Powder supply device for basic shaft type metal 3D printer

A technology of 3D printer and powder supply device, which is applied in the direction of solid separation, chemical instruments and methods, additive manufacturing, etc. It can solve the problems of not being able to meet the requirements of printers, low powder sifting efficiency of powder sieving machines, and high equipment complexity. Meet the needs of rapid processing, simple structure, and improve the effect of sieving powder efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

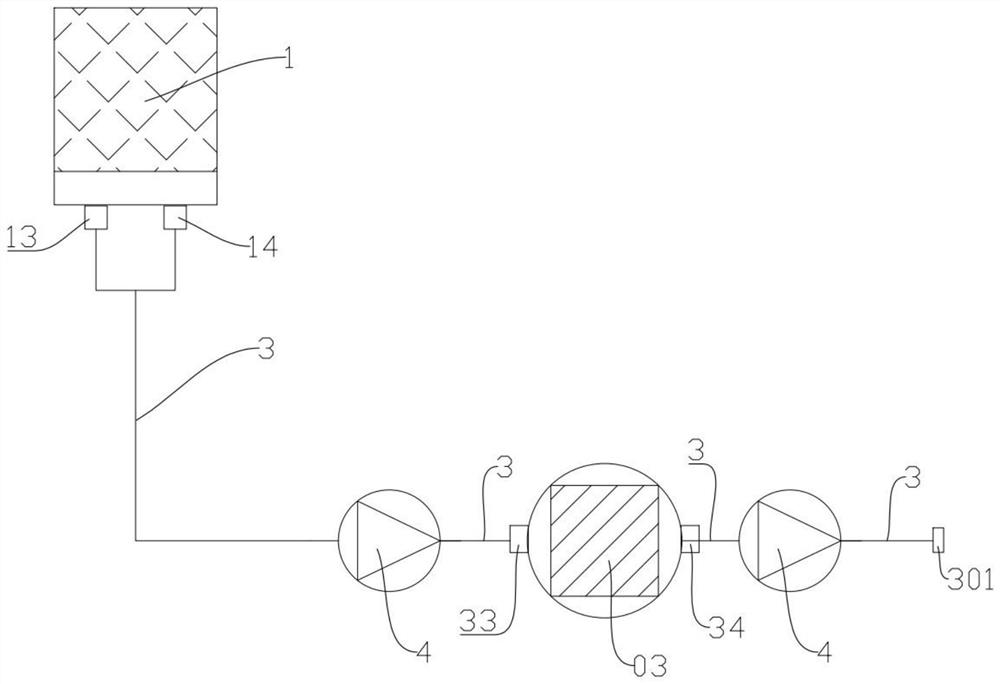

[0066] Such as Figures 1 to 11 As shown, a powder supply device for a shaft-type metal 3D printer is characterized in that it includes a sieving machine and a metering powder feeding device;

[0067] Both the first discharge port and the second discharge port of the sieving machine are connected to the feed port of the metering powder feeding device through the powder feeding pipe;

[0068] A vacuum conveyor is provided on the powder feeding pipe between the sieving machine and the metering powder feeding device;

[0069] The outlet of the metering powder feeding device is connected to the powder feeding port through a powder feeding pipe; the powder feeding pipe between the metering powder feeding device and the powder feeding port is provided with a vacuum conveyor;

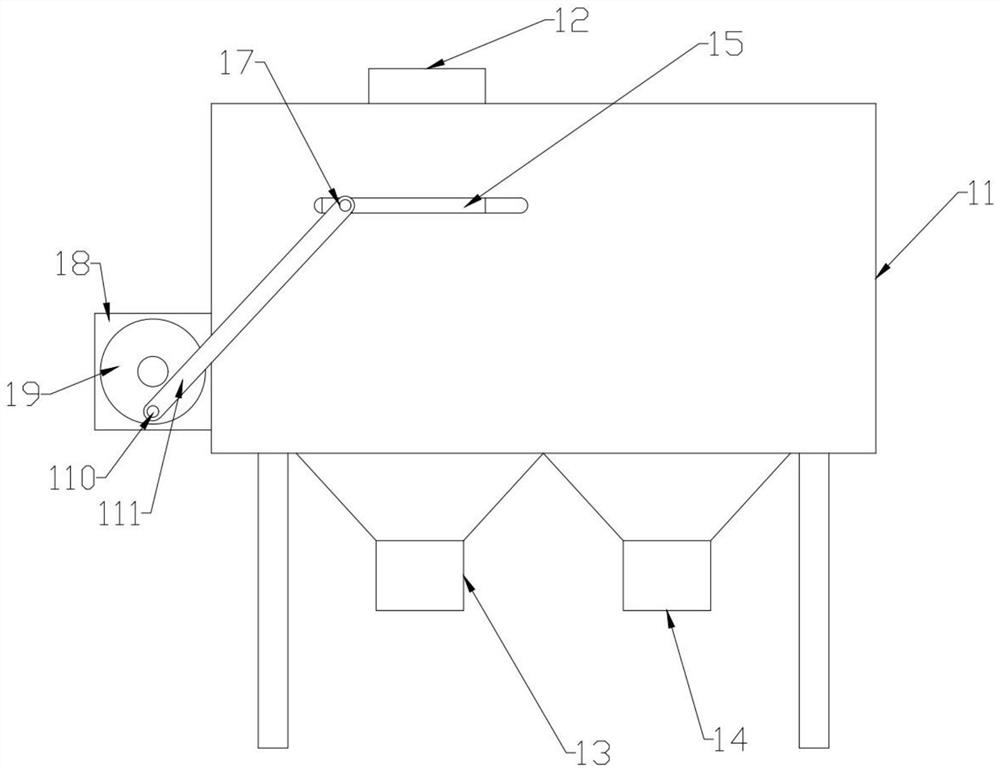

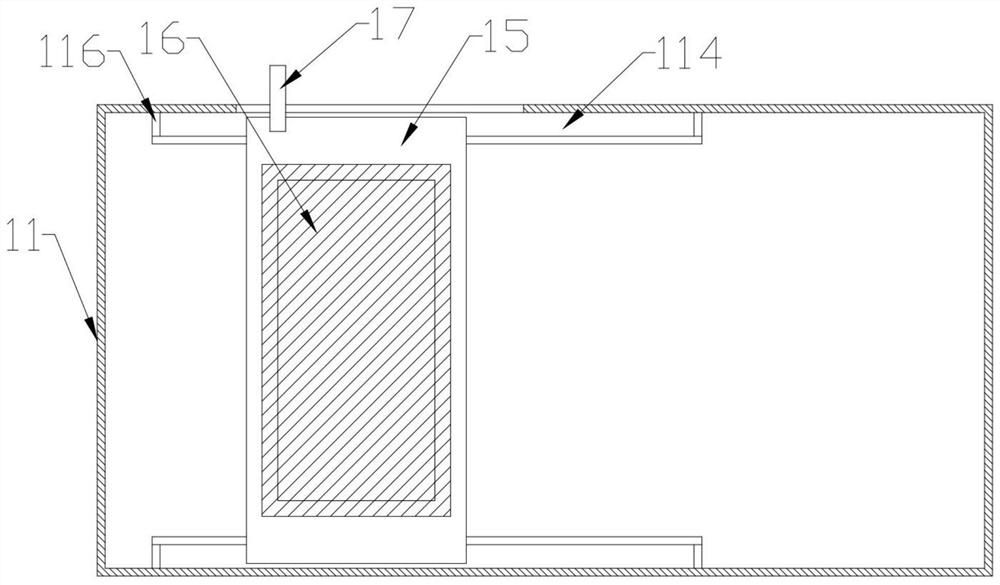

[0070] The powder sieving machine includes a powder sieving box, the top of the powder sifting box is provided with a feed inlet, and the bottom of the sifting box is provided with a first discharge port and ...

Embodiment 2

[0073] Such as Figures 1 to 11 As shown, a powder supply device for a shaft-type metal 3D printer is characterized in that it includes a sieving machine and a metering powder feeding device;

[0074] Both the first discharge port and the second discharge port of the sieving machine are connected to the feed port of the metering powder feeding device through the powder feeding pipe;

[0075] A vacuum conveyor is provided on the powder feeding pipe between the sieving machine and the metering powder feeding device;

[0076] The outlet of the metering powder feeding device is connected to the powder feeding port through a powder feeding pipe; the powder feeding pipe between the metering powder feeding device and the powder feeding port is provided with a vacuum conveyor;

[0077] Described powder sieving machine, specific structure is as Figure 2 to Figure 4 As shown, it includes a powder sifting box, the top of the powder sifting box is provided with a feed inlet, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com