Method for recycling upper part residual coal and backfilling goaf by utilizing full-mechanized caving mining in extremely thick coal seam

A technology for extra-thick coal seams and goafs, applied in the field of coal mining, can solve problems such as sorting, achieve the effects of liberating permanent sluggish reserves, relieving corporate pressure, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

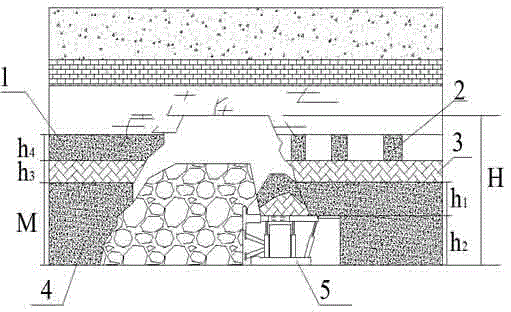

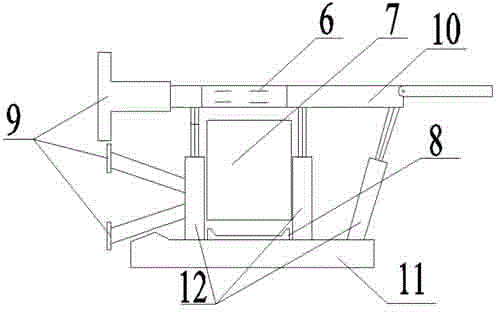

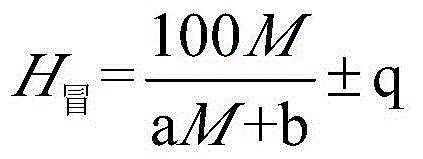

[0033] Such as figure 1 , figure 2 As shown, the two situations that may occur in the upper thin coal seam are: the entire layer abandons coal 1 or the residual coal pillar 2, the upper thin coal seam is below the interlayer rock layer 3, the interlayer rock layer 3 is an extra-thick coal seam 4, and M is an extra-thick coal seam Working face height, H is the height of the caving zone calculated by the above formula, h 2 is the height of working face in extra-thick coal seam, h 1 is the top-coal caving height, h 3 is the interlayer thickness between two coal layers, h 4 is the thickness of the upper residual coal or abandoned coal, when h 3 + h 4 <H, it can be considered that the upper abandoned coal or residual coal can be extracted by the method shown in the present invention.

[0034] With the normal advancement of the fully mechanized caving mining face of the extra-thick coal seam, the top coal in the upper part of the extra-thick coal seam 4, the interlayer rock l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com