Flue gas desulfurization control system of large coal-fired power plant

A control system, a technology for coal-fired power plants, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc. Level of automation, saving time and money, effect of pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

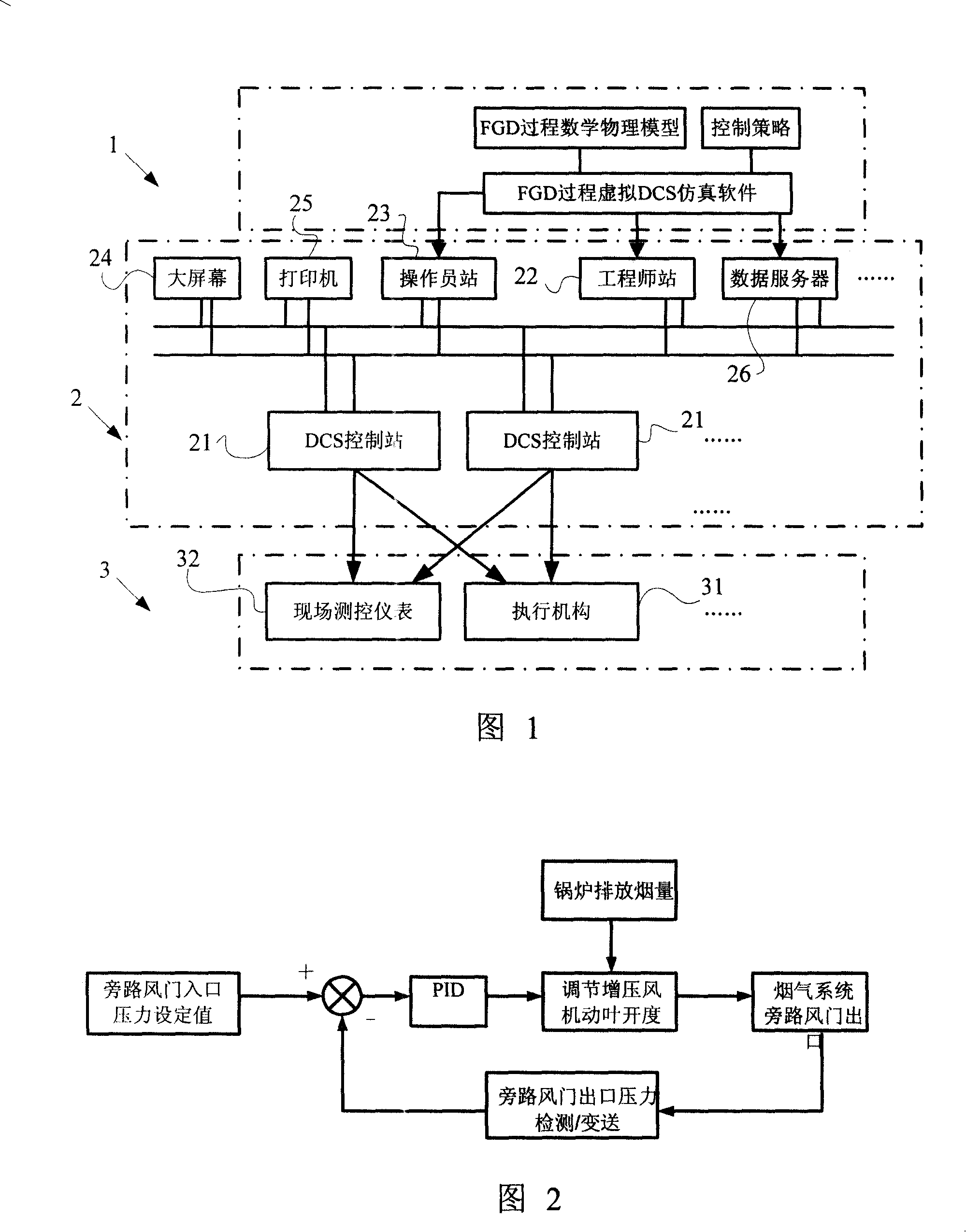

[0026] As shown in Figure 1, the flue gas desulfurization control system of a large-scale coal-fired power plant of the present invention includes a "virtual machine" part 1, a DCS control system 2 and a "real power" part 3 connected in sequence, wherein:

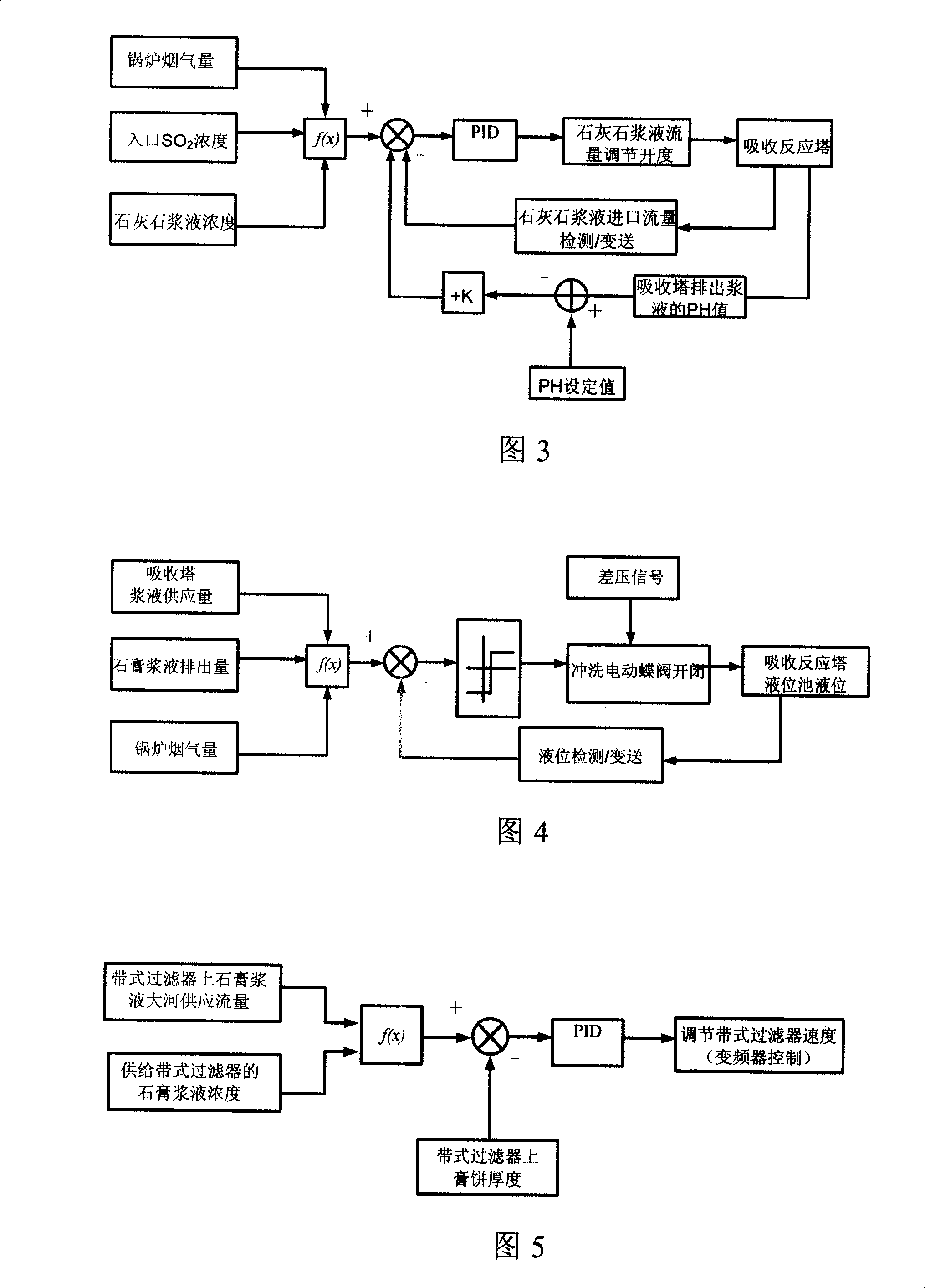

[0027] The "virtual machine" part 1 is the flue gas desulfurization simulation platform, including physical and mathematical models of several subsystems of flue gas desulfurization, several control loops, flue gas desulfurization start-stop sequence control system, alarm and thermal chain protection device. Several subsystems of flue gas desulfurization include: absorption tower unit, flue gas reheating unit, limestone slurry preparation unit and gypsum dehydration unit. Several control loops include: booster fan pressure control loop, limestone slurry flow control loop, absorption tower liquid level control loop and gypsum dehydration control loop.

[0028] The DCS control system 2 includes each control point 21 that is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com