Stainless steel high-pureness smelting method

A smelting method and stainless steel technology, applied in the improvement of process efficiency, furnaces, electric furnaces, etc., can solve the problems of stainless steel ingots with low impurity content, and achieve the effects of preventing oxidation, reducing inclusions, and controlling pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

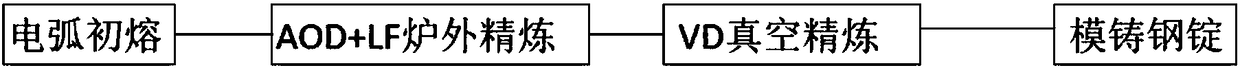

Method used

Image

Examples

Embodiment 1

[0042] The scrap steel and pig iron that have been fully baked are used for electric arc smelting, and the use of scrap steel and pig iron as raw materials for stainless steel has greater flexibility. The molten iron and stainless steel return materials can be adjusted according to the market nickel price and stainless steel return material price fluctuations and supply conditions. proportion.

[0043] (1) arc smelting

[0044] Vacuum electric arc furnace is used for smelting. When the vacuum degree of vacuum induction melting furnace reaches 60Pa, high-purity argon gas is introduced to 0.1MPa and the temperature is raised rapidly until the charge is completely melted.

[0045]In order to obtain lower tapping P, adopt the method of large slag amount (≥600kg / t) and multiple slag flow, electric furnace tapping: P≤0.05%, Si≤0.4%, electric furnace tapping temperature≥1600℃.

[0046] The impurity elements are analyzed and recorded during the electric furnace smelting process. The ...

Embodiment 2

[0062] The scrap steel and pig iron that have been fully baked are used for electric arc smelting, and scrap steel and pig iron are used as raw materials for stainless steel. The supply has greater flexibility, and the molten iron and stainless steel return can be adjusted according to the fluctuation of market nickel price and stainless steel return material price and supply conditions. Ratio of material.

[0063] (1) arc smelting

[0064] Vacuum electric arc furnace is used for smelting. When the vacuum degree of vacuum induction melting furnace reaches 60Pa, high-purity argon gas is introduced to 0.1MPa and the temperature is raised rapidly until the charge is completely melted.

[0065] In order to obtain lower tapping P, adopt the method of large slag amount (≥600kg / t) and multiple slag flow, electric furnace tapping: P≤0.05%, Si≤0.4%, electric furnace tapping temperature≥1600℃.

[0066] The impurity elements are analyzed and recorded during the electric furnace smelting...

Embodiment 3

[0080] The smelting of stainless steel uses high-quality scrap steel, pig iron or molten iron, and the alloy that has been fully baked for initial melting.

[0081] (1) arc smelting

[0082] Vacuum electric arc furnace is used for smelting. When the vacuum degree of vacuum induction melting furnace reaches 60Pa, high-purity argon gas is introduced to 0.1MPa and the temperature is raised rapidly until the charge is completely melted.

[0083] In order to obtain lower tapping P, adopt the method of large slag amount (≥600kg / t) and multiple slag flow, electric furnace tapping: P≤0.05%, Si≤0.4%, electric furnace tapping temperature≥1600℃.

[0084] The impurity elements are analyzed and recorded during the electric furnace smelting process. Harmful elements As≤0.007%, Sn≤0.004%, Sb≤0.010%, Pb≤0.001%, Bi≤0.001%, Cu≤0.20%.

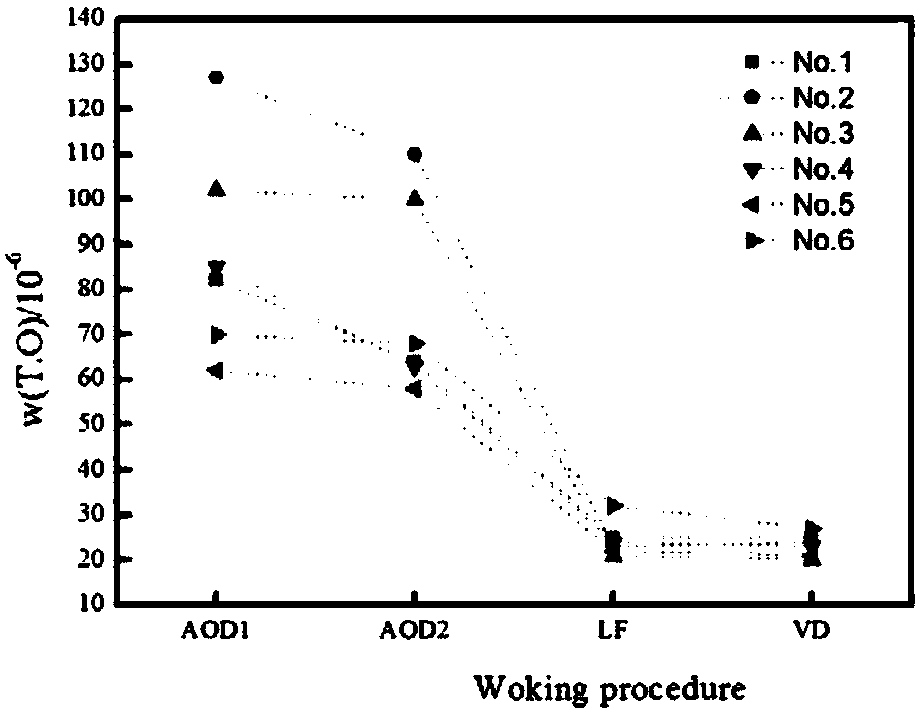

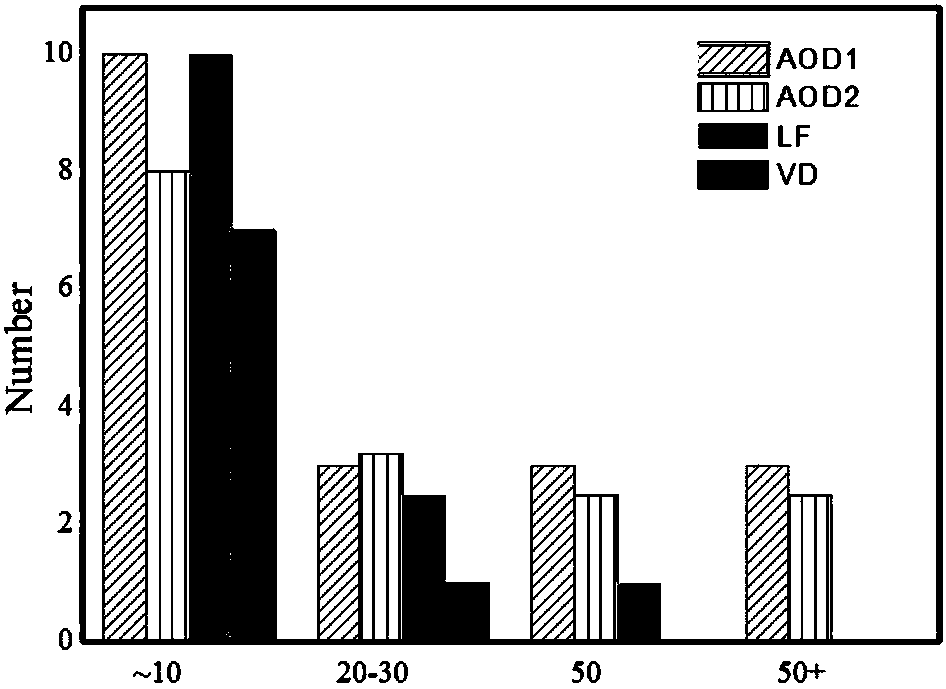

[0085] (2) Using AOD+LF refining outside the furnace. In the decarburization period, the decarburization effect is realized by adjusting the partial pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com