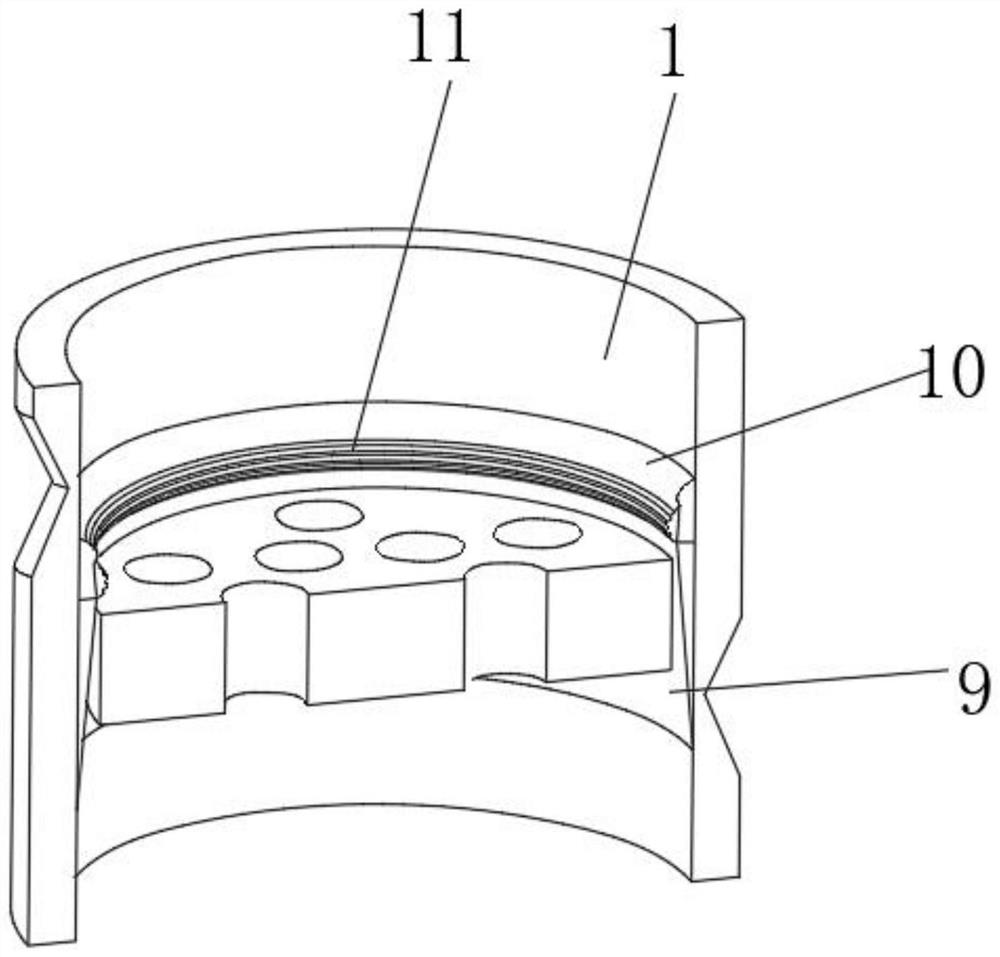

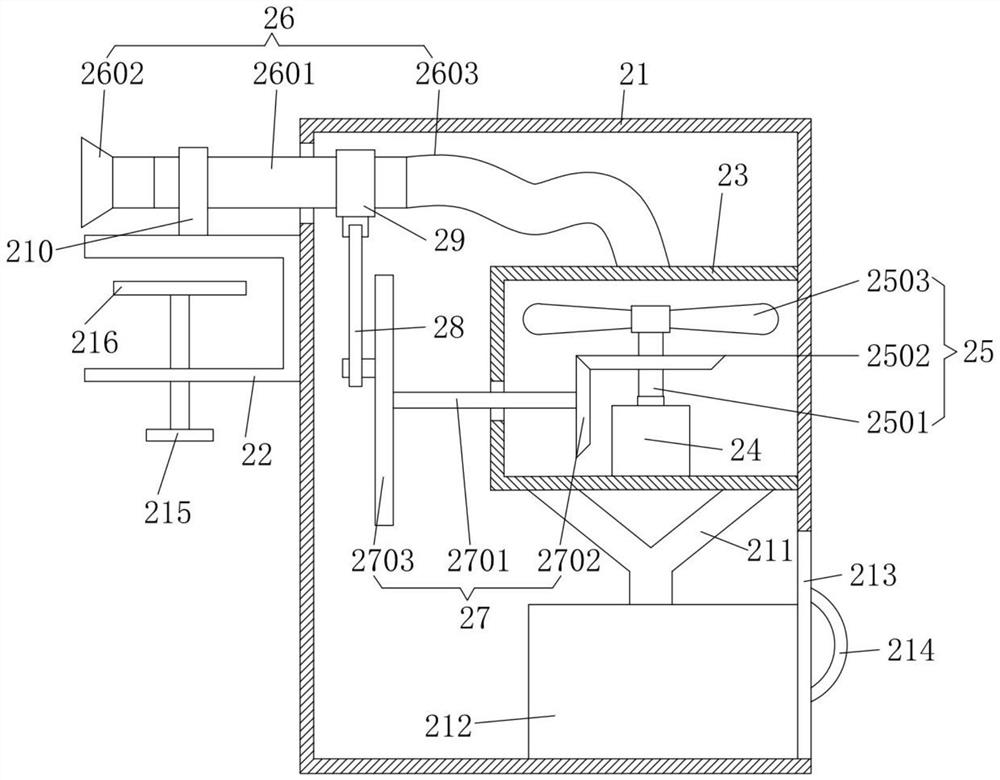

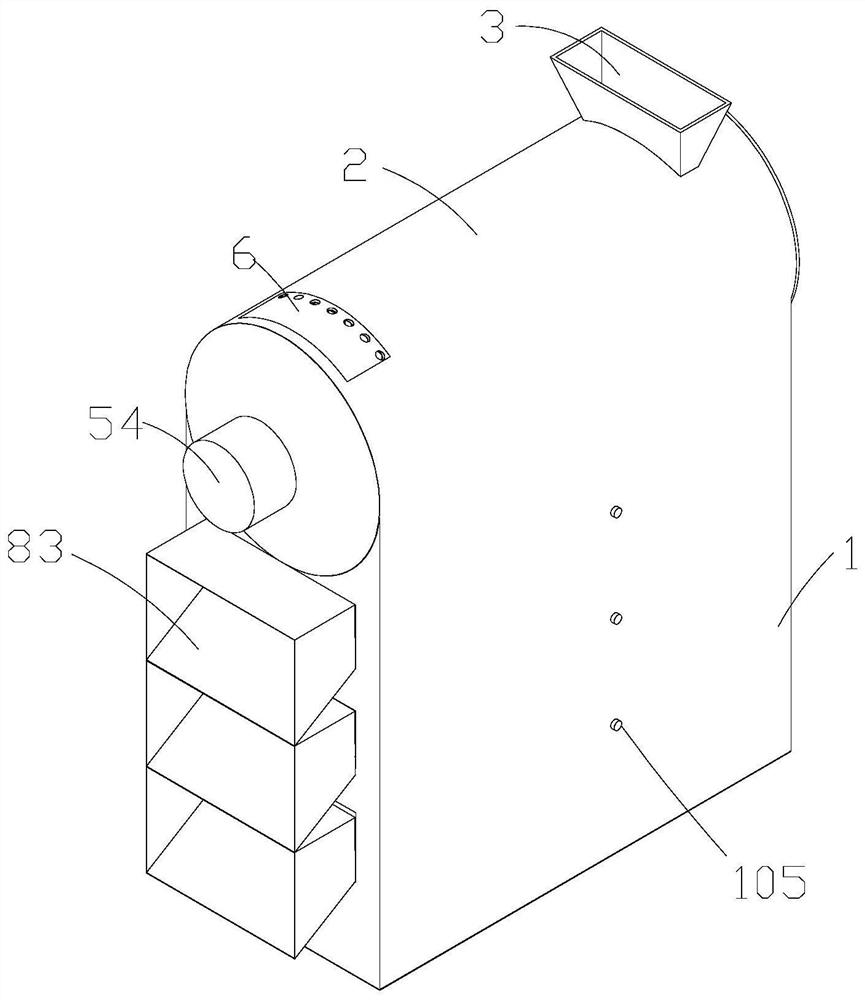

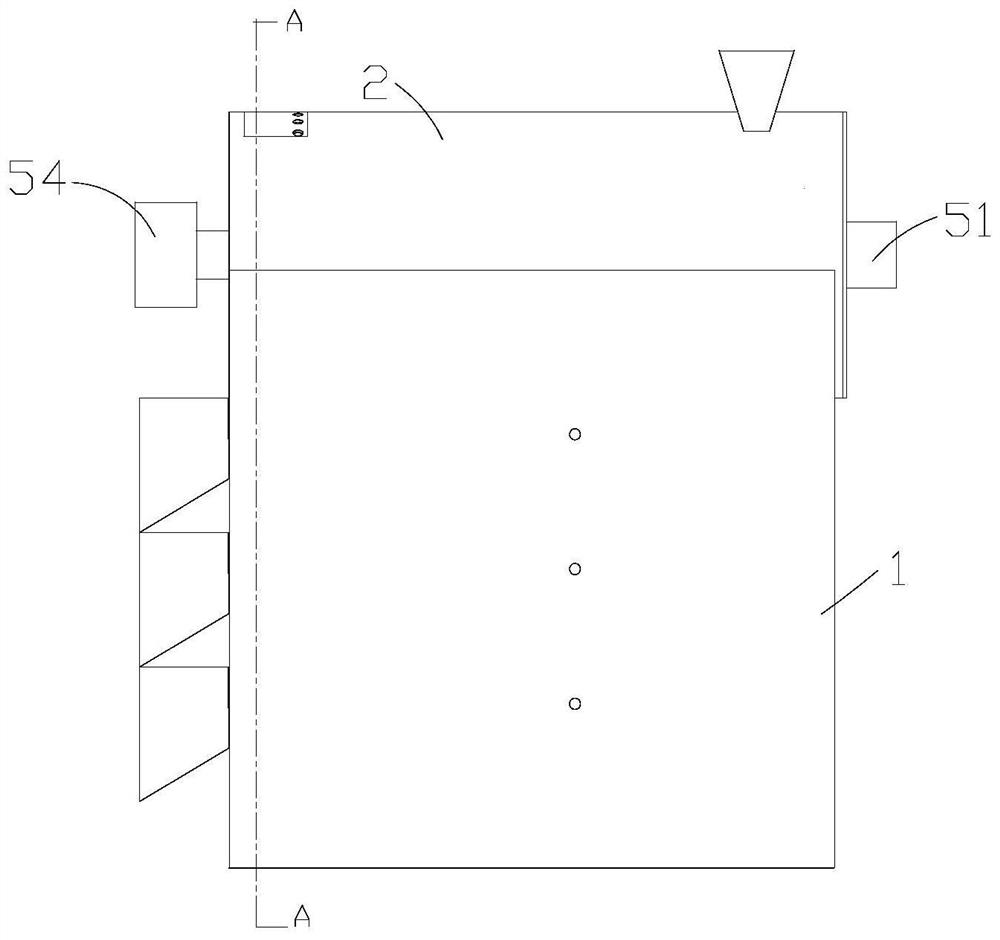

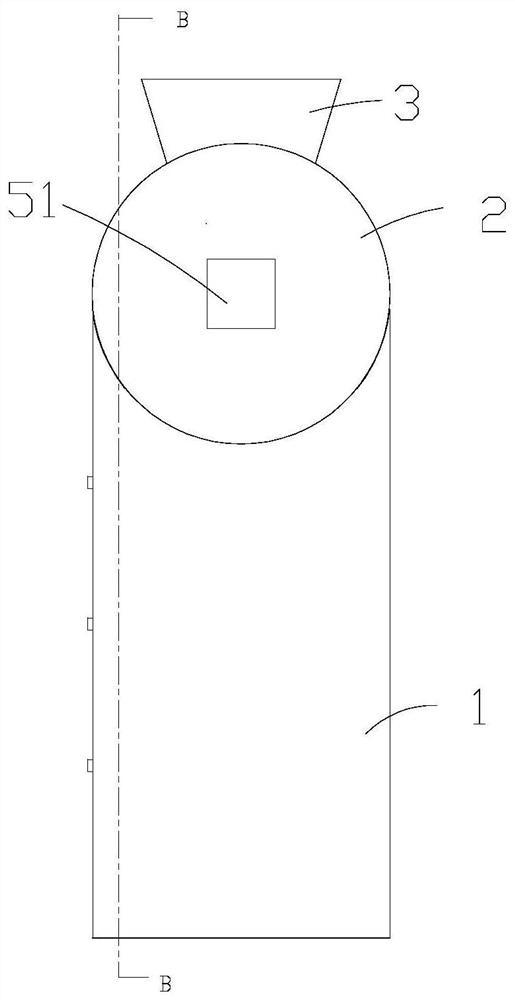

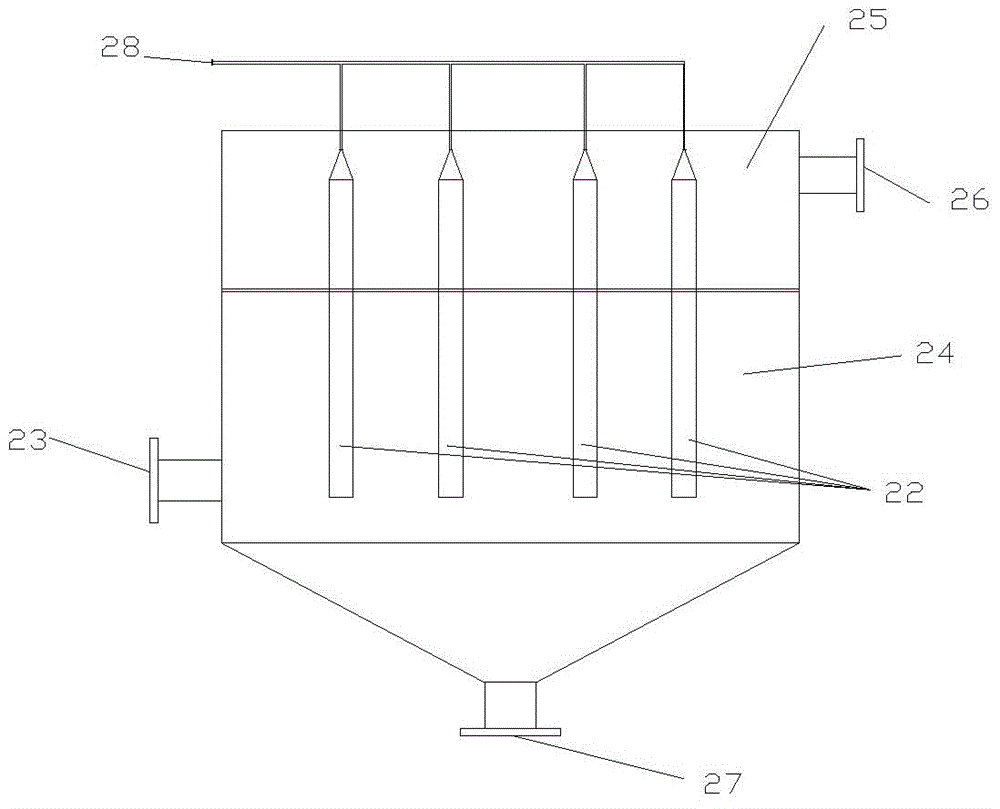

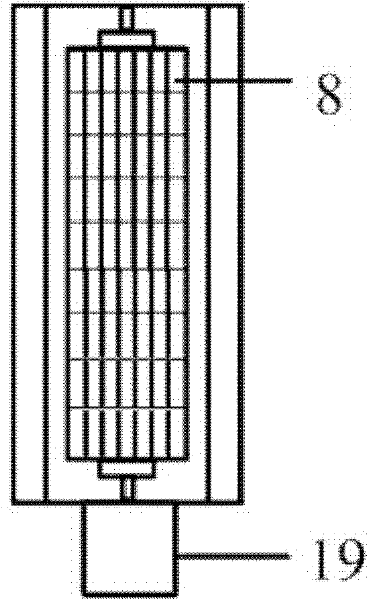

Drum-type rice sieve device

ActiveCN107297332ARealize automatic screeningEasy loading and unloadingSievingGas current separationCouplingBroken rice

The invention relates to a rice sieve device, in particular to a drum-type rice sieve device. The drum-type rice sieve device comprises a motor, a speed reducer, a speed reducer output shaft, a coupler, a first bearing, a first rotating rod, a first shaft, a drum, a seal cover, a second rotating rod, a second shaft, a second supporting seat, a sieve, a dust box, a first supporting seat, a supporting box, a shield, a hopper and a second bearing. The left end of the first shaft is connected with the coupler while the right end of the first shaft is fixedly connected with the drum, the right end of the drum is fixedly connected with the second shaft, the first rotating rod is in key joint with the first shaft, the second rotating rod is in key joint with the second shaft, the sieve is fixed to the dust box through screws, and the dust box is put on the ground. The drum-type rice sieve device has advantages that light impurities in rice can be completely blown out by a fan and a large-pore screen, intact rice grains are screened out under the action of centrifugal force, the sieve is driven by elastic force of springs to separate broken rice and small soil grains, and accordingly labor intensity is relieved, and rice sieving efficiency is improved.

Owner:蚌埠市江淮米业有限公司

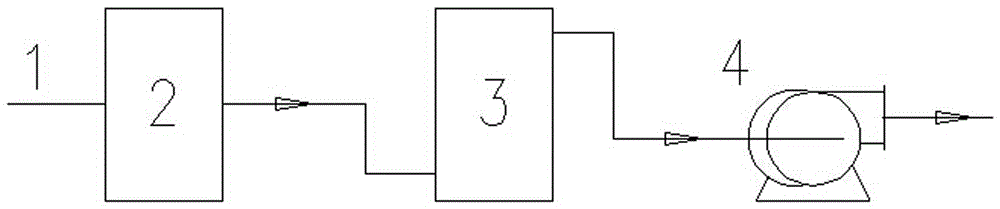

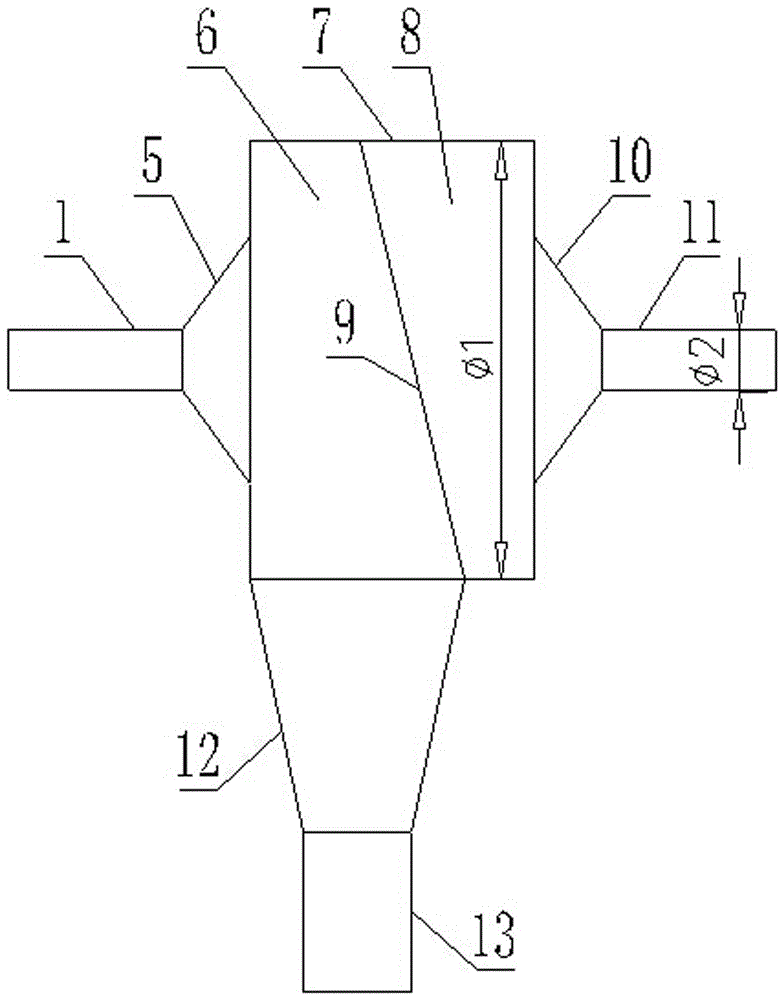

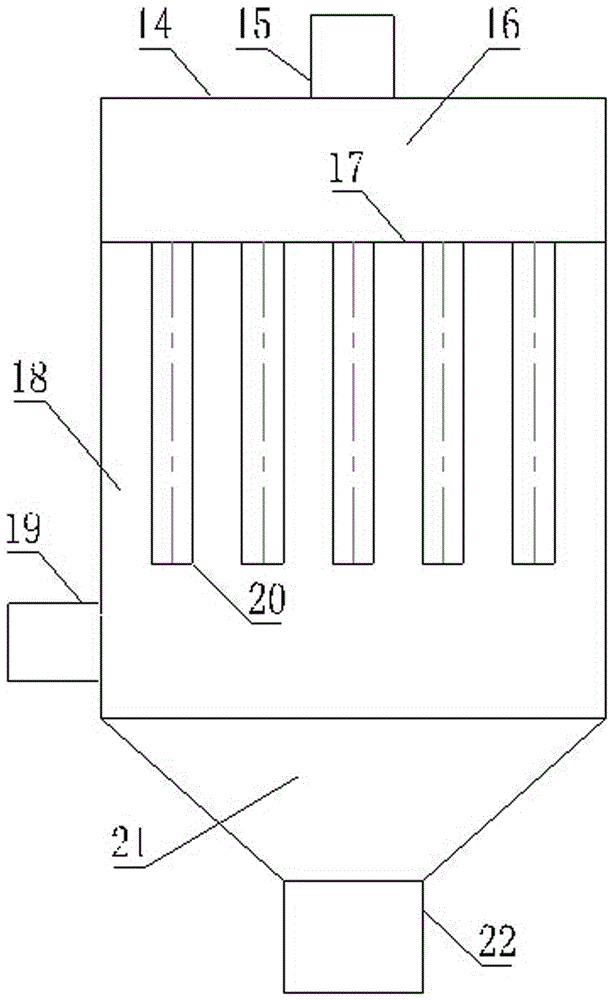

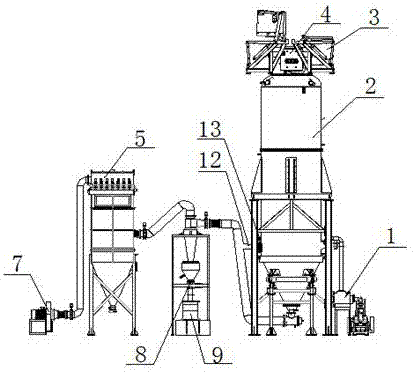

Catalytic agent screening system and method

The invention discloses a catalytic agent screening system and method. The catalytic agent screening system comprises a catalytic agent separating device, an inlet of the catalytic agent separating device is connected with a rubber hose used for conveying converter catalytic agents, an outlet of the catalytic agent separating device communicates with an inlet of a catalytic agent powder collecting device, and an outlet of the catalytic agent powder collecting device communicates with the input end of a fan. Automatic catalytic agent screening is achieved through the catalytic agent separating device, the catalytic agent powder collecting device, the fan and the like. Under the effect of negative pressure wind of the fan, catalytic agent conveying is achieved, catalytic agent screening and collecting and collected catalytic agent powder recycling are completed through the catalytic agent separating device and the catalytic agent powder collecting device correspondingly, the catalytic agent screening cost is lowered, and civilized production is achieved.

Owner:JINCHUAN GROUP LIMITED

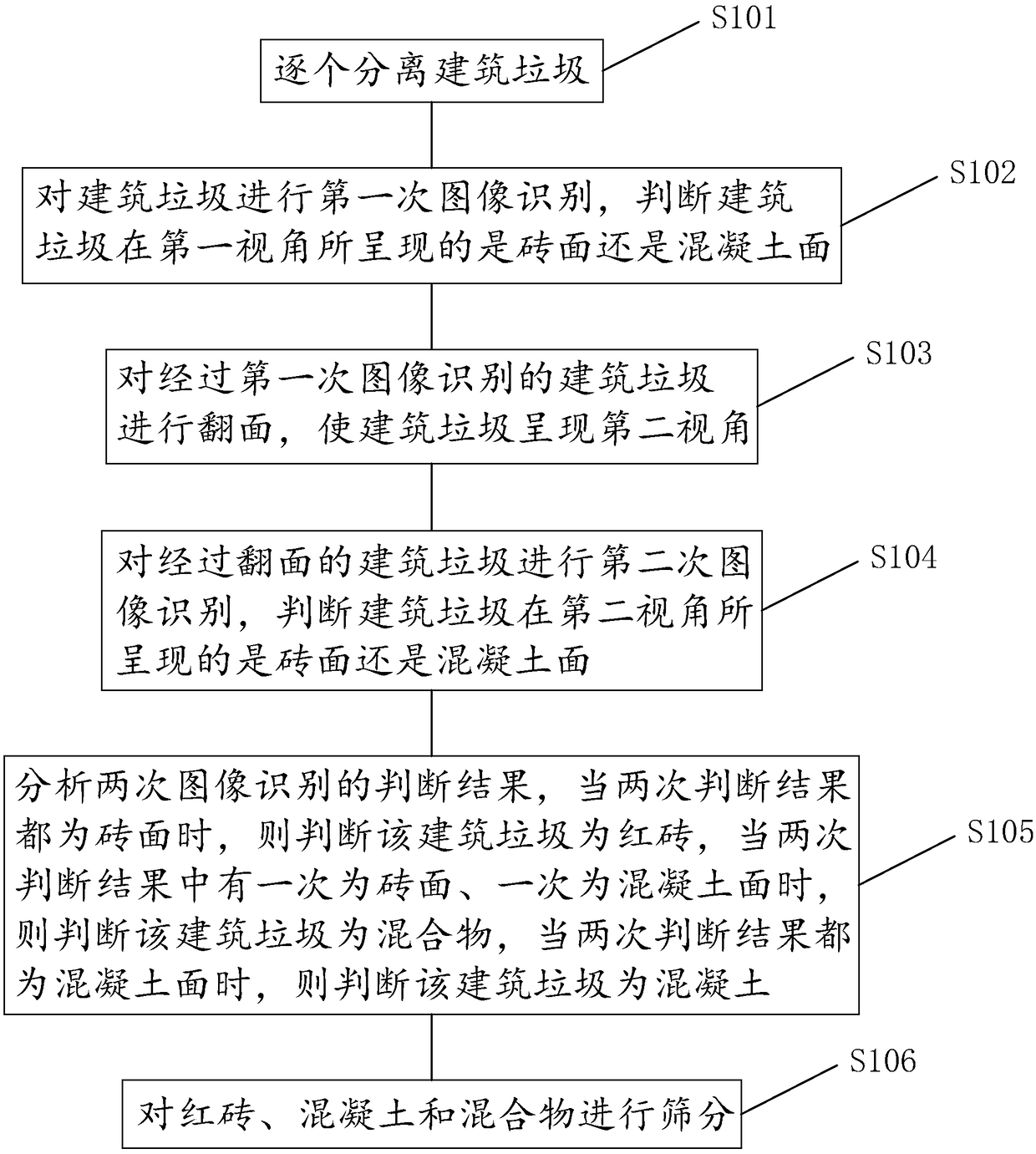

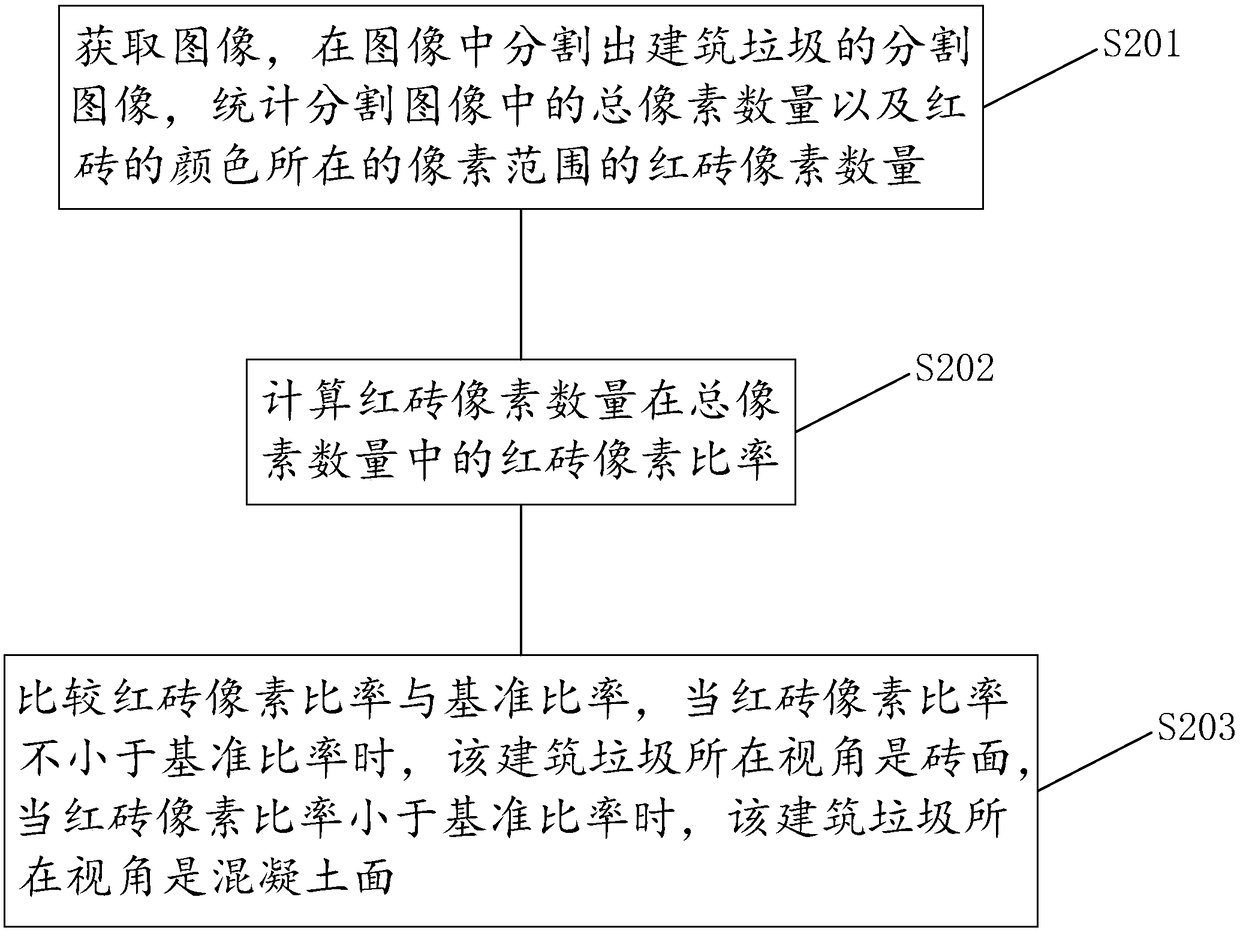

Method for screening red bricks and concrete through image identification and system thereof

ActiveCN108273759AAutomatic screeningRealize automatic screeningSortingImage identificationImaging processing

The invention discloses a method for screening red bricks and concrete through image identification and a system thereof. Through separation of construction garbage one by one and comprehensive identification to screening, an image processing technology is used for screening the red bricks and the concrete and mixtures of the red bricks and the concrete to realize automatic screening of the construction garbage.

Owner:成都建工预筑科技有限公司

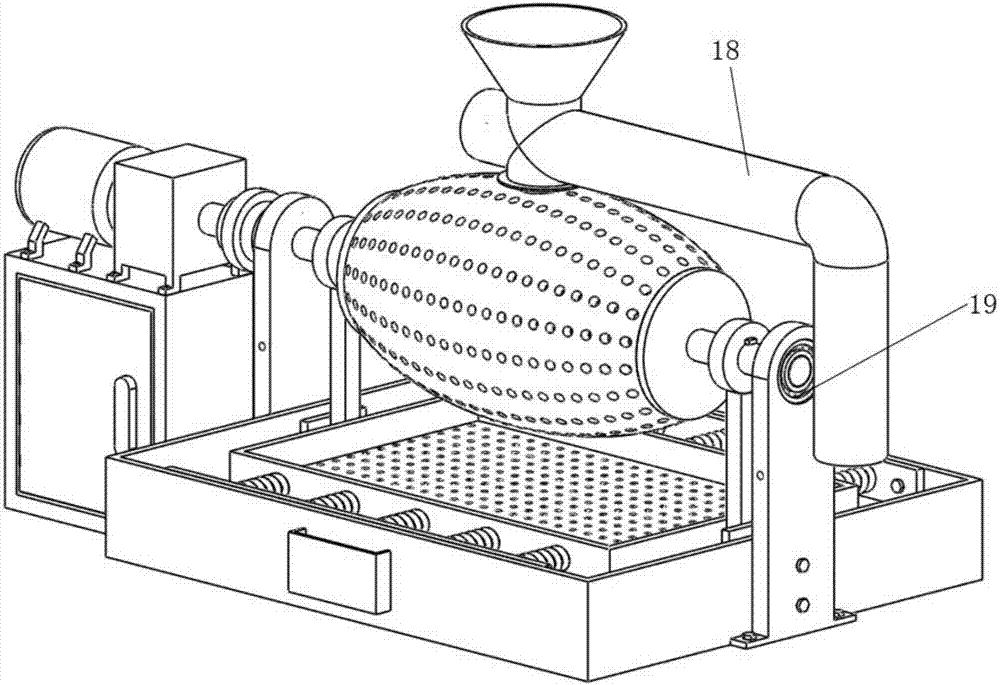

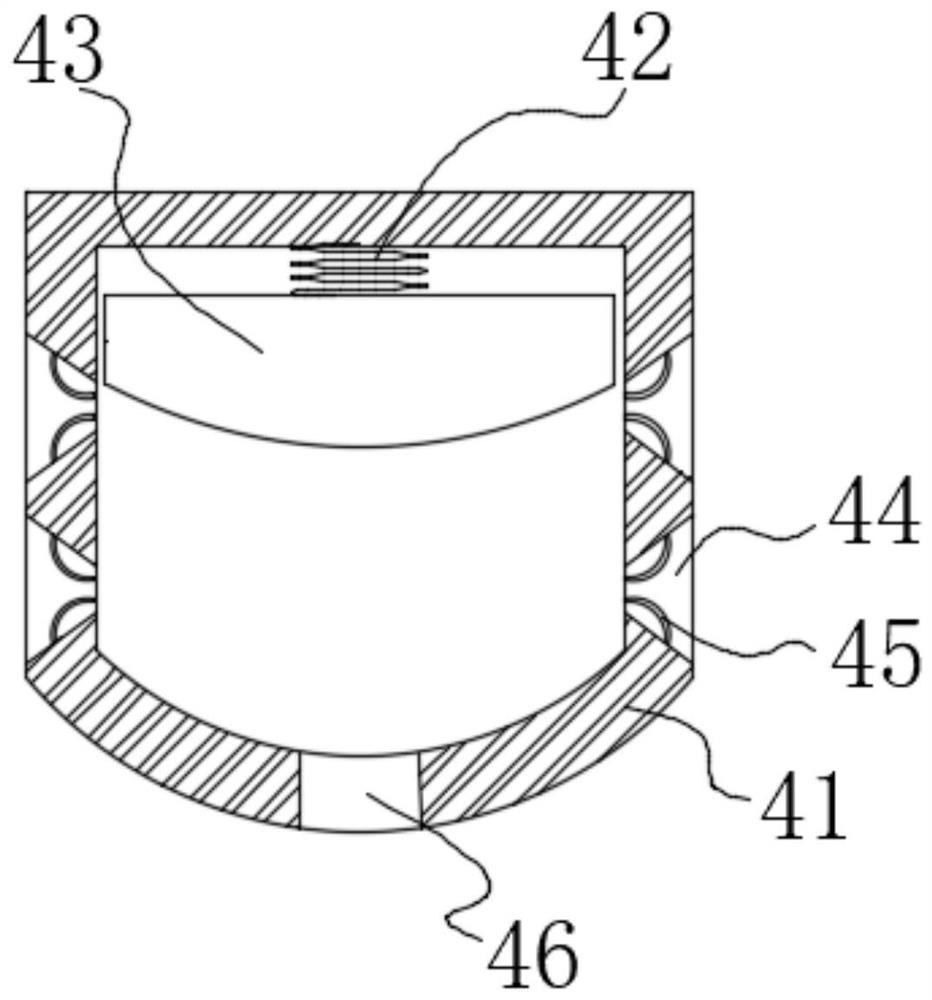

Powder coating packaging machine for screening particles

ActiveCN110000079AImprove screening efficiencyRealize automatic screeningSievingScreeningSelf lockingEngineering

The invention belongs to the technical field of packaging equipment, and particularly relates to a powder coating packaging machine for screening particles. The powder coating packaging machine comprises a discharging ring barrel mechanism, a transmission mechanism, a rotating barrel, a fixing support and the like, wherein the discharging ring barrel mechanism internally provided with the transmission mechanism is fixedly arranged on the fixing support; the powder coating packaging machine can be used for screening different particles of a powder coating from a hopper through a fine screeningcylinder and a coarse screening cylinder which are alternately lifted, so that the screening efficiency of the coating is improved; and the powder coating packaging machine can drive the coarse screening cylinder and the fine screening cylinder to alternately ascend and descend through a first rack and a second rack through only one self-locking motor, so that the automatic screening of the powdercoating is realized, the production cost of equipment is reduced, the control system of the motor is simplified, and the equipment is easier to operate.

Owner:诸暨市圣元塑胶材料有限公司

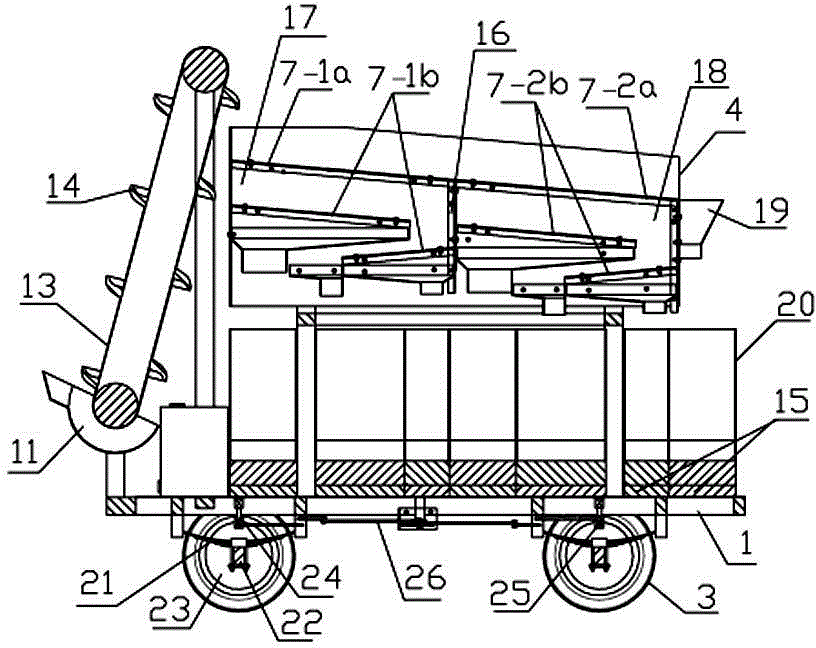

Double-bud section sugarcane seed continuous supply device

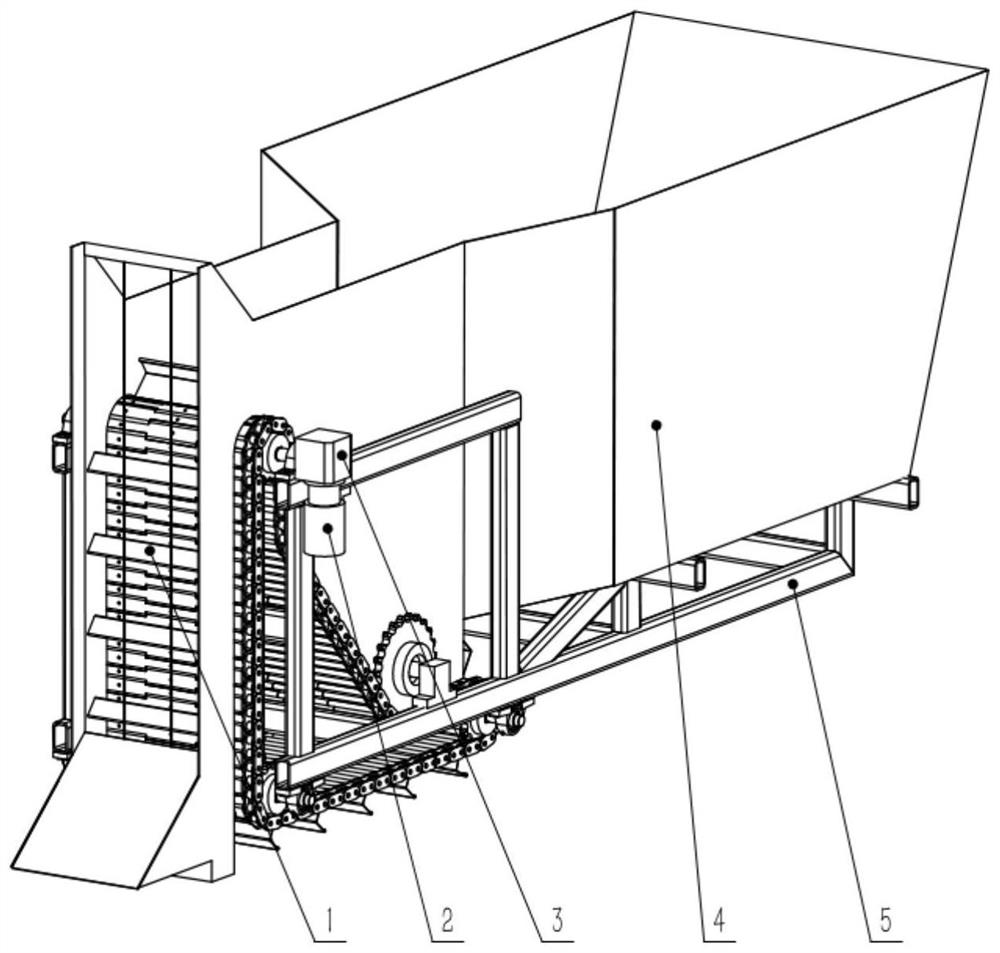

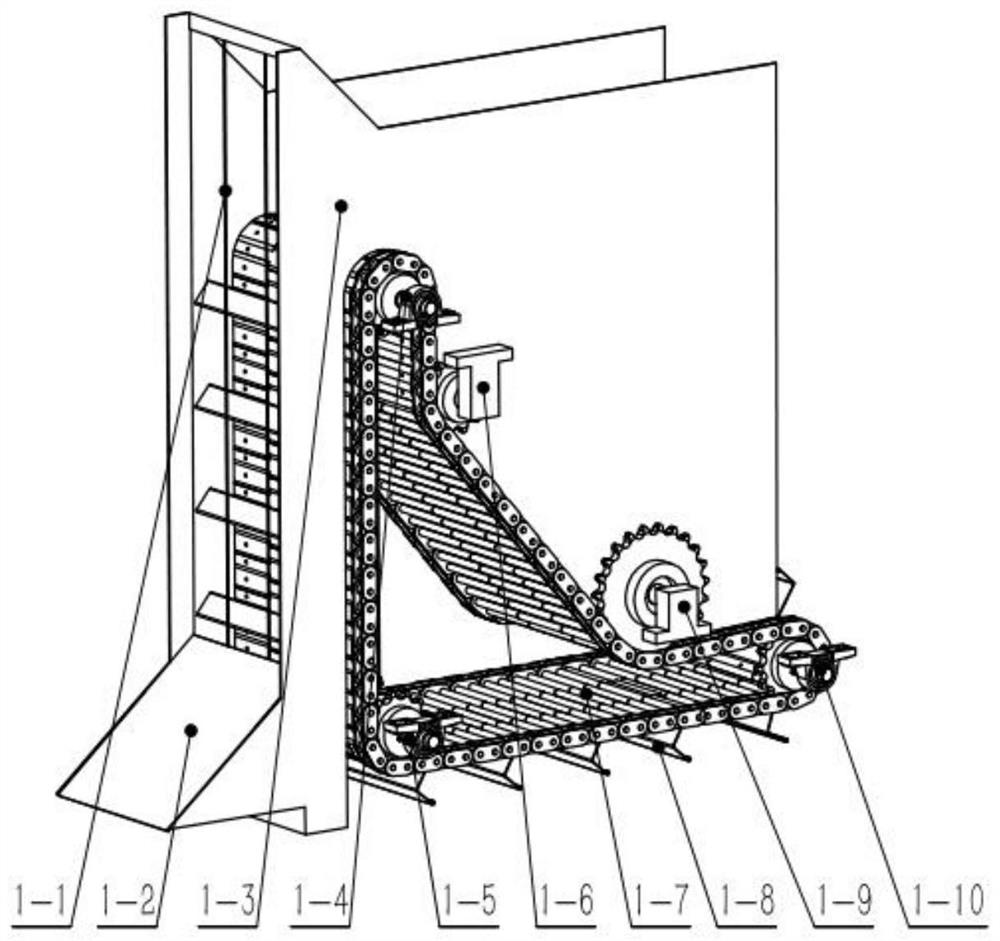

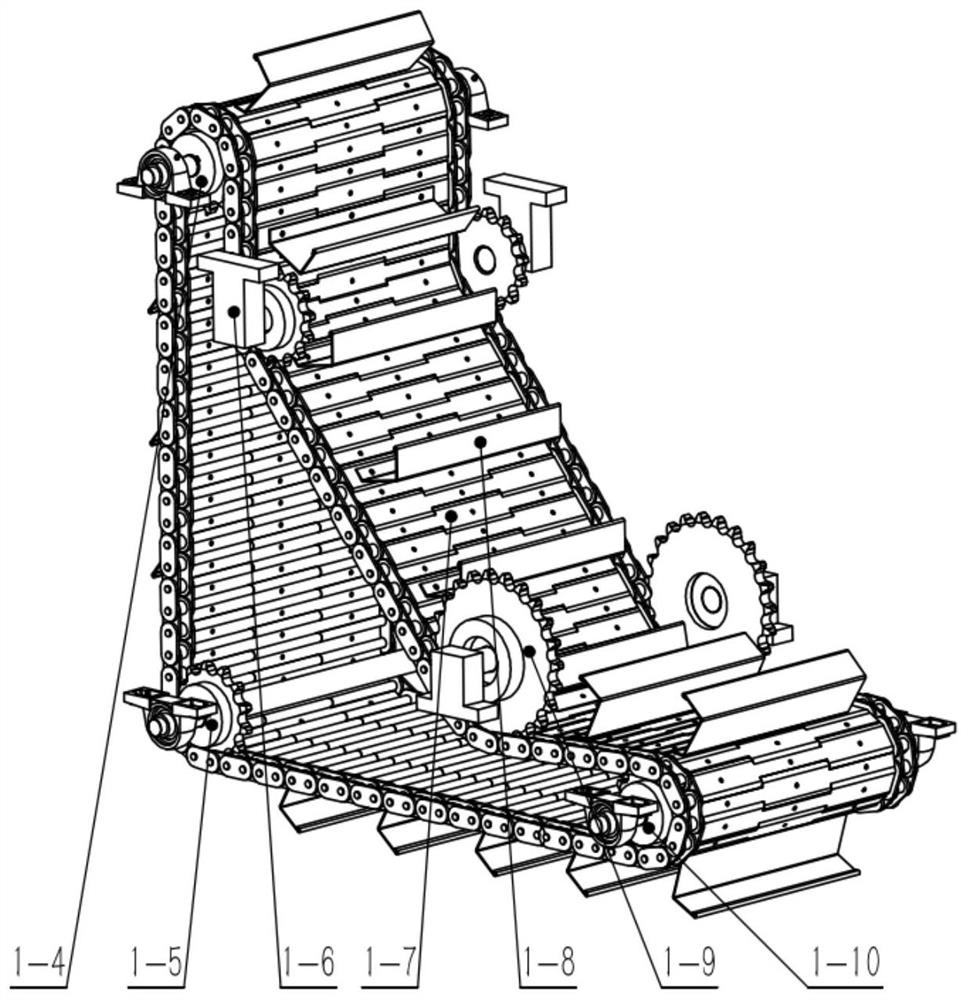

PendingCN112772073AEfficient deliveryAvoid overheadPlantingAgricultural scienceAgricultural engineering

The invention discloses a double-bud section sugarcane seed continuous supply device which comprises a rack, a sugarcane box and a conveying mechanism. The sugarcane box is installed on the rack and used for providing sugarcane seeds for the conveying mechanism, and the conveying mechanism is installed on the rack and located at the front side of the sugarcane box; the conveying mechanism comprises a conveying belt rotatably mounted on the rack and a plurality of sugarcane grooves; the conveying belt is triangular, the front side section of the conveying belt is a seed falling section, and the rear side section of the conveying belt is a seed arrangement section, wherein the seed arrangement section is divided into an inlet section, a lifting section and a redundancy discharging section in sequence from back to front, wherein the inlet section is horizontally arranged or inclines downwards from front to back; the lifting section inclines downwards from front to back, and the included angle between the lifting section and the horizontal plane is larger than that between the inlet section and the horizontal plane, and the redundancy discharging section is vertically arranged; and the sugarcane grooves are formed in the outer side face of the conveying belt at intervals. According to the double-bud section sugarcane seed continuous supply device, the seeds can be continuously, uniformly and orderly fed into a sugarcane collecting box of a seed-metering device, the labor intensity of workers is reduced, and the working efficiency is improved.

Owner:GUANGXI UNIV FOR NATITIES +2

Fitting cutting device

ActiveCN107498110APrecise positioningImplement automatic classificationMetal sawing devicesMetal working apparatusElectricityPulp and paper industry

The invention relates to the field of cutting, in particular to a fitting cutting device. The fitting cutting device comprises a supporting table. A through groove is formed in the supporting table which is connected with a first air cylinder, a second air cylinder and a clamping jaw, and a motor is fixed to the free end of an output shaft of a third air cylinder; a disk saw is fixedly connected with an output shaft of the motor, and a collecting box is located below the disk saw; a waste collecting mechanism comprises a fourth air cylinder and a collecting box which is fixedly connected with the free end of an output shaft of the fourth air cylinder, and the through groove is internally provided with a pressure sensor; and the distance between the pressure sensor and one end of the supporting table is equal to the size of a standard fitting, and the pressure sensor is electrically connected with the fourth air cylinder through a first controller. When the technical scheme is adopted, the fitting can automatically move, the cutting position of the fitting does not need to be manually adjusted, meanwhile firm positioning is achieved on the fitting, and the stable-cutting effect is achieved; and the cut fitting is also automatically screened, the labor intensity is relieved, and the working efficiency is improved.

Owner:重庆市璧山区强顺机械有限公司

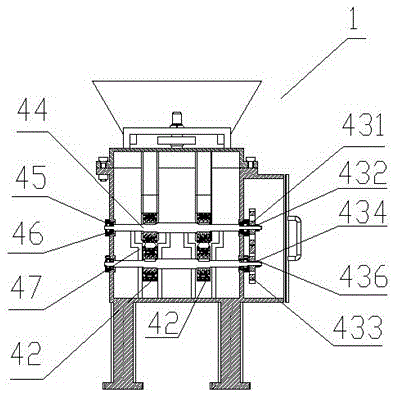

Crushing and identifying device for pulverizer screen

PendingCN110449250AReduce workloadRealize automatic reclaimingFeeding-stuffGrain treatmentsEngineeringMechanical engineering

The invention discloses a crushing and identifying device for a pulverizer screen. The device comprises a supporting frame table, a chute pipe, a photographing frame, a vibration feeder, a material taking box and a discharging channel, wherein the chute pipe, the photographing frame and the vibrating feeder are arranged on the supporting frame table, the material taking box is fixed on the circumferential wall of the chute pipe through a connecting sleeve, the discharging channel is welded to the material taking box, the feeding end of the discharging channel is arranged right below the material taking box, and the discharging end of the discharging channel is located right above the vibration feeder. Automatic material taking and automatic screening and recognizing can be realized, the workload of workers is reduced, and the working efficiency is improved.

Owner:HUAZHONG AGRI UNIV

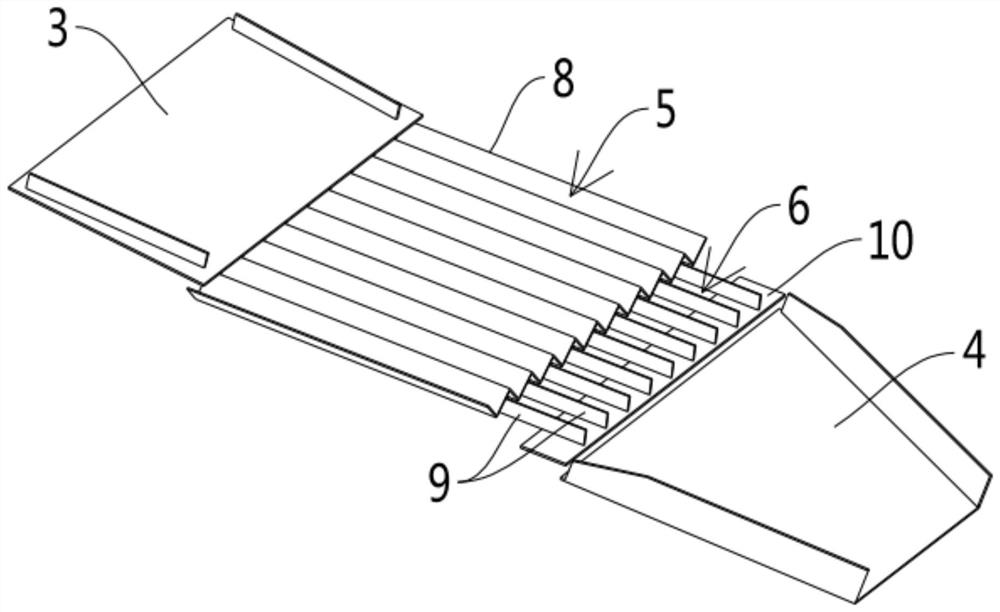

Blanking machine

InactiveCN102671855ARealize automatic screeningIncrease productivitySievingScreeningWorking environmentEngineering

The invention discloses a blanking machine, comprising a vibration groove, a sieve arranged in a groove body of the vibration groove and a vibration device capable of driving the vibration groove to generate vibration, wherein in a working procedure, to-be-sieved tablets are fed to a screen in the groove body of the vibration groove; the vibration device is started; the vibration device is capable of driving the vibration groove connected with the vibration device to vibrate; the tablets do a parabolic path motion forwardly on the screen along a vibration direction of the vibration groove; when the tablets fall down after being thrown, medical powders on the surfaces of the tablets can be dropped from the surfaces of the tablets and is fallen to the bottom part of the groove body through the screen; so that the blanking machine provided by the invention can realize automatical sieving of the tablets; compared with manual sieving in the prior art, production efficiency is increased greatly; simultaneously, an operator can be released; production cost is reduced; the medical powders can be collected into the bottom space of the groove body without spreading towards ambient environment; and working environment is improved.

Owner:YICHANG HEC CHANGJIANG PHARMA CO LTD

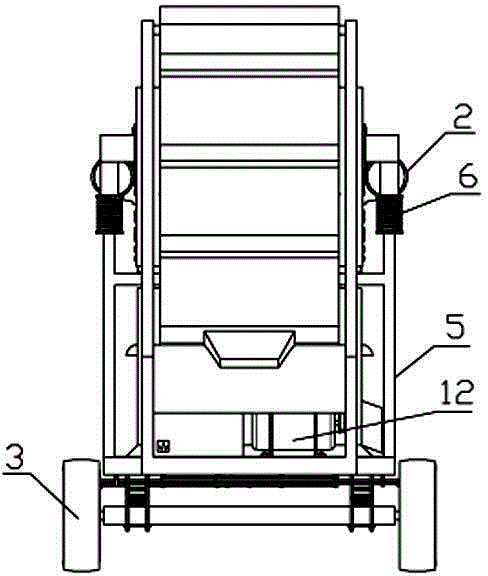

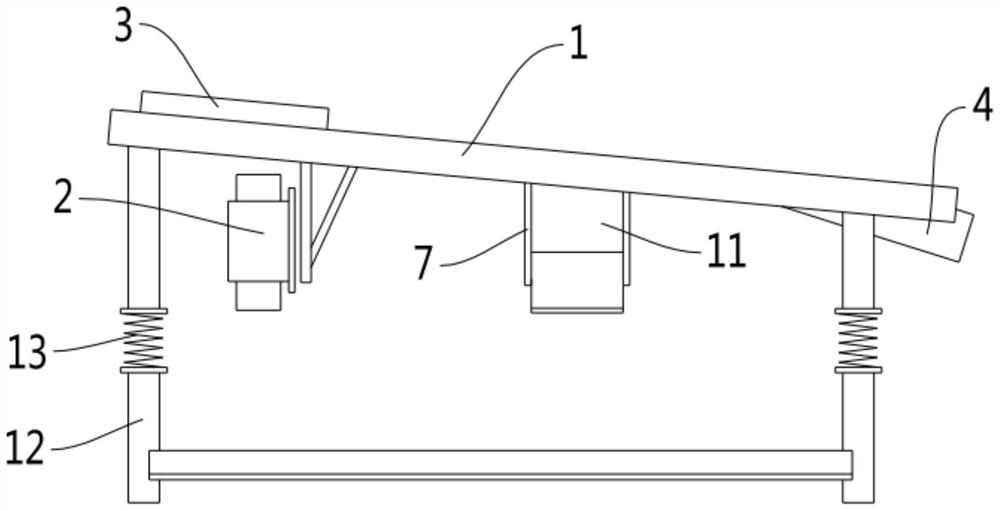

Mobile aggregate screening device

InactiveCN104588315ASimple structureOperation saves time and effortSievingScreeningDrive motorConstruction aggregate

The invention discloses a mobile aggregate screening device. The mobile aggregate screening device comprises an underframe, as well as a storage mechanism and a screening mechanism which are arranged on the underframe; traveling wheels and an automatic charging mechanism are arranged on the underframe; the screening mechanism comprises a screening cabin; screening cabin supports are arranged on two sides of the underframe; a vibrating spring is connected to the upper end of each screening cabin support; the screening cabin is fixedly connected to the tops of the screening cabin supports through the vibrating springs; multiple stages of sieve plates are obliquely connected into the screening cabin in a layered manner; a discharge funnel is arranged below each stage of sieve plate; the storage mechanism comprises a plurality of storage cabins which are arranged below the discharging funnels and are provided with discharging holes; feeding holes in the upper parts of the storage cabins respectively correspond to all stages of discharging funnels; the automatic charging mechanism comprises a feeding cabin arranged at the front end of the underframe and a conveying belt which extends from the interior of the feeding cabin to a position above the screening cabin and is driven by a drive motor to work; conveying grooves are uniformly distributed in the outer surface of the conveying belt. The mobile aggregate screening device is simple in structure, time-saving and labor-saving to operate, much more in grading quantity, high in working efficiency and convenient for analysis research.

Owner:YELLOW RIVER ENG CONSULTING

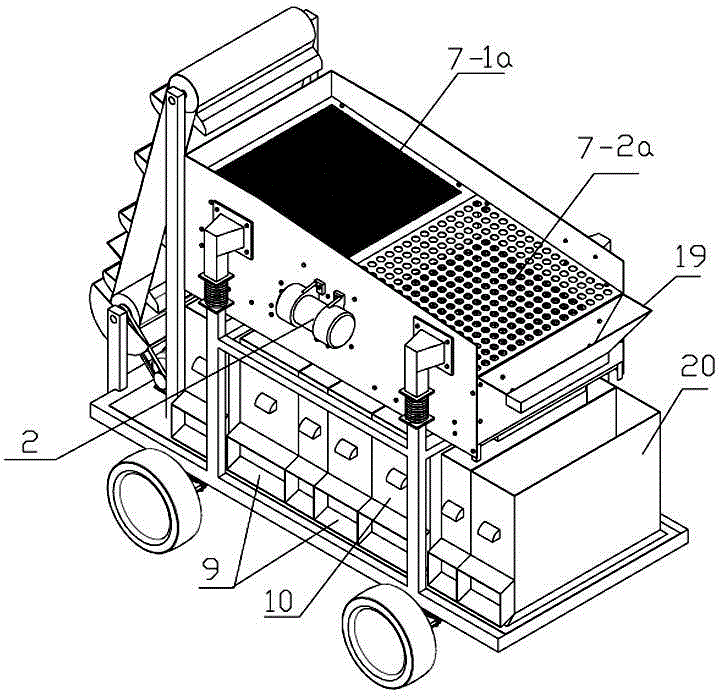

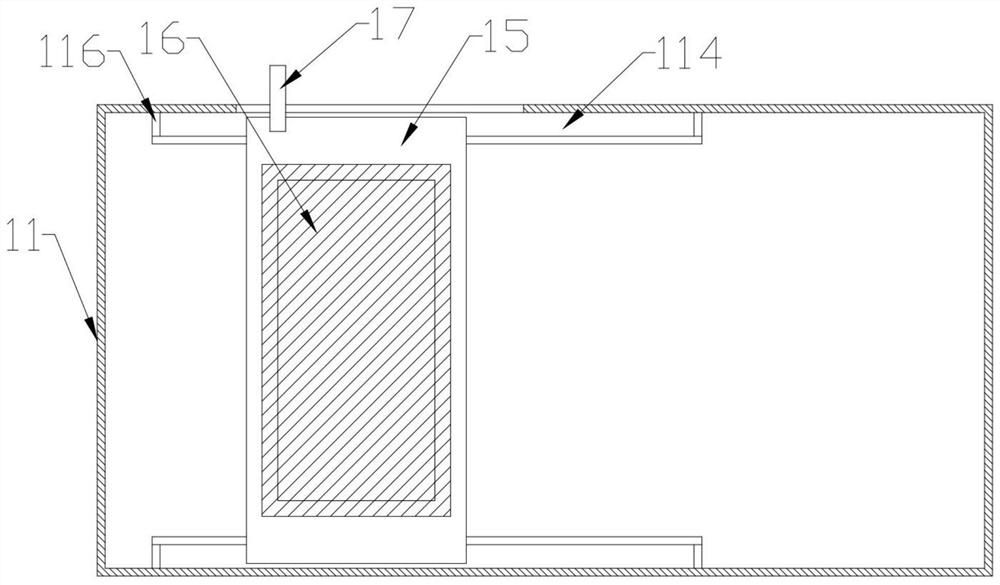

Powder supply device for basic shaft type metal 3D printer

InactiveCN112719301ASimple structureEasy to useSievingAdditive manufacturing apparatusComputer printingProcess engineering

The invention discloses a powder supply device for a basic shaft type metal 3D printer. The powder supply device is characterized by comprising a screening machine and a metering powder feeding device; a first discharging port and a second discharging port of the screening machine are communicated with a feeding port of the metering powder feeding device through powder feeding pipes; a vacuum conveyor is arranged on a powder feeding pipe between the screening machine and the metering powder feeding device; a discharge port of the metering powder feeding device is communicated with a powder supply port through the powder feeding pipe; and a vacuum conveyor is arranged on the powder feeding pipe between the metering powder feeding device and the powder supply port. The powder supply device for the basic shaft type metal 3D printer is simple in structure and convenient to use; the powder screening machine and the metering powder feeding device are used in cooperation; operation such as screening, metering and conveying can be efficiently conducted on metal powder; the screened and qualified metal powder is provided into a powder spreading device of an SLM metal printer or a powder cylinder of a printing cavity; and a series of operations such as automatic screening, metering and conveying are realized.

Owner:ZHEJIANG YIDONG TECH CO LTD

Ore crushing device suitable for mineral exploration

PendingCN114570463AAvoid errorsImprove cooling efficiencySievingScreeningWater storageClassical mechanics

The ore crushing device suitable for mineral exploration comprises a crushing box, the upper surface of the crushing box is fixedly connected with a pretreatment box communicating with the crushing box, the side wall of the pretreatment box penetrates through and is rotationally connected with two first hollow pipes, and the sides, located on the pretreatment box, of the first hollow pipes are fixedly sleeved with primary crushing rollers; and the side wall of the pretreatment box is connected with a first driving mechanism for driving the two first hollow pipes to synchronously and reversely rotate. Crushing work is completed through mutual cooperation of all the structures, the water storage mechanism can convey cooling water into the first hollow pipe and the second hollow pipe, in this way, under the heat conduction effect, the primary crushing roller and the secondary crushing roller can be cooled, and therefore the influence of the temperature on a sample is reduced, and the sample crushing efficiency is improved. And therefore, sample detection errors caused by temperature rise can be effectively avoided.

Owner:山东省地质矿产勘查开发局第五地质大队

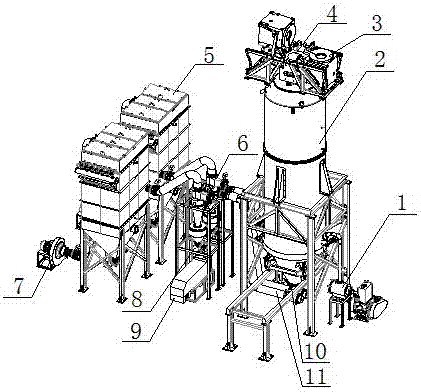

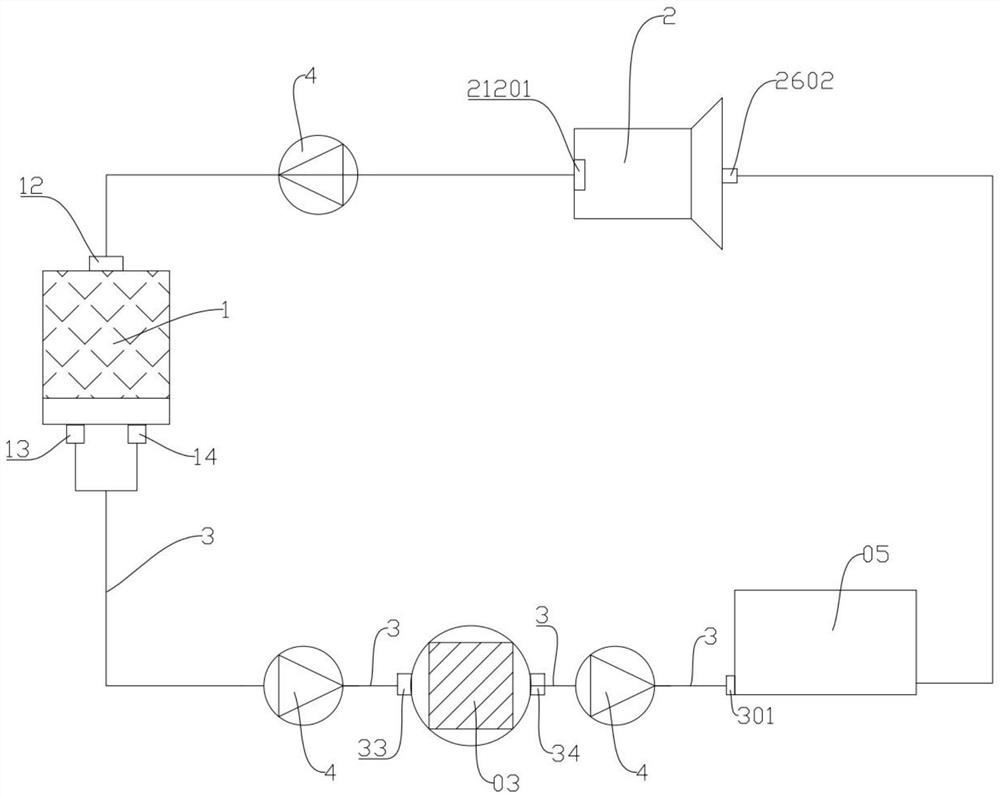

Large-yield efficient gas atomization powder manufacturing apparatus

The invention provides a large-yield efficient gas atomization powder manufacturing apparatus which comprises a smelting system, an atomization system, a powder feeding system, a dust removal system, a screening system and a vacuum-pumping system. The smelting system comprises two or more smelting furnace; the atomization system comprises a transition material bag and an atomization tower; and the powder feeding system, the dust removal system and the screening system are sequentially connected. The powder feeding system comprises a herringbone connector, an air pipe and an air pipe branch pipe. The design of multiple smelting furnaces, dual pipes, dual dust removal equipment and the like are adopted, when one of the dual facilities breaks down, equipment use is not influenced, the halt production maintaining risk is greatly decreased, and atomization powder manufacturing of 2-5 t / furnace can be achieved; and according to the vacuum-pumping system, an atomization chamber is pumped to be vacuum before atomization, filling of protective atmosphere is then carried out, the oxygen content in the atomization environment is reduced to a large extent, and the oxygen content in the powder is reduced.

Owner:湖南旭博冶金科技有限公司

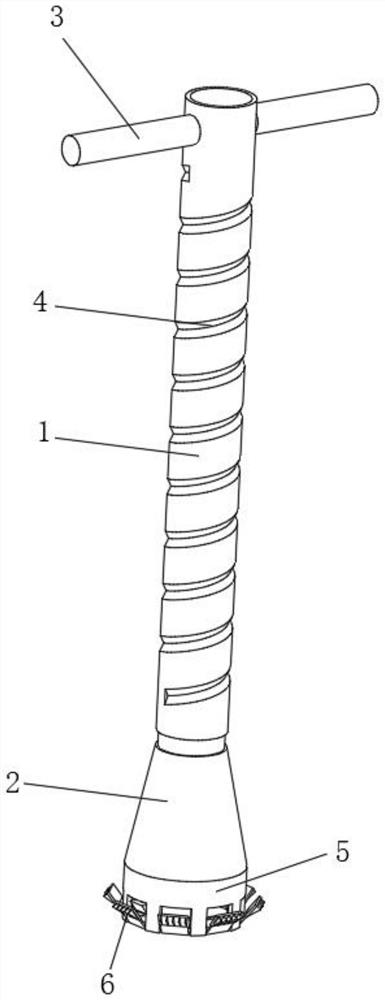

Geotechnical engineering detection sampling device

ActiveCN112798329AImprove firmnessRealize automatic screeningWithdrawing sample devicesHandrailGeotechnical engineering

The invention relates to a geotechnical engineering detection sampling device. The device comprises a sampling insertion pipe; the bottom of the sampling insertion pipe is fixedly connected with a squeezing taper pipe; the outer side of the sampling insertion pipe and the two sides, close to the top, of the sampling insertion pipe are symmetrically and fixedly connected with rotating handrails; the outer surface of the sampling insertion pipe is uniformly provided with driving threads; an inserting and taking circular groove is fixedly connected to the bottom end of the exterior of the squeezing taper pipe; stone removing mechanisms are evenly arranged at the bottom of the inserting and taking circular groove; a compact pressing plate is slidably connected to the middle position of the interior of the sampling insertion pipe; and screening holes are evenly formed in the surface of the compact pressing plate; resistance-increasing taper plates are uniformly and fixedly connected to the surface of the interior of the sampling insertion pipe; and the inner side surfaces of the resistance-increasing taper plates are in corresponding contact with the outer side surface of the compact pressing plate. The invention relates to the technical field of engineering detection. According to the geotechnical engineering detection sampling device, rock soil on the inner side of the bottom of the device is removed outwards, blockage caused by accumulation of stones below the device is avoided, and the sampling precision is improved.

Owner:SHANDONG GUANGXIN ENG TESTING GRP CO LTD

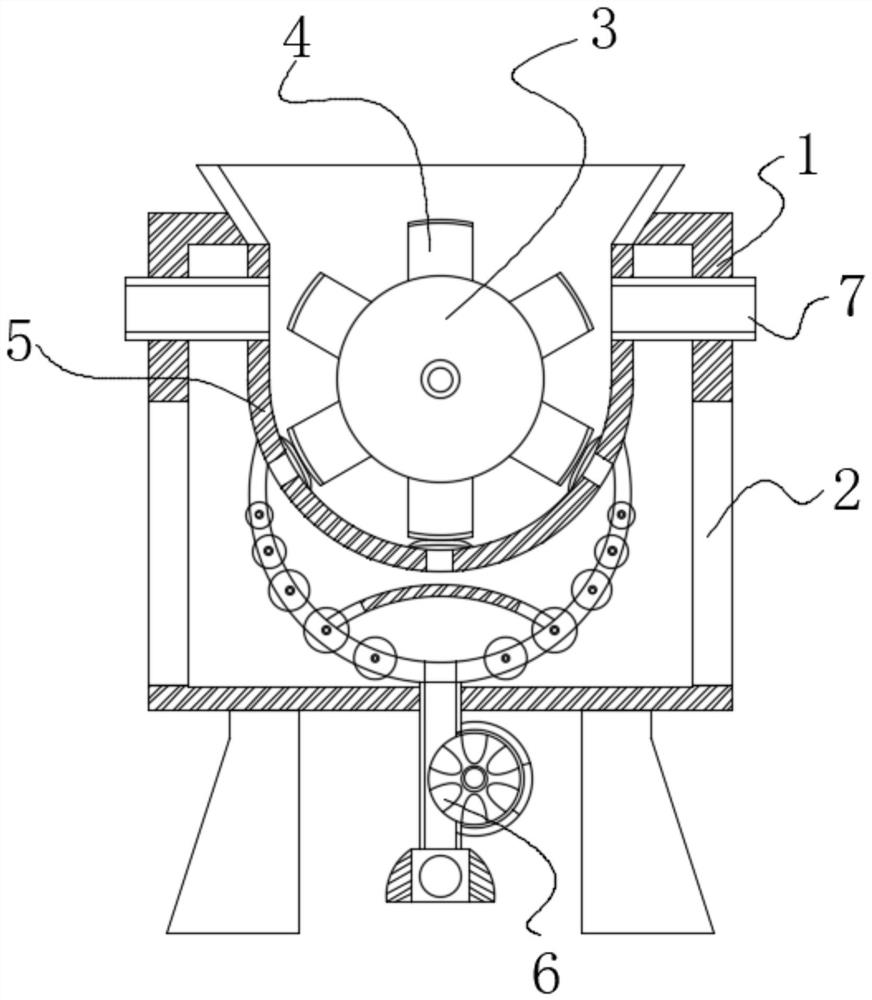

Grinding and screening device for soil heavy metal detection

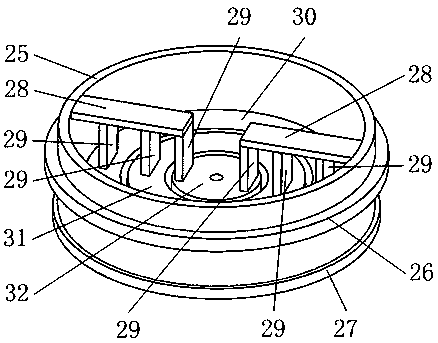

PendingCN109187143AGood for fallingRealize automatic screeningPreparing sample for investigationSoil heavy metalsSprocket

The invention discloses a grinding and screening device for soil heavy metal detection. The grinding and scanning device comprises a case and a grinding filter screen driven by a vibration motor; a bottom plate is installed in the grinding filter screen in a swinging mode through a first central shaft; a guide hopper is arranged below the case; a collection box positioned below the guide hopper isinstalled below the case in a sliding mode; a guide plate is mounted in the case through a second central shaft in a deflection way; a first chain wheel is fixed on the first central shaft; a secondchain wheel is fixed on the second central shaft; a tension roller is rotationally installed on the case; a drive chain is installed between the tension roller, the first chain wheel and the chain wheel; the drive chain is driven by a power device; the drive chain drives the bottom plate to swing between a screening station and a leading-out station, and drives the guide plate to swing between a guide station and an avoiding station; the case is further provided with an impurity outlet; and a collection box is arranged outside the case. The grinding and screening device provided by the invention can be used for grinding and screening the soil, and automatically leading out stones and grinding balls which are remained in the grinding filter screen.

Owner:江苏新锐环境监测有限公司

Metal powder circulating device for basic shaft type metal 3D printer

PendingCN112719306ASimple structureEasy to useSievingAdditive manufacturing apparatusMetallurgyComputer printing

The invention discloses a metal powder circulating device for a basic shaft type metal 3D printer. The metal powder circulating device comprises a powder suction device, a powder screening machine and a metering powder feeding device. A powder storage cylinder of the powder suction device communicates with a feeding port of the powder screening machine through a powder conveying pipe. A first discharging port and a second discharging port of the screening machine communicate with a feeding port of the metering powder feeding device through powder feeding pipes. A discharge port of the metering powder feeding device communicates with the powder supply port through a powder feeding pipe. The metal powder circulating device for the basic shaft type metal 3D printer is simple in structure and convenient to use, the suction head of the powder suction device extends into a printing cavity to recycle metal powder, the recycling treatment effect can be effectively guaranteed, it is guaranteed that redundant metal powder can meet the requirement of next printing, and then, the metering powder feeding device is cooperated for use, and the screened and qualified metal powder is provided for a powder spreading device in / in a powder cylinder of the printing cavity of the SLM metal printer (in the printing chamber).

Owner:ZHEJIANG YIDONG TECH CO LTD

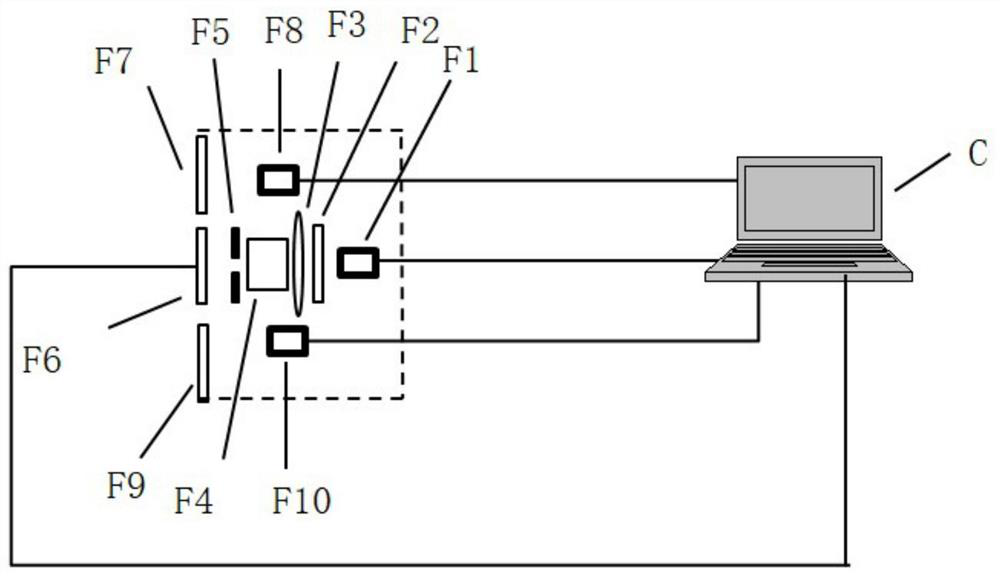

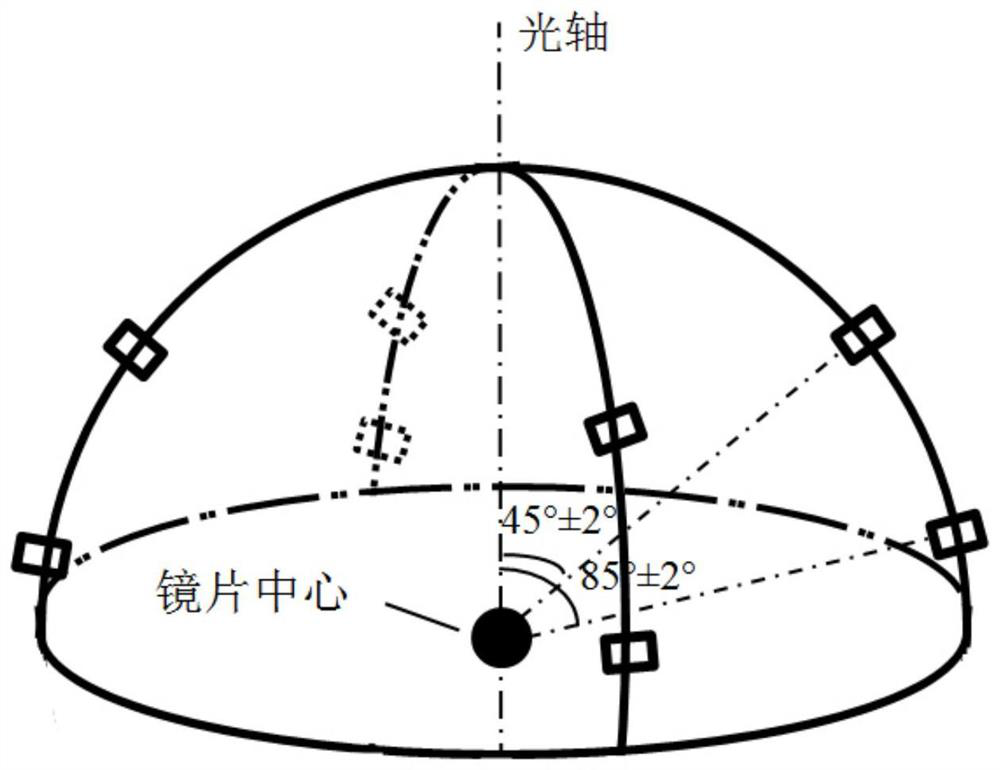

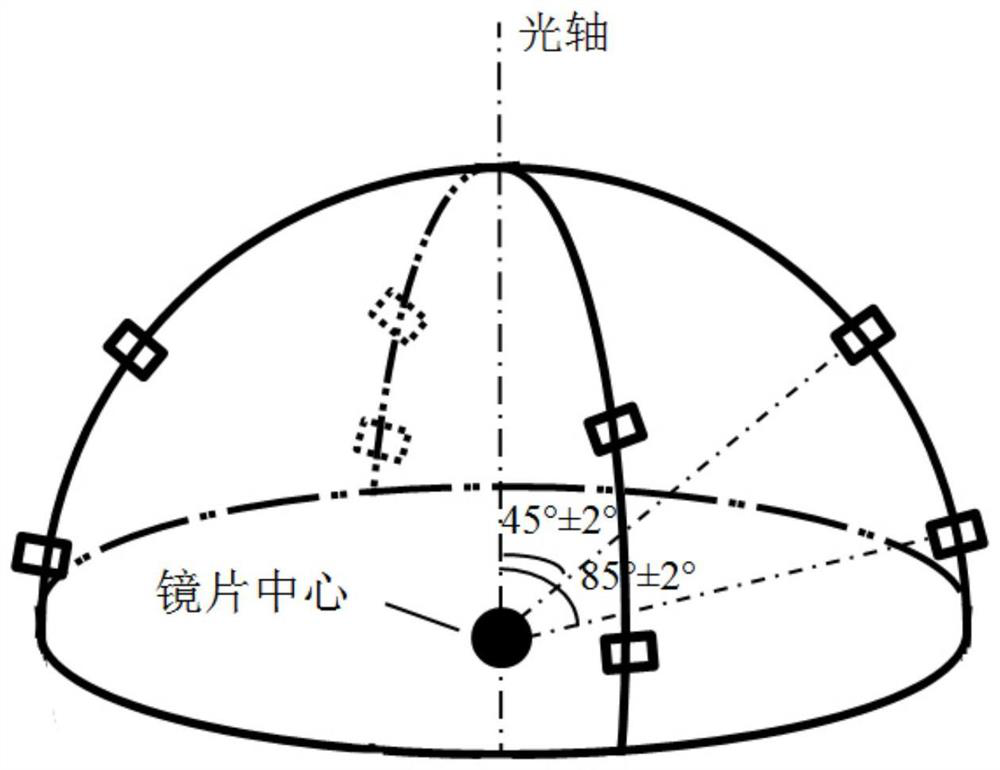

Online automatic optical performance detecting and lens screening method

The invention discloses an online automatic optical performance detecting and lens screening method. According to the method, real-time online detection of the yellowness of spectacle lenses on a flow production line can be realized, and real-time screening work can be carried out on unqualified products. According to the method, a detector is adopted for one-time wide spectrum collection, and the detection time is greatly shortened. According to the method, a transmission mode and a reflection mode are matched to measure the yellowness of the spectacle lenses, so that the reliability and the accuracy are improved. According to the method, a lighting source adopts a light homogenizing device for light homogenizing, and meanwhile, a pulse type lighting mode is adopted, so that the measurement accuracy can be improved. According to the method, the unqualified products can be automatically screened out, the manpower is greatly saved, and meanwhile, if many unqualified products exist in the production line, an alarm can be given in time to warn that the percent of pass of products in the batch is low, and the quality of raw materials is required to be checked or machining technological parameters are required to be optimized in time.

Owner:江苏汇鼎光学眼镜有限公司

Cutting off technology of fittings

ActiveCN107745157APrecise positioningImplement automatic classificationMetal sawing devicesSortingBiochemical engineeringUltimate tensile strength

The invention relates to the fitting field and specifically relates to the cutting off technology of fittings. The method comprises following steps: step 1: preparing a cutting off device; step 2: setting the time and speed for the cylinder and placing fittings; step 3: clamping the fittings and cutting; step 4: recovering the material; step 5: repeating the step 1 to step 4 and completing the last cutting; step 6: collecting fittings which do not reach the standard. By means of the technical scheme of the invention, fittings can move automatically without the need to adjust the cutting position artificially; at the same time, the fittings can be firmly positioned and stable cutting is achieved; automatic screening of fittings is also realized; the work intensity is reduced and work efficiency is increased.

Owner:重庆市璧山区强顺机械有限公司

Automatic garbage classification equipment

ActiveCN111672748ARealize automatic screeningImprove the efficiency of sub-screeningSievingScreeningProcess engineeringRefuse Disposals

The invention discloses automatic garbage classification equipment. The automatic garbage classification equipment comprises a shell, a drying channel, a feeding port, a spiral plate, a drying device,an air outlet hole, a filter net, a screening device and a discharging port. The screening device comprises screening mechanisms, vibration mechanisms, material outlets and cleaning mechanisms. The three screening mechanisms are arranged and embedded in the shell in a left-right moving manner and incline relative to the bottom face of the shell. Through rotation of the spiral plate, garbage stacked in the drying channel is automatically pushed towards the discharging port; meanwhile, in the pushing process, the drying device is started; the garbage in the drying channel is dried; furthermore,the dried garbage falls onto the screening device; and the vibration mechanisms are further started, the garbage is sequentially screened on three screening mechanisms through vibration, garbage different in size is automatically screened, the trouble of manual screening is saved, and the garbage treatment efficiency is improved.

Owner:CHANGSHA YUCHENG ENVIRONMENTAL LANDSCAPE ENG CO LTD

A kind of graphene high-energy catalytic physical exfoliation preparation device and method

ActiveCN112110441BRealize automatic screeningAvoid situations where subsequent use is affectedGrapheneHigh energyGraphite

The invention discloses a graphene high-energy catalytic physical stripping preparation device and method. The preparation device includes a fixed box, and an air blowing table for blowing hot air is installed on the bottom inner wall of the fixed box, and a blowing table is installed directly above the air blowing table. The centrifugal column connected with the fixed box and driven by the driver, the present invention can automatically sieve out the aqueous solution containing large-size graphene during the preparation of graphene through the centrifugal screening cylinder, discharge printing column and atomizing column, and the aqueous solution Fast drying, so that graphene is attached to the surface of the flexible pattern substrate in powder form. During implementation, the graphene aqueous solution is sucked through the centrifugal screening cylinder, and then the centrifugal column is driven to drive the centrifugal screening cylinder to rotate, so that large-sized graphene is centrifuged along with the aqueous solution. Sieve out, and then spray the filamentous graphene aqueous solution towards the flexible pattern substrate through the spray printing hole, and at the same time quickly dry the sprayed filamentary graphene aqueous solution through the diversion sleeve, so that the graphene is directly attached to the flexible pattern in powder form. Patterned base surface.

Owner:东莞钜蕾实业有限公司

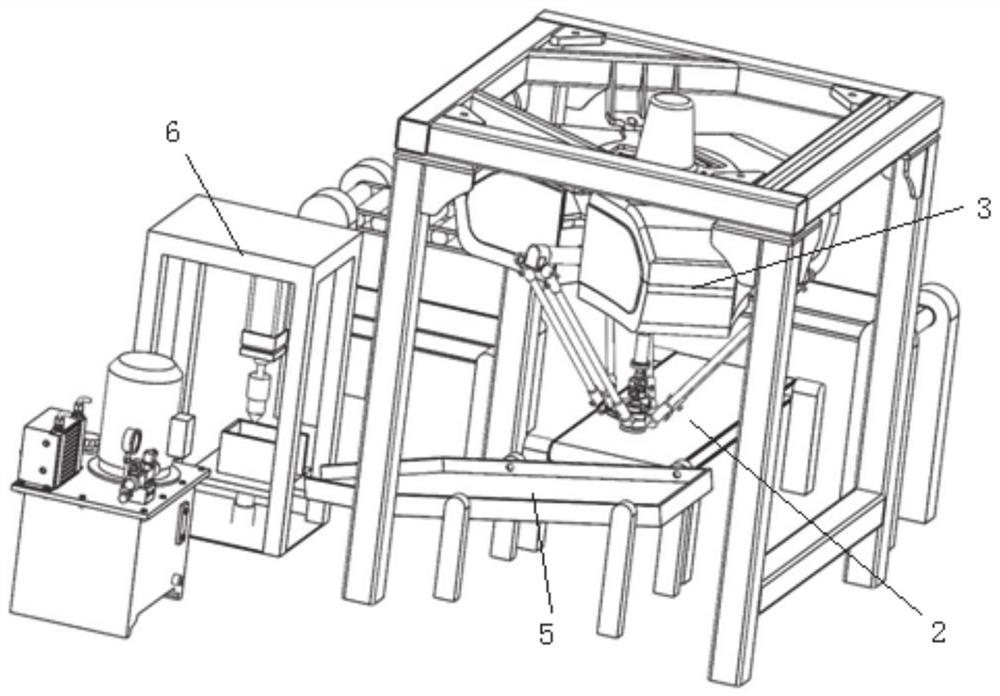

Rock-soil block hardness testing device and working method

PendingCN111965056ARealize automatic screeningMeet the needs of the testInvestigating material hardnessStructural engineeringConveyor belt

The invention relates to a rock-soil block hardness testing device and a working method. The device comprises a screening mechanism, the screening mechanism is provided with a plurality of rotating rollers which are arranged in an arrayed mode and can rotate. The screening mechanism is provided with a first area and a second area. A transition region is arranged between the first region and the second region; the rollers in the transition area are wound with a conveyor belt; the distance between two adjacent rotating rollers in the first area is smaller than the distance between two adjacent rotating rollers in the second area; a first conveying mechanism is arranged under the second area, a parallel robot is arranged above the tail end of the first conveying mechanism, an obliquely-arranged material guiding plate is arranged on one side of the tail end of the first conveying mechanism, a hardness testing mechanism is arranged on one side of the tail end of the material guiding plate,and the testing device is high in working efficiency and meets engineering requirements.

Owner:山东大学日照智能制造研究院

Screw vibration screening machine

PendingCN111974691ARealize automatic screeningEfficient screeningGradingElectric machineryEngineering

The invention discloses a screw vibration screening machine. The screw vibration screening machine comprises a rack. A vibration motor is arranged on the rack. The rack is provided with a feed channeland a discharge channel. A plurality of parallel guide channels are arranged between the feed channel and the discharge channel. One ends of the guide channels are connected with the feed channel, and the other ends of the guide channels are connected with the discharge channel. The bottoms of the guide channels are provided with screening holes. A receiving trough is arranged below the screeningholes. A plurality of parallel steel angles are arranged between the feed channel and the discharge channel. The guide channels are formed on the steel angles. Guide plates are arranged on the two sides of the steel angles. A barrier strip is fixed to the bottoms of the guide plates. The screening holes are formed in the positions, not provided with the barrier strip, of the guide plate. The screw vibration screening machine has the characteristics of being rapid in screening and convenient to use and is complete in overall function and high in practicality.

Owner:浙江俊荣五金工业有限公司

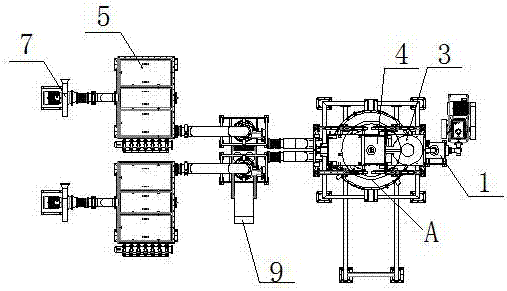

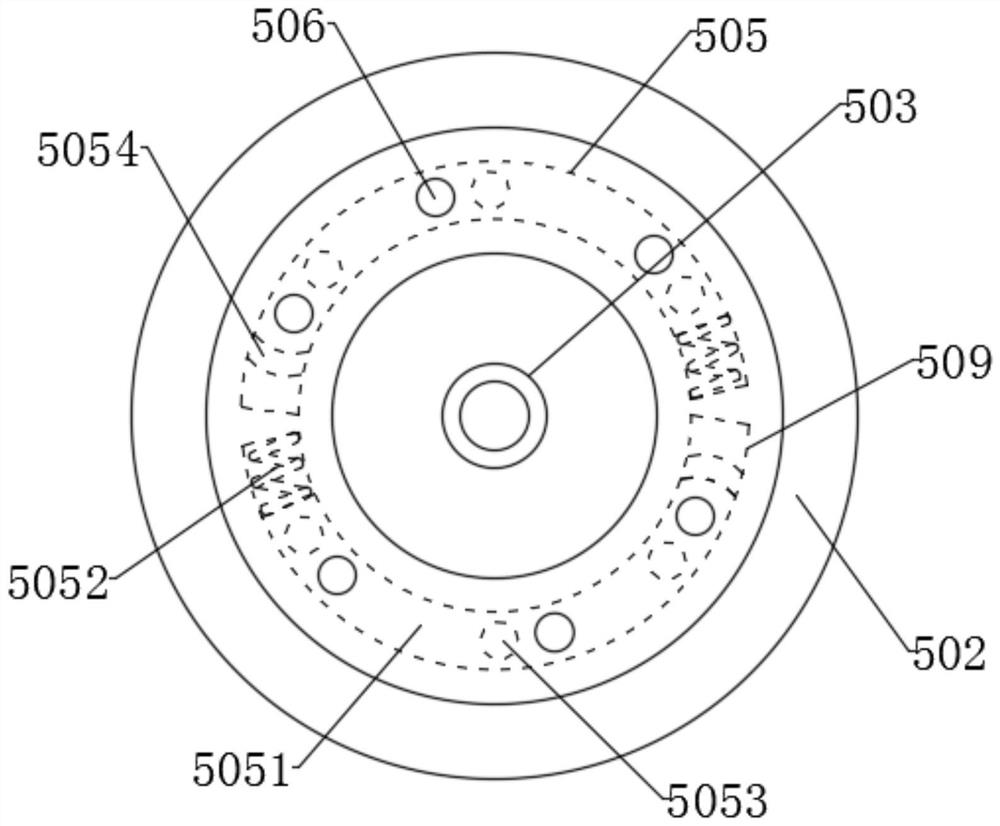

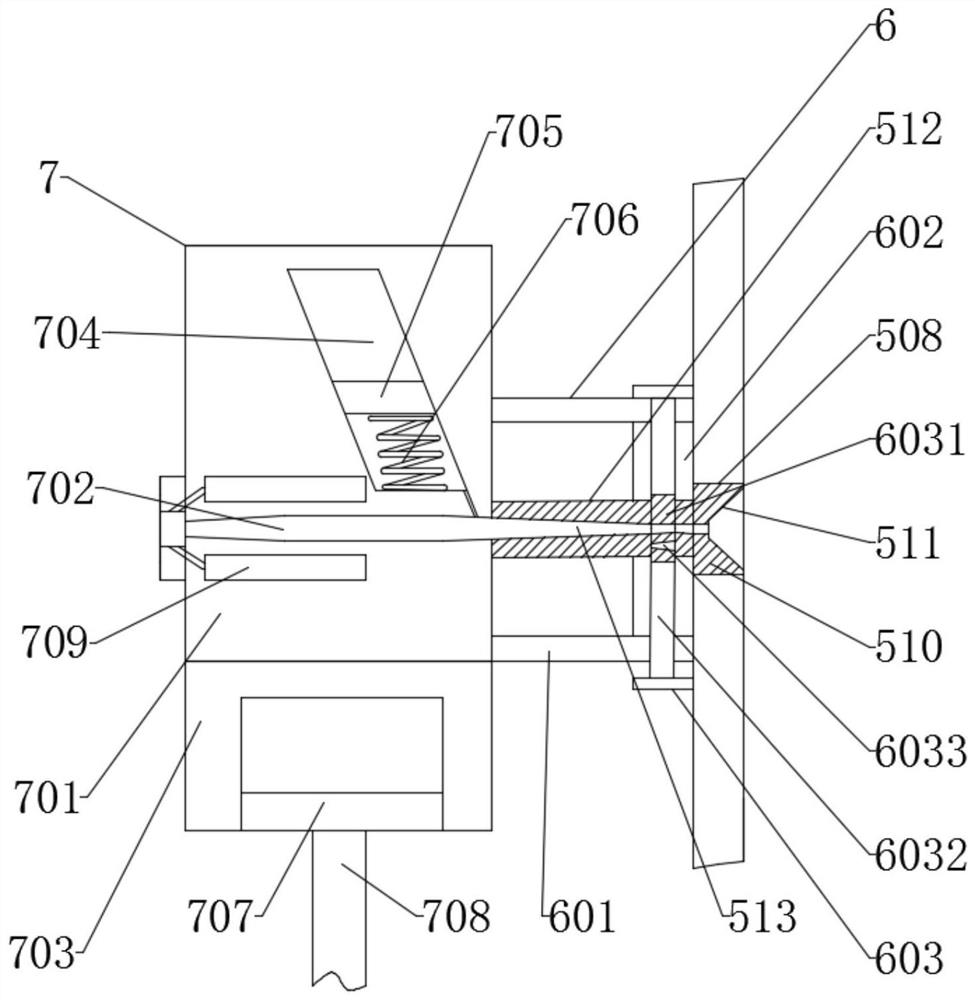

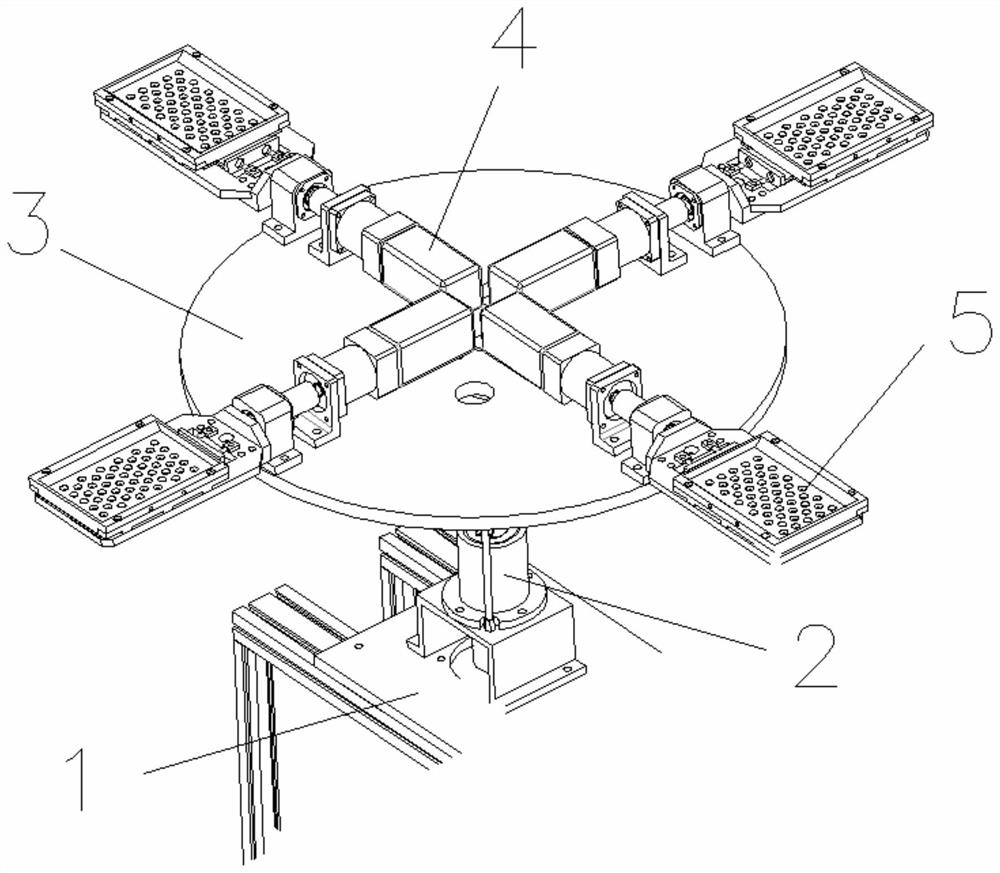

Method and device for automatic screening of detonator delay body

ActiveCN107176896BRealize automatic screeningQuality improvementDetonatorsProcess engineeringManufacturing line

The invention discloses a detonator delay body automatic screening method. The invention adopts a circular circulation station, and the stations are set in sequence as an upper delay body station, an inverted delay body station and a filling station. Such a method is convenient for automation The production is carried out, and the production safety and efficiency are high, and a matching automatic production line is designed. The invention not only realizes the automatic screening of the delay body, but also avoids the hidden dangers of production safety and quality caused by the manual screening of the delay body. Uncontrollable problems, while the production safety and production efficiency are high, the wear of the extension body is reduced, and the pass rate of the product is good.

Owner:XIANGNAN EXPLOSION APPLIANCES HUNAN PROV

Method for producing tar, semi-coke and synthetic fuel gas by low-degree of coalification powdered coal

ActiveCN103497784BReliable waySafe wayLiquid hydrocarbon mixture productionSpecial form destructive distillationCoal conversionProcess engineering

The invention relates to a method for producing tar, semi-coke and synthetic fuel gas by low-degree of coalification powdered coal. The method comprises the steps of low-degree of coalification powdered coal pre-drying, dry powdered coal separation, low-degree of coalification powdered coal conversion, light gaseous product dedusting, light gaseous product separation and collection, pyrolysis product semi-coke recovery and the like. The method provided by the invention provides a safe and reliable way for realizing efficient utilization of the powdered coal. The method provided by the invention is high in throughput and high in heat exchange efficiency, and can automatically sieve raw material grains, so that load on a coal preparation system is reduced, and yield of a light product is increased. Compared with the prior art, the method provided by the invention has the advantages that inert component content and tar dustiness in the synthetic fuel gas are effectively reduced, heat transfer efficiency and conversion reaction speed are effectively improved, and yield of tar and synthetic fuel gas products is increased, wherein the tar dustiness is less than 0.1mg / kg. The method has the characteristics of low energy consumption and low environment pollution, thereby having very important economic significance and social significance and having a great application prospect.

Owner:THE NORTHWEST RES INST OF CHEM IND

Soybean screening and dust removing device

InactiveCN113318987APrevent outflowAvoid circulationDirt cleaningCleaning using gasesAgricultural engineeringAgricultural science

Owner:李华

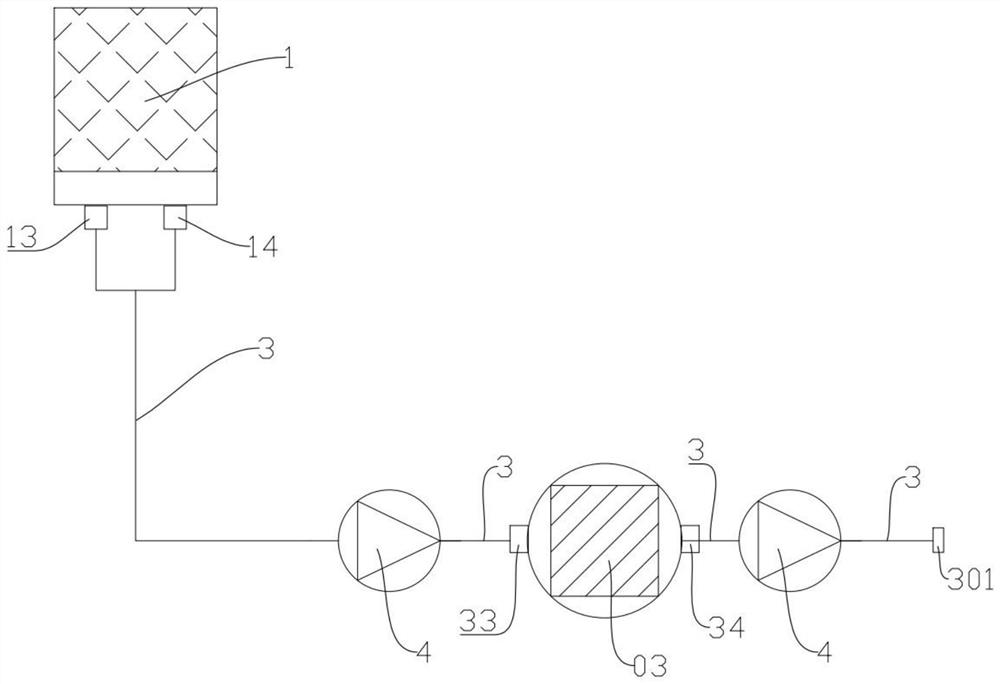

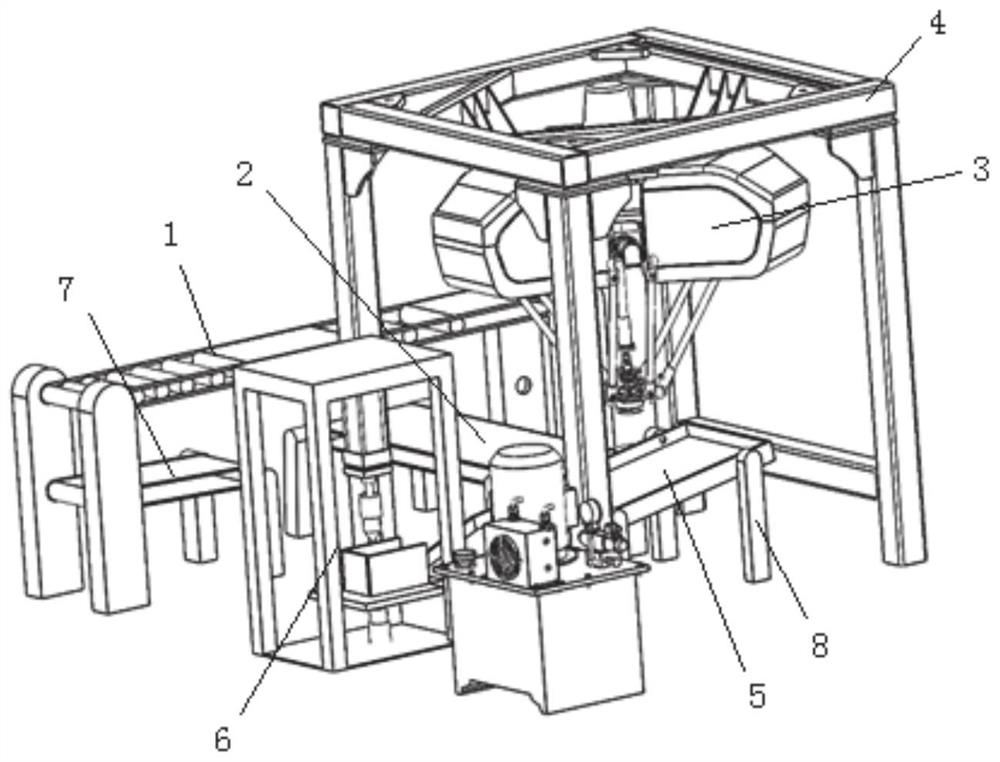

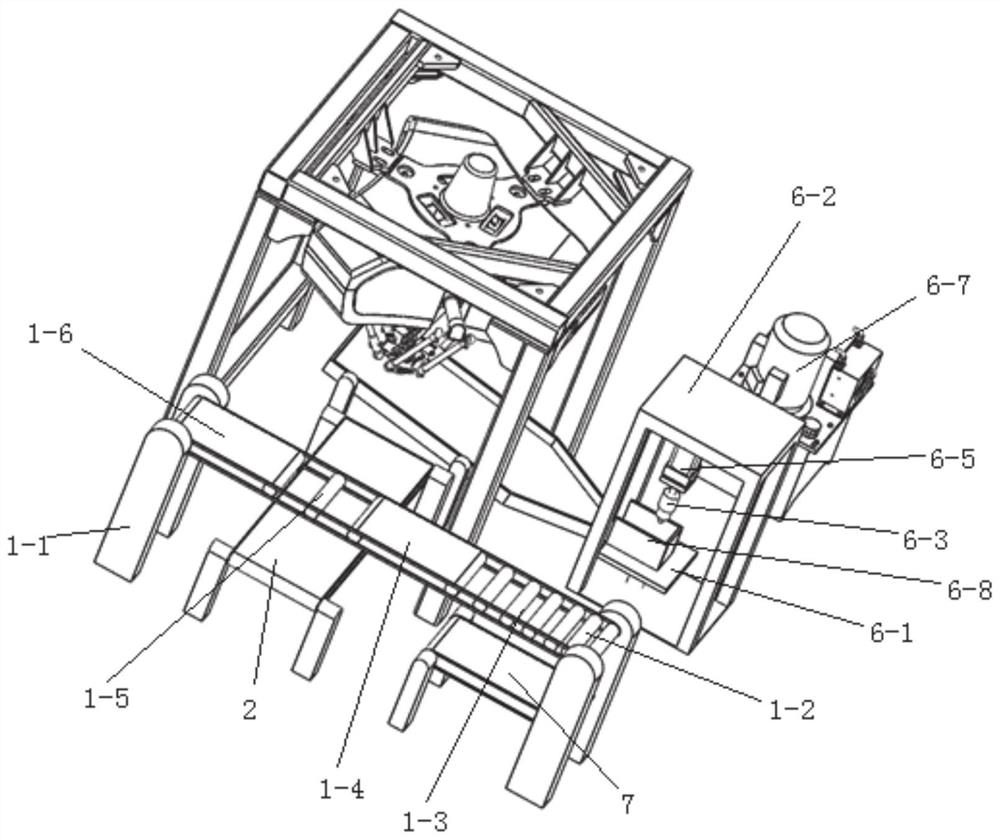

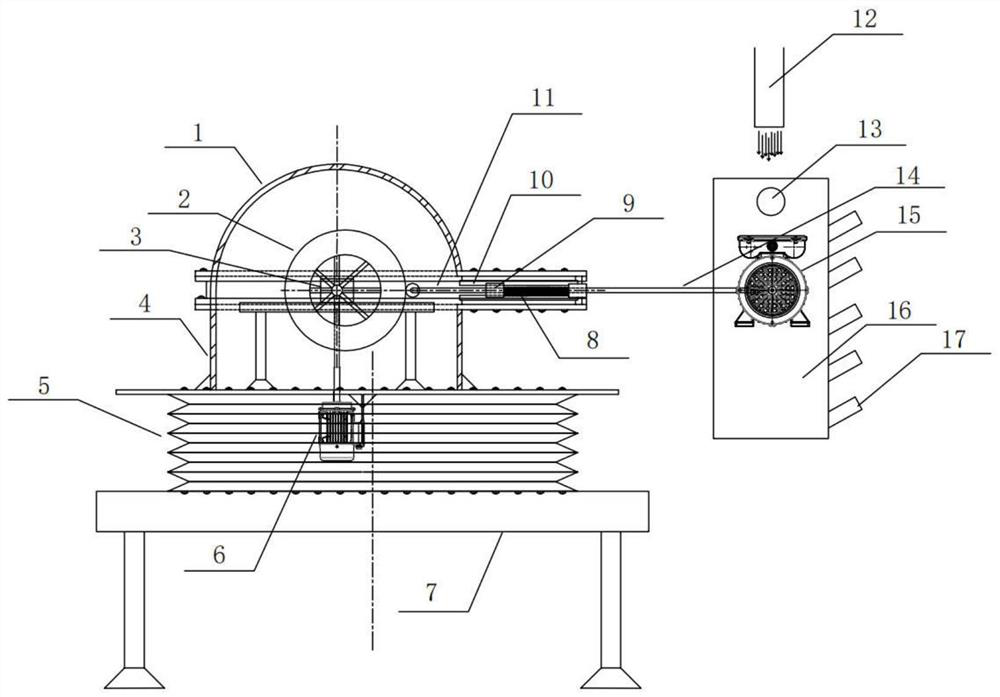

Arm type automatic screening equipment and method for screening granularity of ore pulp in dressing plant through arm type automatic screening equipment

ActiveCN114453235ARealization of automatic screeningEasy to take awaySievingScreeningReciprocating motionElectric machinery

The invention discloses arm type automatic screening equipment and a method for screening the granularity of ore pulp in a dressing plant through the arm type automatic screening equipment. The arm type automatic screening equipment comprises a swing system, a sleeve screen box and a sleeve screen flushing water system. The swing system body comprises a reciprocating motion part composed of an eccentric wheel and a push rod mechanism and a swing part with a rubber spring as a connecting piece. The swing part is composed of a fixed rack, a movable rack and a rubber spring, the fixed rack is connected with the movable rack through the rubber spring, the eccentric wheel rotates along with the motor to generate unbalanced mass force to enable the movable rack to swing, and screening is carried out in cooperation with sleeve screen washing water. After screening is completed, the whole sleeve screen is rotated by an angle through the stepping motor, the pulp is conveniently taken away by washing water, and the pulp is discharged from the pulp discharging opening. The device can simulate screening operation in an actual dressing plant, replaces repeated mechanical operation of workers, and can realize automatic screening of ore pulp; the method for screening the ore pulp through the device is simple in process and convenient to operate, and industrial production is met.

Owner:CENT SOUTH UNIV

A device for measuring the yellowness of spectacle lenses

Owner:江苏汇鼎光学眼镜有限公司

Digitalized paddy rice seed testing machine

ActiveCN101905215BEvenly dispersedSolve adhesionGas current separationIndividual particle analysisAgricultural scienceRice grain

The invention relates to an online non-destructive testing method which is suitable for automatically measuring and recording the total grain number, the filled grain number, the maturing rate, the grain lengths, the grain widths and the length-width ratio of a single plant or single-batch paddy rice in the paddy rice seed testing process for agricultural scientific research personnel. The digitalized paddy rice seed testing machine mainly comprises six functional modules of a bar code recognizer, a grain transfer device, an air separation device, an image acquisition device, a PLC (Programmable Logic Controller) and a computer system. The digitalized paddy rice seed testing machine can be used for separating filled grains and empty and shriveled grains by utilizing the air separation device, dynamically acquiring grain parameters by utilizing a machine vision technology and simultaneously measuring the total grain number and the filled grain number of the paddy rice, thereby overcoming a bottleneck that the traditional testing measure can not simultaneously acquire the total grain number and the filled grain number and realizing the detection to the grain-size parameters of the paddy rice at the same time of calculating the paddy rice grain number. The invention can be also widely applied to the seed testing work of other grain crops.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com