Method for recycling arsenic-containing waste residues

A recycling and waste slag technology, applied in the field of hazardous waste resource utilization, can solve problems such as complex resource utilization process and difficult disposal of arsenic-containing waste residue, achieve significant economic and environmental benefits, alleviate random stacking, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

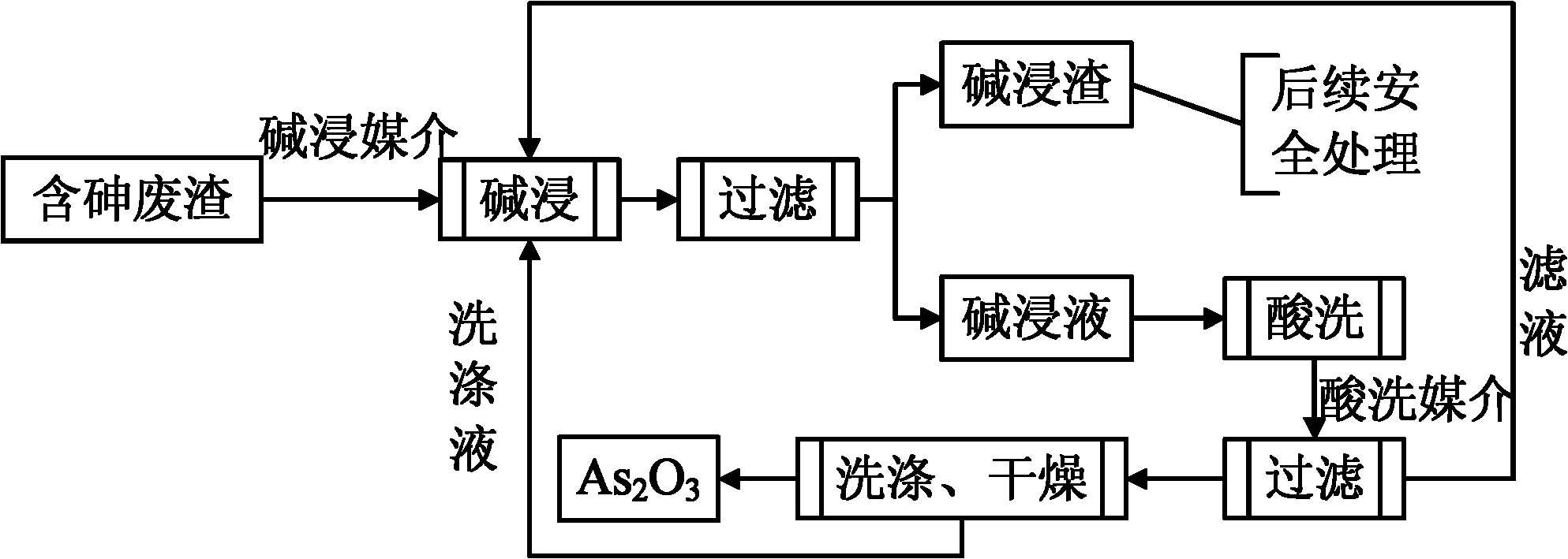

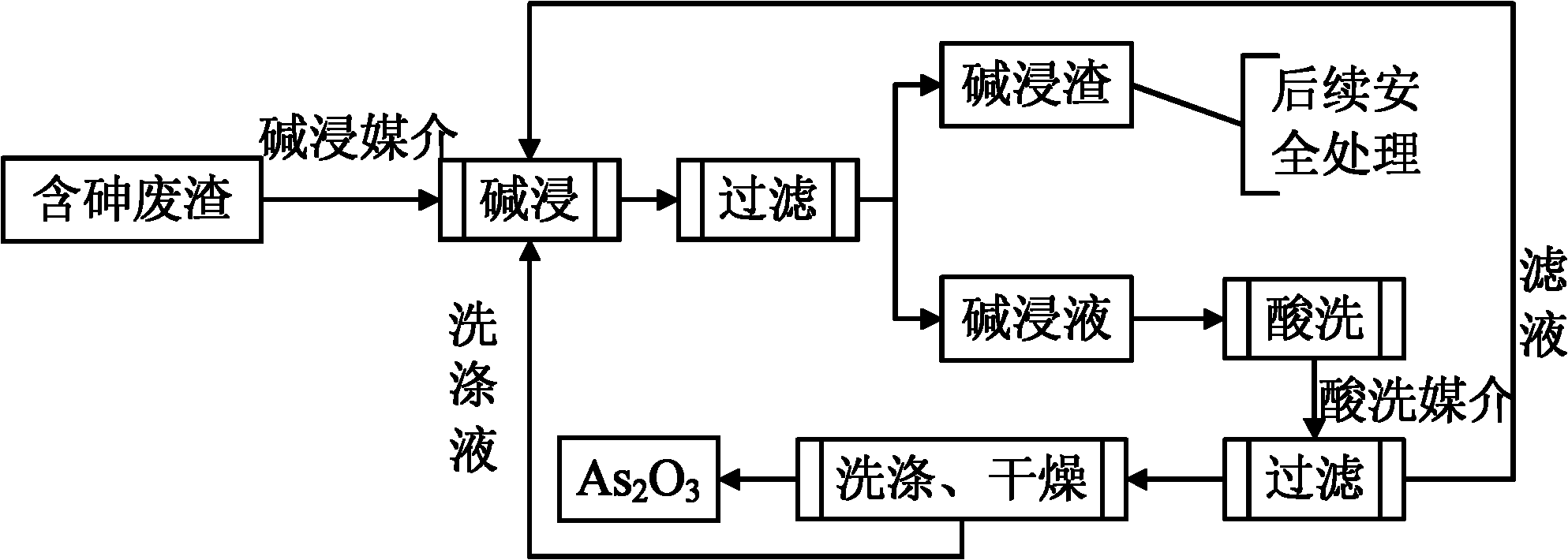

Image

Examples

Embodiment 1

[0031] The object of treatment is arsenic-containing tailings slag from a chemical plant. The slag is in the form of yellow mud, and the arsenic content in the slag is 288.8 mg / kg. X-ray diffractometer (XRD) detection shows that the arsenic in the arsenic-containing tailings slag is mainly composed of As 2 S 3 and As 2 o 3 form exists. The separation and preparation of arsenic trioxide from the arsenic-containing waste residue specifically includes the following steps:

[0032] (1) Add NaOH and arsenic-containing tailings slag with a mass ratio of 0.6 into the tank reactor, add water to mix as an alkaline leaching medium, control the mass ratio of water to NaOH and arsenic-containing tailings slag mixed solids to be 5, and adjust the stirring speed to 200r / min, mechanically stirred at room temperature for 30min, filtered to obtain alkali leaching solution and alkali leaching residue.

[0033](2) For the alkaline immersion solution obtained in step (1), add concentrated su...

Embodiment 2

[0038] The processing object is the same as that in Embodiment 1.

[0039] (1) Control the mass ratio of KOH and arsenic-containing tailings slag to 1.4, add water as the alkali leaching medium for mixing and stirring, and control the liquid-solid ratio of the alkali leaching medium and KOH and arsenic-containing tailings slag mixed solid to 3, stirring speed 200r / min, stirring time 60min , filtered, and filtered to obtain alkali leaching solution and alkali leaching residue.

[0040] (2) For the alkaline immersion solution obtained in step (1), add concentrated sulfuric acid with a volume fraction of 10% as the pickling medium, and place the mixture in an oscillator for pickling for 1 hour at a pickling temperature of 15°C and an oscillator speed of 200r / min , the oscillation is over, centrifuged, filtered to obtain pickling solution and pickling precipitate.

[0041] (3) The pickling precipitate in step (2) is washed twice with 1% dilute sulfuric acid by volume fraction, an...

Embodiment 3

[0045] The treatment object was the same as in Example 1, and the alkaline leaching medium used was the arsenic-containing alkaline leaching solution produced by leaching the arsenic-containing waste residue with NaOH solid alkali, wherein the As concentration was 38.4g / L, the pH was 11.47, and the COD was 3.62mg / L.

[0046] (1) Control the mass ratio of NaOH and arsenic-containing tailings slag to 1.0, add arsenic-containing alkali leaching solution as the alkali leaching medium for mixing and stirring, control the liquid-solid ratio of the alkali leaching medium and NaOH and arsenic-containing tailings slag mixed solid to 10, and stir at a speed of 200r / min, stirring time 180min, filtered to obtain alkali leaching solution and alkali leaching residue.

[0047] (2) For the alkaline immersion solution obtained in step (1), add concentrated sulfuric acid with a volume fraction of 10% as the pickling medium, and place the mixture in an oscillator for pickling for 2 hours at a pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com