Metering and calibrating method and metering and calibrating device for sound source identifying and positioning system

A positioning system and sound source identification technology, applied in the field of positioning, can solve the problems of verification and use units, and achieve the effect of efficient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

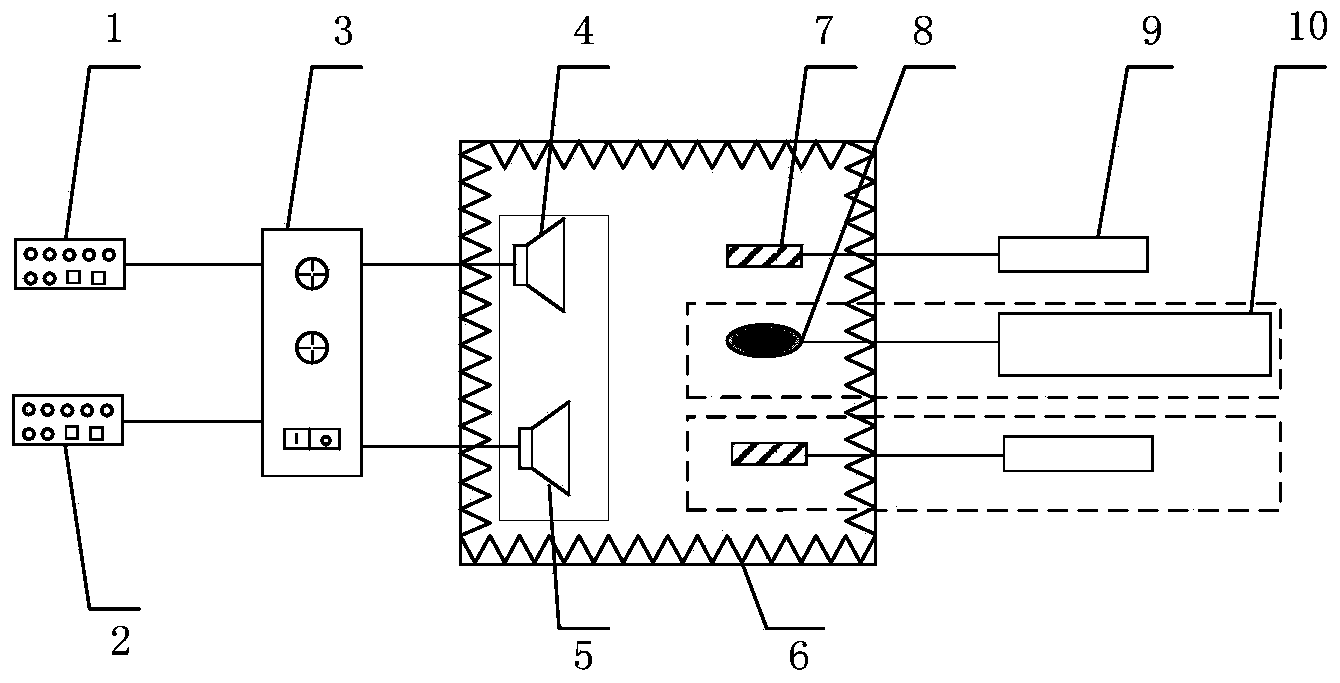

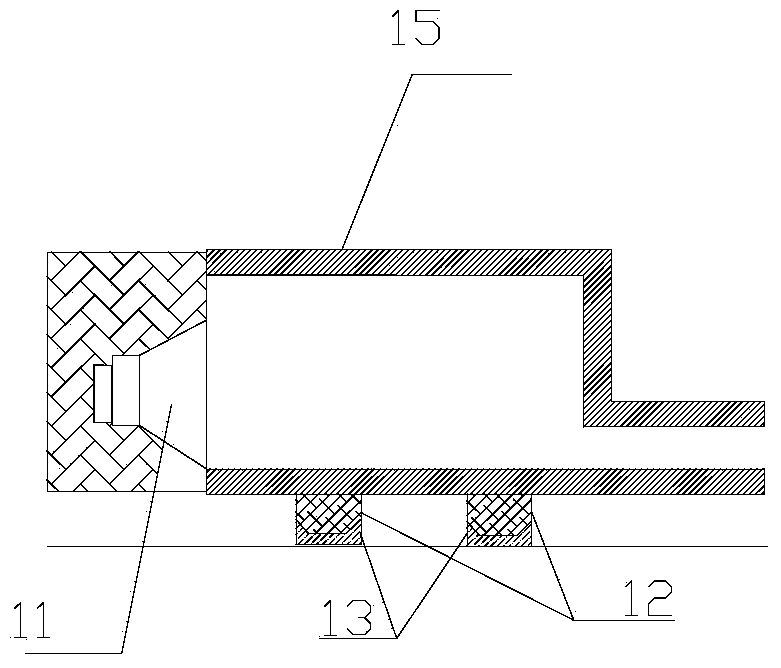

[0030] Such as figure 1 As shown, the outputs of the audio signal generators 1 and 2 are respectively connected to the two input ends of the power amplifier 3, and the two outputs of the power amplifier 3 are respectively connected to the standard sound sources 4 and 5. Standard point sound source selection Figure 4 The shown tapered cross-section waveguide standard point sound source composed of the loudspeaker 11 and the tapered cross-section waveguide airtight casing 14 is selected Figure 6 The standard sound source system of the tapered cross-section waveguide is shown, and the lateral spatial resolution of the sound source identification and positioning system (beamforming method) is measured and calibrated in the full anechoic chamber 6.

[0031] The measurement frequency points are selected according to 1 / 3 octave. For the measurement frequency point of 1000 Hz, the working standard microphone 7 is arranged 1 m directly in front of the standard sound source 4 . pas...

Embodiment 2

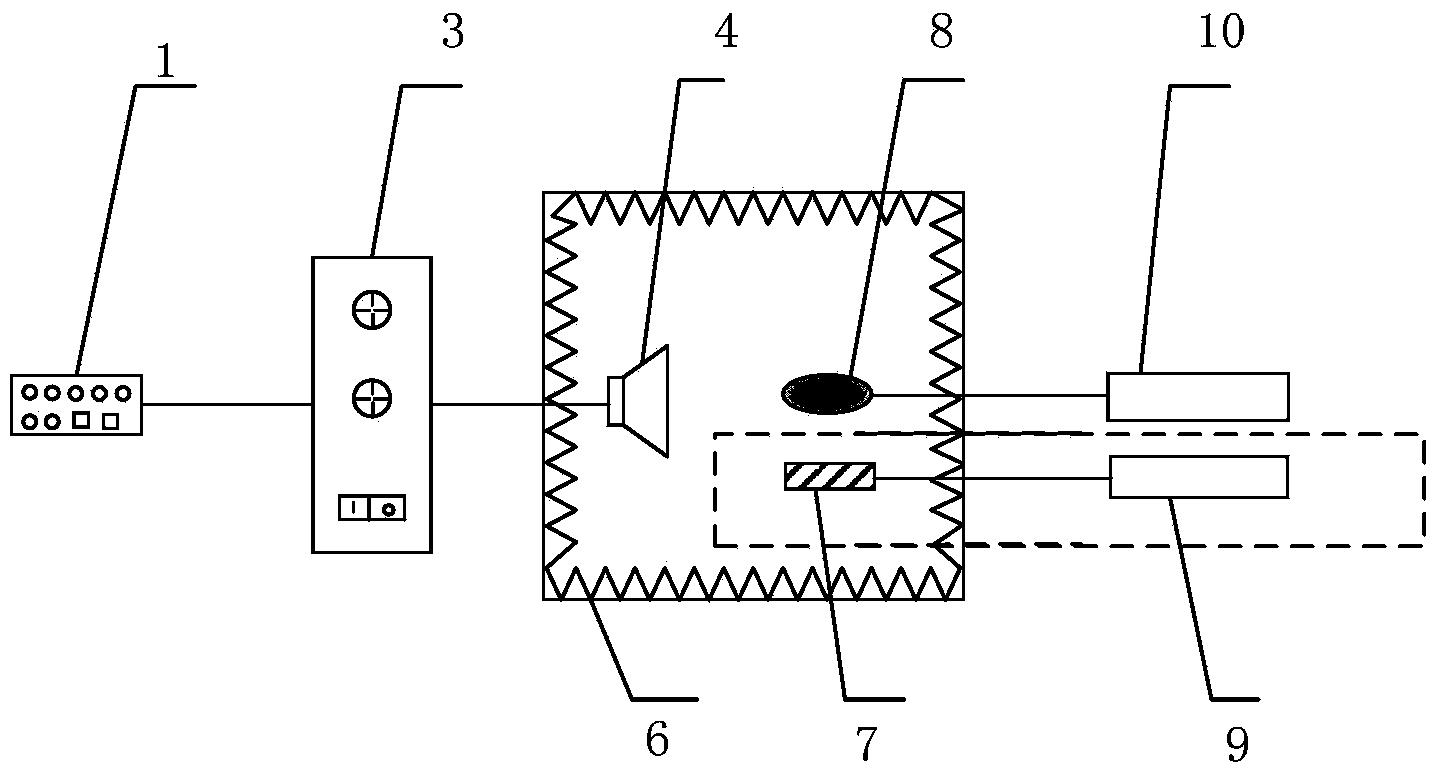

[0039] Such as figure 2 As shown, the output of the audio signal generator 1 is connected to the input of the power amplifier 3, and the output of the power amplifier 3 is connected to the standard sound source 4. Standard point sound source selection image 3 The shown abrupt cross-section waveguide standard point sound source composed of the loudspeaker 11 and the abrupt cross-section waveguide airtight casing 15 is selected Figure 5 The shown waveguide standard sound source system with abrupt cross-section is used to measure and calibrate the main-side lobe suppression ratio of the sound source identification and positioning system (beamforming method) in the full anechoic chamber 6.

[0040] Arrange the working standard microphone 7 1m in front of the standard sound source 4, set the frequency of the sinusoidal signal output by the audio signal generator 1 to 1000 Hz, and adjust the output voltage amplitude U1 so that the sound pressure level at the standard microphone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com