Patents

Literature

36results about How to "Efficient metering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

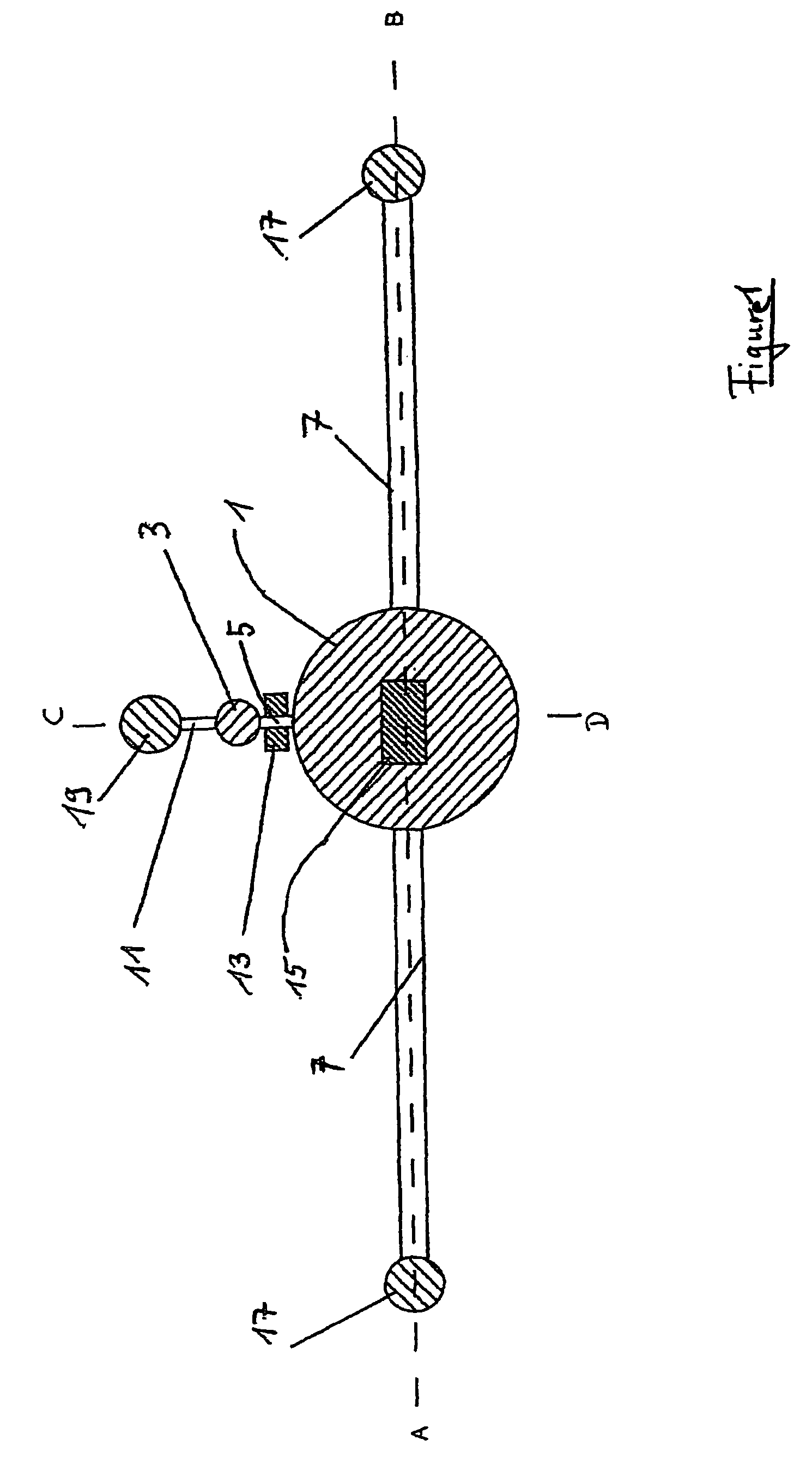

Razors

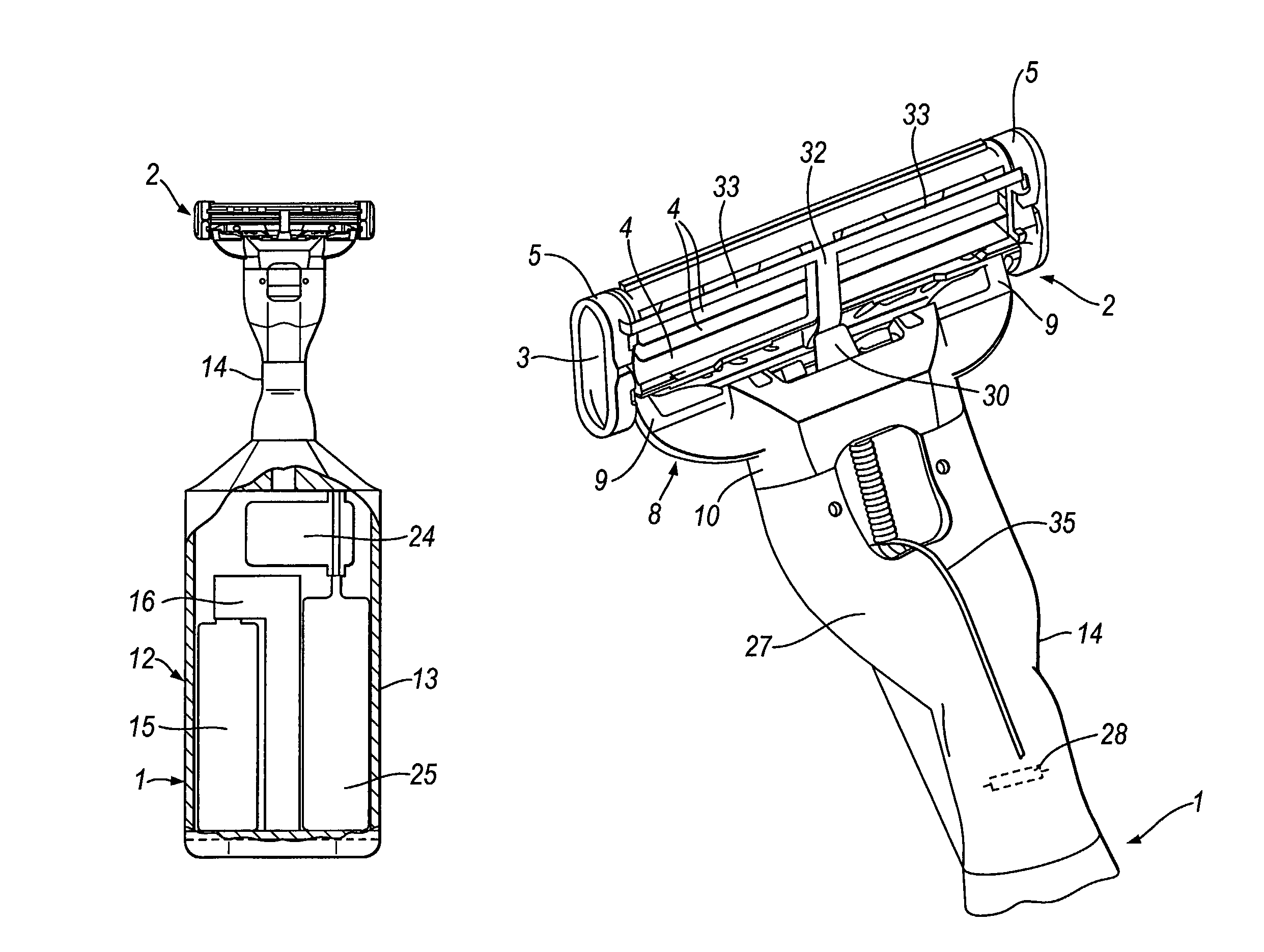

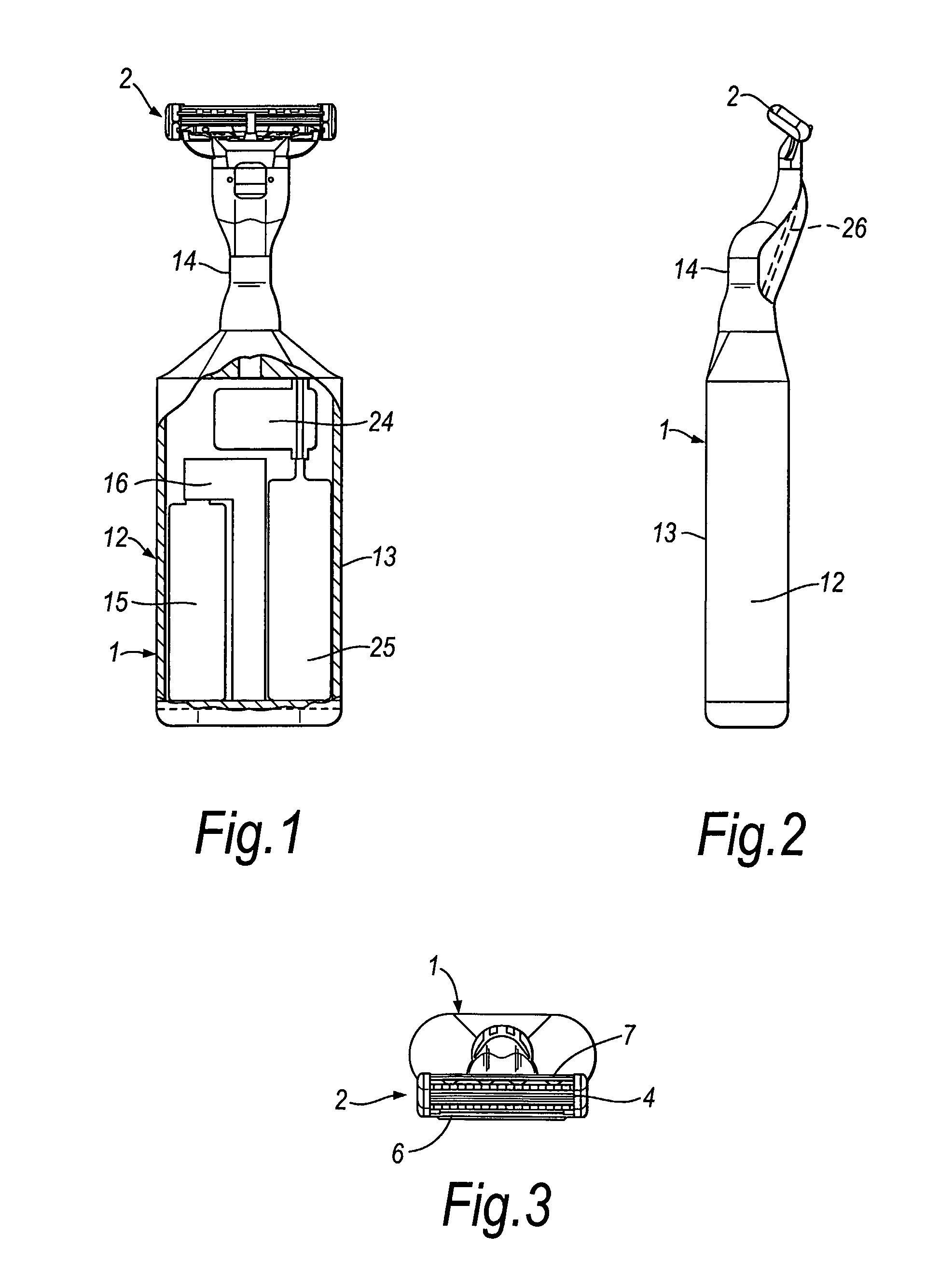

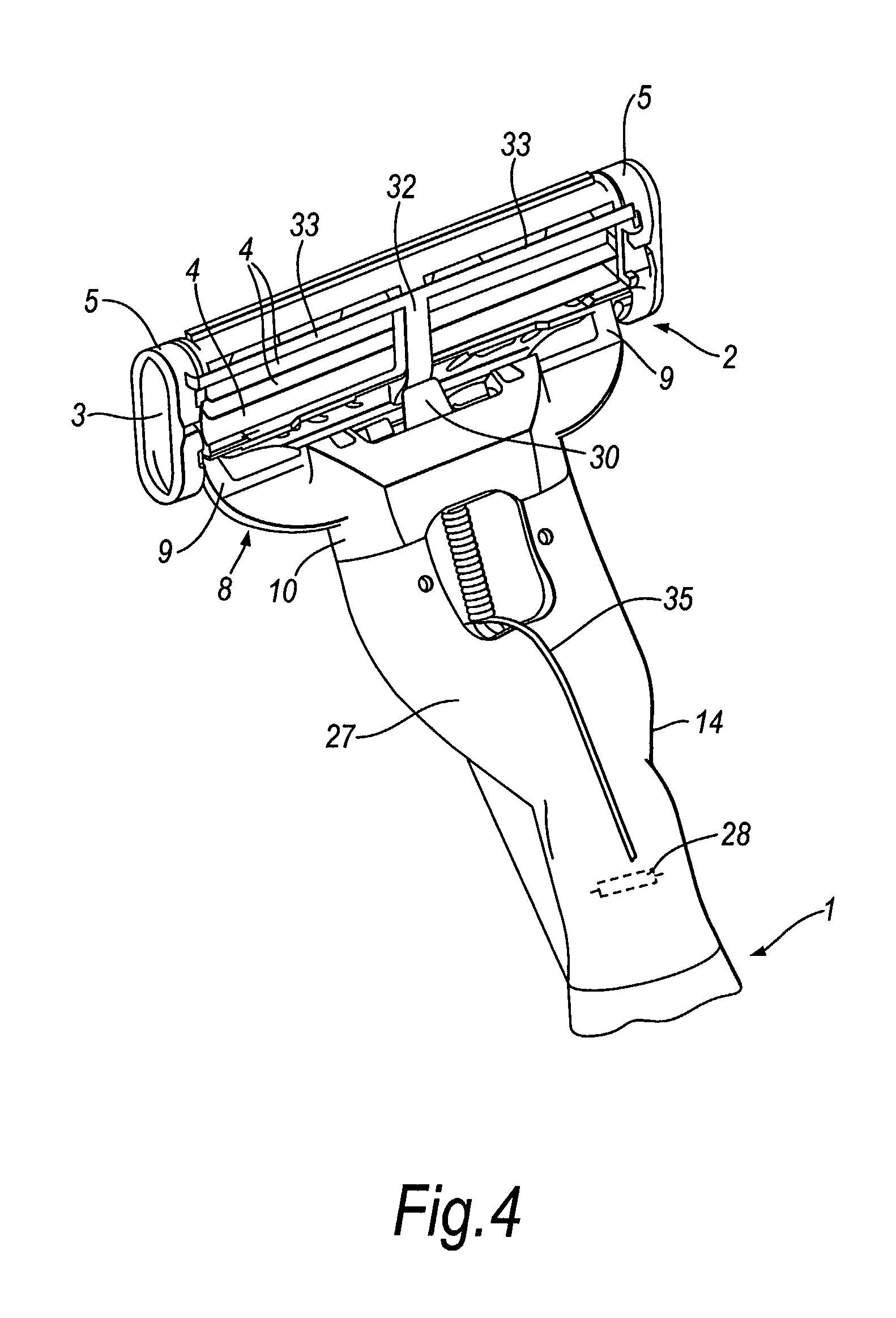

ActiveUS20080289185A1Slow charging rateAcceptable dispensing rateThrusting weaponsWeapon componentsRazor stropEngineering

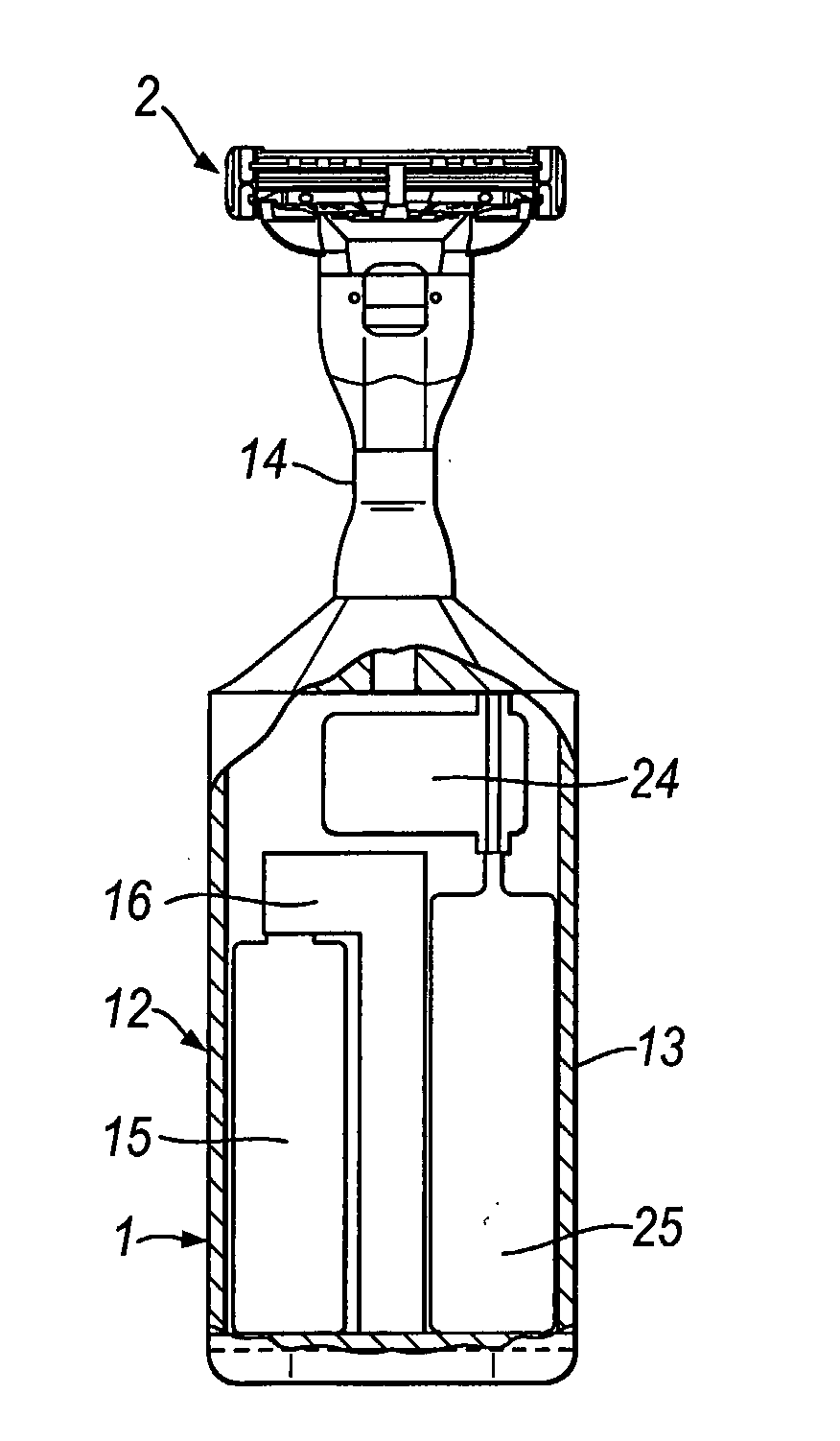

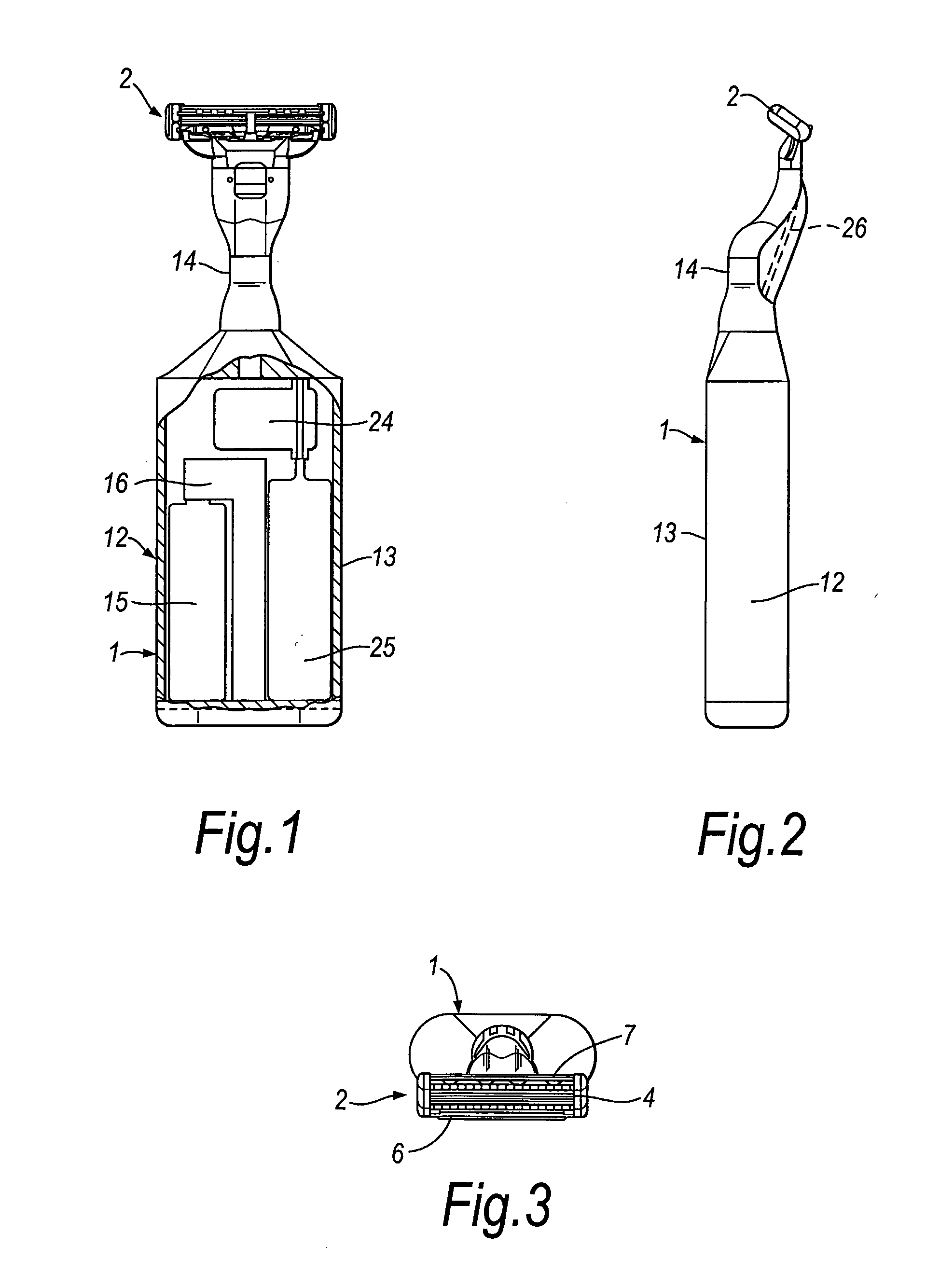

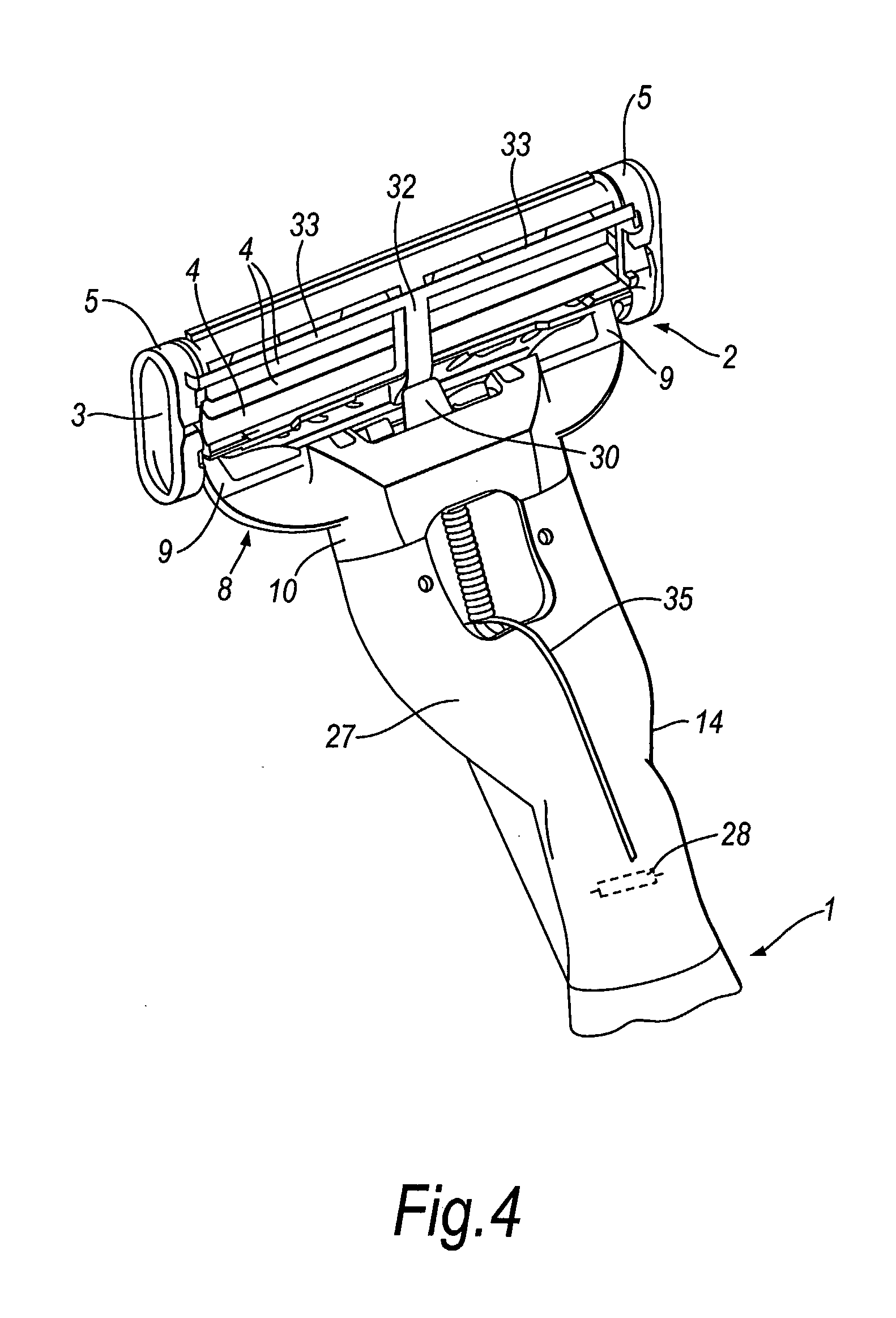

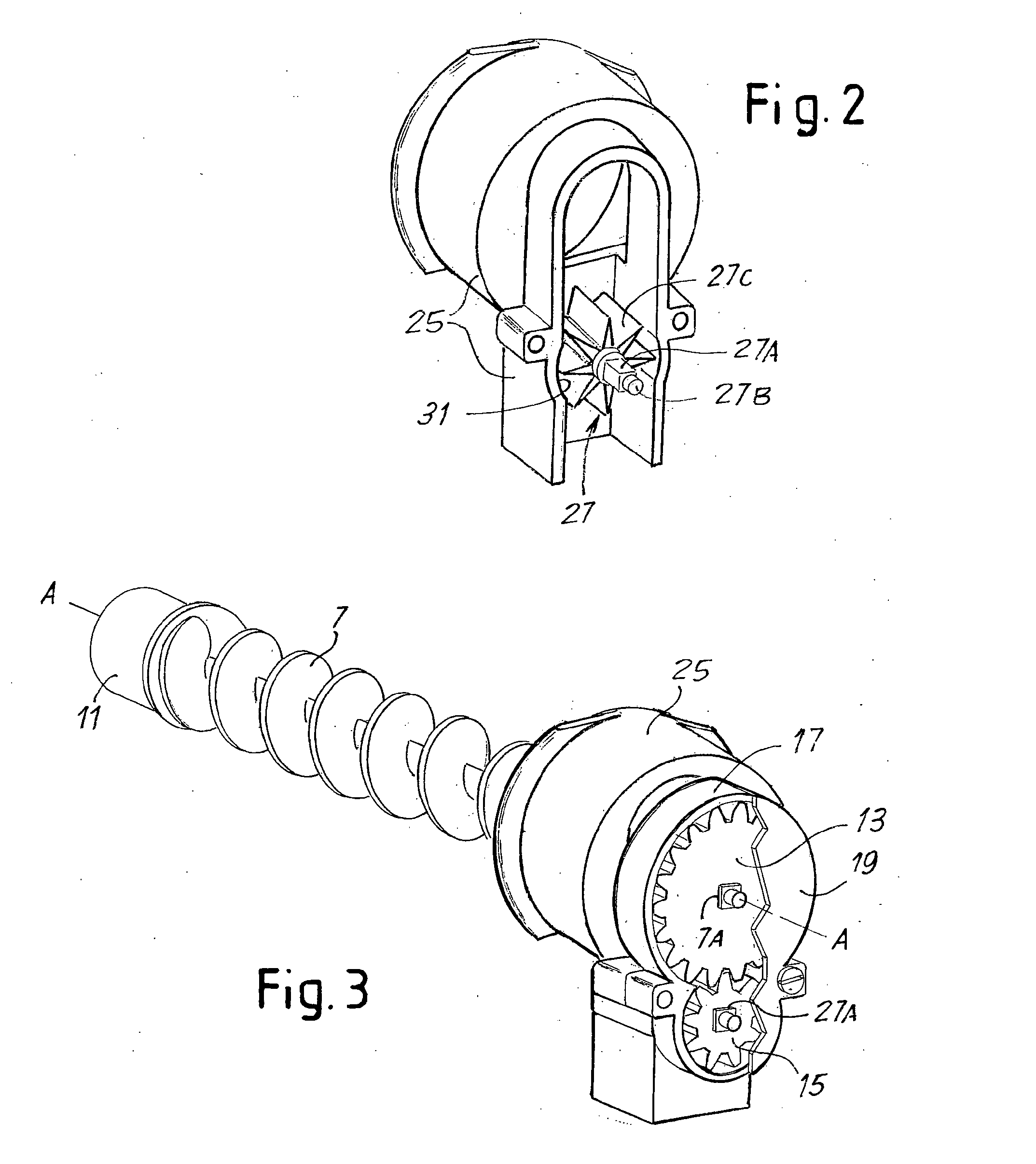

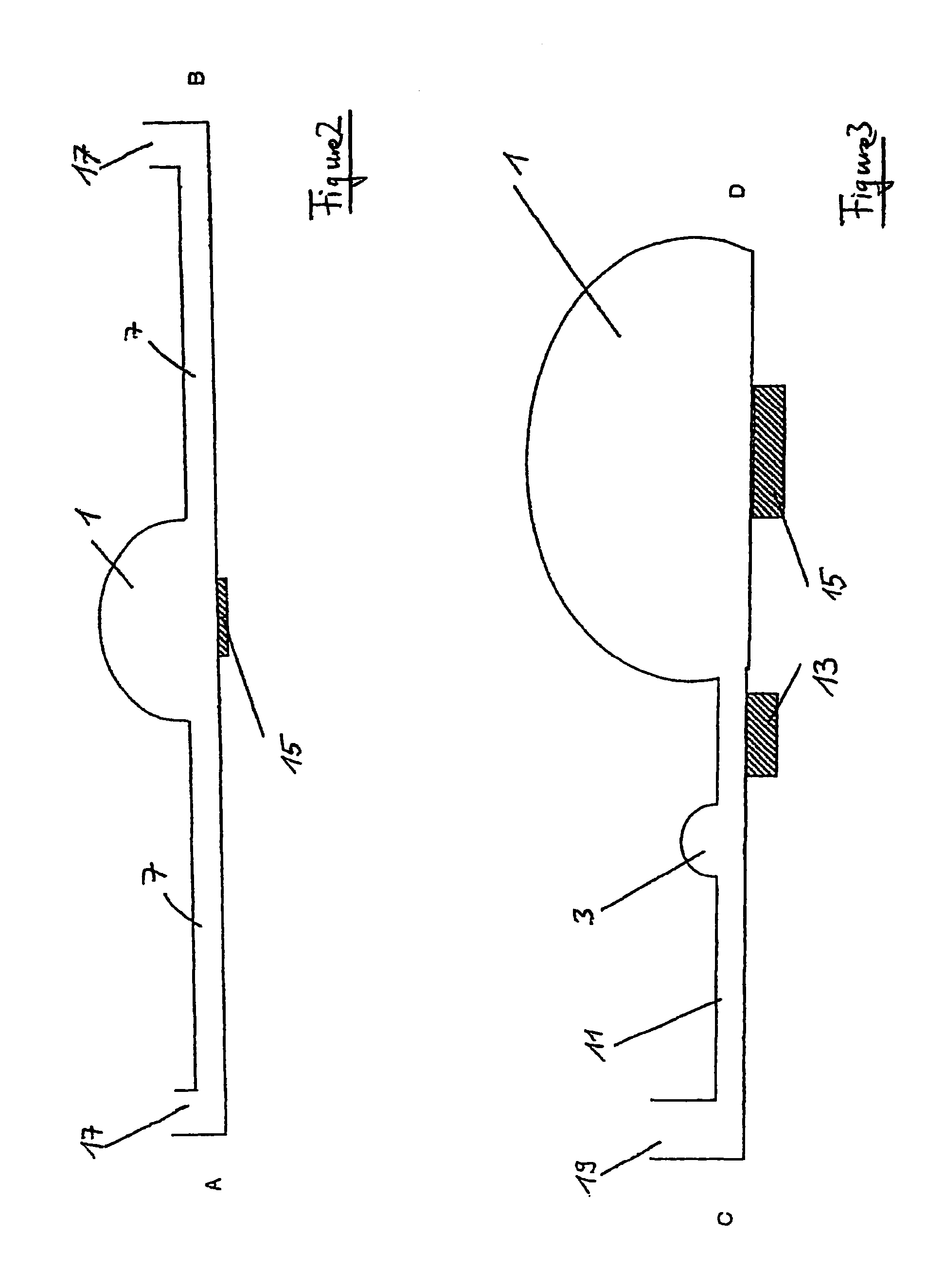

A razor, especially a safety razor, comprises a fluid delivery system including a pump (24) for conducting a fluid, such as a lubricant, from a reservoir (25) for application to the skin, and a control device (16) for actuating the pump (24) when the razor is brought into contact with the skin by a person holding the razor, and deactuating the pump (24) after a certain time of actuation, e.g. 0.1 to 2 seconds. The control device is arranged to ensured a delay of 1 to 10 seconds between successive actuations, and so that the pump is actuated only every second third or fourth shaving stroke.

Owner:THE GILLETTE CO

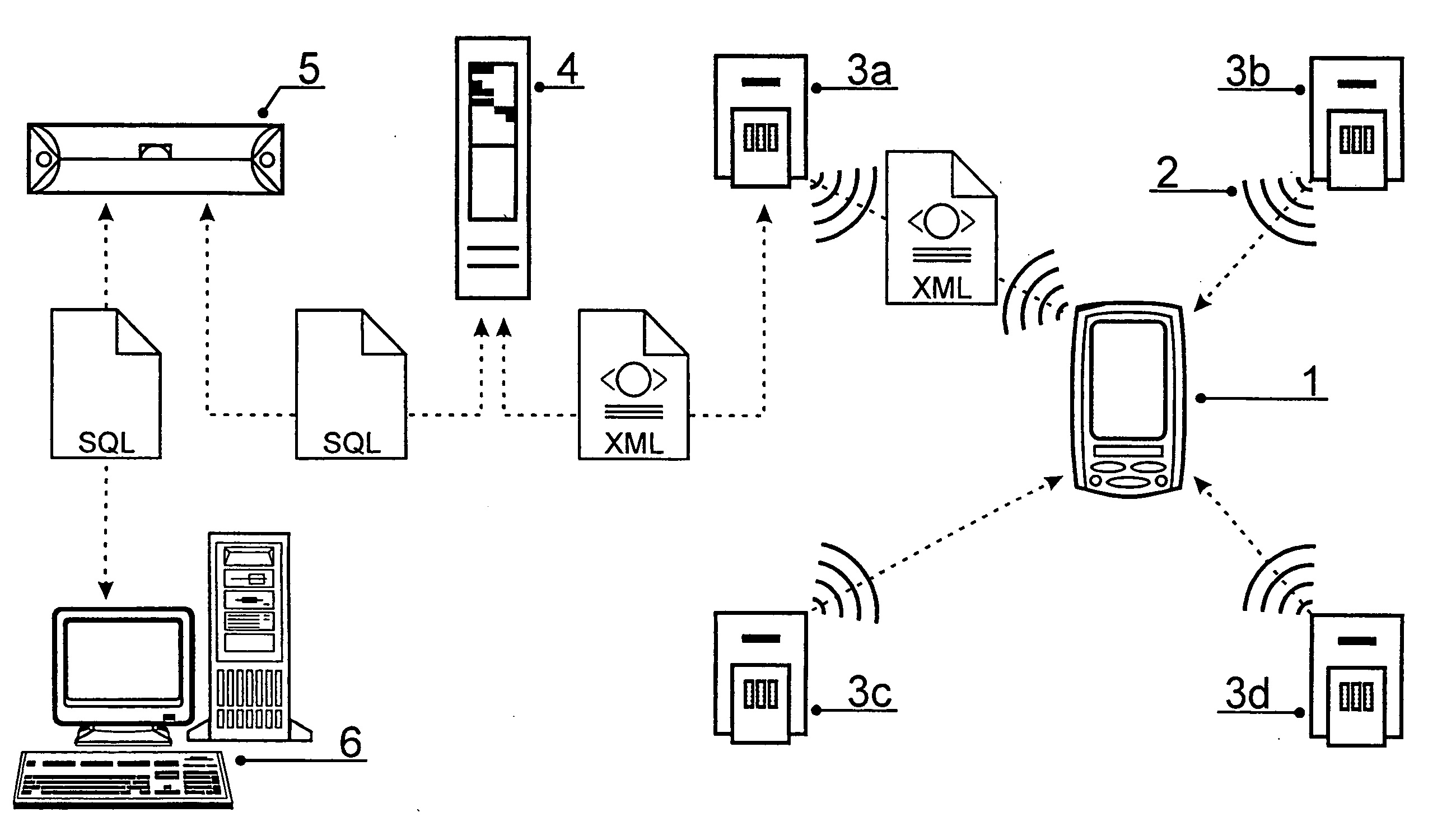

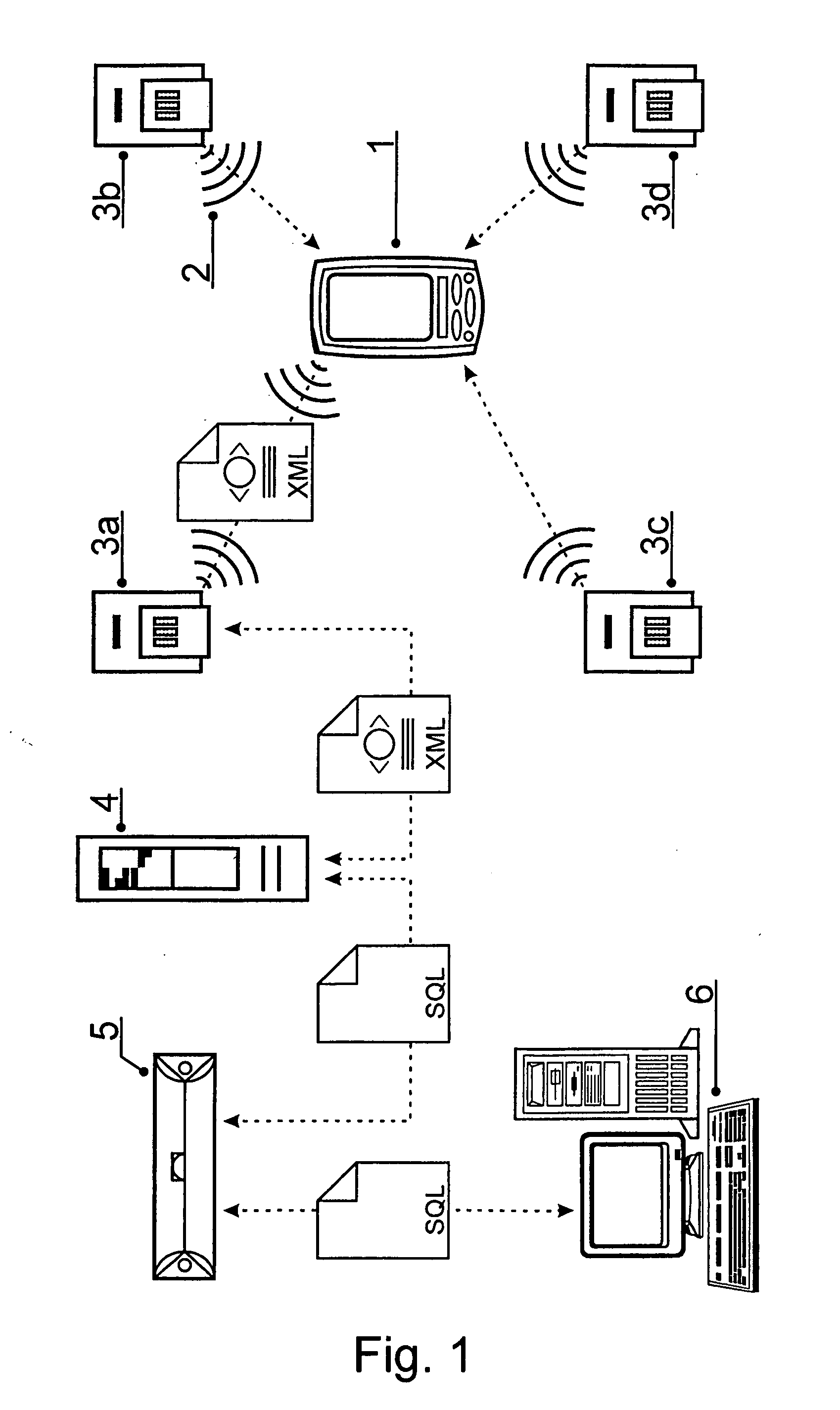

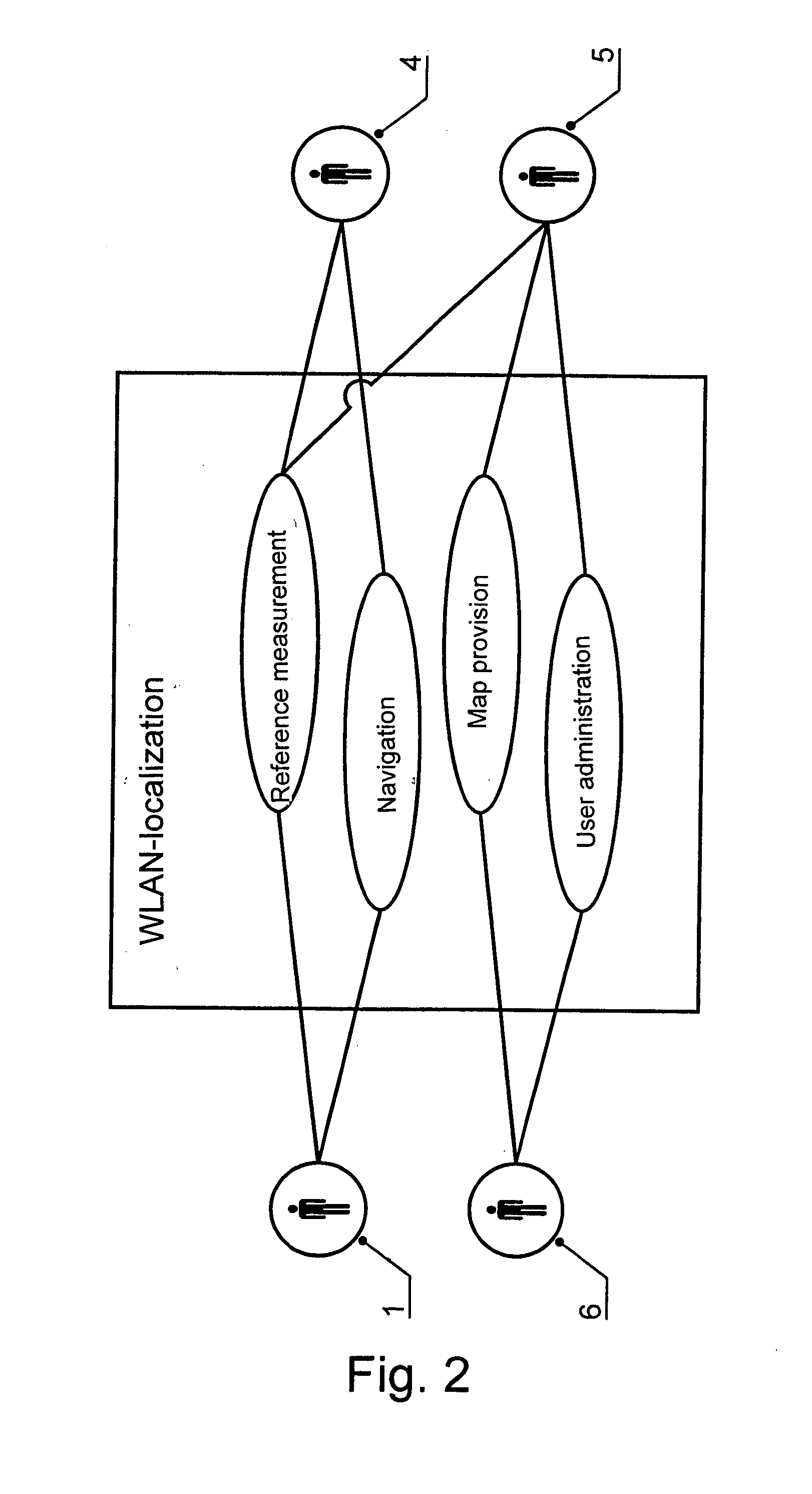

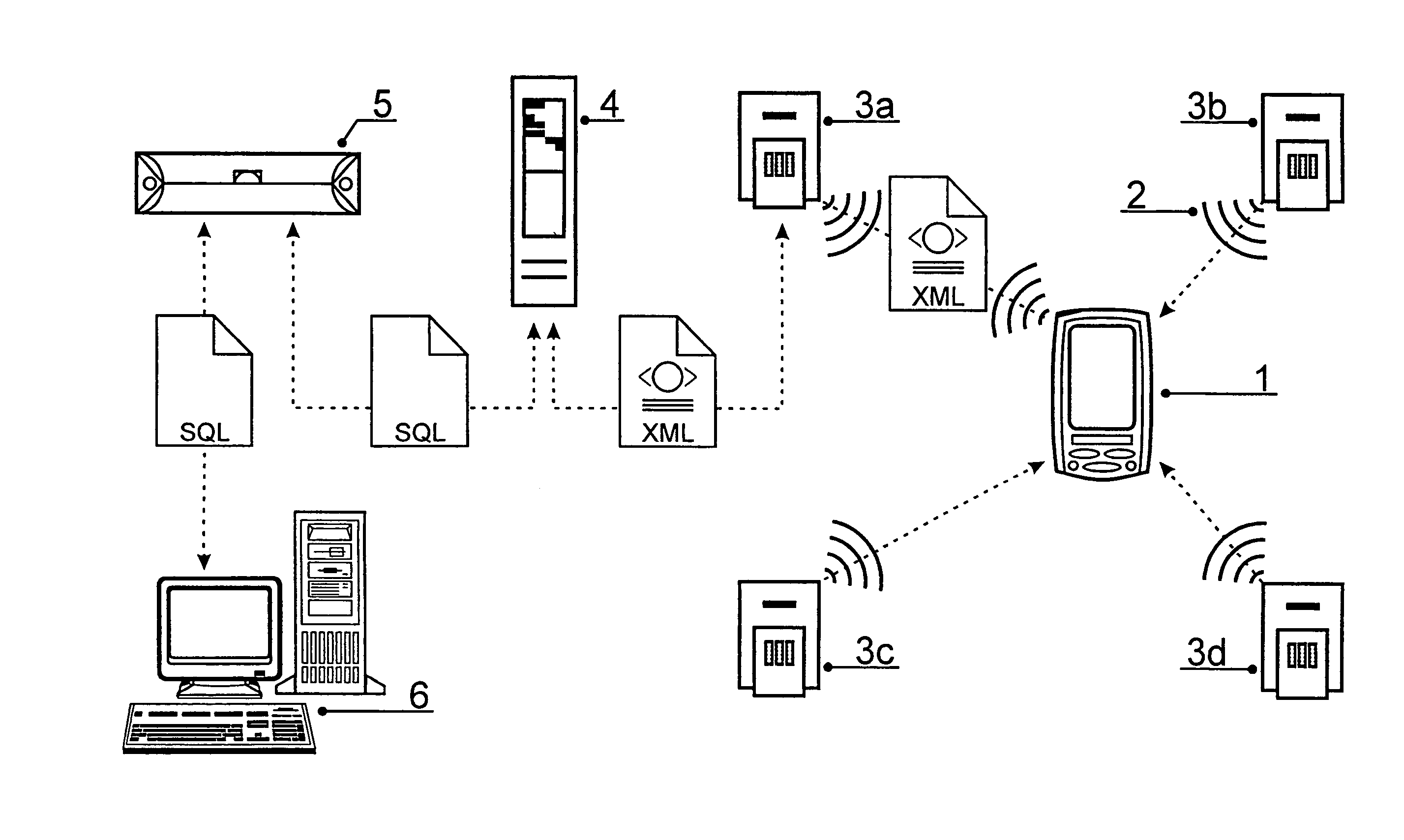

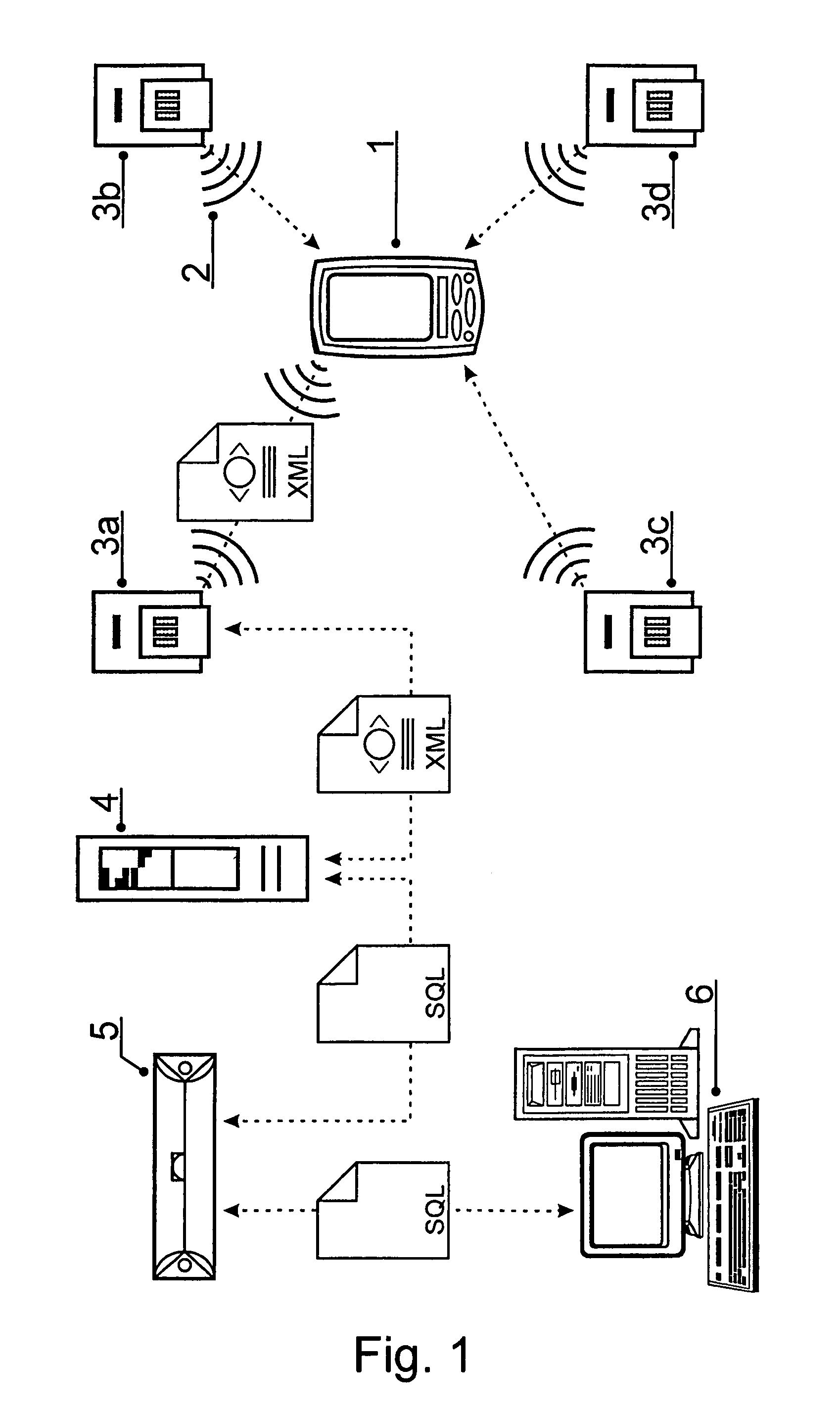

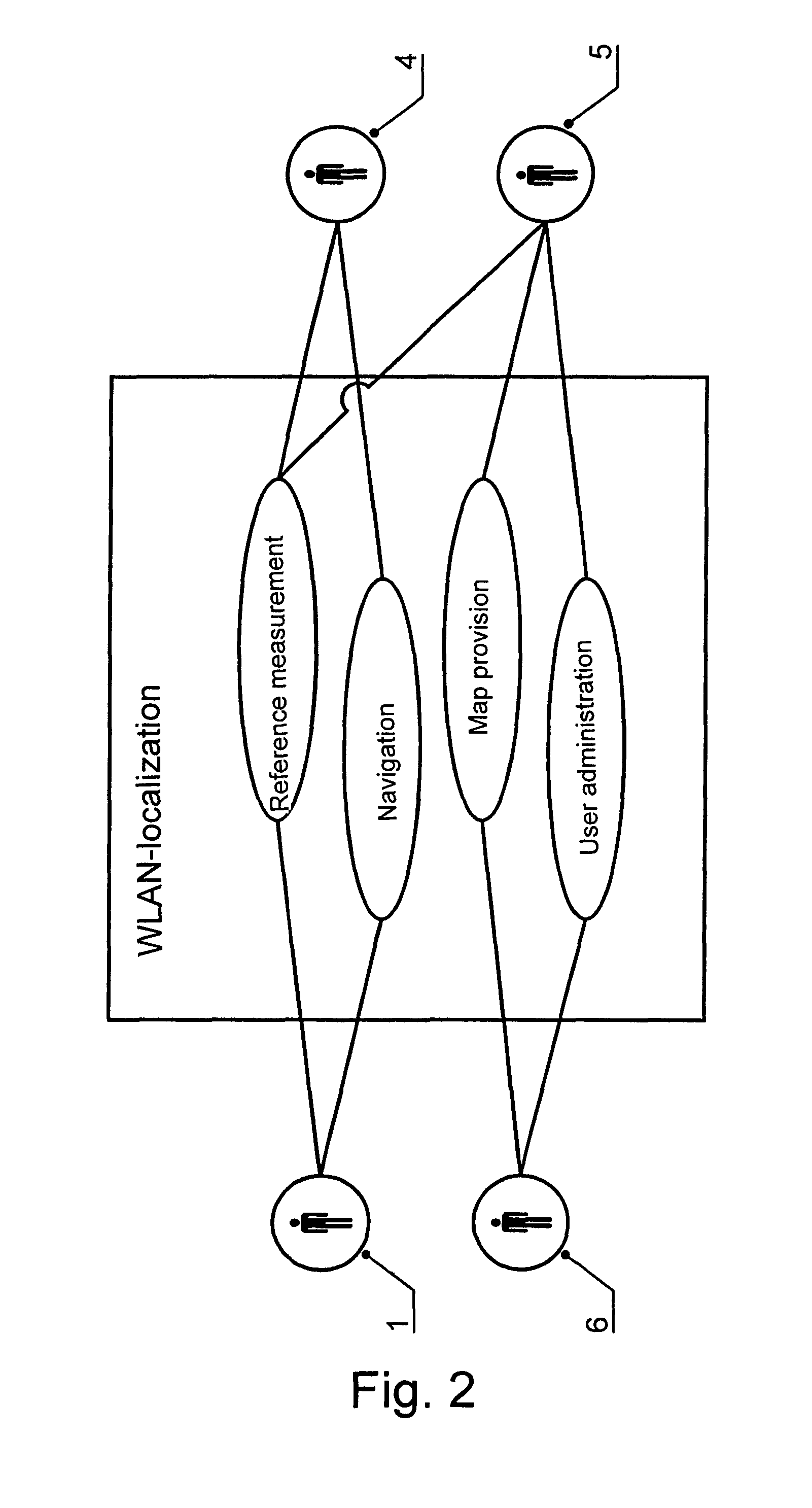

Method and system for the localization of a mobile WLAN client

ActiveUS20070081496A1High positioning accuracyReduce in quantityNetwork topologiesPosition fixationDatabase serverClient-side

A method and a system for the localization of a mobile WLAN client, located within a WLAN network of multiple WLAN stations. Static reference points are ascertained by measuring field strengths of the WLAN stations at spatial coordinates, aided by WLAN client(s), and assignment of the measured field strengths to the spatial coordinates in terms of data records. Self-learning ascertainment of further dynamic reference points is obtained by measuring field strengths of the WLAN stations, aided by WLAN client(s) moving through the region of the network, and assignment of the measured field strengths in terms of data records to the respective spatial coordinates calculated for this purpose, in the database server. This may be done to localize a WLAN client by selecting a plurality of nearest matched data records of static and dynamic reference points whose subsequently calculated center of gravity corresponds to the estimated position of the WLAN client.

Owner:DEUTSCHE TELEKOM AG

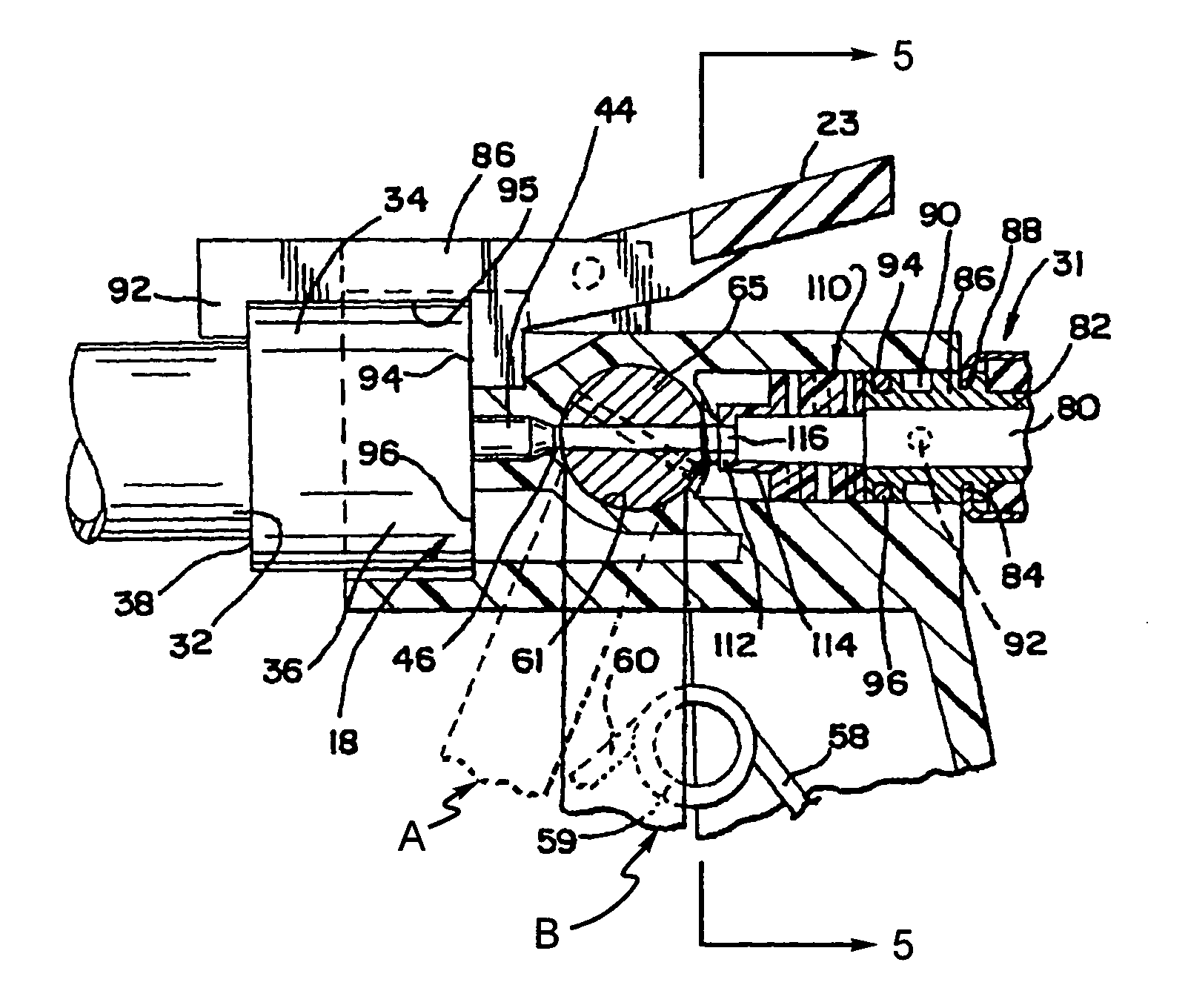

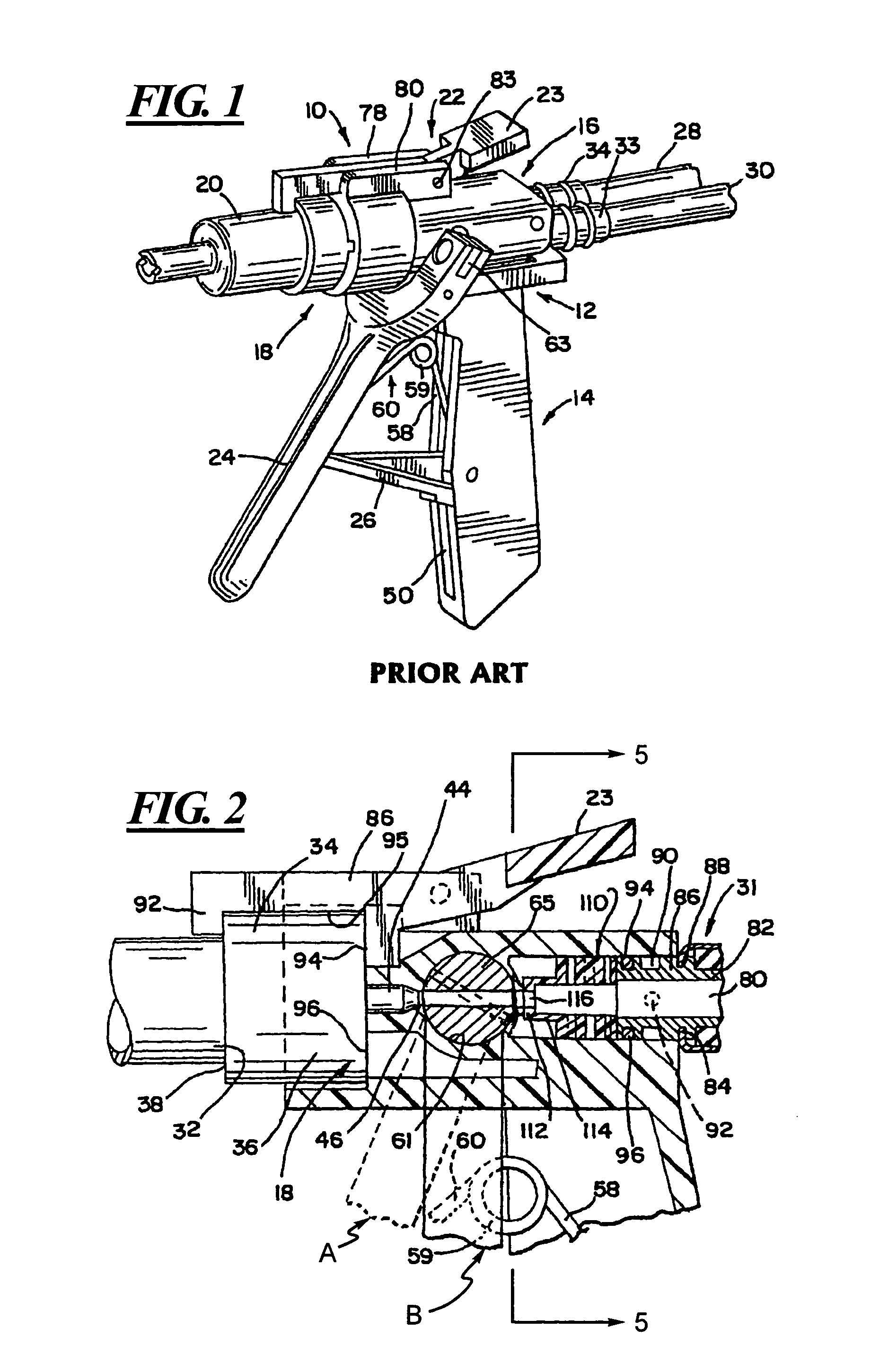

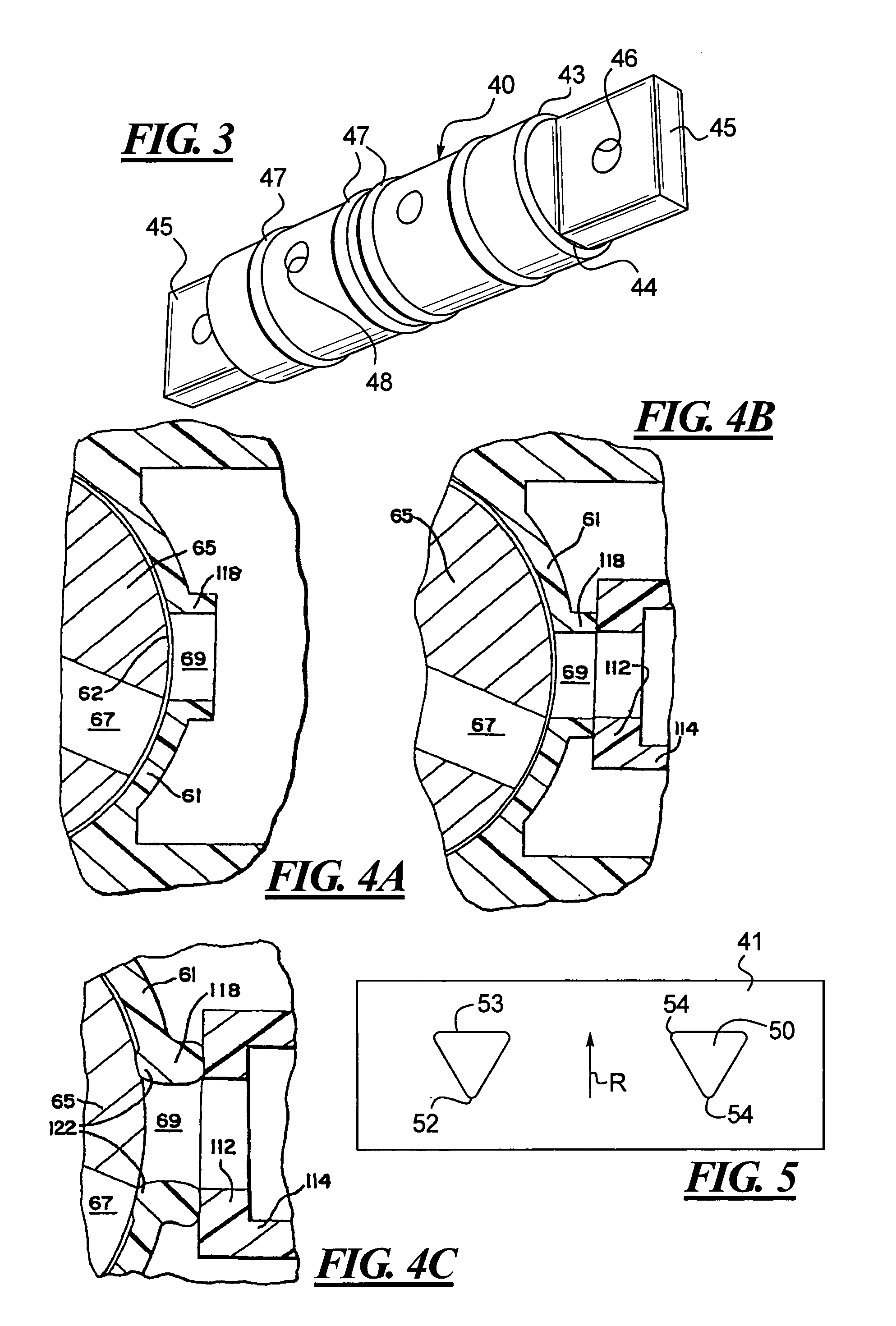

Multi-component foam dispenser with improved flow metering means

InactiveUS6991185B2Allocation is accurateAccurate measurementSpray nozzlesLiquid spraying apparatusSpool valveEngineering

An improved metering apparatus is provided for use with a foam dispenser that disperses beads of foam after mixing streams of two foam components together. The dispenser has a pair of seal passages formed in a body portion of the dispenser and a spool valve rotated mounted in the body portion. The spool valve has a pair of flow passages formed in it that can be rotated into mating alignment with the seal passages formed in the dispenser body. The spool valve flow passages have circular cross-sections while the seal passages have non-circular cross-sections, and preferably triangular cross-sections.

Owner:FLEXIBLE PRODS

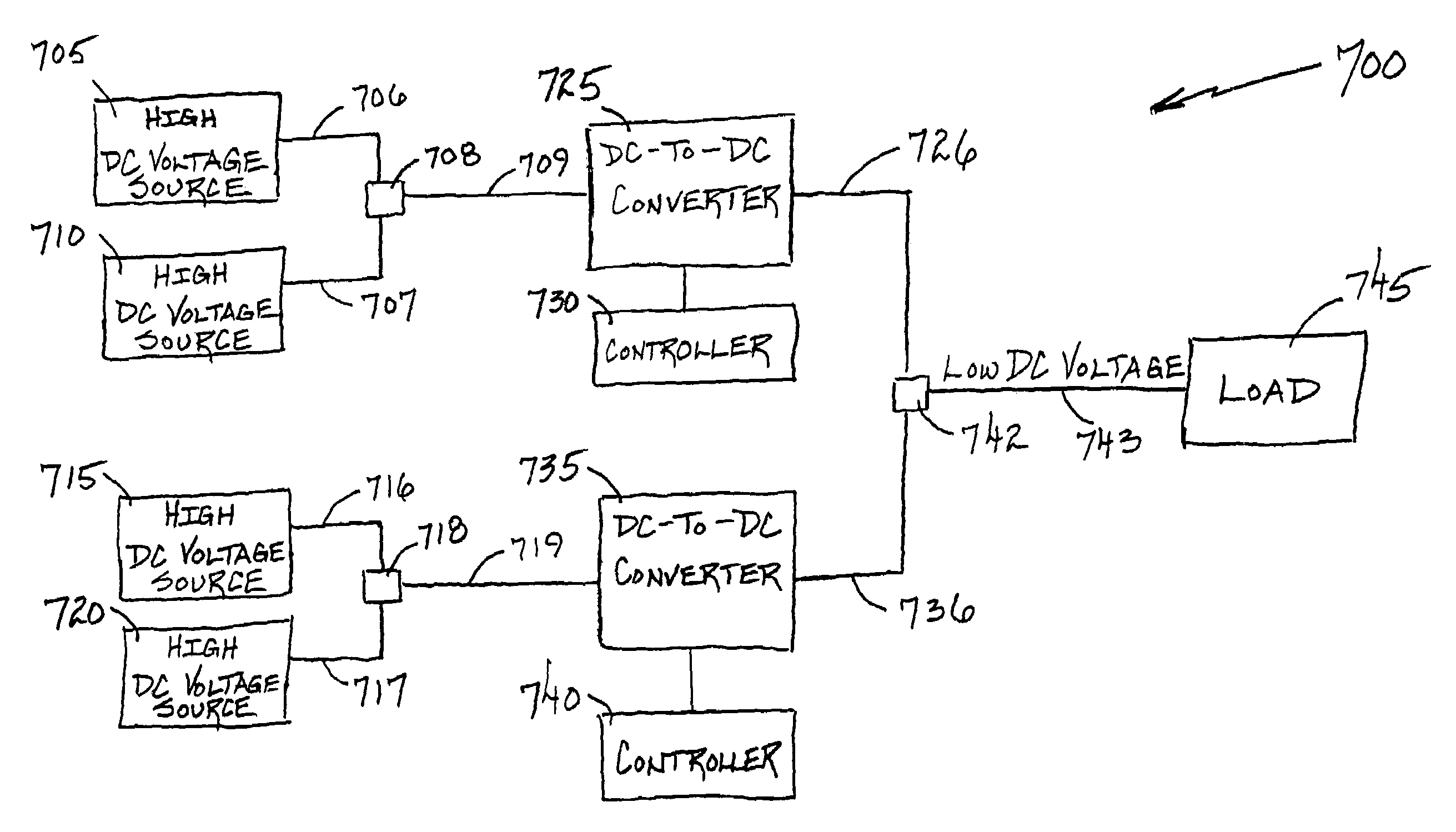

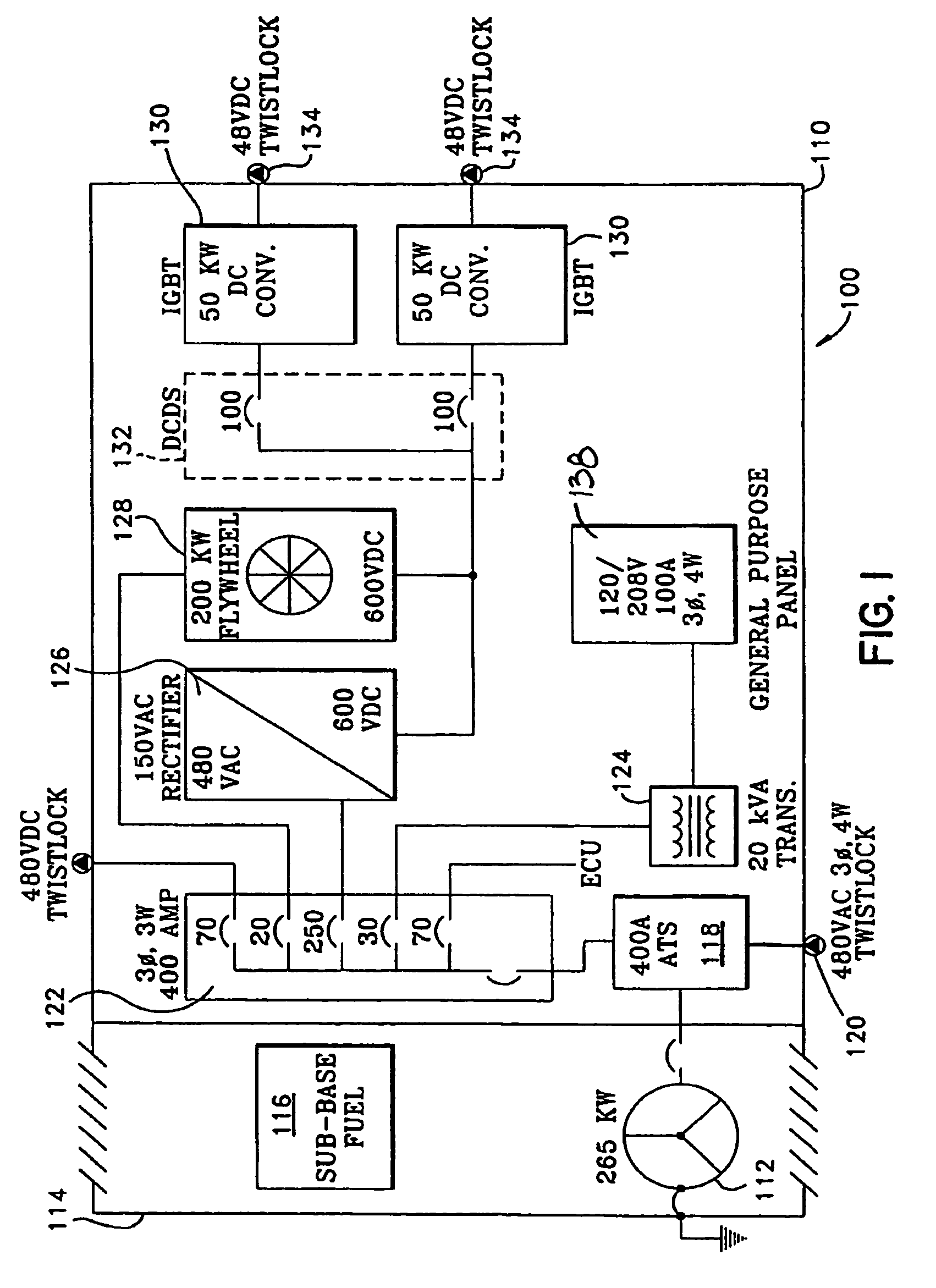

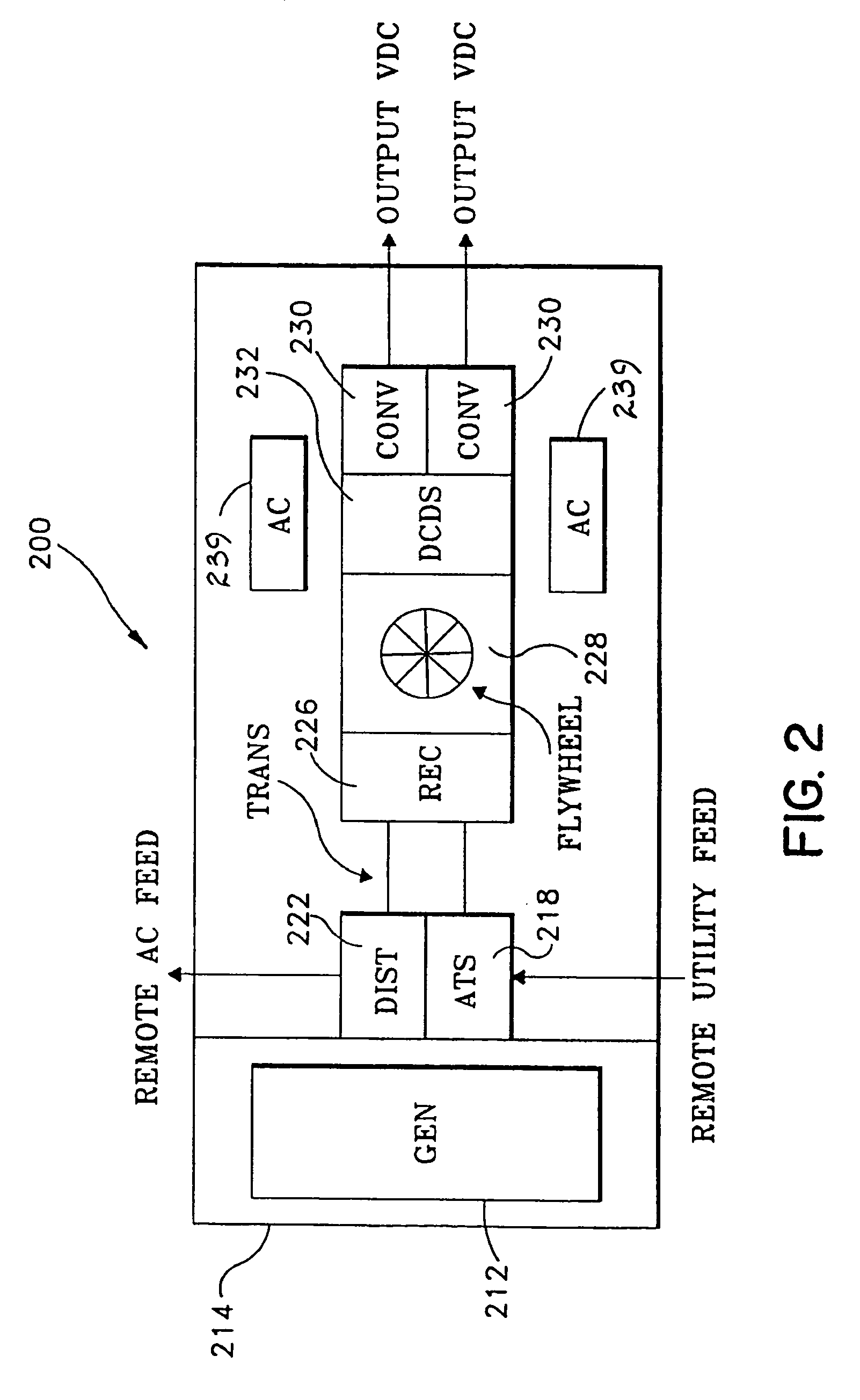

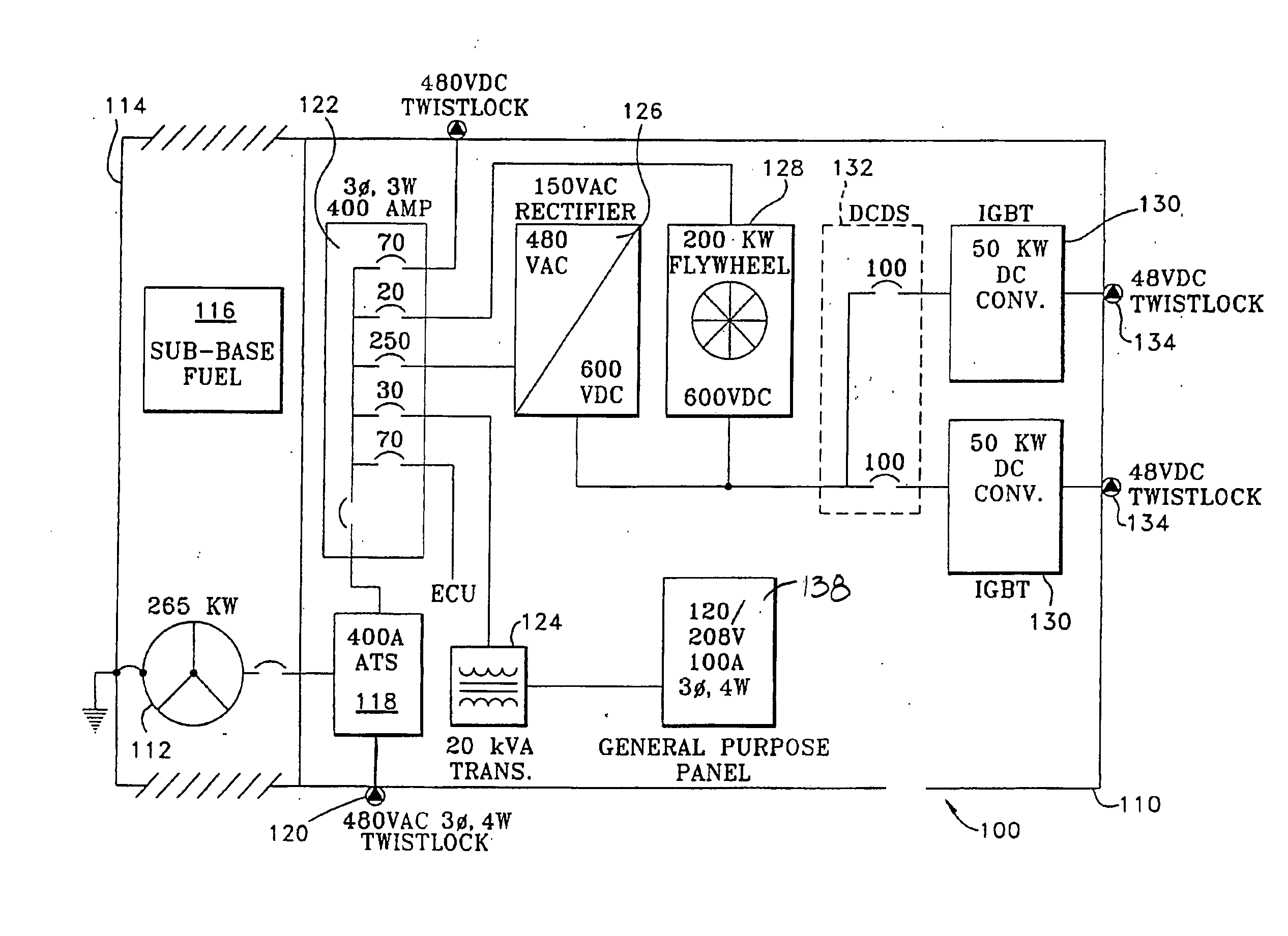

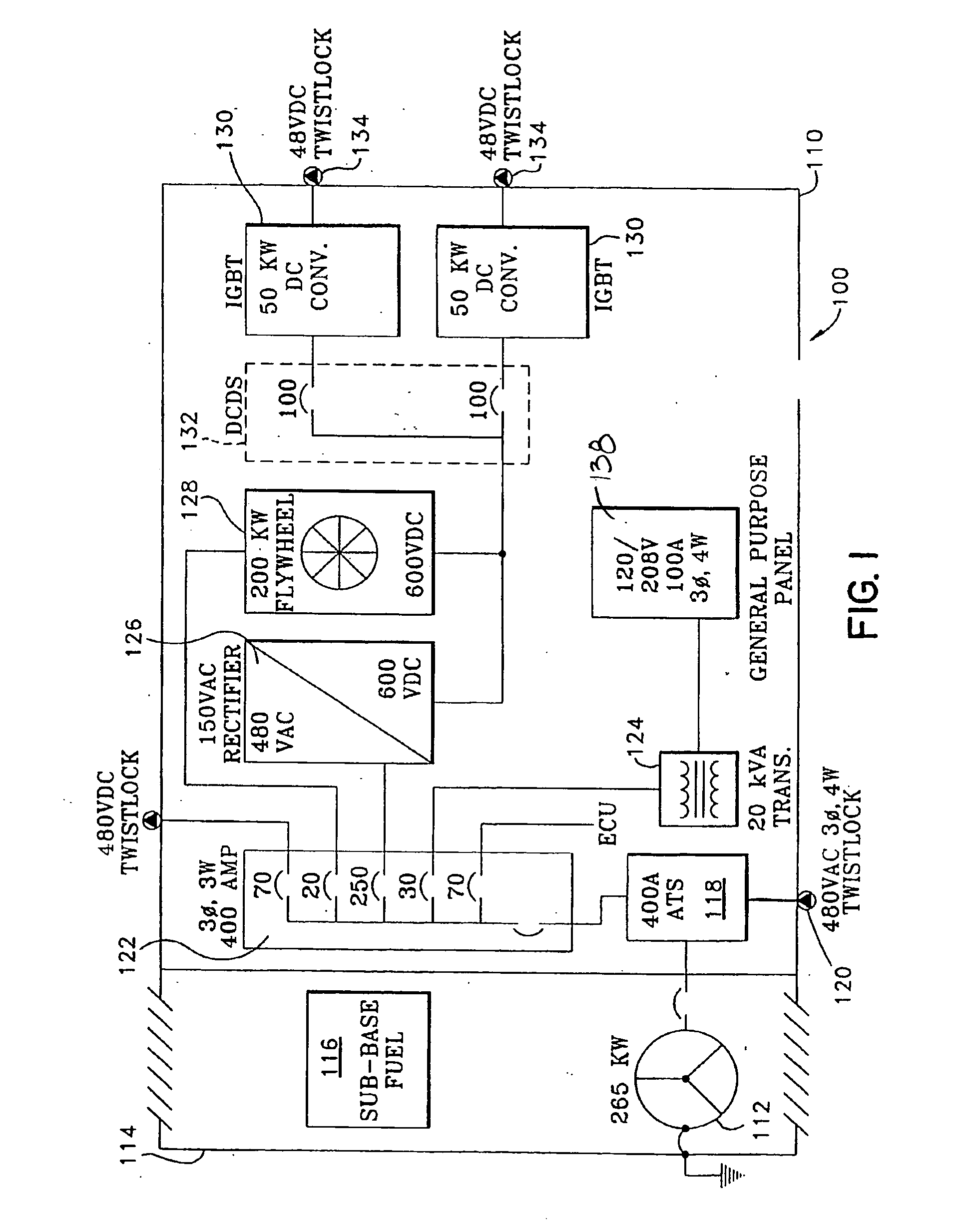

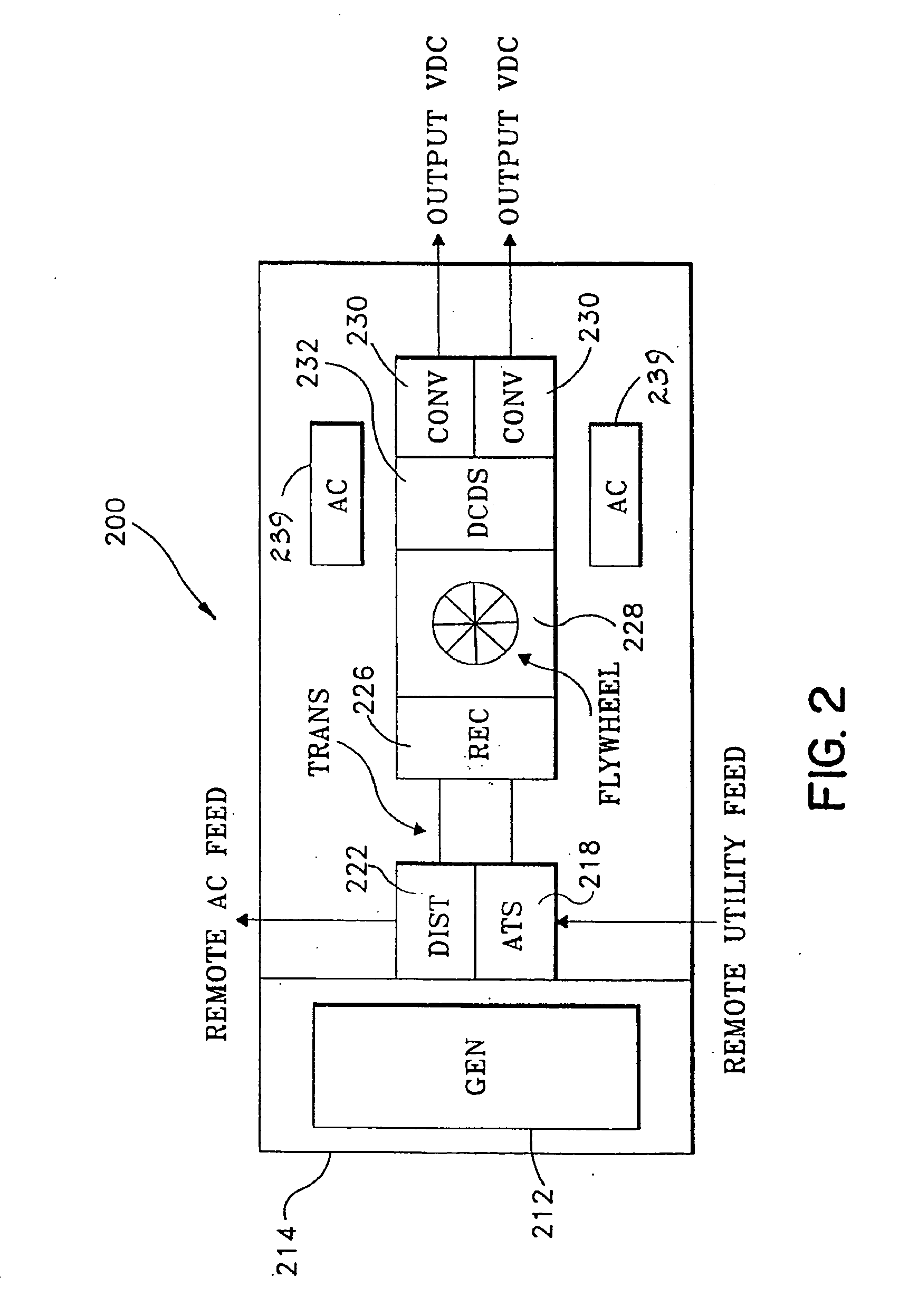

Apparatus for providing high quality power

ActiveUS7141894B2Improve power reliabilityLower requirementDc network circuit arrangementsBatteries circuit arrangementsChemical storageData center

The system disclosed herein is primarily utilized in the 23–48 volt DC telco, data center and industrial production industry. It will effectively replace today's requirement of purchasing, installing, maintaining and replacing chemical storage batteries. The solution will be capable of deployment partially and in full, inside the building, outside of the building in environmentally enclosed containers or in a mobile version. Additionally, the distribution voltage application will allow for reduction in the size of the power distribution wiring as well as creating an environment that requires less cooling of the critical equipment. This effectively leads to less infrastructure space and equipment, i.e. UPS, air conditioning units, static switch units, generators and chillers, for the same amount of processing, and significantly increases overall system reliability. The system regulates AC power and produces DC power that is considered uninterruptible and that is high quality in nature.

Owner:VALIDUS DC SYSTEMS

Razors

ActiveUS8186063B2Efficient meteringAvoid overdoseThrusting weaponsWeapon componentsRazor stropEngineering

A razor, especially a safety razor, comprises a fluid delivery system including a pump (24) for conducting a fluid, such as a lubricant, from a reservoir (25) for application to the skin, and a control device (16) for actuating the pump (24) when the razor is brought into contact with the skin by a person holding the razor, and deactuating the pump (24) after a certain time of actuation, e.g. 0.1 to 2 seconds. The control device is arranged to ensured a delay of 1 to 10 seconds between successive actuations, and so that the pump is actuated only every second third or fourth shaving stroke.

Owner:THE GILLETTE CO

Apparatus for providing high quality power

InactiveUS20070052294A1Reduce DC rippleTotal current dropDc network circuit arrangementsBatteries circuit arrangementsConvertersControl theory

Owner:VALIDUS DC SYSTEMS

Dispensing device for loose products for the preparation of beverages, and machine containing said dispensing device

InactiveUS20100236419A1Avoid steamReduce speedMovable measuring chambersVolume measurement and fluid deliveryGlobe valveEngineering

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

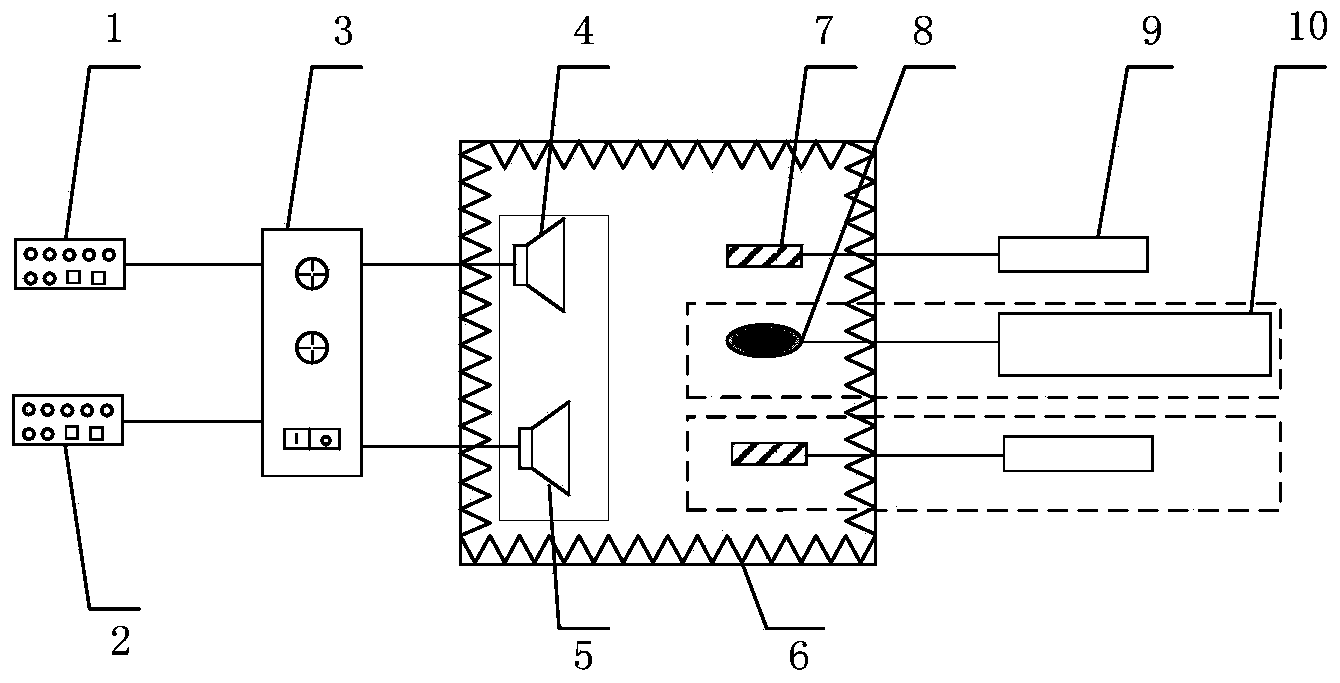

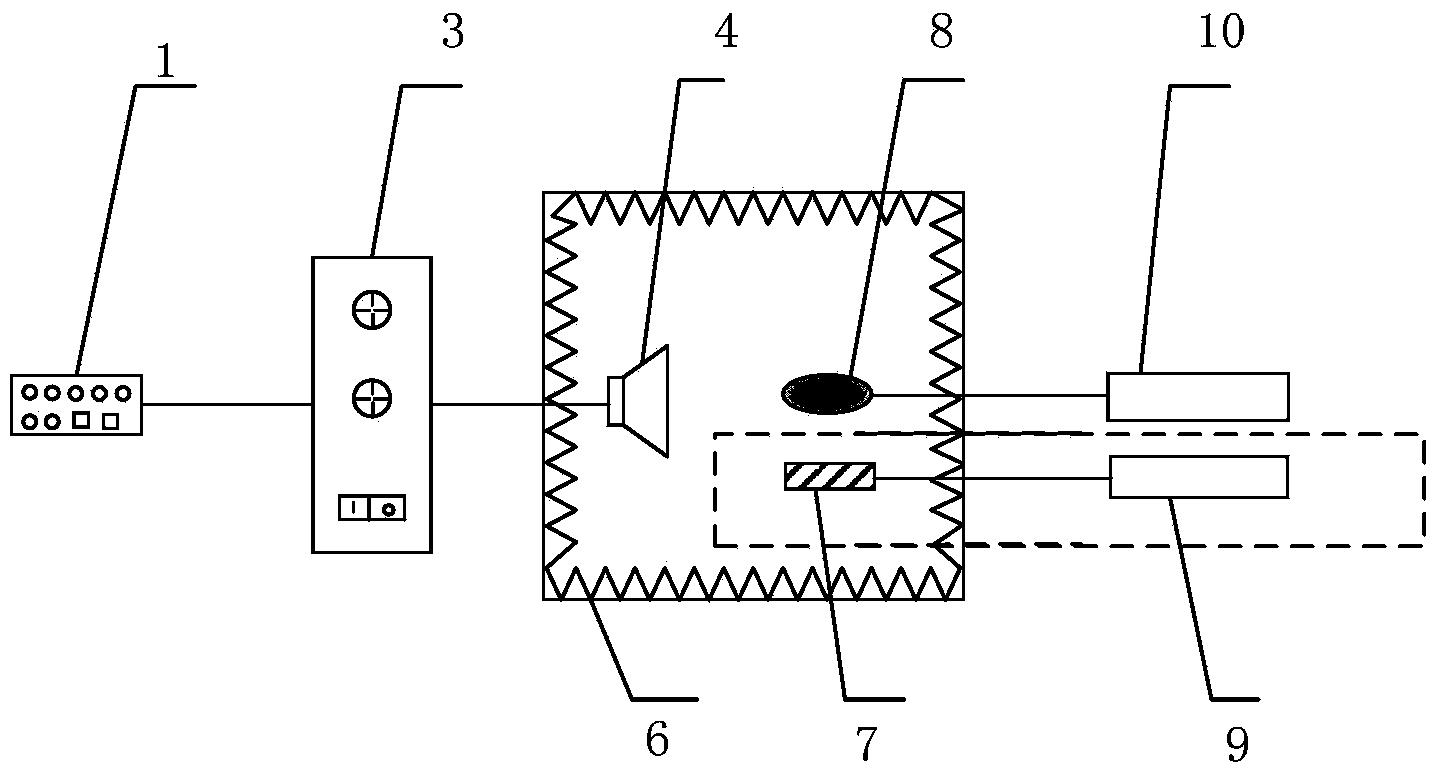

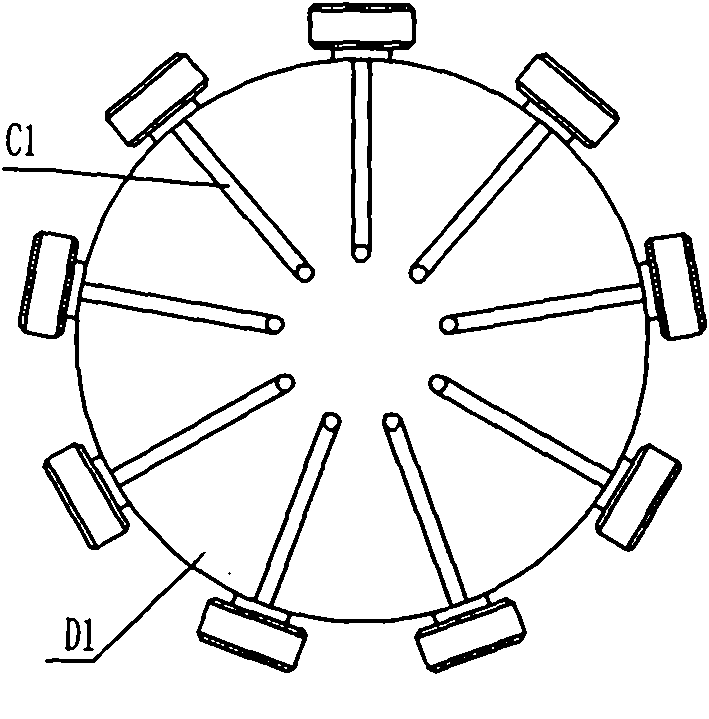

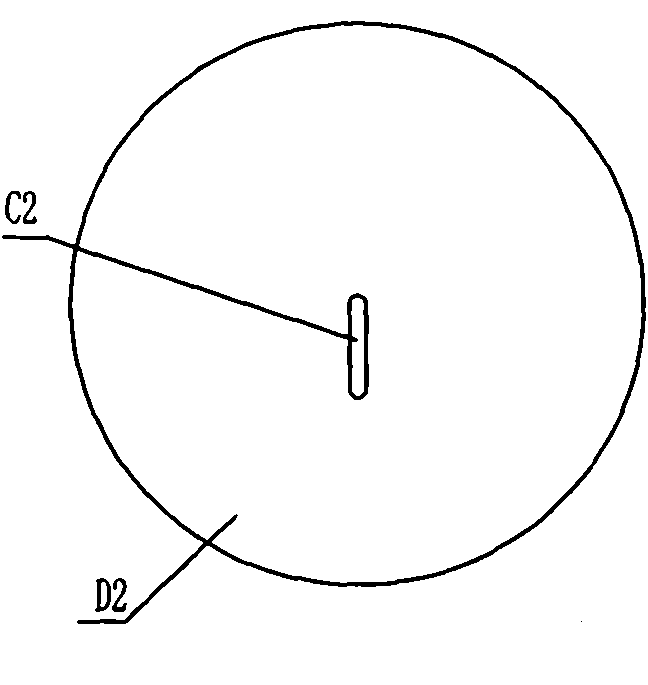

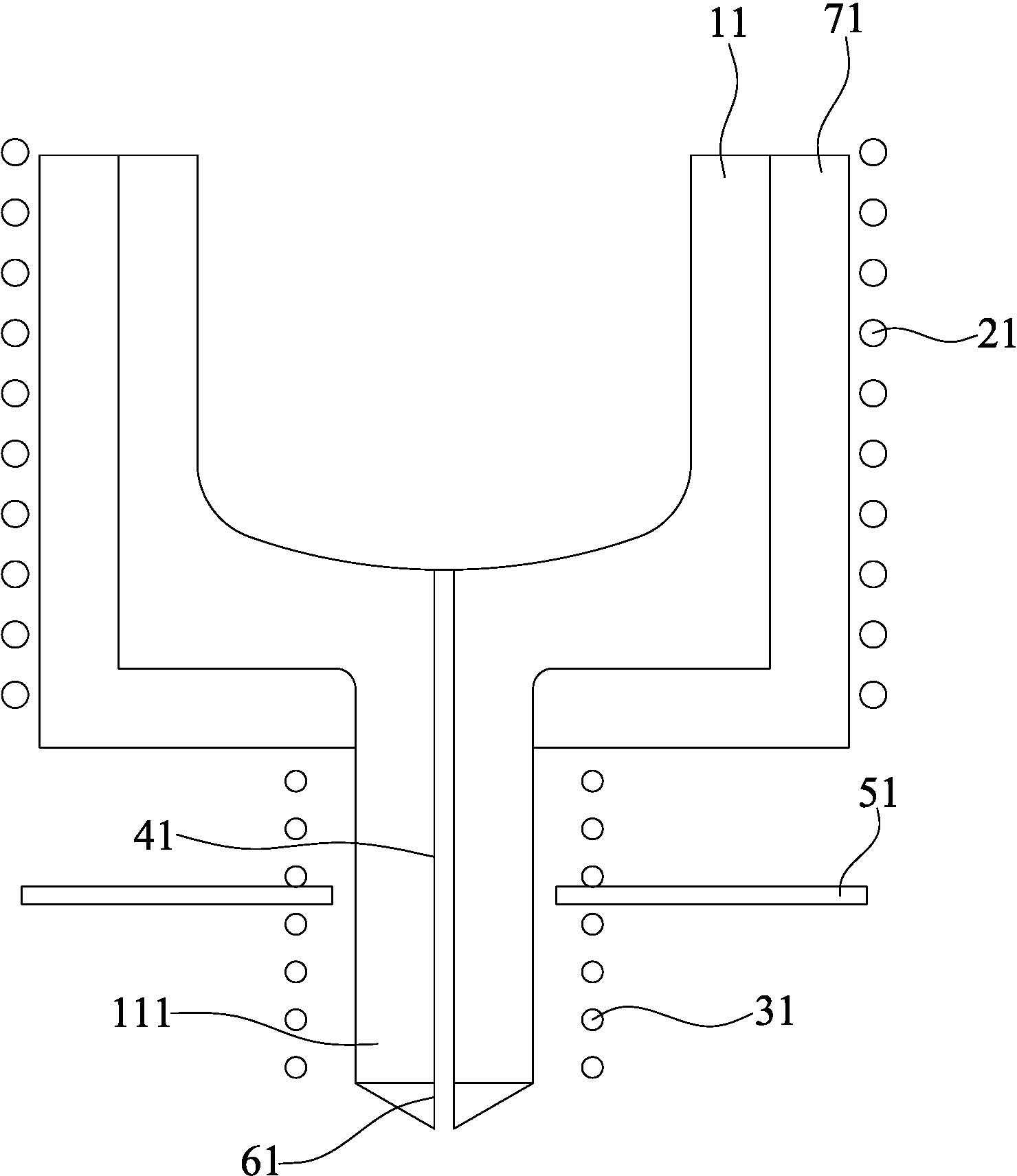

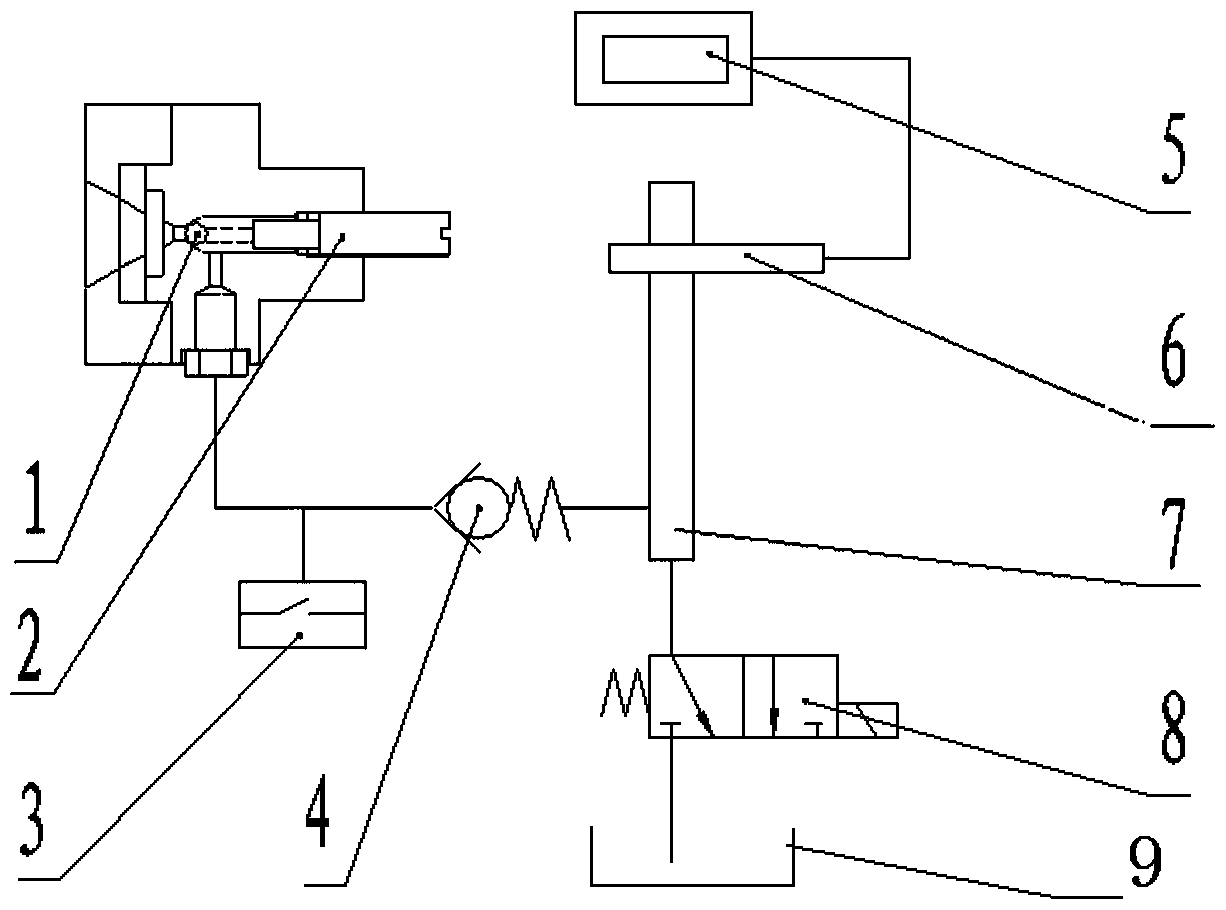

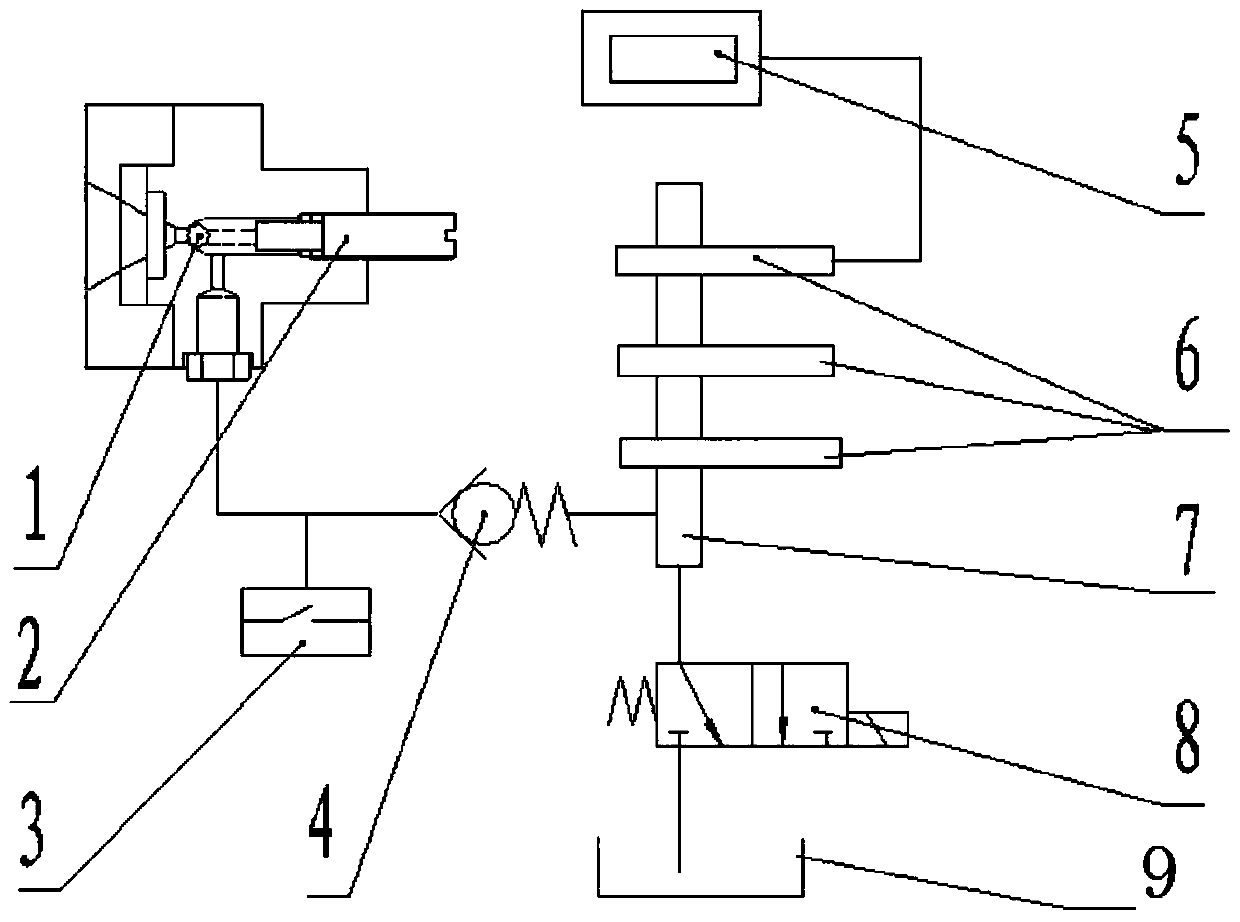

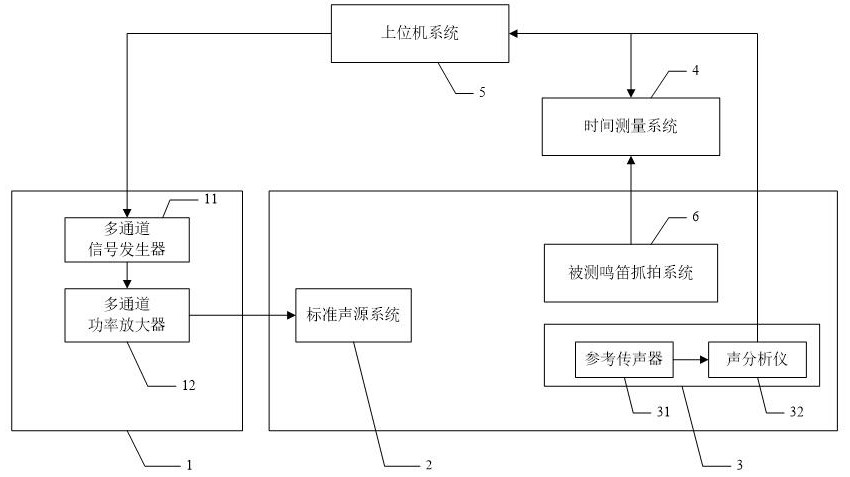

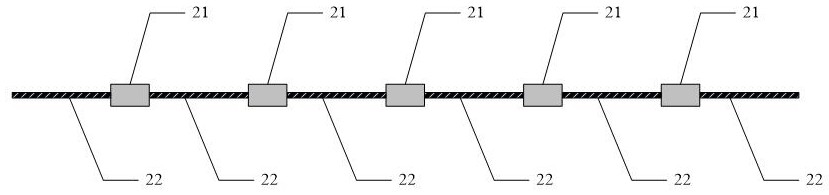

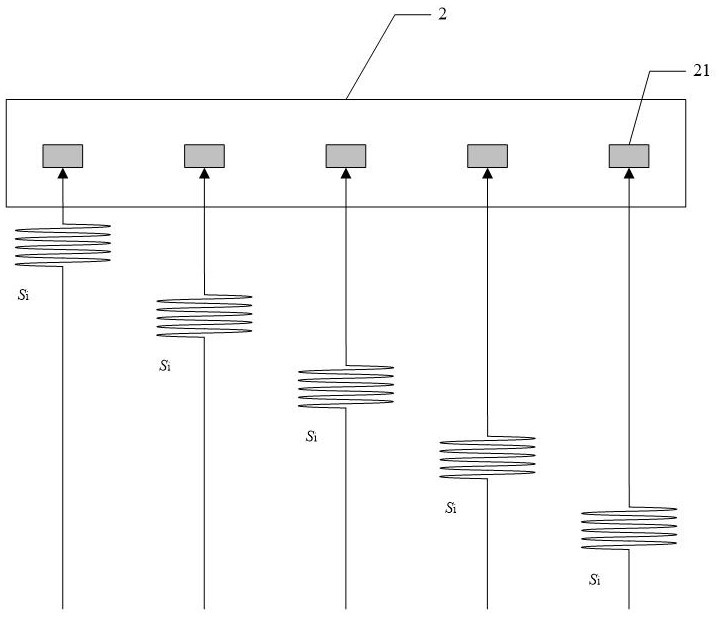

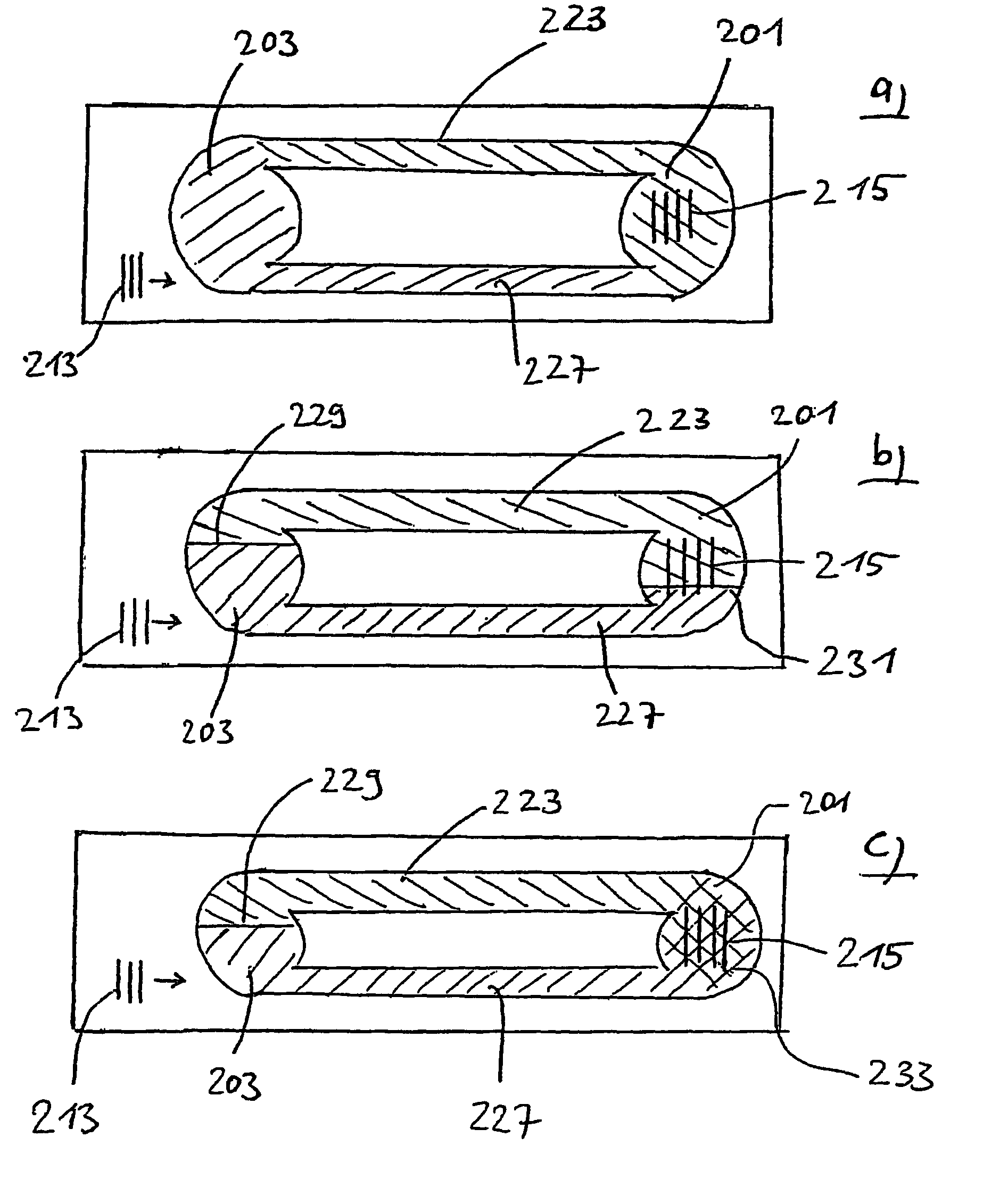

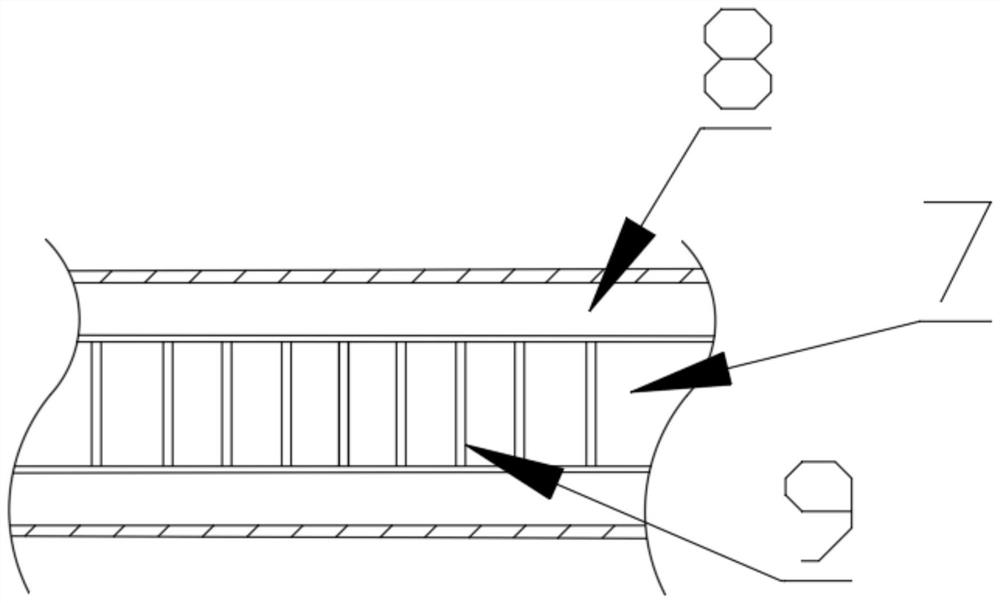

Metering and calibrating method and metering and calibrating device for sound source identifying and positioning system

The invention relates to a metering and calibrating method and a metering and calibrating device for a sound source identifying and positioning system. A two-point sound source sounding method is adopted for calibrating transverse spatial resolution of the sound source identifying and positioning system (a beam forming method), and a single-point sound source sounding method is adopted for calibrating a main lobe suppression ratio and a side lobe suppression ratio of the sound source identifying and positioning system, so that the sound source identifying and positioning system can be metered and calibrated precisely. According to the metering and calibrating device, a variable cross-section waveguide tube scheme is adopted for realizing approximate point sound sources, linear guide rails and corresponding slide block structures are adopted, and an upper computer controls motor drive to achieve precise change of the distances of the point sound sources. The metering and calibrating method and the metering and calibrating device achieve accurate and efficient metering of the sound source identifying and positioning system and provide a reference mode for metering and calibrating the sound source identifying and positioning system.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

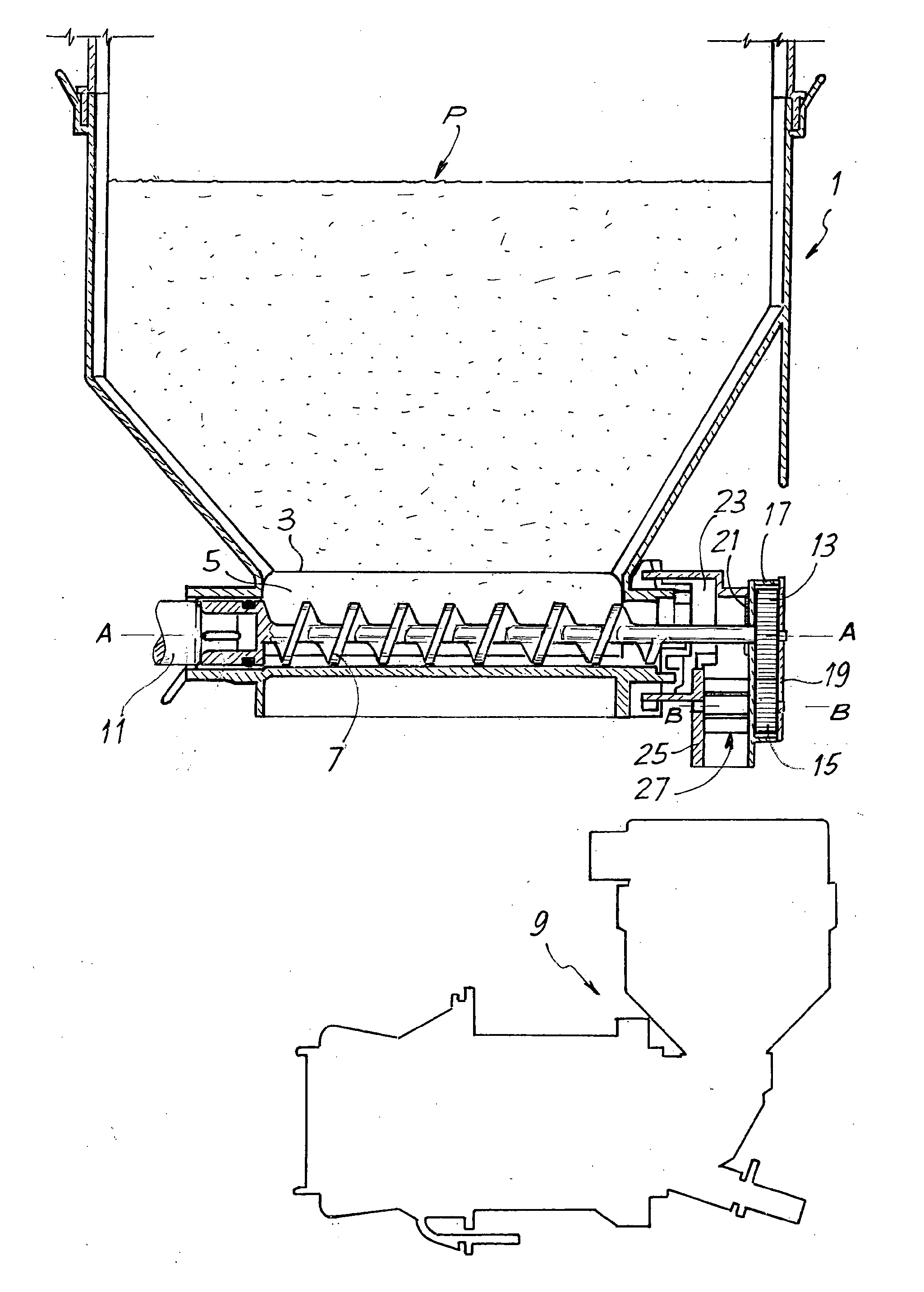

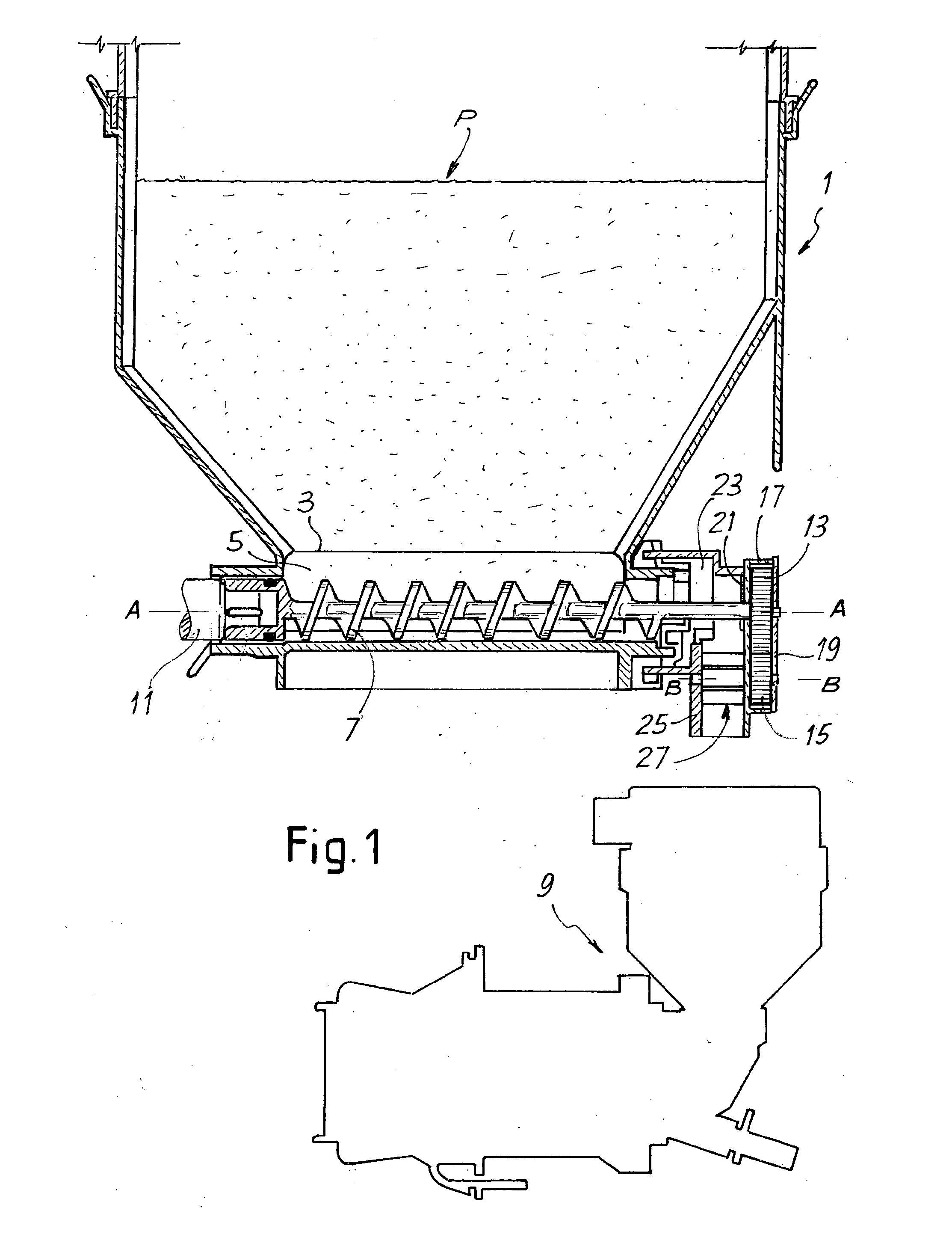

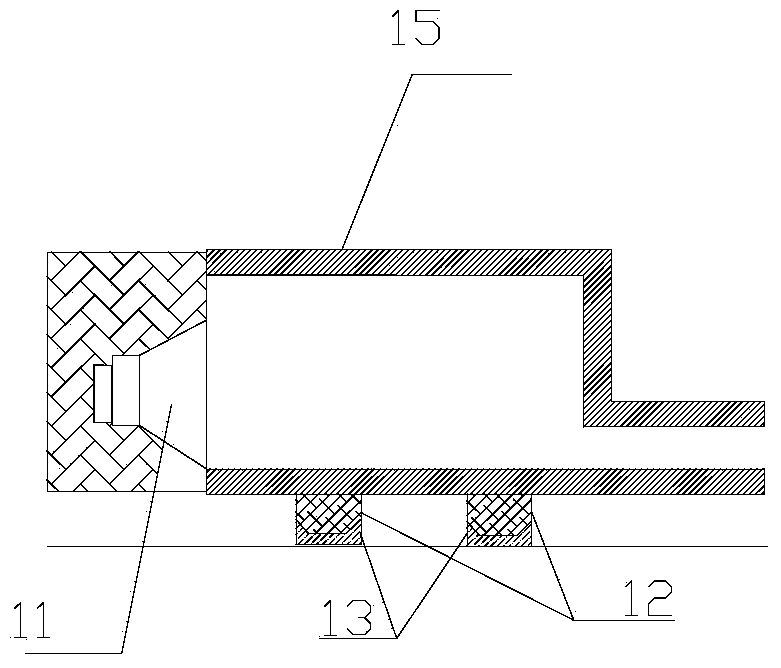

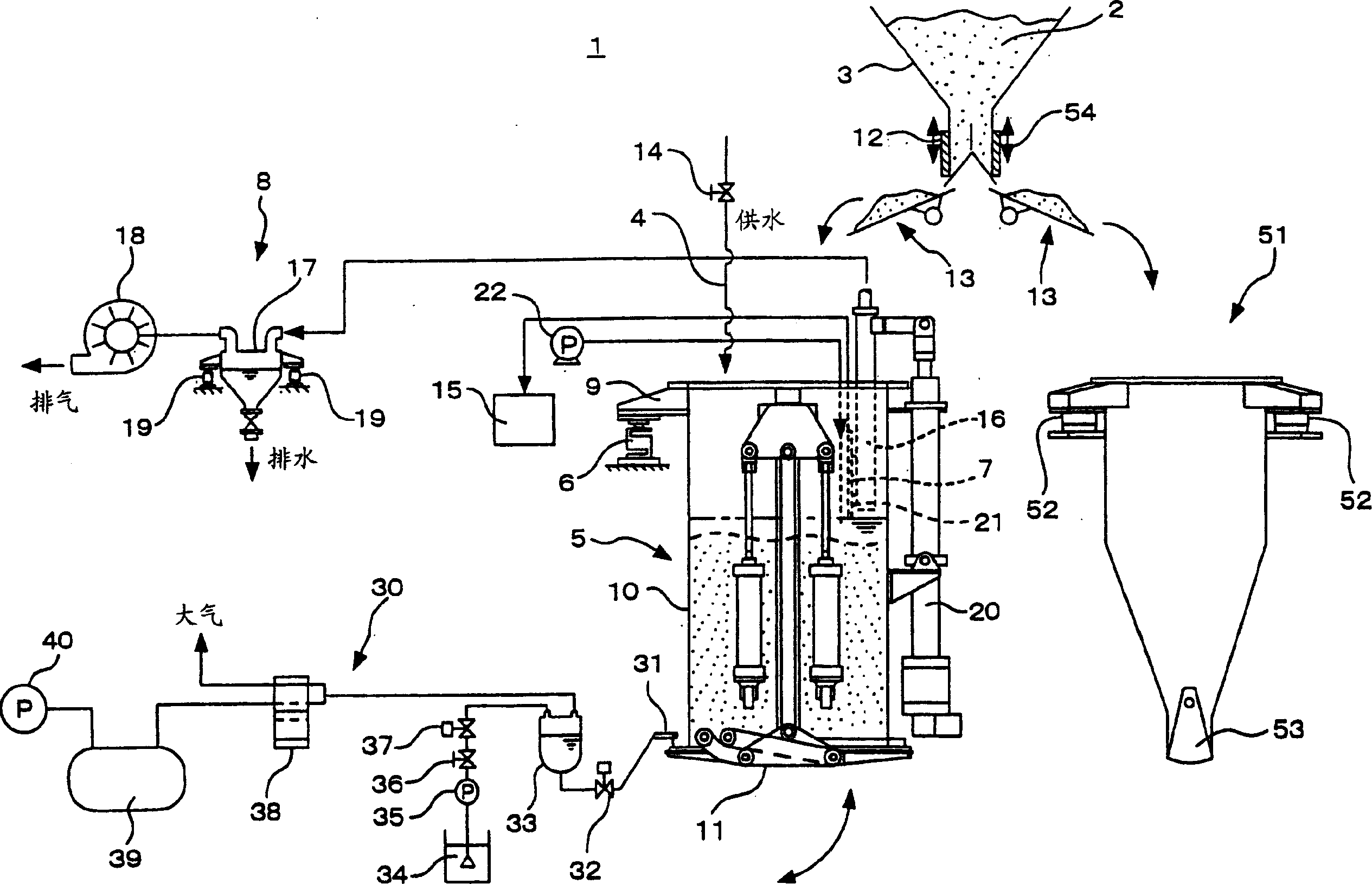

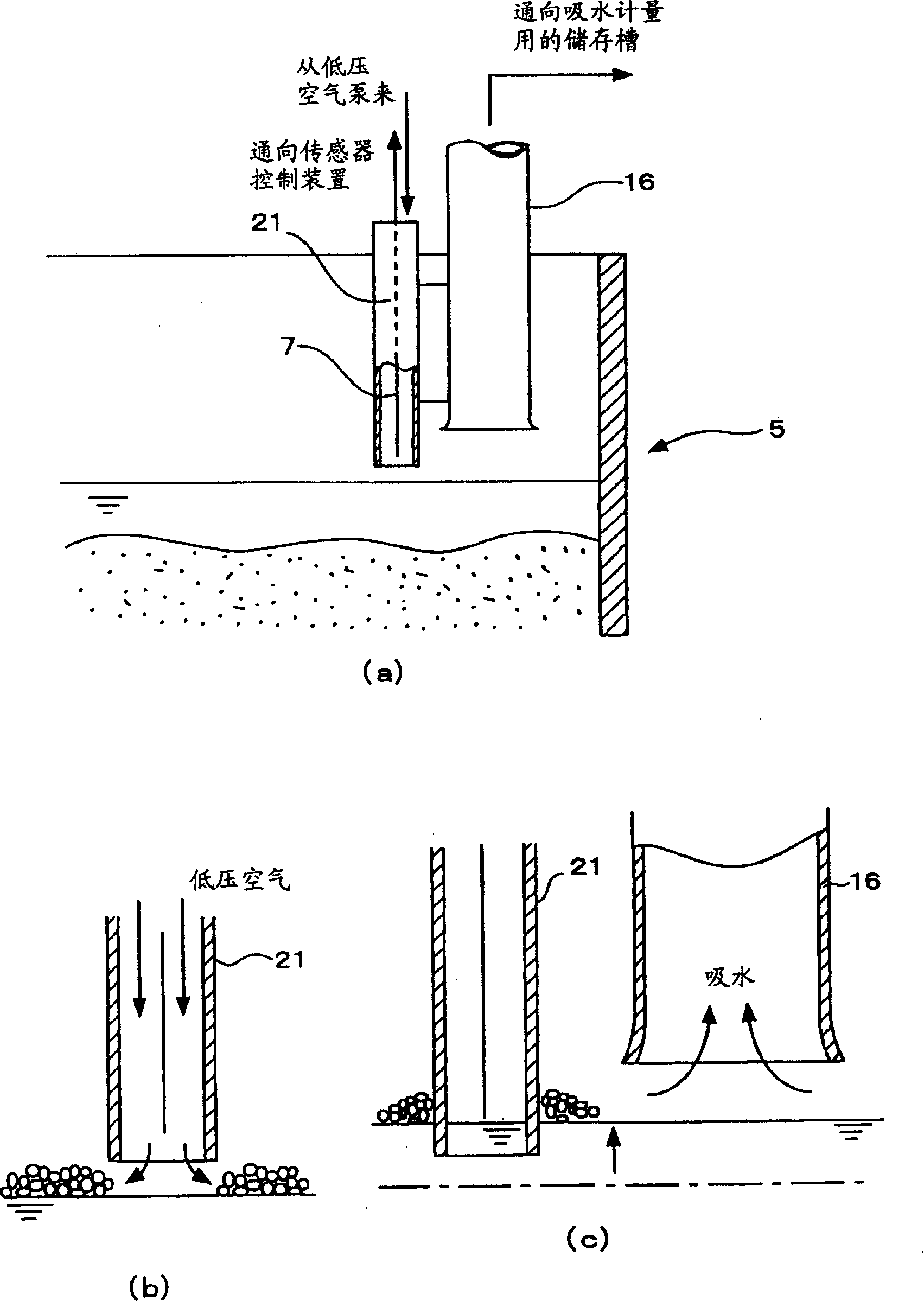

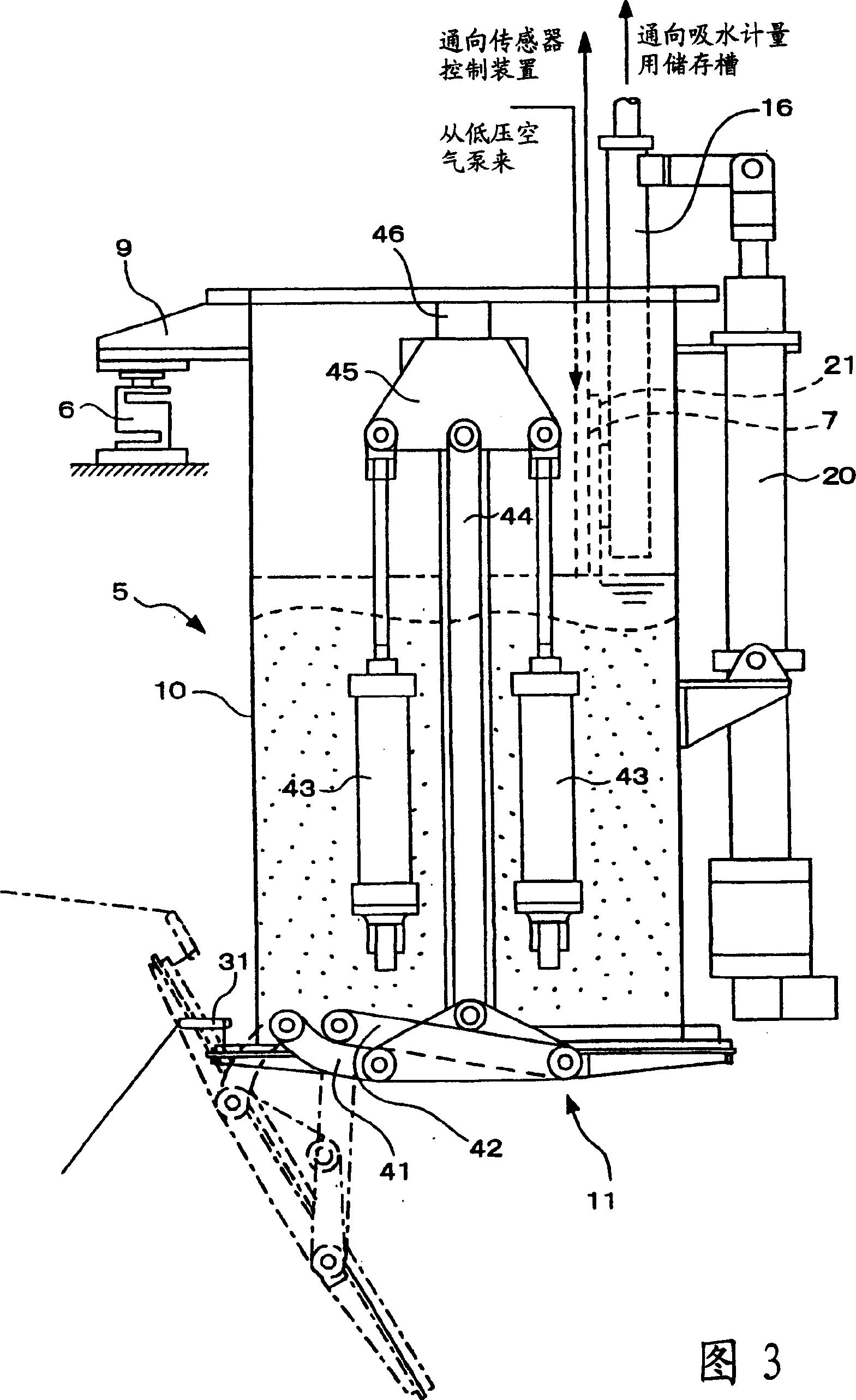

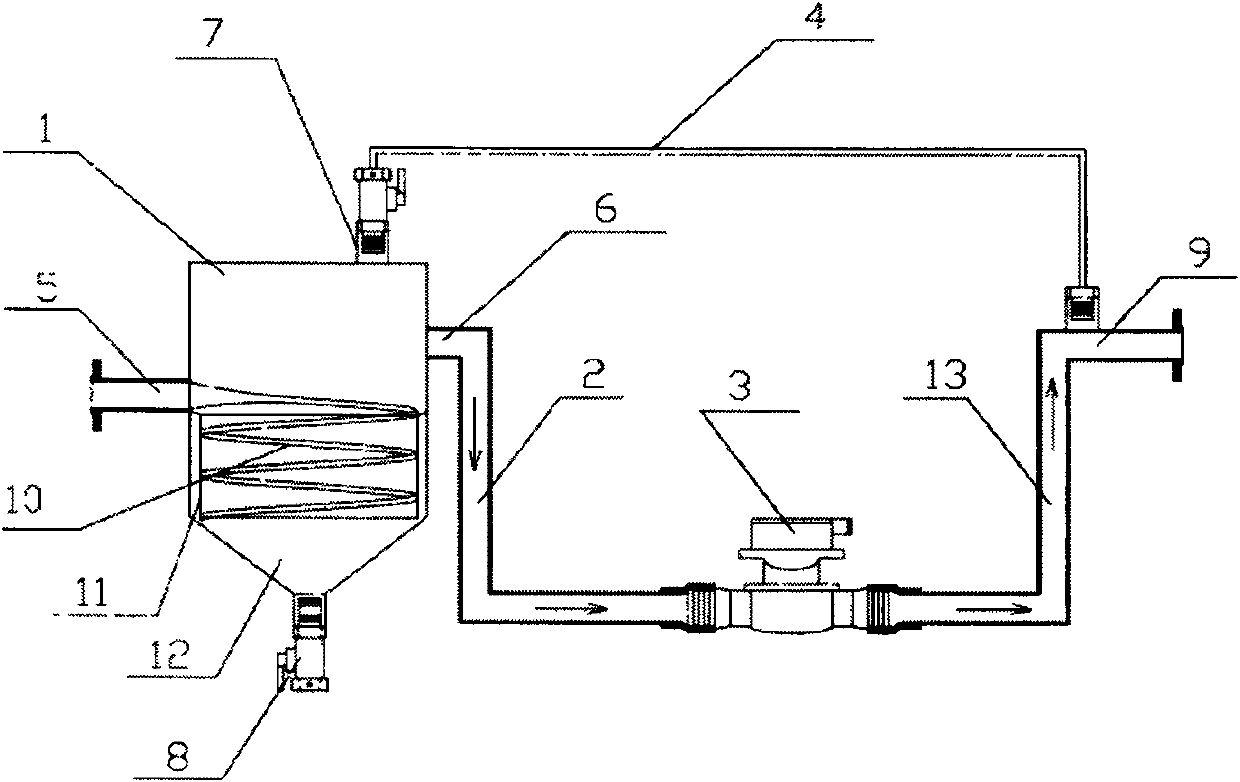

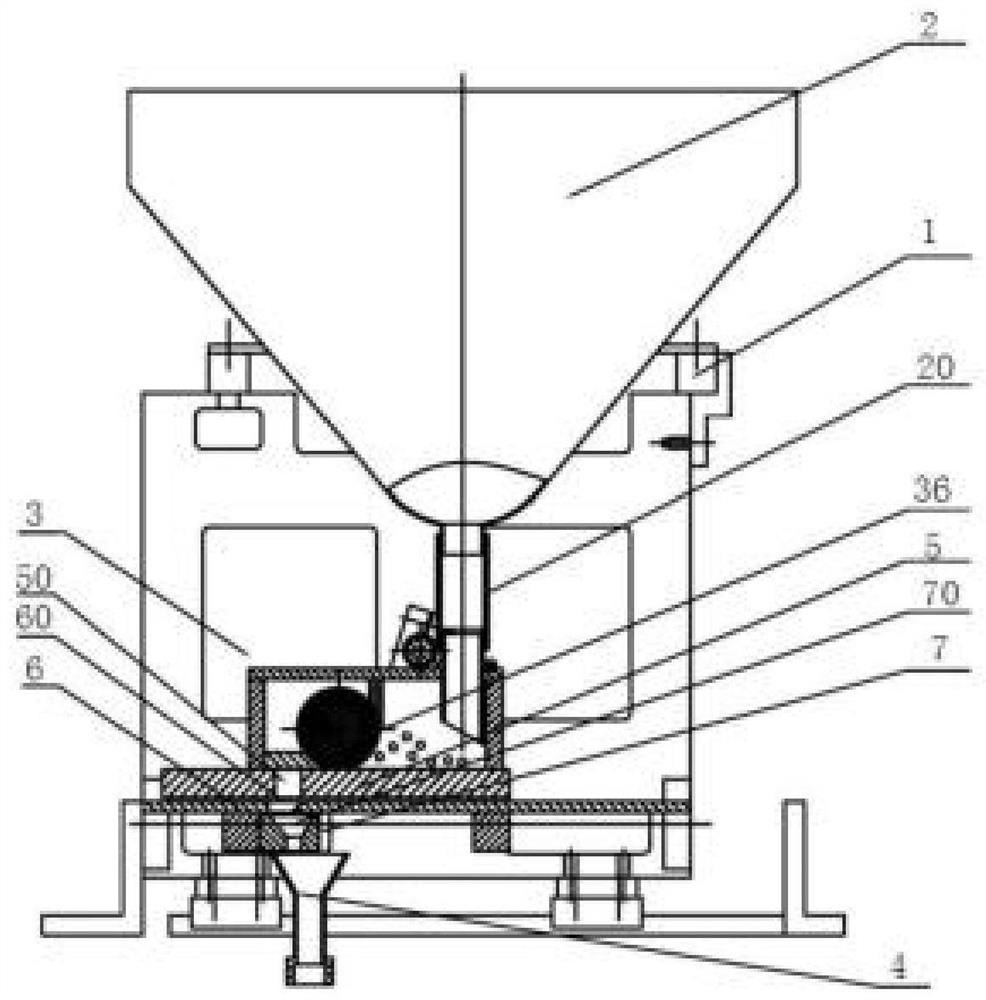

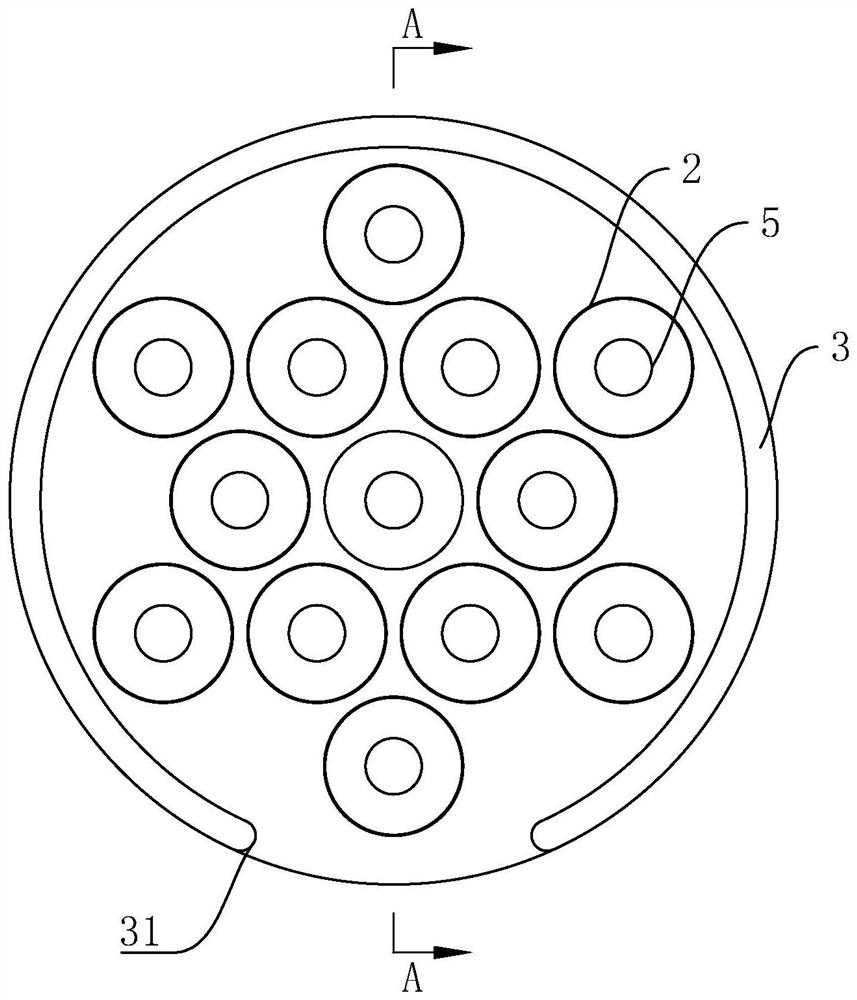

Weighing equipment for concrete material

InactiveCN1652908APrecise managementHigh precisionWeighing apparatus for materials with special property/formMaterial testing goodsWater levelLoad cell

A measuring apparatus (1) for concrete materials, comprising an aggregate hopper (3) as aggregate feed means for feeding fine aggregate (2) as aggregate, a water supply pipe (4) as water supply means, an aggregate measuring bin (51) for storing and measuring the fine aggregate (2) supplied from the aggregate hopper (3), a measuring tank (5) for storing the fine aggregate (2) supplied from the aggregate hopper (3) as water-immersed aggregate together with water supplied through the water supply pipe (4), a load cell (6) as water-immersed aggregate mass measuring means for measuring the mass of the water-immersed aggregate in the measuring tank, an electrode sensor (7) as water level measuring means for measuring the water level of the water-immersed aggregate in the measuring tank (5), and a water level holding device (8) as water level holding means for holding the water level of the water-immersed aggregate in the measuring tank (5) at a desired water level.

Owner:OHBAYASHI GUMI LTD

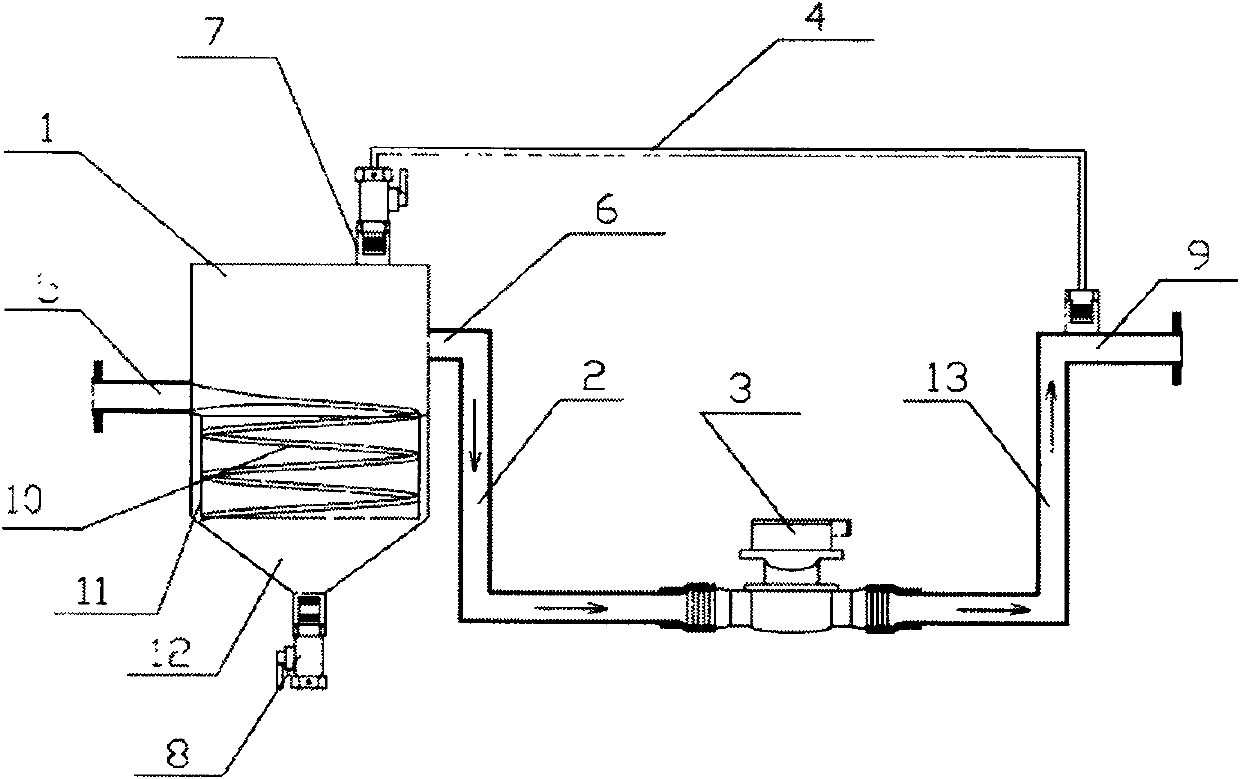

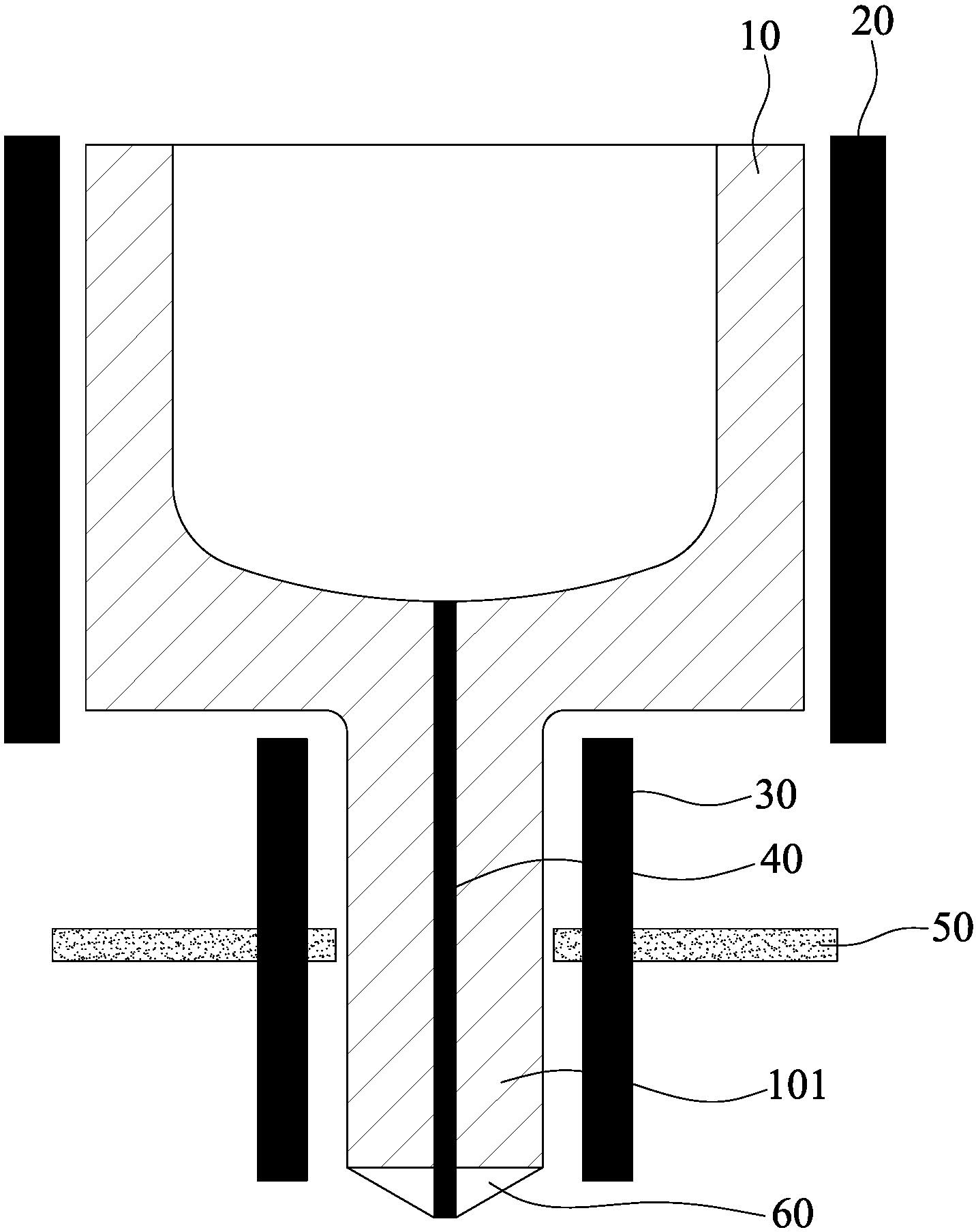

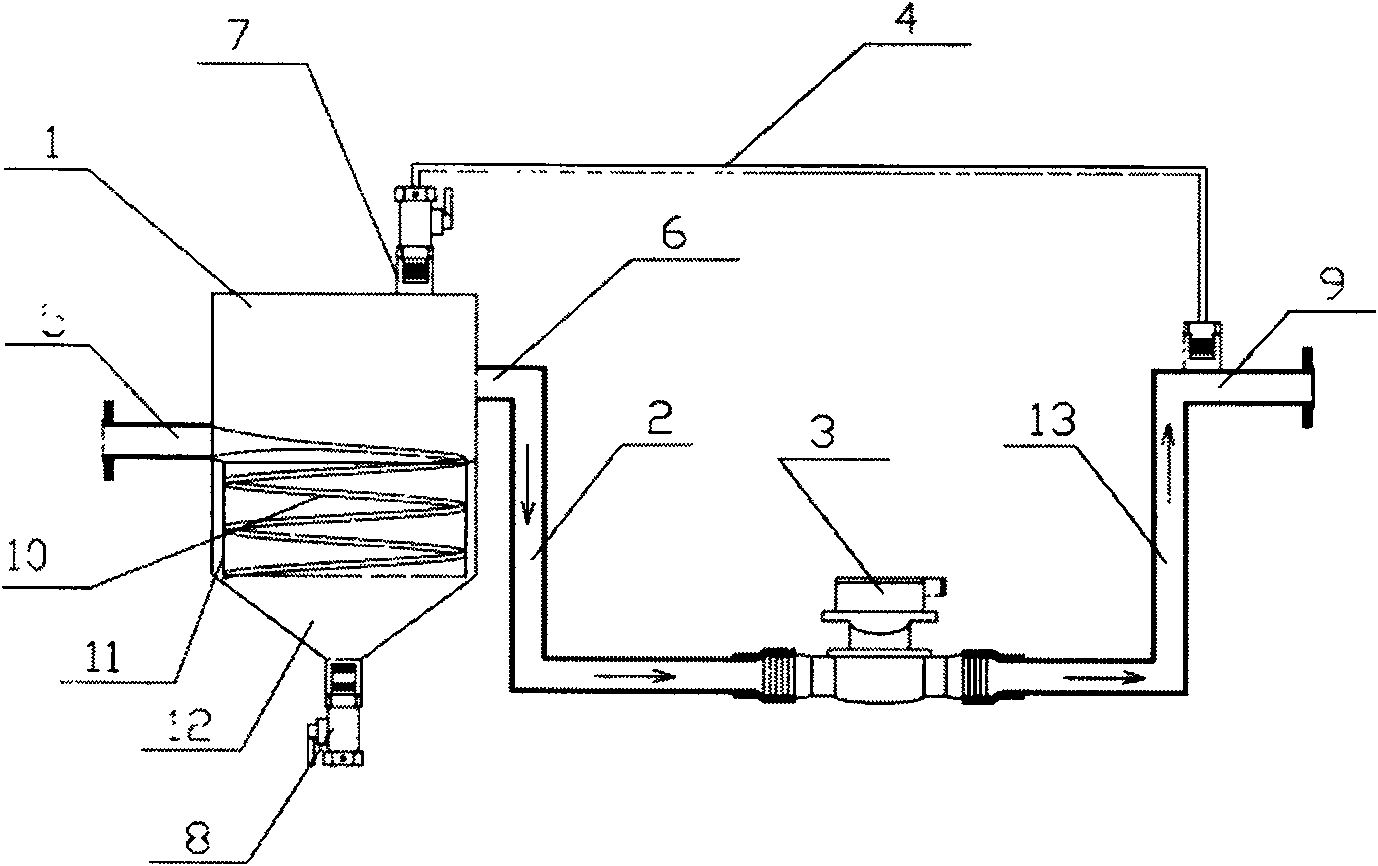

Device and method for measuring output liquid of coal bed methane well

The invention discloses a device and a method for measuring output liquid of a coal bed methane well. The device comprises a buffer vessel, a fluid flowmeter and a connecting pipe, wherein the buffer vessel is provided with an inlet and an output of output liquid, the top of the buffer vessel is provided with a gas outlet, and the bottom of the buffer vessel is provided with a solid phase outlet; the fluid flowmeter and the connecting pipe constitute a U-shaped pipeline, and the fluid flowmeter is at the bottom of the U-shaped pipeline; and two ends of an exhaust pipe are respectively connected with the gas outlet of the buffer vessel and the liquid outlet of the U-shaped pipeline. The method is as follows: after the output liquid of the coal bed methane well is separated by the buffer vessel, the output liquid passes through the flowmeter to be measured. The method enables the liquid to be separated from solid phase coal dust and gas prior to passing through the flowmeter, and only the liquid passes through the fluid flowmeter. Therefore, the measuring accuracy is improved. When the output liquid is small in amount, the physical principle of the U-shaped pipeline is used for improving the measuring accuracy. The measuring method is high in accuracy, can be used for metering the output liquid of the coal bed methane well, the output oil or water in an oil gas well or other similar working conditions.

Owner:潘军

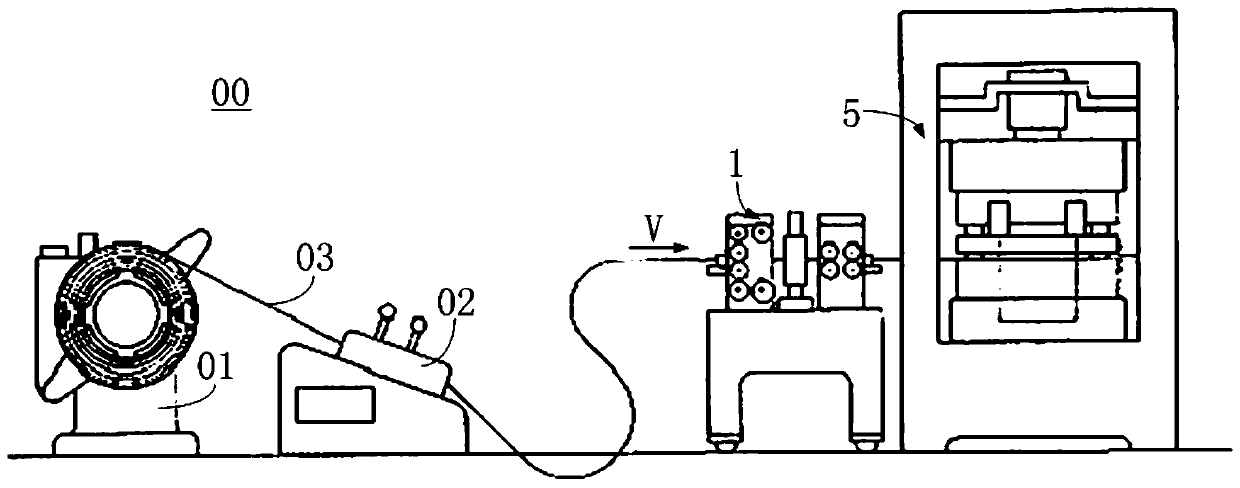

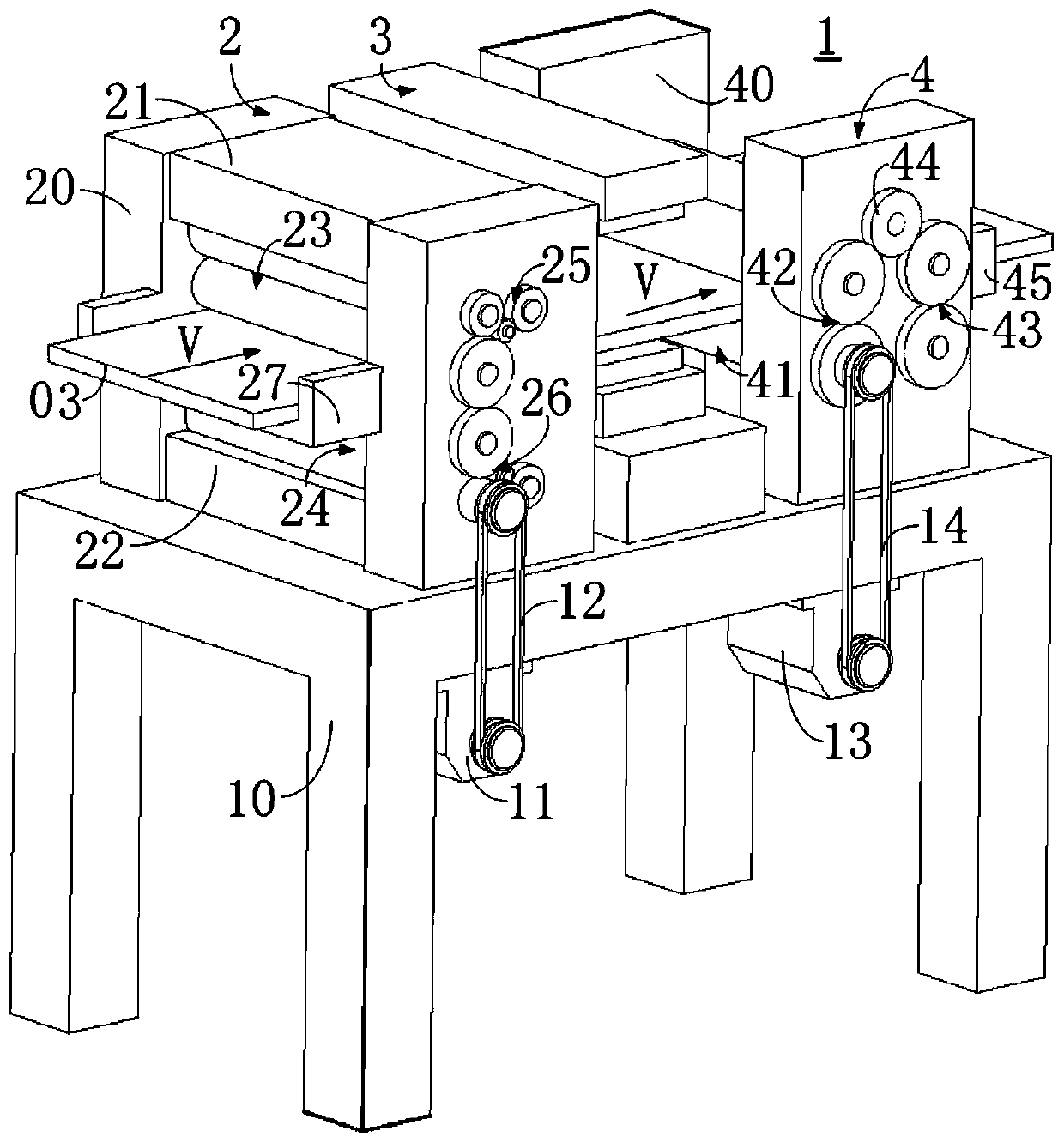

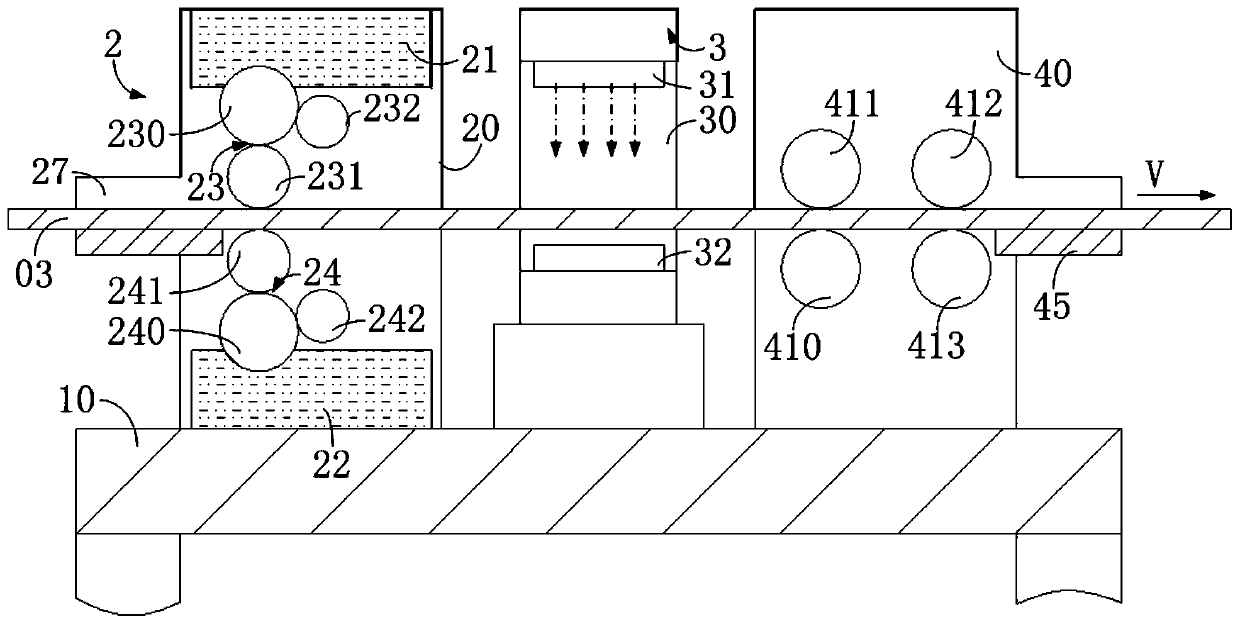

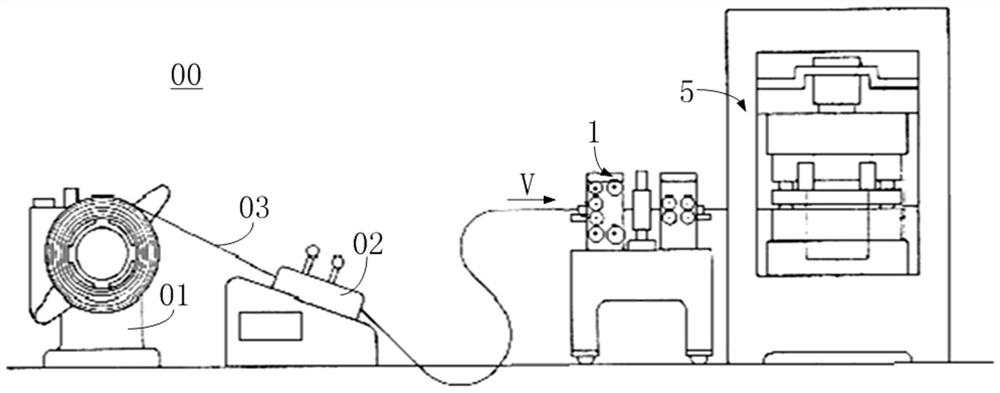

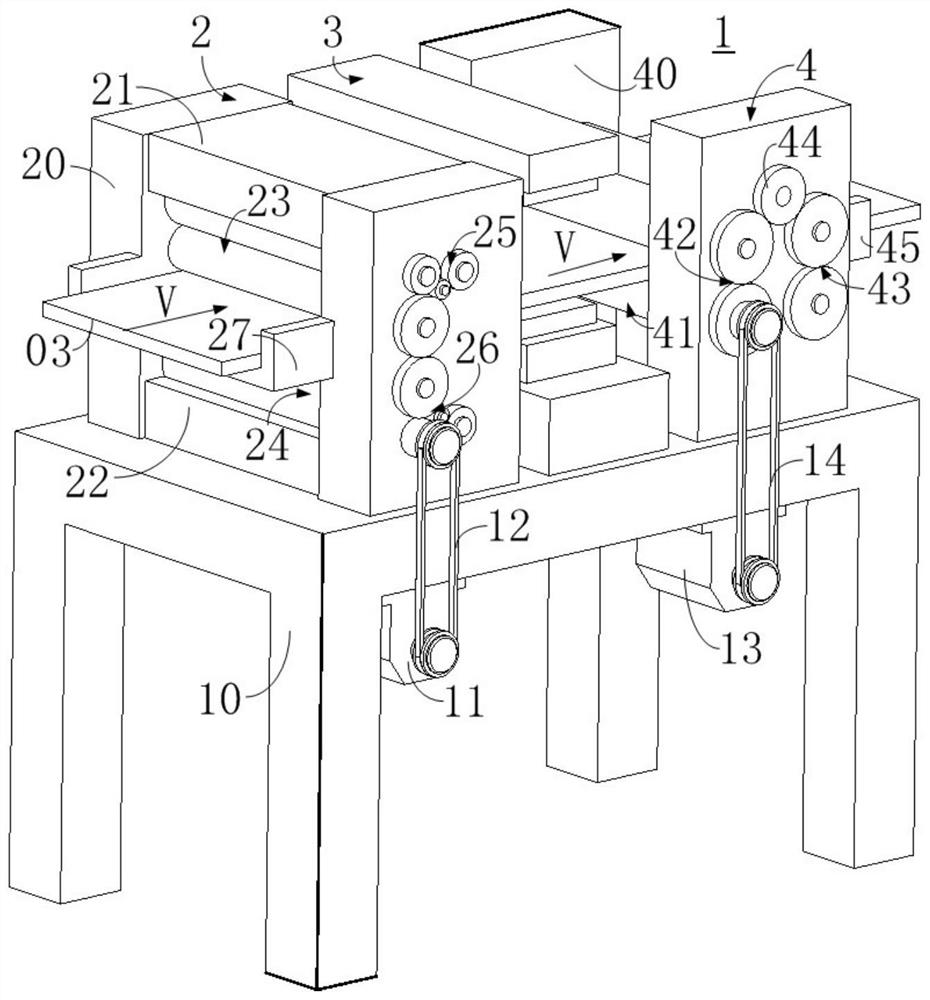

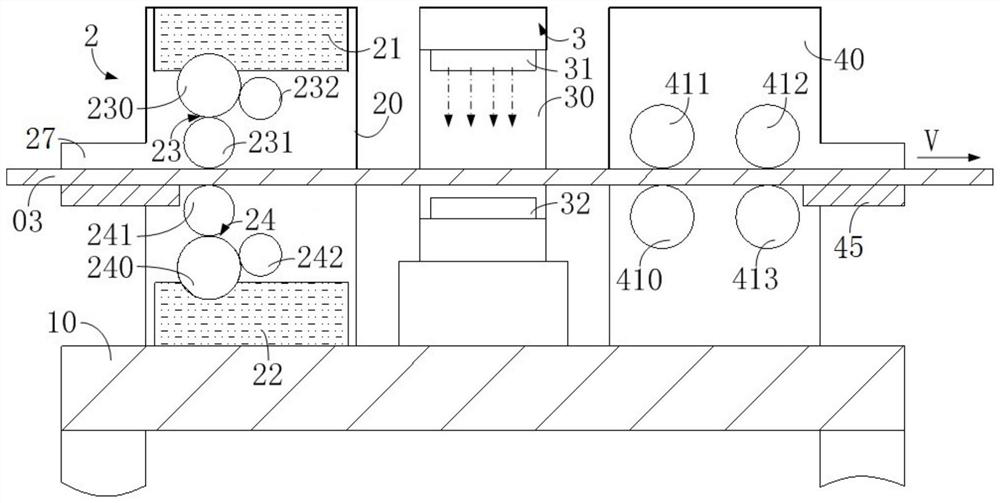

Processing device and processing method for high-performance motor iron core

ActiveCN110064562AImprove processing efficiencyEasy to processPretreated surfacesManufacturing stator/rotor bodiesPunchingEngineering

The invention relates to the technical field of motor manufacturing, in particular to a processing device and a processing method for a high-performance motor iron core. The processing device comprises a coiling device, a leveling device, a coating and thickness measuring device and a punching device. A steel strip coiled on the coiling device in the processing device can be automatically releasedby depending on self tension and elastic force, the discharged steel strip is leveled by the leveling device to become more flat, and subsequent processing is facilitated. The coating and thickness measuring device can apply coating to the upper and lower surfaces of the steel strip and can detect the thickness of the steel strip and the thickness of the coating on the steel strip, and excessivecoating and moisture on the steel strip can be squeezed out. The punching device can punch the steel strip into steel sheets in a certain size, the steel sheets can be heated and solidified, and the steel sheets are automatically stacked and transported. The entire processing device can be automatically carried out, the processing efficiency is high, manual work is not needed, labor cost is saved,automated production is facilitated, and the modern processing needs can be better met.

Owner:曹海东 +2

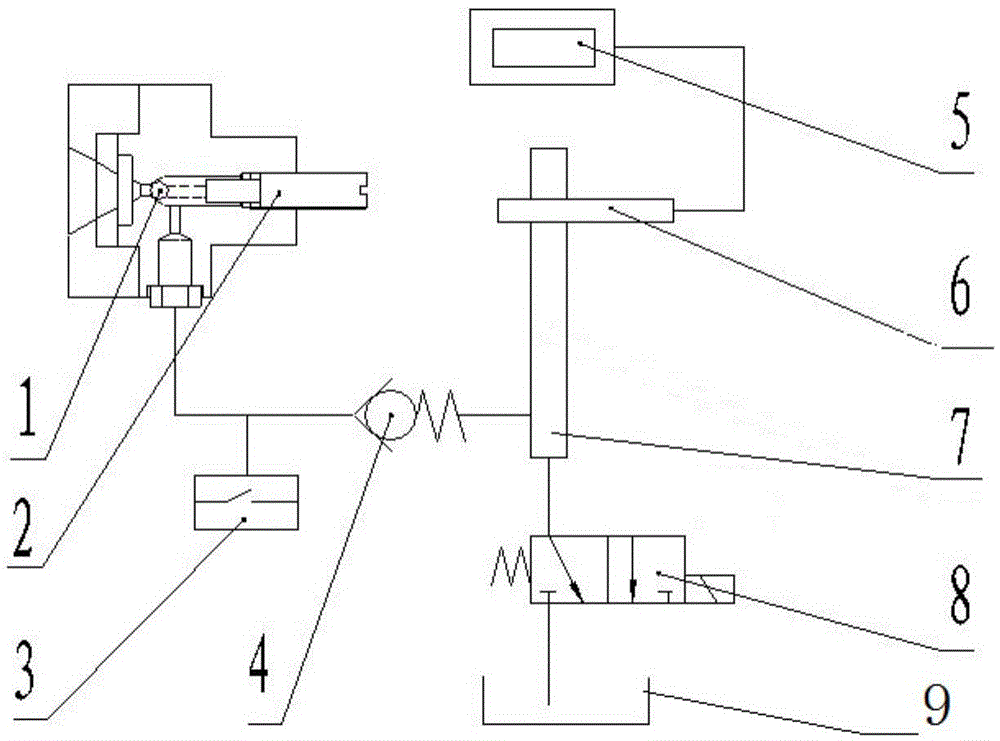

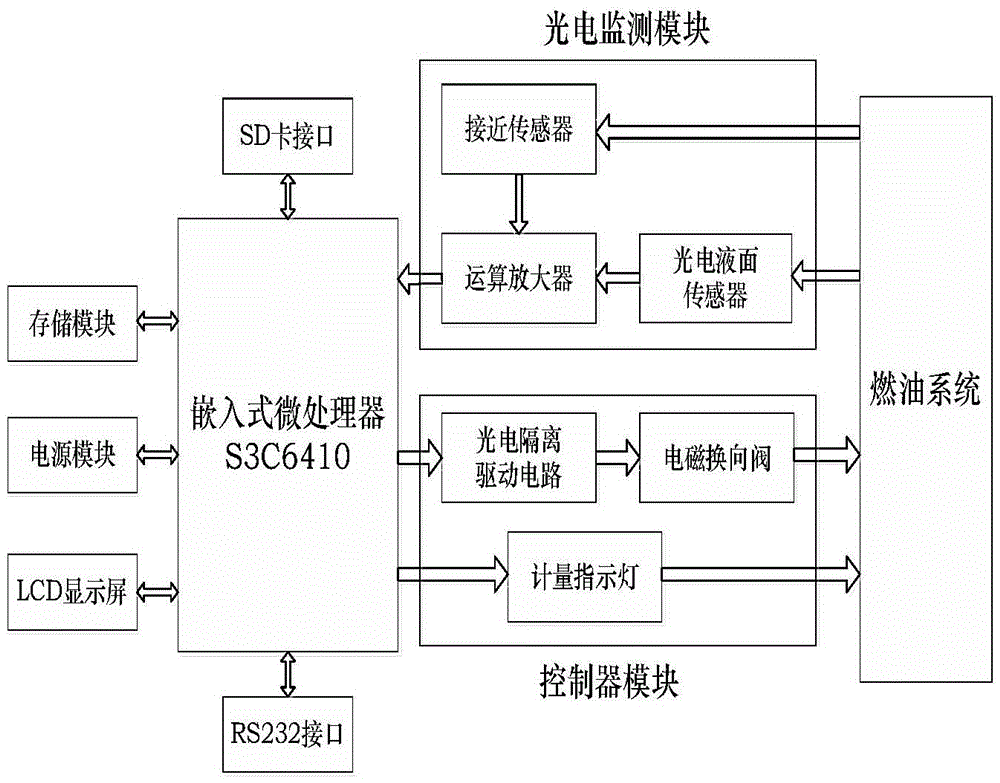

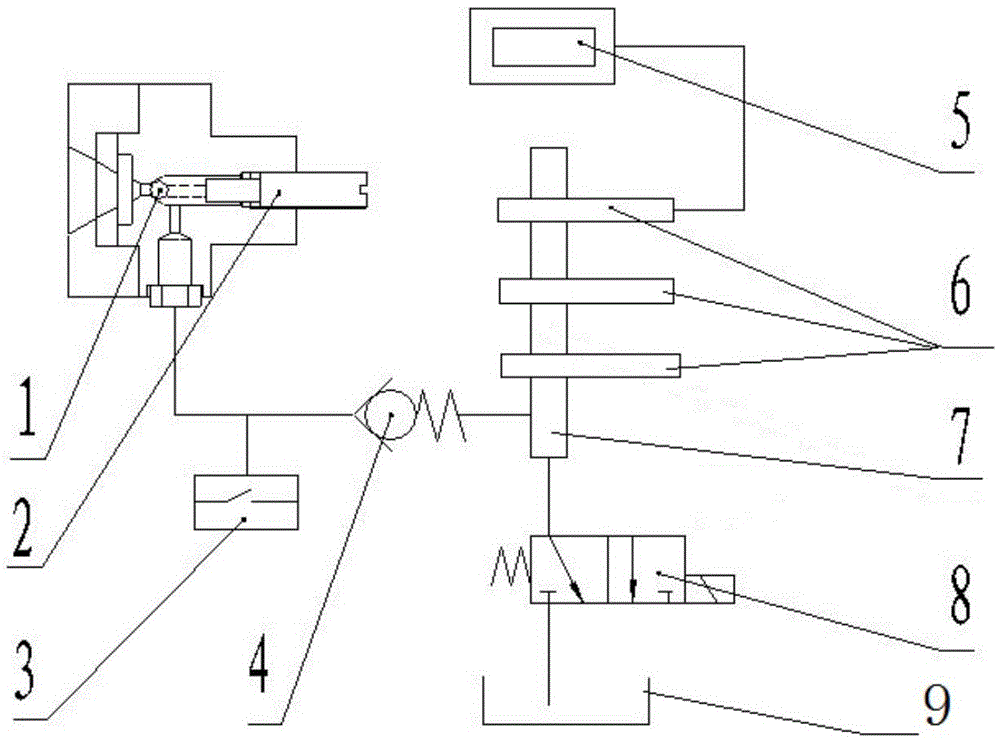

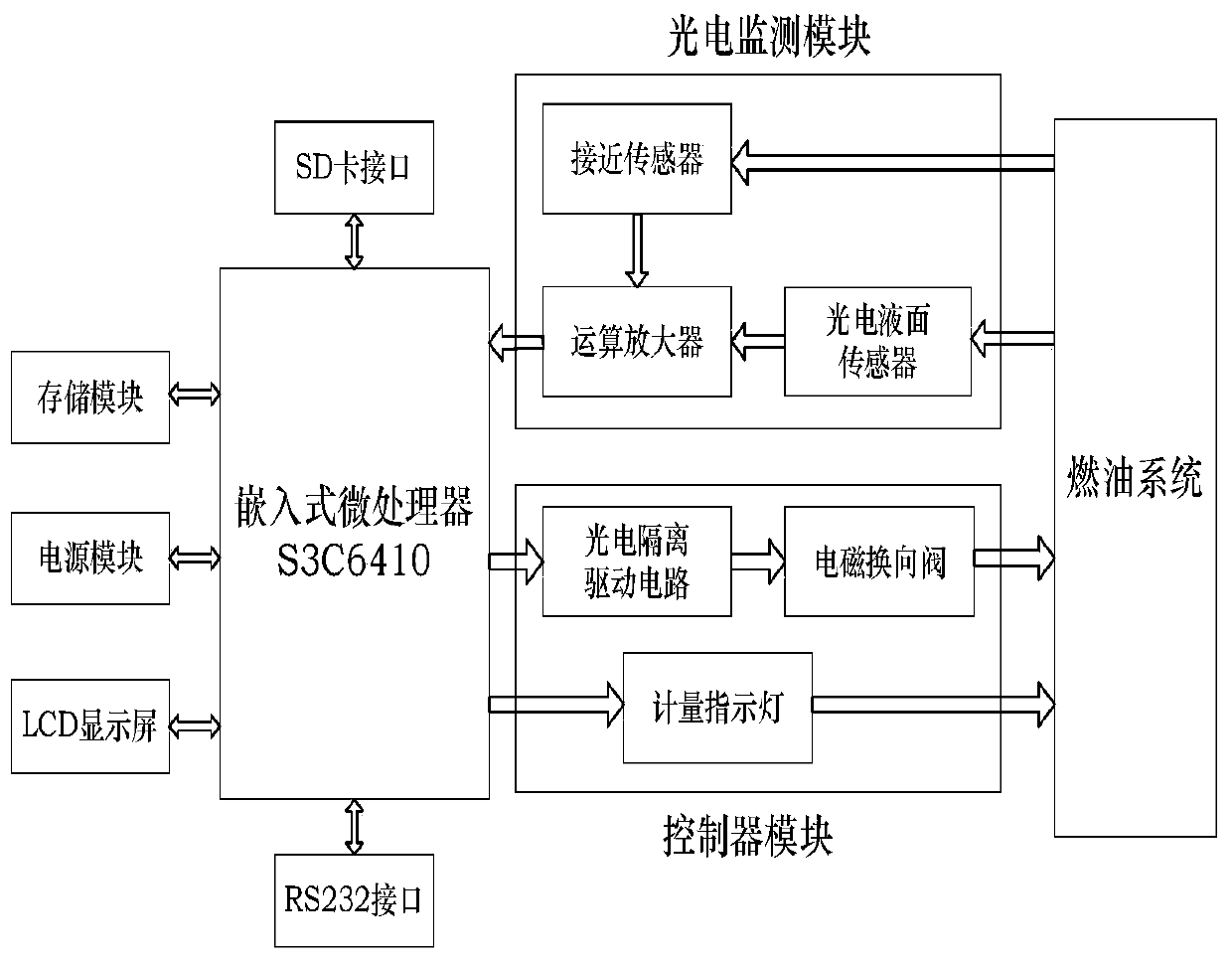

Metering system for fuel of PT pump fuel injector and metering method of metering system

InactiveCN105464871ASimple structureCalculation speedEngine testingFuel injection apparatusTraffic volumeInjector

The invention relates to a metering system for fuel of a PT pump fuel injector and a metering method of the metering system. Two kinds of metering systems for fuel of the PT pump fuel injector are provided, wherein the first system comprises a container for containing fuel to be metered, and a controller, and the controller is connected with at least one upper limit liquid level detection device used for detecting the set upper limit height threshold value of the quantity of fuel to be metered in the container, and further connected with a counting device used for counting the number of fuel injection times of the fuel injector. The second system comprises a container for containing fuel to be metered and a controller, wherein the controller is connected with a counting device used for counting the set number of fuel injection times, and further connected with a fuel amount detecting device used for detecting the amount of the fuel which is to be metered and is injected into the container by the fuel injector according to the set number of fuel injection times. The mode of fixing the amount and measuring the number of times is adopted in the first kind of metering system. The mode of fixing the number of times and measuring the total amount is adopted in the second kind of metering system. Both the metering systems can achieve detection on constant volume high-impact and non-continuous small flow of fuel injected by the PT fuel injector.

Owner:中国人民解放军防空兵学院

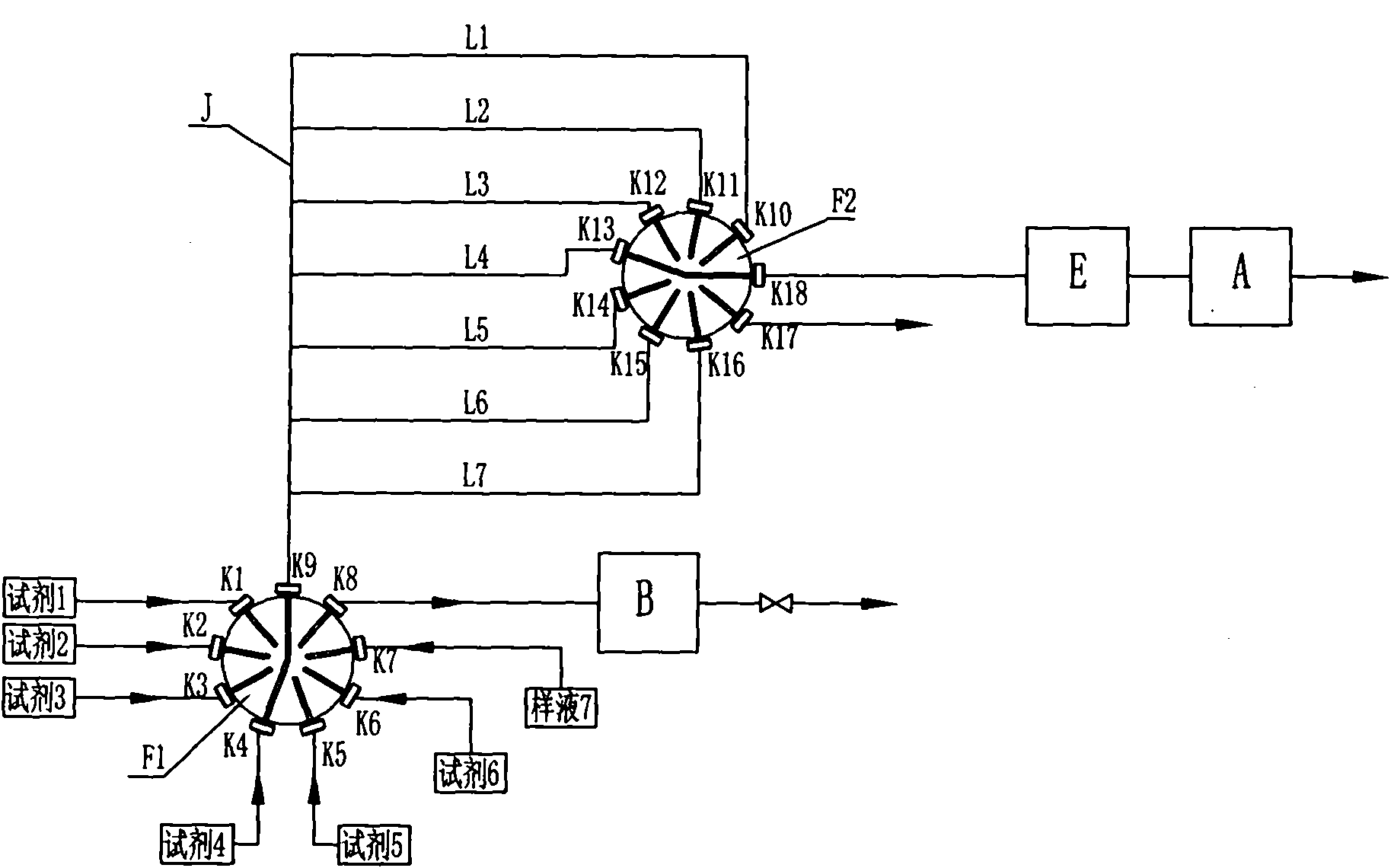

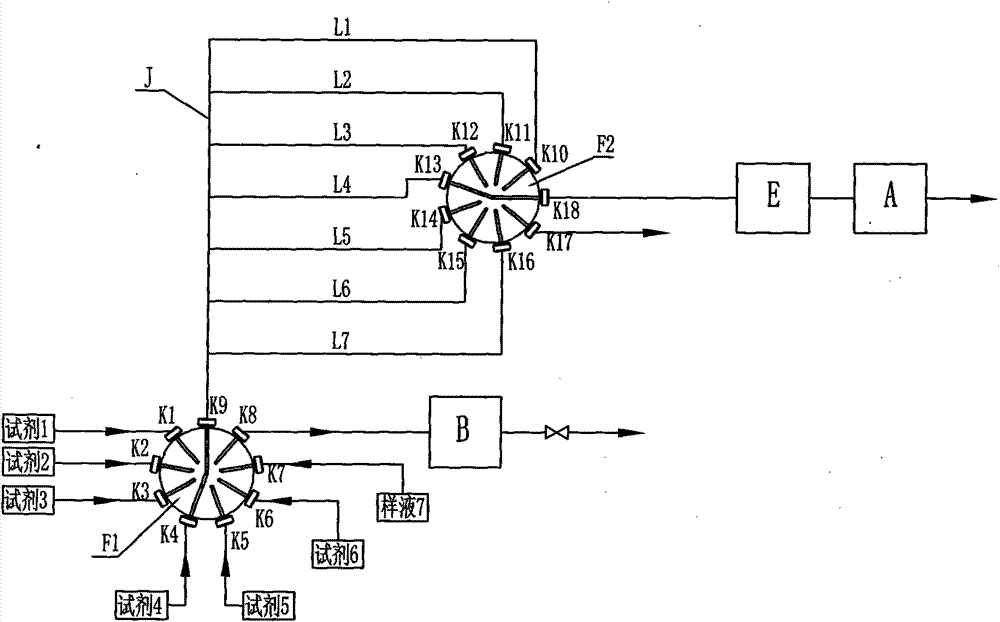

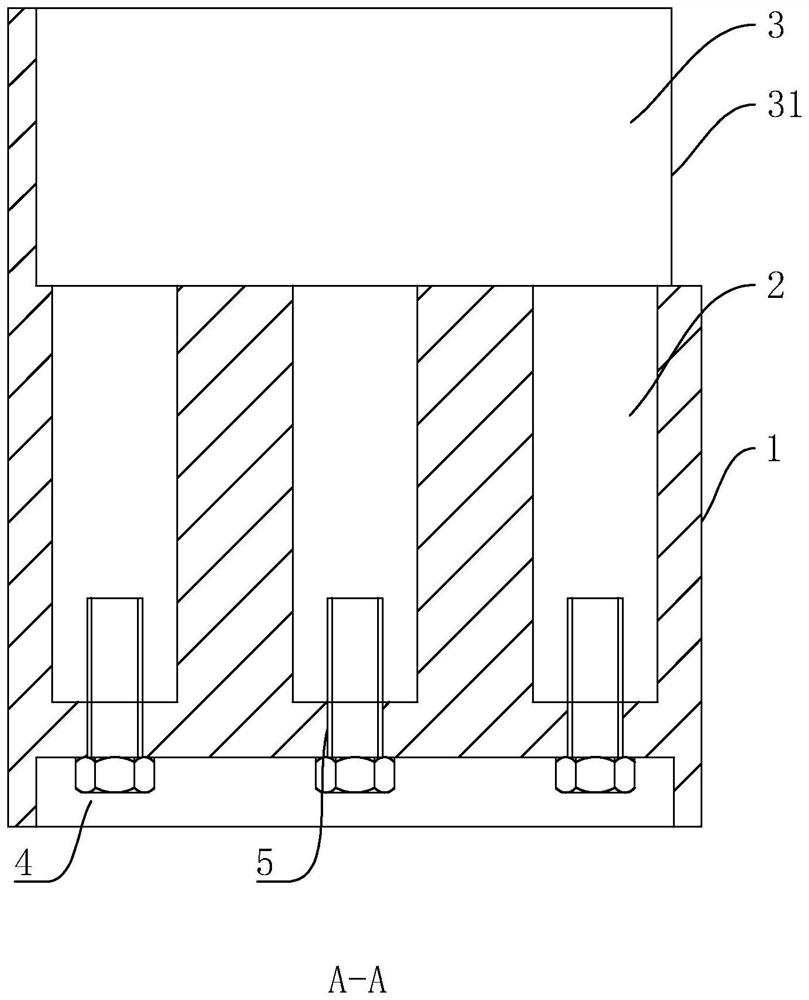

Metering device of automatic analysis meter

The invention relates to a metering device of an automatic analysis meter, which belongs to the technical field of automatic analysis metering. The device comprises a liquid flow driver, a first control valve and a second control valve, wherein liquid flow storage and transportation passages are connected between the two control valves, the number of respective paths of the two control valves is greater than or equal to the number of the liquid flow storage and transportation passages, ports at one side of the first control valve paths are externally connected with test specimens or devices through pipelines, ports at the other side of the first control valve paths are communicated with ports at one side of the liquid flow storage and transportation passages through first public passages,ports at the other side of the liquid flow storage and transportation passages are respectively and correspondingly connected with ports at one side of the second control valve paths, ports at the other side of the second control valve paths are connected with the liquid flow driver, and the volume of the liquid flow storage and transportation passages and the fist public passages is a fixed value matched with the specimen metering volume. Because the volume of the liquid flow storage and transportation passages and the fist public passages can be precisely processed into various fixed valuesaccording to the metering volume of various test specimens, the device of the invention can complete the precise, stable and efficient metering on various test specimens.

Owner:郭永亮

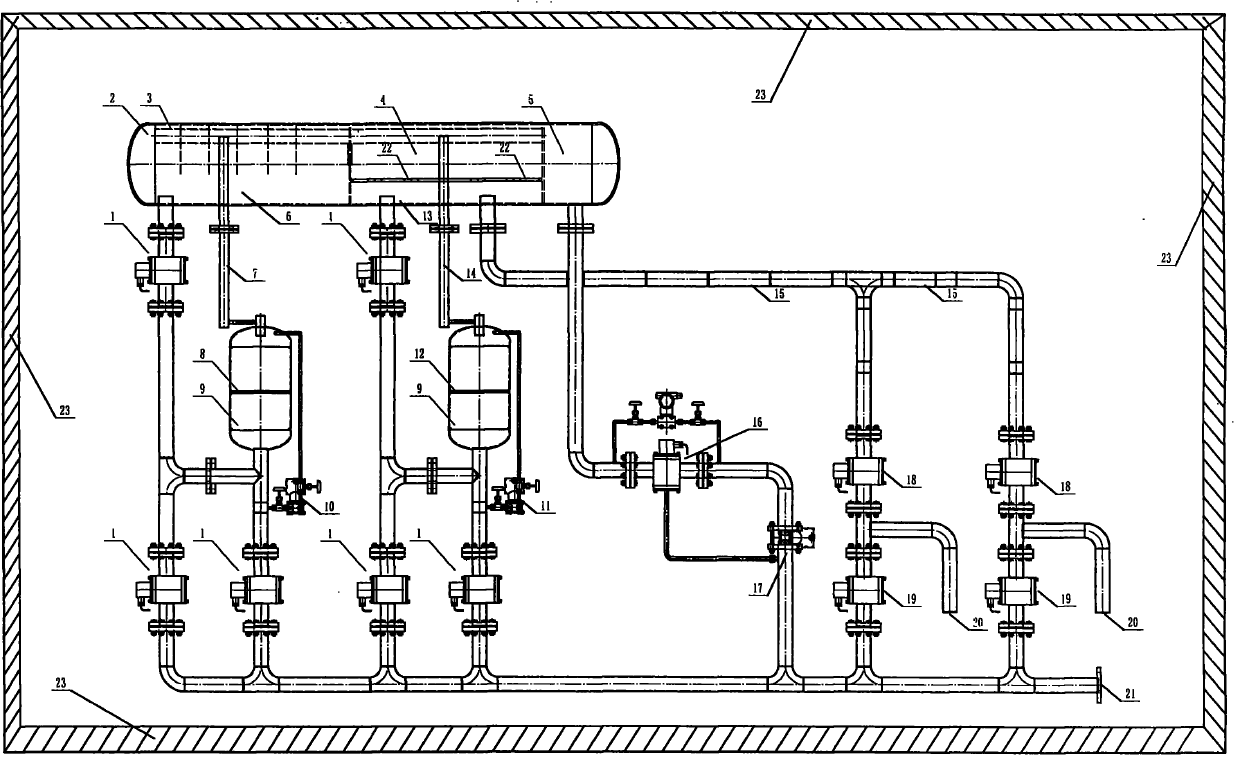

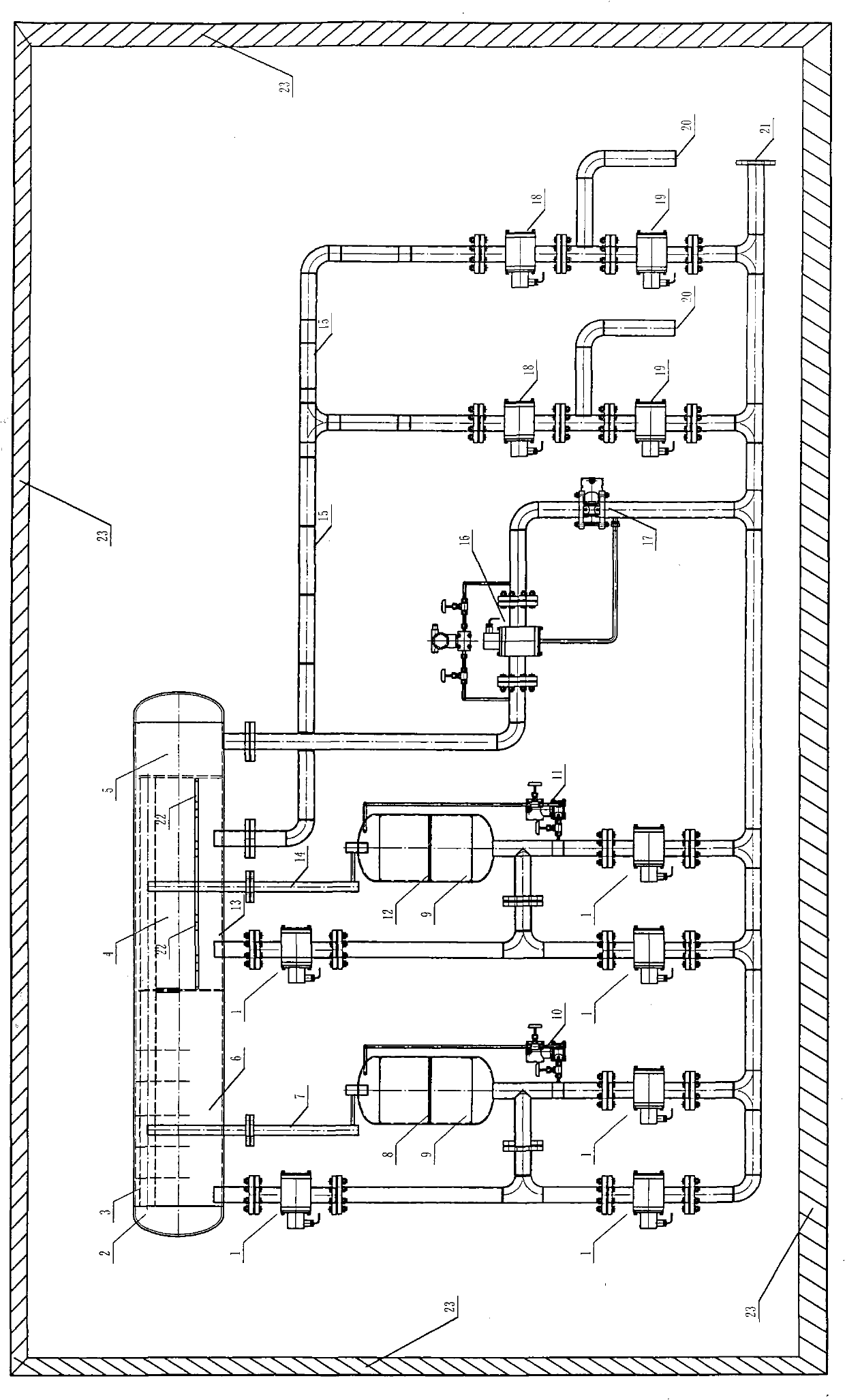

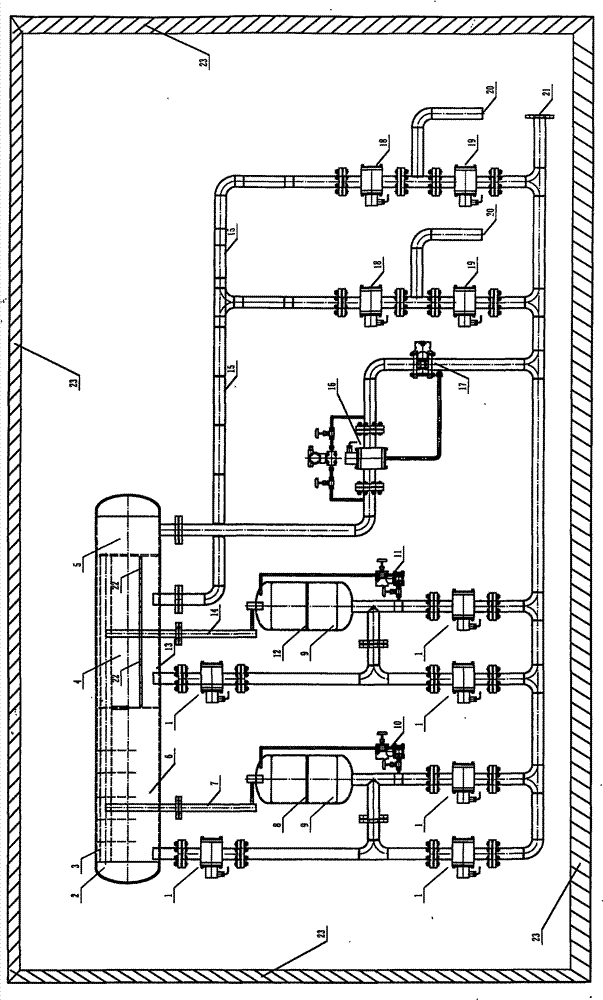

Unattended digital multi-well automatic metering device and method

InactiveCN101906958ARealize three-phase meteringSolve metering bottlenecksSurveyFluid removalLine tubingOil water

The invention relates to an unattended digital multi-well automatic metering device and an unattended digital multi-well automatic metering method, which belong to metering technology and overcome the defects of other technology. A triphase piston separator, a pipeline, a piston liquid meter and pipe valves are arranged in a constant-temperature theftproof metering room. The metering process of the method comprises gas-liquid separation, piston oil-water separation, liquid-free gas metering, piston type water metering, piston type oil metering and balanced conflux output.

Owner:濮阳圣元火炬工程有限公司

Material taking device of high temperature reaction furnace

InactiveCN102650499AAchieving normal response workAchieve closureCharge manipulationTemperature controlSlag

The invention discloses a material taking device of a high temperature reaction furnace. Main furnace heating equipment is arranged on the outer edge of a furnace body, wherein a flow guide channel is arranged at the lower part of the furnace body; a pouring nozzle is arranged at the outer end of the flow guide channel; the flow guide channel is arranged in a flow guide seat connected with the furnace body; and a thermal switch system for controlling the temperature of the flow guide seat is arranged at the outer part of the flow guide seat. Reactive substances in the flow guide channel are solidified or melted through temperature control changes conducted by the thermal switch system, so that the flow guide channel is closed or connected, normal reaction operation of the reaction furnace is realized and reactants can be taken out. The reactive substances are only contacted with the external environment at a distance from the pouring nozzle to a die or a container, so that oxidation reaction of the reactive substances is controlled; as the flow is guided below a liquid level, the phenomenon of slag inclusion can be completely avoided from occurring to floating reactants, so that fresh gas cannot be wrapped into the floating reactants to form more air holes and air bubbles; and the flow guide channel can be rapidly opened and closed under the temperature control, so that the metering of pouring can be well controlled and the aim of accurate pouring is achieved.

Owner:SOLAR ENERGY&MATERIALS IN

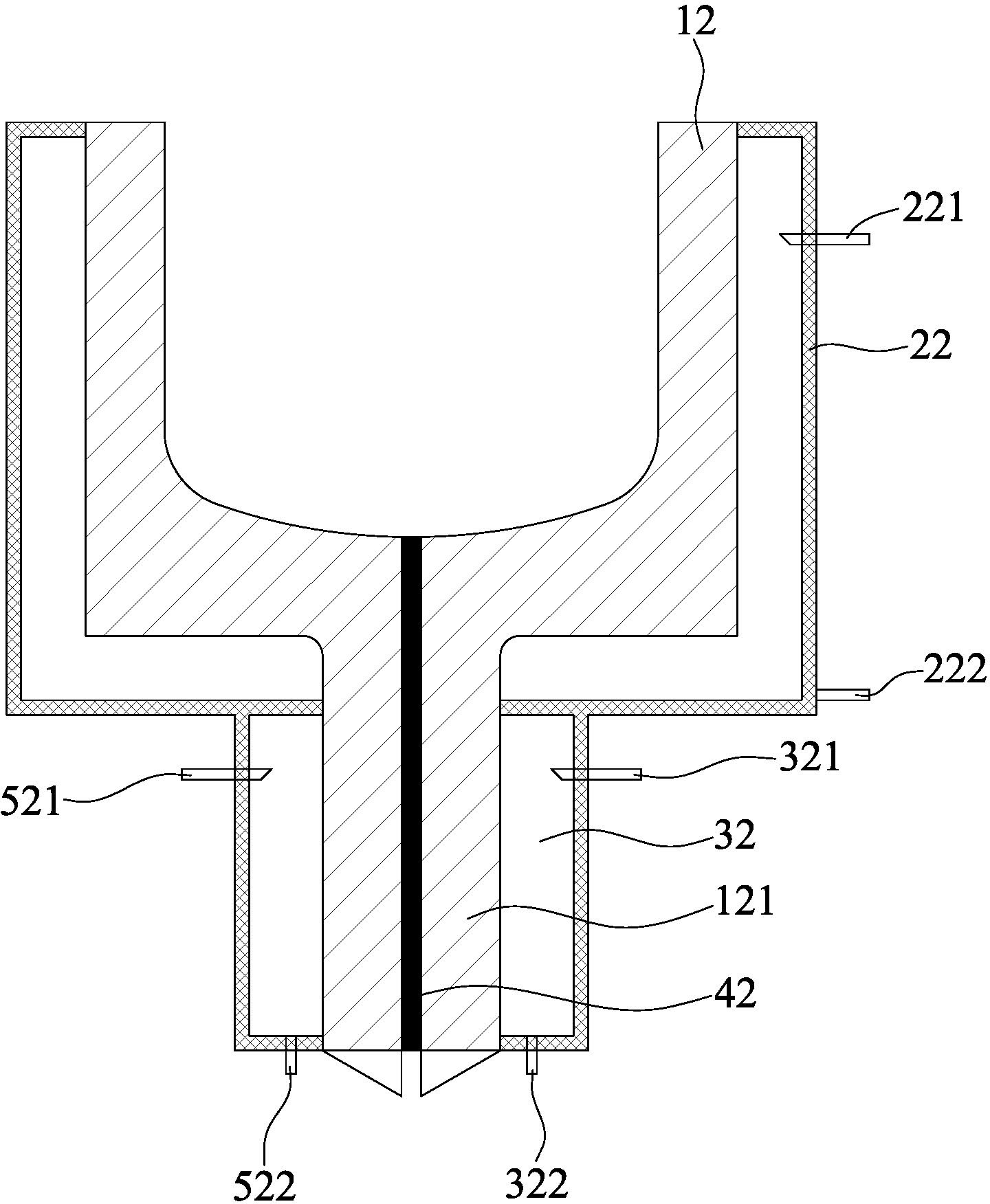

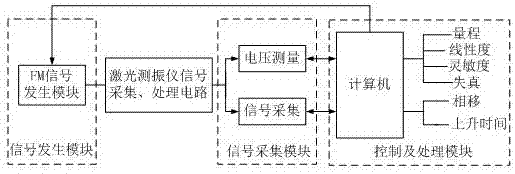

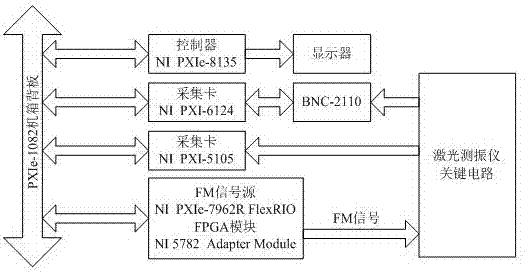

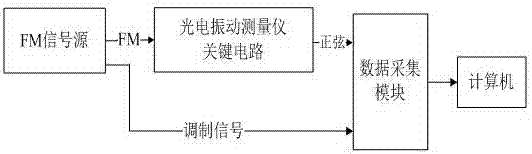

Circuit measurement calibration method and calibration device of three-dimensional photoelectric vibration measuring instrument

PendingCN107356321ASolve the calibration methodTroubleshoot device issuesSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansHemt circuitsEngineering

The present invention relates to a measurement calibration method of a three-dimensional photoelectric vibration measuring instrument system and a key circuit calibration device of the three-dimensional photoelectric vibration measuring instrument system. A measurement calibration mode that a traditional standard vibration table excitation method is adopted to perform measurement calibration on a three-dimensional photoelectric vibration measuring instrument is limited by a vibration table, and the measurement frequency and amplitude of the traditional standard vibration table excitation method are limited. According to the measurement calibration method of the present invention, electrical signal excitation is used to replace actual physical quantity excitation to perform measurement calibration on the photoelectric vibration measuring instrument, that is, FM signals are directly connected into the input ends of the corresponding signal acquisition and processing circuits of the three-dimensional photoelectric vibration measuring instrument to replace physical quantity excitation on the basis of a heterodyne laser interference principle, and therefore, the calibration of the measuring range, linearity, sensitivity, phase shift, delay, rise time, distortion and other parameters of the three-dimensional photoelectric vibration measuring instrument can be realized. With the measurement calibration method and calibration device of the invention adopted, the measurement of the three-dimensional photoelectric vibration measuring instrument system is more accurate, more efficient and more convenient.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

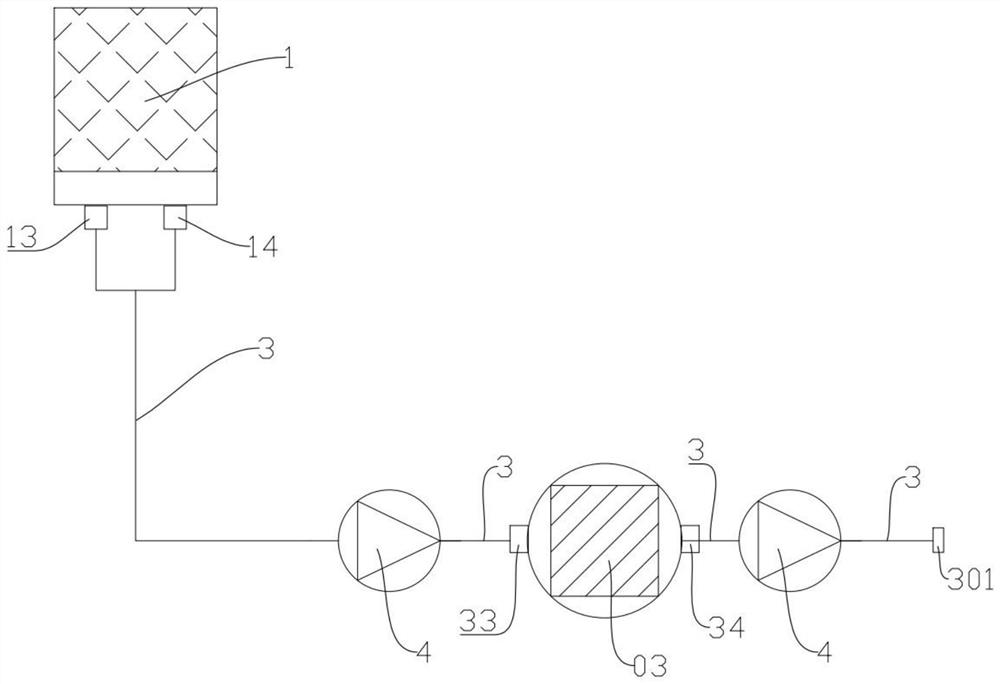

Device and method for measuring output liquid of coal bed methane well

ActiveCN102168549BSolid phase particle reductionEfficient meteringSurveyFluid removalBuffer tankMeasuring output

The invention discloses a device and a method for measuring output liquid of a coal bed methane well. The device comprises a buffer vessel, a fluid flowmeter and a connecting pipe, wherein the buffer vessel is provided with an inlet and an output of output liquid, the top of the buffer vessel is provided with a gas outlet, and the bottom of the buffer vessel is provided with a solid phase outlet; the fluid flowmeter and the connecting pipe constitute a U-shaped pipeline, and the fluid flowmeter is at the bottom of the U-shaped pipeline; and two ends of an exhaust pipe are respectively connected with the gas outlet of the buffer vessel and the liquid outlet of the U-shaped pipeline. The method is as follows: after the output liquid of the coal bed methane well is separated by the buffer vessel, the output liquid passes through the flowmeter to be measured. The method enables the liquid to be separated from solid phase coal dust and gas prior to passing through the flowmeter, and only the liquid passes through the fluid flowmeter. Therefore, the measuring accuracy is improved. When the output liquid is small in amount, the physical principle of the U-shaped pipeline is used for improving the measuring accuracy. The measuring method is high in accuracy, can be used for metering the output liquid of the coal bed methane well, the output oil or water in an oil gas well or other similar working conditions.

Owner:BEIJING WANPULONG ENERGY TECH

Method and system for the localization of a mobile WLAN client

ActiveUS7974632B2Improve localizationPrecise positioningNetwork topologiesPosition fixationTelecommunicationsDatabase server

A method and a system for the localization of a mobile WLAN client, located within a WLAN network of multiple WLAN stations. Static reference points are ascertained by measuring field strengths of the WLAN stations at spatial coordinates, aided by WLAN client(s), and assignment of the measured field strengths to the spatial coordinates in terms of data records. Self-learning ascertainment of further dynamic reference points is obtained by measuring field strengths of the WLAN stations, aided by WLAN client(s) moving through the region of the network, and assignment of the measured field strengths in terms of data records to the respective spatial coordinates calculated for this purpose, in the database server. This may be done to localize a WLAN client by selecting a plurality of nearest matched data records of static and dynamic reference points whose subsequently calculated center of gravity corresponds to the estimated position of the WLAN client.

Owner:DEUTSCHE TELEKOM AG

Fuel metering system and metering method of pt pump fuel injector

InactiveCN105464871BEasy to measureEfficient meteringEngine testingFuel injection apparatusEngineeringFuel injection

The invention relates to a metering system for fuel of a PT pump fuel injector and a metering method of the metering system. Two kinds of metering systems for fuel of the PT pump fuel injector are provided, wherein the first system comprises a container for containing fuel to be metered, and a controller, and the controller is connected with at least one upper limit liquid level detection device used for detecting the set upper limit height threshold value of the quantity of fuel to be metered in the container, and further connected with a counting device used for counting the number of fuel injection times of the fuel injector. The second system comprises a container for containing fuel to be metered and a controller, wherein the controller is connected with a counting device used for counting the set number of fuel injection times, and further connected with a fuel amount detecting device used for detecting the amount of the fuel which is to be metered and is injected into the container by the fuel injector according to the set number of fuel injection times. The mode of fixing the amount and measuring the number of times is adopted in the first kind of metering system. The mode of fixing the number of times and measuring the total amount is adopted in the second kind of metering system. Both the metering systems can achieve detection on constant volume high-impact and non-continuous small flow of fuel injected by the PT fuel injector.

Owner:中国人民解放军防空兵学院

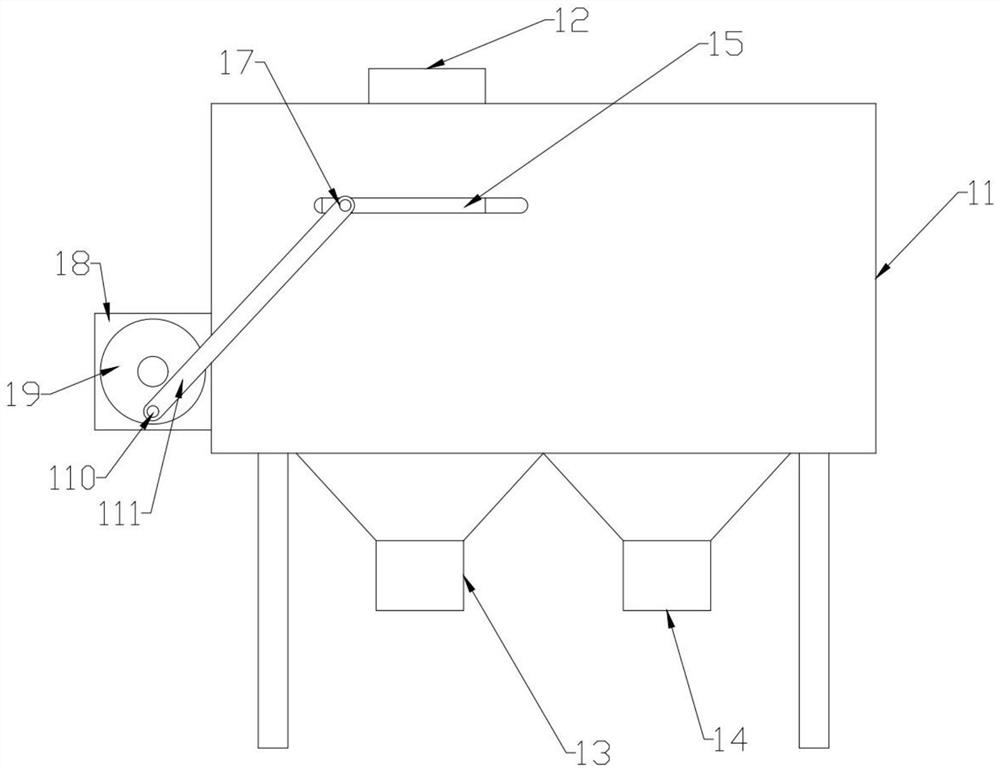

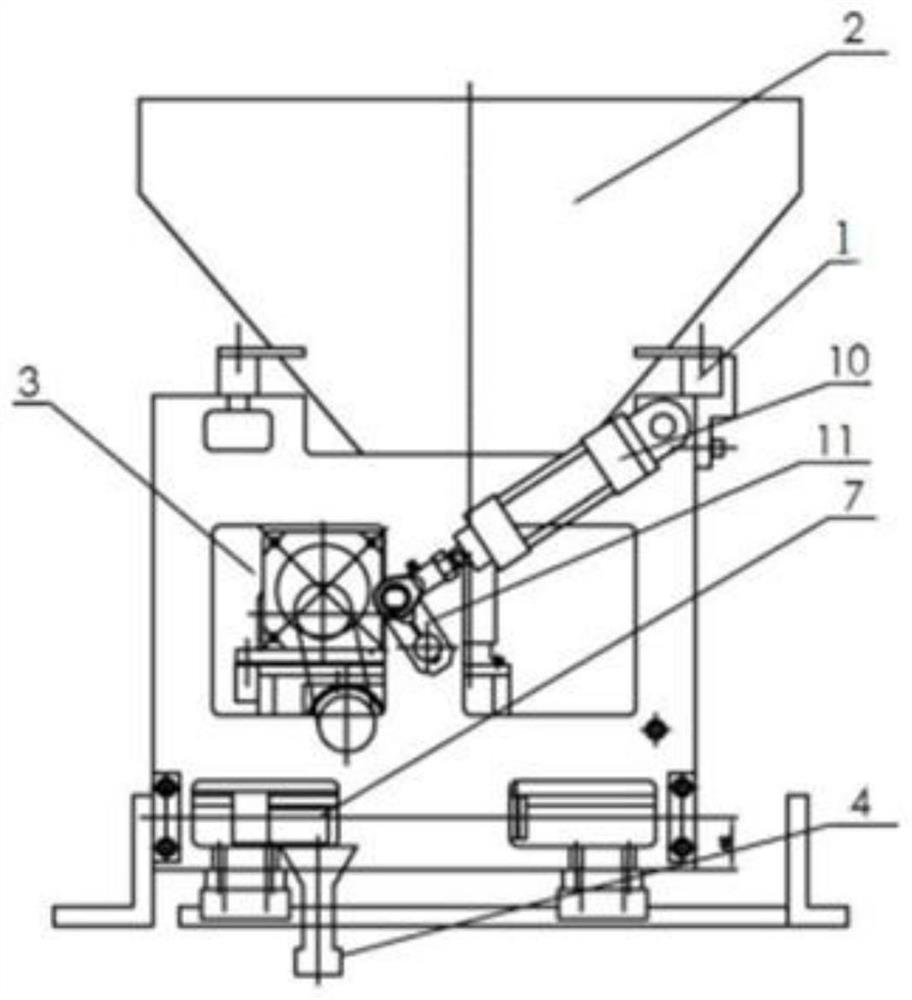

Powder supply device for basic shaft type metal 3D printer

InactiveCN112719301ASimple structureEasy to useSievingAdditive manufacturing apparatusComputer printingProcess engineering

The invention discloses a powder supply device for a basic shaft type metal 3D printer. The powder supply device is characterized by comprising a screening machine and a metering powder feeding device; a first discharging port and a second discharging port of the screening machine are communicated with a feeding port of the metering powder feeding device through powder feeding pipes; a vacuum conveyor is arranged on a powder feeding pipe between the screening machine and the metering powder feeding device; a discharge port of the metering powder feeding device is communicated with a powder supply port through the powder feeding pipe; and a vacuum conveyor is arranged on the powder feeding pipe between the metering powder feeding device and the powder supply port. The powder supply device for the basic shaft type metal 3D printer is simple in structure and convenient to use; the powder screening machine and the metering powder feeding device are used in cooperation; operation such as screening, metering and conveying can be efficiently conducted on metal powder; the screened and qualified metal powder is provided into a powder spreading device of an SLM metal printer or a powder cylinder of a printing cavity; and a series of operations such as automatic screening, metering and conveying are realized.

Owner:ZHEJIANG YIDONG TECH CO LTD

Metering turnover cabinet system based on RFID

InactiveCN111612982AAccurate measurementAccurate access managementCo-operative working arrangementsApparatus for meter-controlled dispensingComputer hardwareEmbedded system

The invention discloses a metering turnover cabinet system based on RFID. The metering turnover cabinet system comprises: a metering device pasted with a uniquely corresponding RFID code label; a turnover cabinet integrated with a touch display screen, an identity authentication sensor and a metering turnover control module, wherein the turnover cabinet is provided with a plurality of storage grids for storing the metering equipment; and the identity information module that is carried by a user. By adopting the metering turnover cabinet system, accurate and efficient metering equipment accessmanagement can be realized; an unmanned and intelligent turnover cabinet is realized, and the human resource cost is reduced.

Owner:SHENZHEN COMTOP INFORMATION TECH

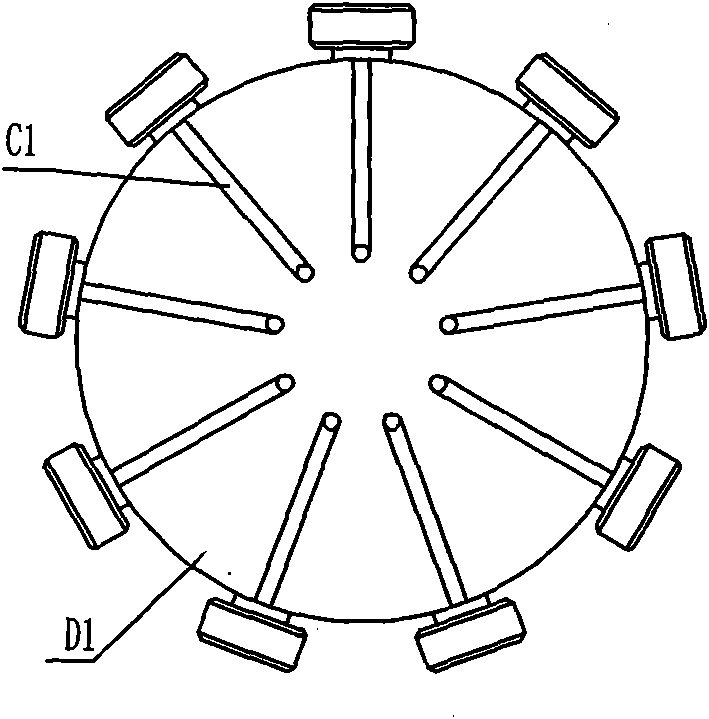

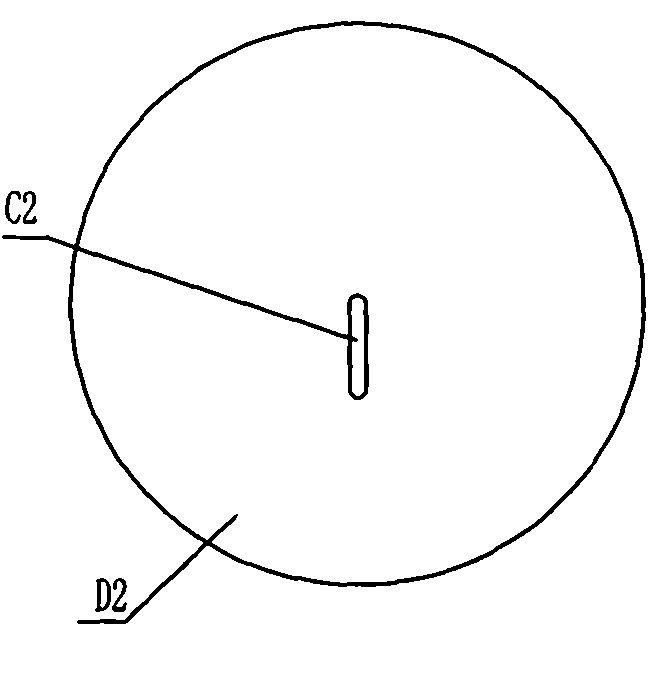

Dynamic parameter calibration method and calibration device for whistling snapshot system

ActiveCN112511817ABreak through the limitations of static bidsEfficient meteringRoad vehicles traffic controlPosition fixationSound imageMicrophone

The invention relates to a whistling snapshot system dynamic parameter metering calibration method and a calibration device thereof. According to the method, the noise distribution of a moving sound source is simulated by adopting a method of sequentially producing sound by each sound array element of a standard sound source system, the dynamic positioning error of the whistling snapshot system iscalibrated, and the response time of the whistling snapshot system is calibrated by measuring the whistling sound receiving moment of a reference microphone and the sound image generation moment of the whistling snapshot system, and the accurate measurement and calibration of dynamic parameters of the whistling snapshot system are realized. The metering calibration device of the whistling snapshot system comprises a multi-channel signal excitation system, a standard sound source system, a sound signal acquisition and analysis system, a time measurement system and an upper computer system. According to the invention, the dynamic parameters of the whistling snapshot system can be calibrated by adopting the metering calibration method, and the performance of the whistling snapshot system isensured.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

Processing equipment and processing method for high-performance motor iron core

ActiveCN110064562BImprove processing efficiencyEasy to processPretreated surfacesManufacturing stator/rotor bodiesPunchingElectric machinery

Owner:曹海东 +2

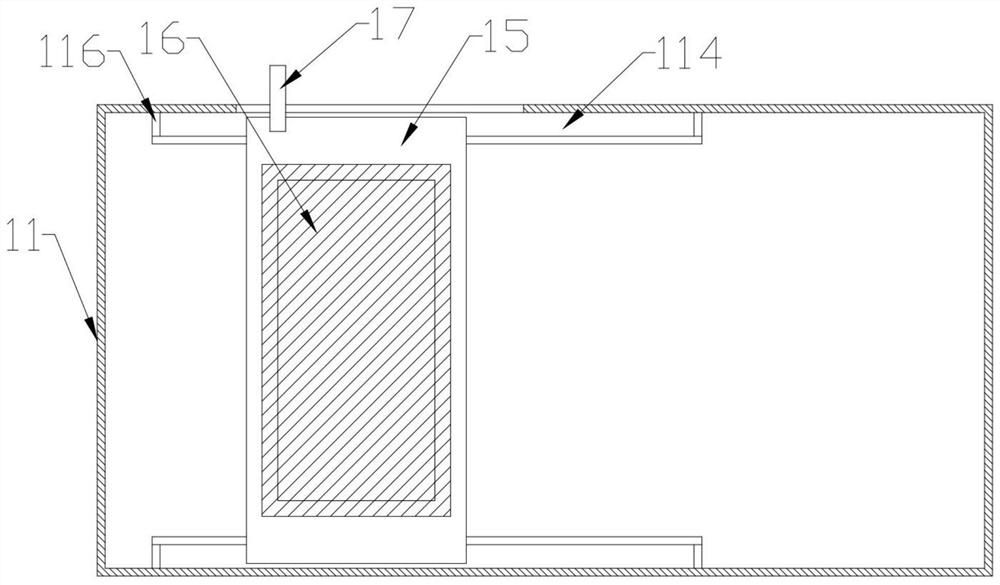

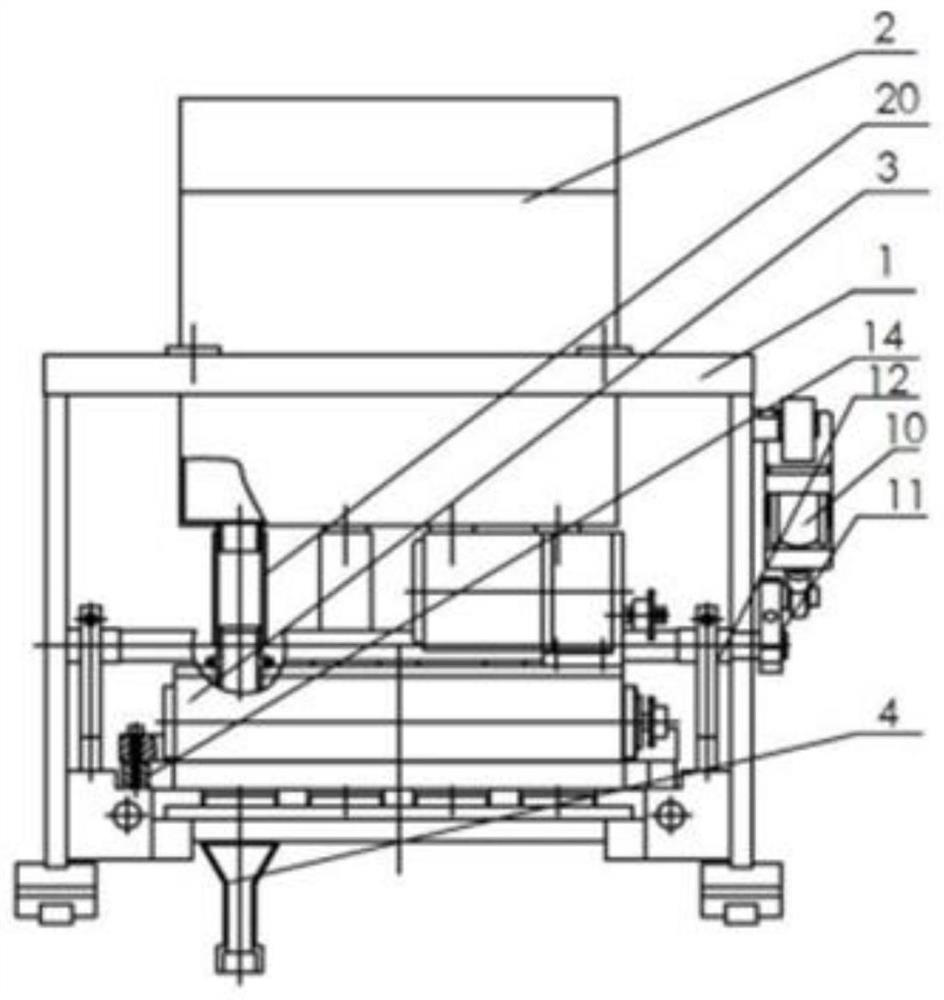

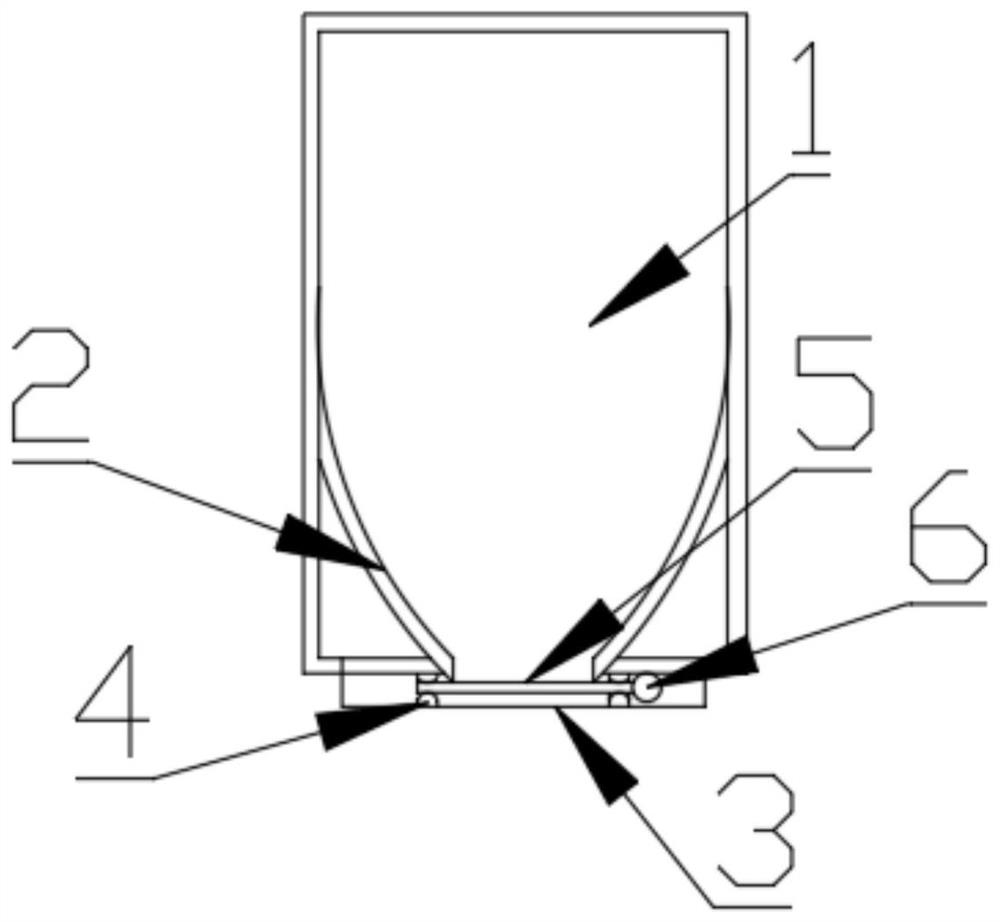

Full-automatic packaging and weighing equipment for medicine dropping pills

PendingCN111806775AAccurate measurementEfficient meteringPackagingMechanical engineeringBiomedical engineering

The invention provides full-automatic packaging and weighing equipment for medicine dropping pills. The full-automatic packaging and weighing equipment for medicine dropping pills comprises a hopper,a material blocking portion, a metering and feeding portion and a discharging bin which are assembled in a rack, wherein the material blocking portion is arranged in the discharging bin below a discharge pipe opening of the hopper, and a material blocking assembly is arranged in the discharging bin; the metering and feeding portion comprises a metering plate, a material supporting plate and a discharging block; and the material blocking assembly comprises a brush roller which is rotationally supported in front of a discharge side position of a metering cavity hole in the discharging bin and isused for brushing and sweeping the discharging plane of the metering plate, and the rotating direction of the brush roller is opposite to the moving direction of the metering plate towards the discharge side. According to the technical scheme, the full-automatic packaging and weighing equipment for the medicine dropping pills has the technical advantages of being accurate in metering, efficient and free of damage to pill materials.

Owner:锦州华博包装机械有限公司

Metering device of automatic analysis meter

The invention relates to a metering device of an automatic analysis meter, which belongs to the technical field of automatic analysis metering. The device comprises a liquid flow driver, a first control valve and a second control valve, wherein liquid flow storage and transportation passages are connected between the two control valves, the number of respective paths of the two control valves is greater than or equal to the number of the liquid flow storage and transportation passages, ports at one side of the first control valve paths are externally connected with test specimens or devices through pipelines, ports at the other side of the first control valve paths are communicated with ports at one side of the liquid flow storage and transportation passages through first public passages,ports at the other side of the liquid flow storage and transportation passages are respectively and correspondingly connected with ports at one side of the second control valve paths, ports at the other side of the second control valve paths are connected with the liquid flow driver, and the volume of the liquid flow storage and transportation passages and the fist public passages is a fixed value matched with the specimen metering volume. Because the volume of the liquid flow storage and transportation passages and the fist public passages can be precisely processed into various fixed valuesaccording to the metering volume of various test specimens, the device of the invention can complete the precise, stable and efficient metering on various test specimens.

Owner:郭永亮

Roller metering cup

PendingCN114004323AEfficient meteringAchieve regulationCounting mechanisms/objectsMechanical engineeringSlow speed

The invention discloses a roller metering cup, relates to the technical field of roller metering, and aims to solve the problems of low speed and low efficiency of metering the number of rollers. The roller metering cup comprises a solid cup body, the cup body is vertically provided with a plurality of metering holes of which the diameters are matched with the diameters of the rollers, and the depth of the metering holes is integer multiples of the height of the rollers.

Owner:王痛快

Method and device for dosing and mixing small amounts of liquid

InactiveUS8186869B2Accurate quantityPrecise mixing of liquidOpening closed containersBottle/container closureEngineeringMechanical engineering

Owner:BECKMAN COULTER INC

Unattended digital multi-well automatic metering device and method

InactiveCN101906958BRealize three-phase meteringSolve metering bottlenecksSurveyFluid removalLine tubingEngineering

The invention relates to an unattended digital multi-well automatic metering device and an unattended digital multi-well automatic metering method, which belong to metering technology and overcome the defects of other technology. A triphase piston separator, a pipeline, a piston liquid meter and pipe valves are arranged in a constant-temperature theftproof metering room. The metering process of the method comprises gas-liquid separation, piston oil-water separation, liquid-free gas metering, piston type water metering, piston type oil metering and balanced conflux output.

Owner:濮阳圣元火炬工程有限公司

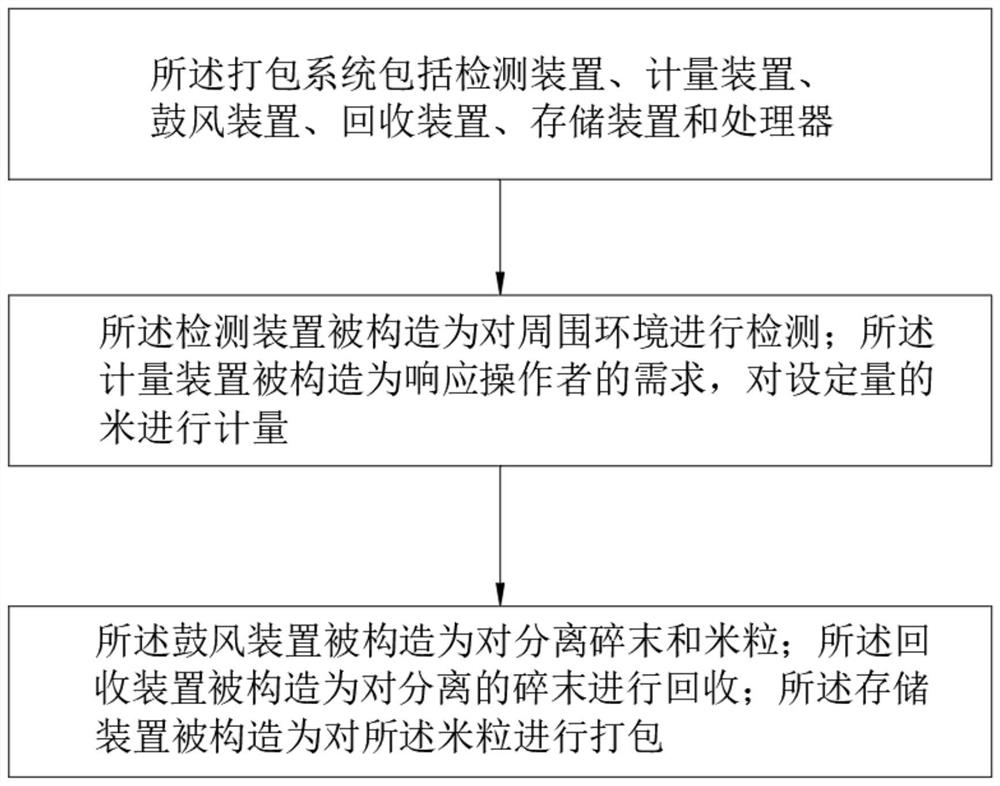

Rice production packaging system based on intelligent control

InactiveCN112722349AEfficient meteringAccurate collectionLarge containersPackaging automatic controlAgricultural engineeringBroken rice

The invention provides a rice production packaging system based on intelligent control. The packaging system comprises a detection device, a metering device, a blower device, a recovery device, a storage device and a processor, wherein the detection device is configured to detect the surrounding environment; the metering device is configured to respond to requirements of an operator and meter a set amount of rice; the blower device is configured to separate the broken rice from the rice grains; the recovery device is configured to recover the separated broken rice; and the storage device is configured to pack the rice grains. According to the packaging system, the blower device and the recovery device are symmetrically arranged at the two sides of a conveying pipeline, the broken rice is recovered or concentrated on the basis of cooperative use of the blower device and the recovery device, and waste of the broken rice is prevented.

Owner:常德振邦米业有限公司

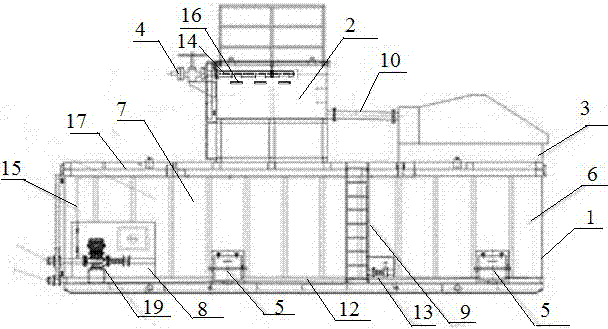

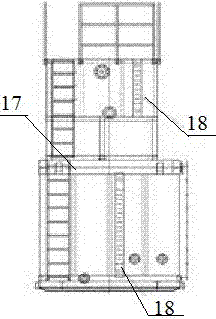

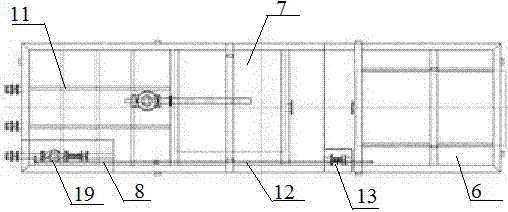

Oil well fracturing flowback fluid recovery sand removal device

ActiveCN104533373BReduce the cost of harmless treatmentReduce the risk of contaminationFluid removalFlushingFracturing fluidSmall footprint

The invention belongs to the technical field of fracturing fluid recovery in the oil-field development process and particularly relates to an oil well fracturing flowback fluid recovering and desanding device. The oil well fracturing flowback fluid recovering and desanding device comprises a fluid storage tank, a buffer tank and a vibrating screen. The fluid storage tank is open. The buffer tank and the vibrating screen are both arranged on the top of the fluid storage tank. One side of the buffer tank is provided with a flowback fluid inlet. The buffer tank is communicated with the vibrating screen through a communicating pipeline. By the adoption of the oil well fracturing flowback fluid recovering and desanding device, flowback fluid can meet the performance requirement for reutilization after being treated and be applied to operation of a next well, so the harmless treatment cost of waste is lowered, t the flowback fluid polllutes the environment is reduced, construction materials are saved, and energy conservation and emission reduction are achieved. The oil well fracturing flowback fluid recovering and desanding device has the advantages that the settling time is short, continuous treatment of the flowback fluid can be achieved, and the occupied area of a settling pond is small, and is a oil well fracturing flowback fluid efficient recovering, separating, metering and storing device.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com