Treatment method of stockpiled aod stainless steel slag

A technology of stainless steel slag and a treatment method, which is applied to the treatment field of AOD stainless steel slag, and achieves the effects of saving the cost of harmless treatment, simple process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

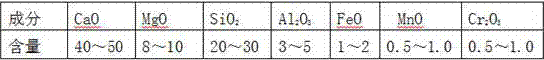

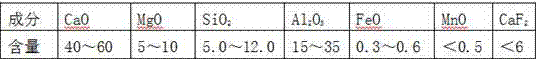

[0026] Embodiment 1: collect the AOD stainless steel slag of stockpiling more than one year, the main chemical composition and content of this stockpile AOD stainless steel slag are: CaO 40%, MgO 8%, SiO 2 20%, Al 2 o 3 3%, FeO 1%, MnO 0.5%, Cr 2 o 3 0.5%, the above contents are all weight contents. The above-mentioned stockpiled AOD stainless steel slag was dried in a drying oven at 105°C for 6 hours and then cooled to room temperature. The tailings after magnetic separation and extraction of magnetic substances were packed in paper or plastic bags and transported to the refining workshop for use. Mix according to the mass ratio of LF refining slag:stocked AOD stainless steel slag=95:5, put the mixed slag into the LF refining furnace, and form the final refining slag after refining at 1500°C for 50 minutes in a reducing atmosphere. After the LF refining is completed, the final refined slag is transported to the slag treatment workshop through the slag tank, and the pos...

Embodiment 2

[0027] Embodiment 2: Collect the AOD stainless steel slag that has been stockpiled for more than one year. The main components and contents of the stockpiled AOD stainless steel slag are: CaO 50%, MgO 10%, SiO 2 30%, Al 2 o 3 5%, FeO 2%, MnO 1%, Cr 2 o 31%, the above contents are all weight contents. The above stockpiled AOD stainless steel slag was dried in a drying oven at 105°C for 5 hours and then cooled to room temperature. The tailings after magnetic separation and extraction of magnetic substances were packed in paper or plastic bags and transported to the refining workshop for use. Mix according to the mass ratio of LF refining slag:stocked AOD stainless steel slag=90:10, put the mixed slag into the LF refining furnace, and form the final refining slag after refining at 1540°C for 40 minutes in a reducing atmosphere. After the LF refining is completed, the final refined slag is transported to the slag treatment workshop through the slag tank, and the post-treatme...

Embodiment 3

[0028] Embodiment 3: Collect the AOD stainless steel slag that has been stockpiled for more than one year. The main components and contents of the stockpiled AOD stainless steel slag are: CaO 45%, MgO 89%, SiO 2 26%, Al 2 o 3 4.5%, FeO 1.7%, MnO 0.92%, Cr 2 o 3 0.88%, the above contents are all weight contents. The above-mentioned stockpiled AOD stainless steel slag is placed in a drying oven, dried at 100°C for 5.5 hours, and then cooled to room temperature. The tailings after magnetic separation and extraction of magnetic substances are packed in paper or plastic bags and transported to the refining workshop for use. According to LF Refining slag: stockpile AOD stainless steel slag = 90:10 mass ratio mixing, put the mixed slag into the LF refining furnace, and form the final refining slag after refining at 1560°C for 35 minutes in a reducing atmosphere. After the LF refining is completed, the final refined slag is transported to the slag treatment workshop through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com