A kind of harmless treatment method of chromium slag

A technology for harmless treatment of chromium slag, which is applied in the field of harmless treatment of chromium slag and resource utilization, high-temperature melting converter steel slag treatment of chromium slag, and can solve the problem of incomplete detoxification, high treatment cost, and difficult wide-ranging harmless treatment technology Problems such as popularization and application, to achieve the effect of low cost of harmless treatment and simplification of the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

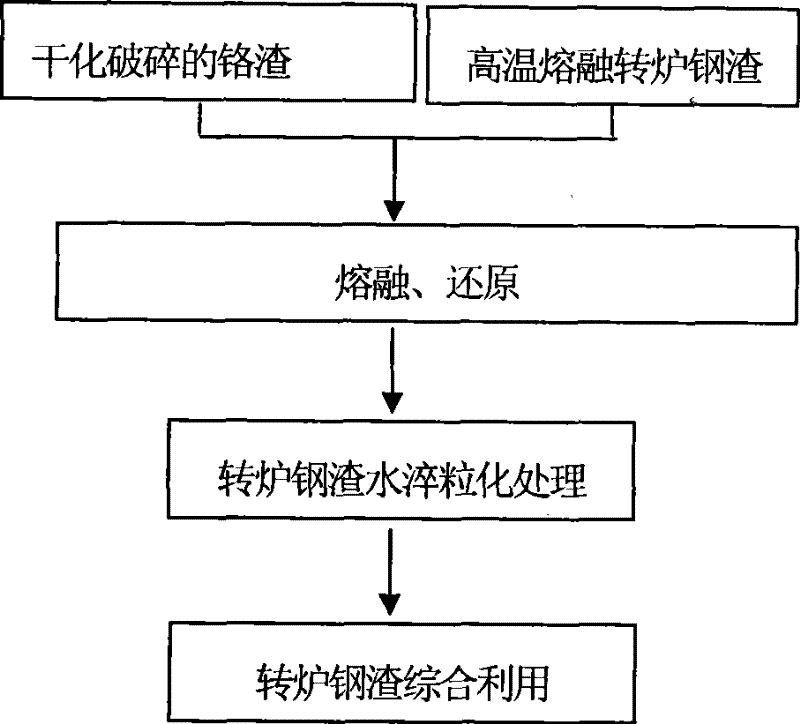

[0041] like figure 1 As shown, about 25 tons of slag is discharged from the converter at a time in a steel factory. Before tapping the converter, 1.25 tons of chromium slag from a chromium salt factory that has been dried and crushed with a particle size of 10mm is put into the empty slag tank, and the converter is melted during the slag discharge. The steel slag is poured into the slag tank, and the high-temperature molten converter steel slag at 1610°C is mixed with the chromium slag for melting and high-temperature reduction reaction. The molten converter steel slag is subjected to water quenching and granulation treatment; from the time when the molten converter steel slag and chromium slag begin to mix and undergo smelting reduction reaction, to when the converter steel slag fused with chromium slag enters the drum and the slag treatment reaction ends, the total reaction time is 8 minutes.

[0042] The converter steel slag after water quenching and granulation treatment ...

Embodiment 2

[0046] In a steel plant, about 25 tons of slag is discharged from the converter at a time. When the converter is discharged, all the molten steel slag is poured into the slag tank, and 0.25 tons of chromium slag, which has been dried and crushed and has a particle size of about 1mm, is sprayed into the room at about 1540 °C with a spray gun. In the high-temperature molten converter steel slag, the chromium slag and the converter steel slag are mixed for melting and high-temperature reduction reaction. After the chromium slag is sprayed, the slag tank is transported to the slag treatment site, and the molten converter steel slag mixed with the chromium slag is poured into a shallow pan for watering. The quenching and granulation treatment starts from the time when the chromium slag is completely sprayed into the molten steel slag, and the steel slag fused with chromium slag is poured into the shallow pan to start the slag treatment and the smelting reduction reaction ends. The wh...

Embodiment 3

[0051] 15 tons of converter slag is discharged at a time in a steel factory. Before the converter is tapped, 0.5 tons of chromium slag from a chromium salt factory that has been dried and broken with a particle size of 5mm is put into the slag tank. When the converter is slag discharged, the slag is poured into the empty slag tank. Inside, 1560°C high-temperature molten converter steel slag is mixed with chromium slag for melting and high-temperature reduction reaction. The total reaction time is 5 minutes.

[0052] Converter steel slag after water quenching and granulation treatment is leached according to "Solid Waste Leaching Toxic Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T299-2007), the total chromium content in the leach solution is 0.079mg / L, and the hexavalent chromium is 0.019mg / L, barium 0.79 mg / L. Others are the same as embodiment 1.

[0053] Composition (%) in chromium slag and converter steel slag in the embodiment 3 of table 4

[0054] El...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com