Metal powder circulating device for basic shaft type metal 3D printer

A 3D printer and recycling device technology, used in metal processing equipment, transportation and packaging, chemical instruments and methods, etc., can solve the problems of low powder feeding efficiency, inability to meet the requirements of printers, and low powder screening efficiency of powder sifting machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

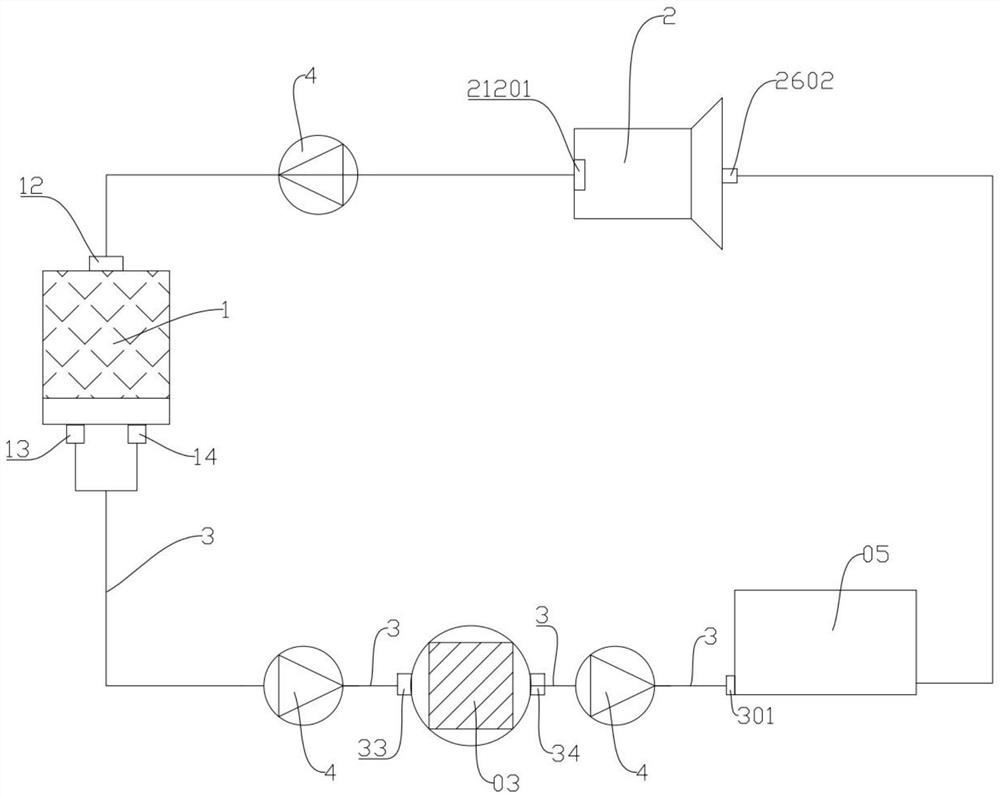

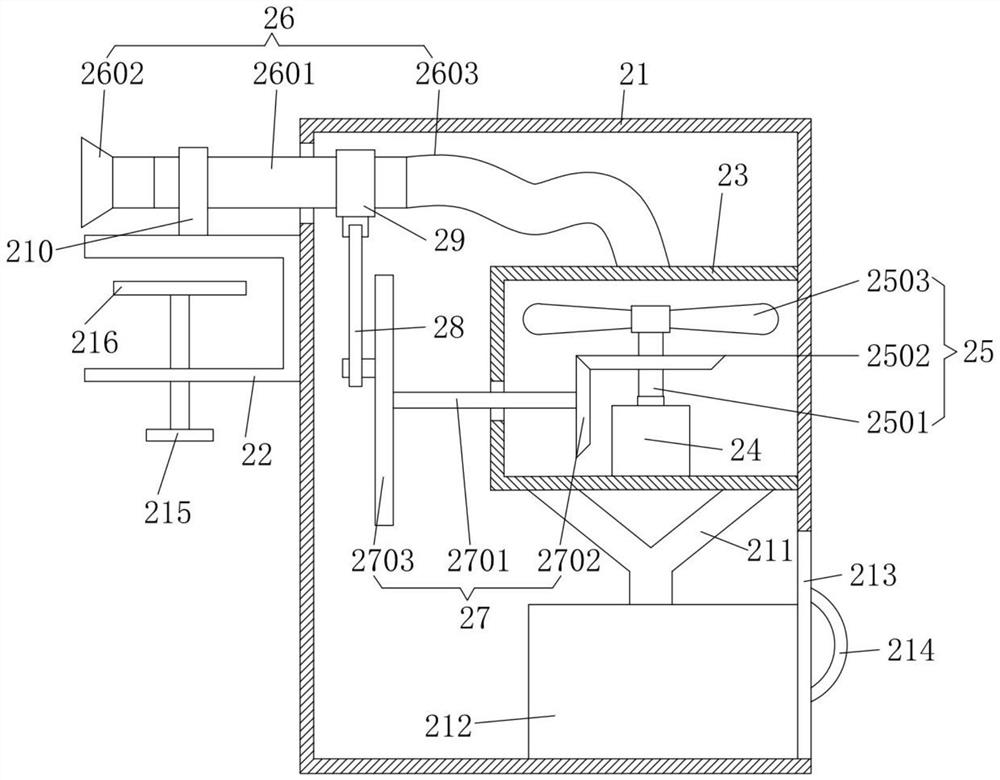

[0082] Such as Figures 1 to 14 As shown, a metal powder circulation device for a base shaft metal 3D printer, including a powder suction device, a powder sieving machine and a metering powder feeding device;

[0083] The powder storage tank of the powder suction device communicates with the feed port of the powder sieving machine through the powder feeding pipe; the powder feeding pipe is provided with a vacuum conveyor;

[0084] Both the first discharge port and the second discharge port of the sieving machine are connected to the feed port of the metering powder feeding device through the powder feeding pipe; the powder feeding pipe between the sieving machine and the metering powder feeding device There is a vacuum conveyor on it;

[0085] The outlet of the metering powder feeding device is connected to the powder feeding port through a powder feeding pipe; the powder feeding pipe between the metering powder feeding device and the powder feeding port is provided with a va...

Embodiment 2

[0090] Such as Figures 1 to 14 As shown, a metal powder circulation device for a base shaft metal 3D printer, including a powder suction device, a powder sieving machine and a metering powder feeding device;

[0091] The powder storage tank of the powder suction device communicates with the feed port of the powder sieving machine through the powder feeding pipe; the powder feeding pipe is provided with a vacuum conveyor;

[0092] Both the first discharge port and the second discharge port of the sieving machine are connected to the feed port of the metering powder feeding device through the powder feeding pipe; the powder feeding pipe between the sieving machine and the metering powder feeding device There is a vacuum conveyor on it;

[0093] The outlet of the metering powder feeding device is connected to the powder feeding port through a powder feeding pipe; the powder feeding pipe between the metering powder feeding device and the powder feeding port is provided with a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com