Material taking device of high temperature reaction furnace

A reclaiming device, high temperature reaction technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

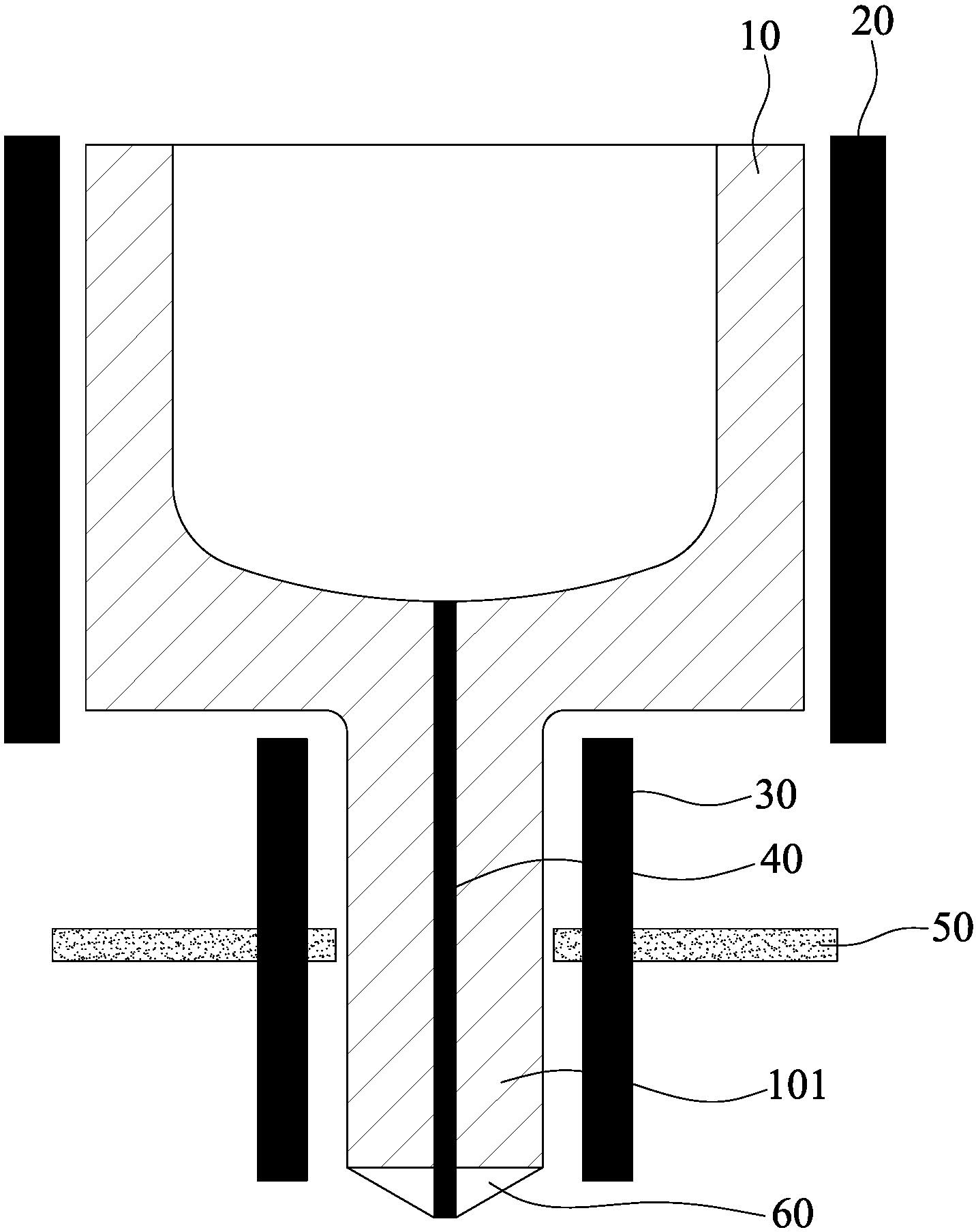

Embodiment 1

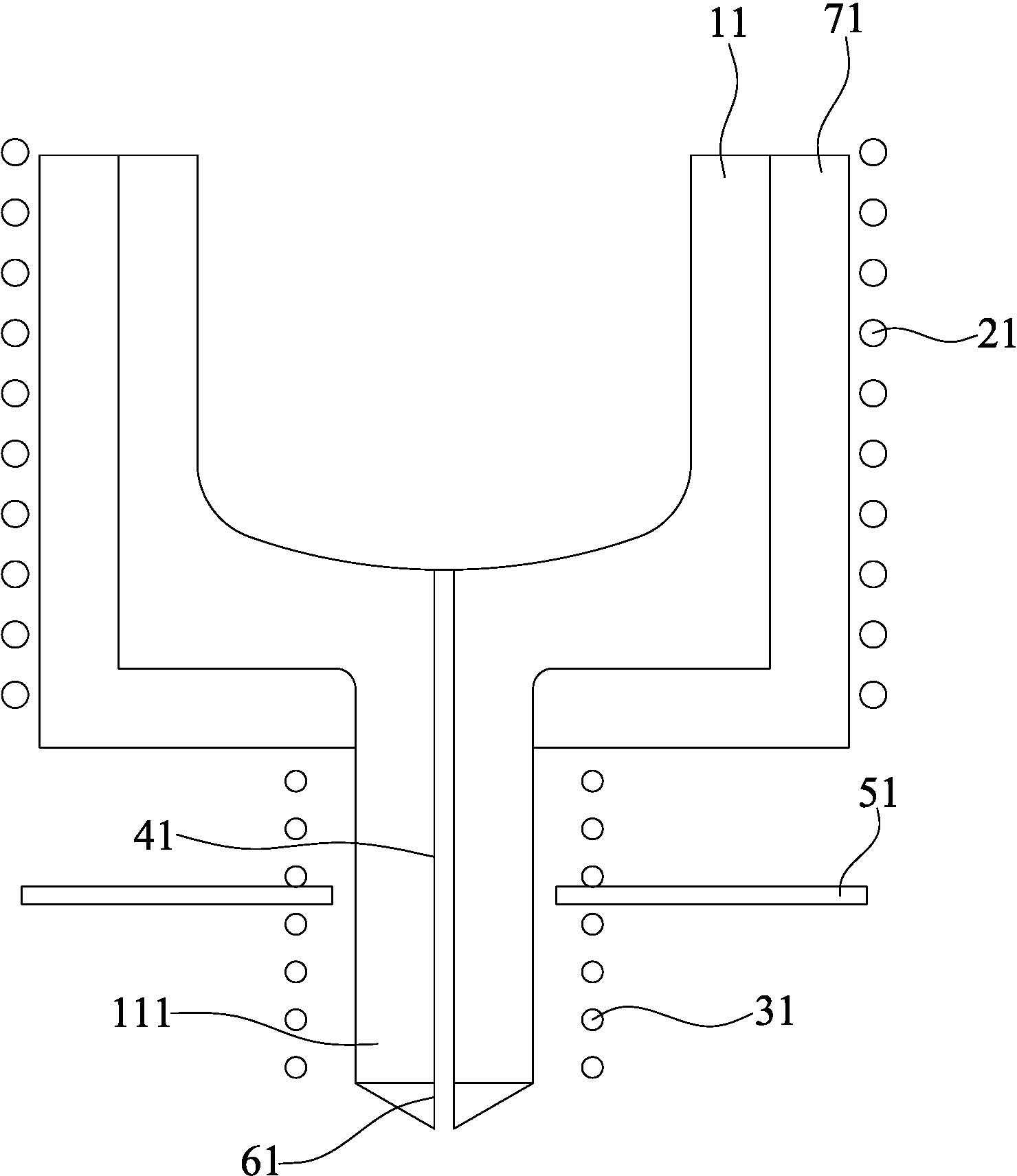

[0044] Such as figure 2 As shown, the reaction furnace in this embodiment 1 is a smelting crucible 11, and a thermal insulation layer 71 is provided outside it; a main furnace induction coil 21 is arranged outside the thermal insulation layer 71; The thermal switch induction coil 31 and the cooling air pipe 51 are provided; in this way, the induction heating of the reaction furnace and the flow guiding channel 41 is realized.

[0045] When working, the upper melting crucible 11 is heated and melted by the induction coil 21 of the main furnace to melt the reaction substance. At this time, the induction coil 31 of the thermal switch is in the non-working state, and the reactant melt flows into the guide channel 41 under the action of gravity, and the melt in the flow When the temperature drops, it condenses into a solid, blocks the guide channel 41, and achieves the effect of turning off the thermal switch. When the reactant melt needs to be discharged, the thermal switch indu...

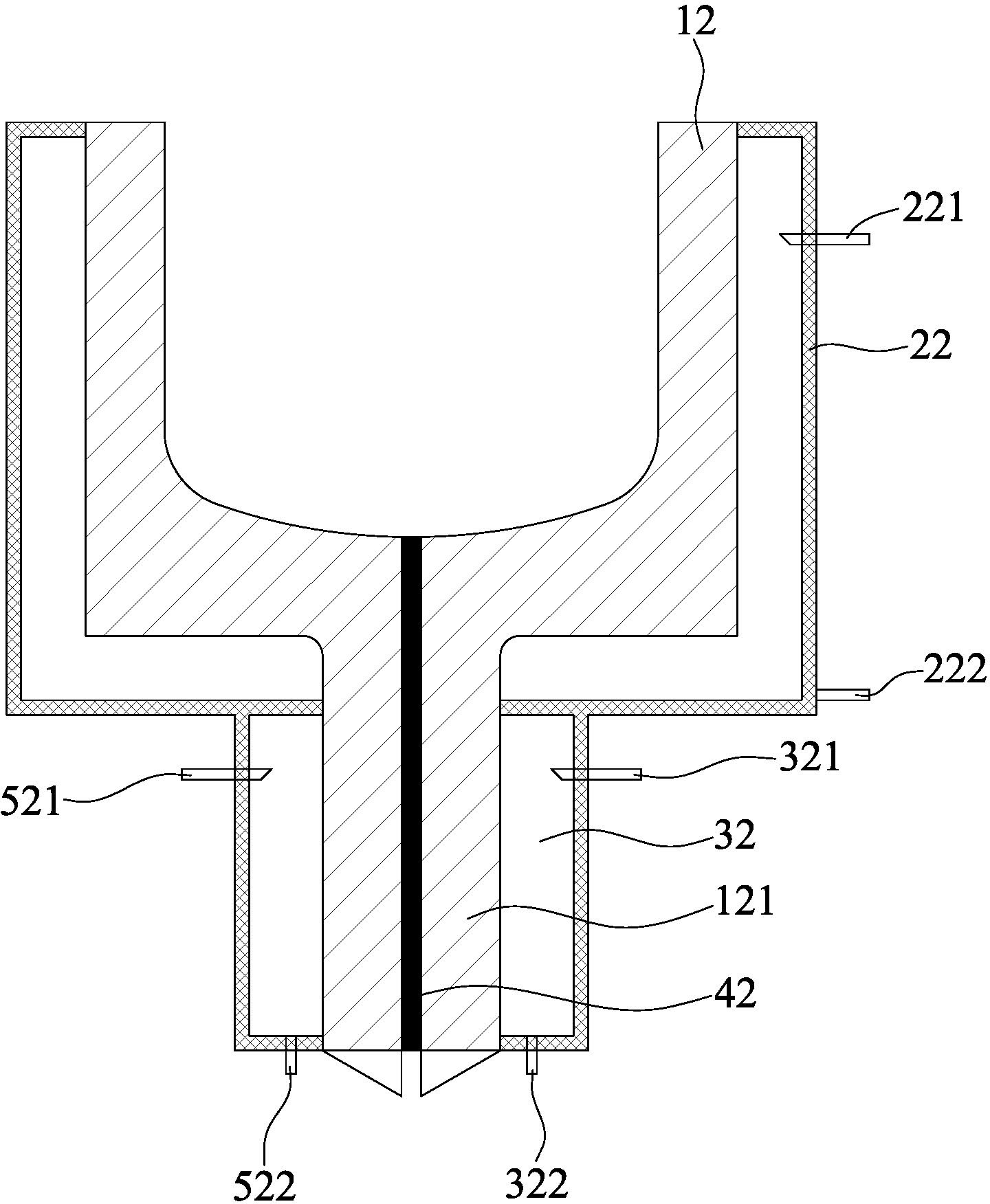

Embodiment 2

[0047] Such as image 3 As shown, the reaction furnace in this embodiment 2 is a smelting crucible 12, and a main furnace heating cylinder 22 is provided outside it, and the main furnace heating cylinder 22 is a closed cylinder, on which a main furnace heating The oil inlet 221 and the hot oil outlet 222 of the main furnace; and the outside of the guide seat 121 is provided with a thermal switch heating cylinder 32, and the heating cylinder 32 is a closed cylinder, and the cylinder is provided with a thermal switch for heating equipment. The inlet 321 and the hot oil outlet 322 are also provided with a cooling substance inlet 521 and a cooling substance outlet 522 on the missing body. In this way, heat conduction heating to the reaction furnace and the flow guiding channel 42 is realized.

[0048] During operation, the upper melting crucible 12 is heated and melted by injecting hot oil into the main furnace heating cylinder 32 to heat and melt the reaction substance. The reac...

Embodiment 3

[0050] Such as Figure 4As shown, the reaction furnace in this embodiment 3 is a smelting crucible 13, and a main furnace resistance heater 23 is provided outside it; a main furnace heat insulation layer 73 is set outside the main furnace resistance heater 23; The outside of the seat 131 is provided with a thermal switch resistance heater 33 , and a thermal switch heat insulation layer 83 is provided outside the thermal switch resistance heater 33 .

[0051] When working, the upper melting crucible 13 is heated and melted by the main furnace resistance heater 23 to melt the reaction substance. At this time, the thermal switch resistance heater 33 is in the non-working state, and the cooling pipe 53 injects the cooling substance, and the reactant melt flows into the flow guide under the action of gravity Channel 43, the temperature of the melt decreases during the flow and condenses into a solid, blocking the guide channel 43 to achieve the effect of turning off the thermal swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com