Oil well fracturing flowback fluid recovery sand removal device

A liquid recovery and flowback technology, which is applied in the direction of mining fluid, flushing wellbore, wellbore/well components, etc., can solve the problems of high environmental risk and difficult treatment of flowback fluid, and achieve short settlement time and reduce harmless The effect of processing cost and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

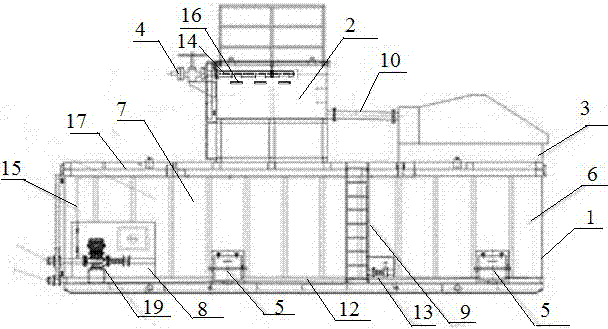

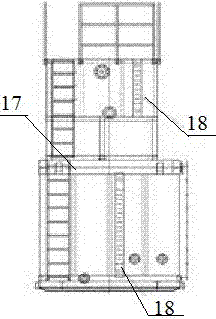

[0019] This embodiment provides an oil well fracturing flowback liquid recovery and desanding device, including a liquid storage tank 1, a buffer tank 2, and a vibrating screen 3. The liquid storage tank 1 is open, and the buffer tank 2 and the vibrating screen 3 are all located in the On the top of the liquid storage tank 1, the side of the buffer tank 2 is provided with a flowback liquid inlet 4, and the buffer tank 2 communicates with the vibrating screen 3 through the communication pipeline 10;

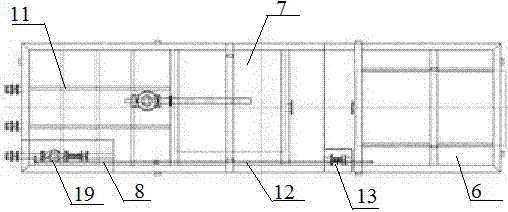

[0020] The liquid storage tank 1 is composed of an isolation area 8, a liquid storage area 7, and a sand settling area 6 arranged horizontally in sequence. 8 is equipped with a centrifugal pump 19, which communicates with the liquid storage area 7 through the pump discharge pipeline, and an overflow plate 9 is provided between the liquid storage area 7 and the sand settling area 6, and the lower part of the liquid storage area 7 and the sand settling area 6 is equipped with The sa...

Embodiment 2

[0023] On the basis of Embodiment 1, the buffer tank 2 is provided with a cleaning pipe 15 connected to the flowback liquid inlet 4, and three strip-shaped through-holes 16 are evenly distributed on the cleaning pipe 15 .

[0024] The fracturing flowback fluid enters the buffer tank 2 through the flowback fluid inlet 4, and the pressure inside the pipe is reduced through the three strip-shaped through holes 16 evenly distributed on the cleaning pipe 15, which facilitates the drainage and sand carrying, and then enters the vibrating screen 3 through the connecting pipeline , the liquid separated in the vibrating screen 3 enters the grit chamber 6, and when the liquid level exceeds the overflow plate 9 after precipitation, the liquid enters the liquid storage area 7 and is discharged through the first liquid discharge line 11. The flowback liquid is recycled; the sand after sedimentation is discharged through the sand cleaning door 5 and can be reused.

Embodiment 3

[0026] On the basis of embodiment 2, the bottom of the liquid storage tank 1 is provided with the second liquid discharge pipeline 12 connecting the isolation area 8, the liquid storage area 7, and the grit chamber 6, and the second liquid discharge line 12 is connected to the liquid storage area 7 and A connecting gate 13 is provided between the grit chambers 6 .

[0027] The fracturing flowback fluid enters the buffer tank 2 through the flowback fluid inlet 4, and the pressure inside the pipe is reduced through the three strip-shaped through holes 16 evenly distributed on the cleaning pipe 15, which facilitates the drainage and sand carrying, and then enters the vibrating screen 3 through the connecting pipeline , the liquid separated in the vibrating screen 3 enters the grit chamber 6, and when the liquid level exceeds the overflow plate 9 after precipitation, the liquid enters the liquid storage area 7 and is discharged through the first liquid discharge line 11. The flowb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com