Pressing type sludge dehydration apparatus and working method thereof

A sludge dehydration and sludge technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve difficult problems such as reducing the water content of sludge, achieve good dehydration effect, prevent and control environmental pollution, and have reasonable design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

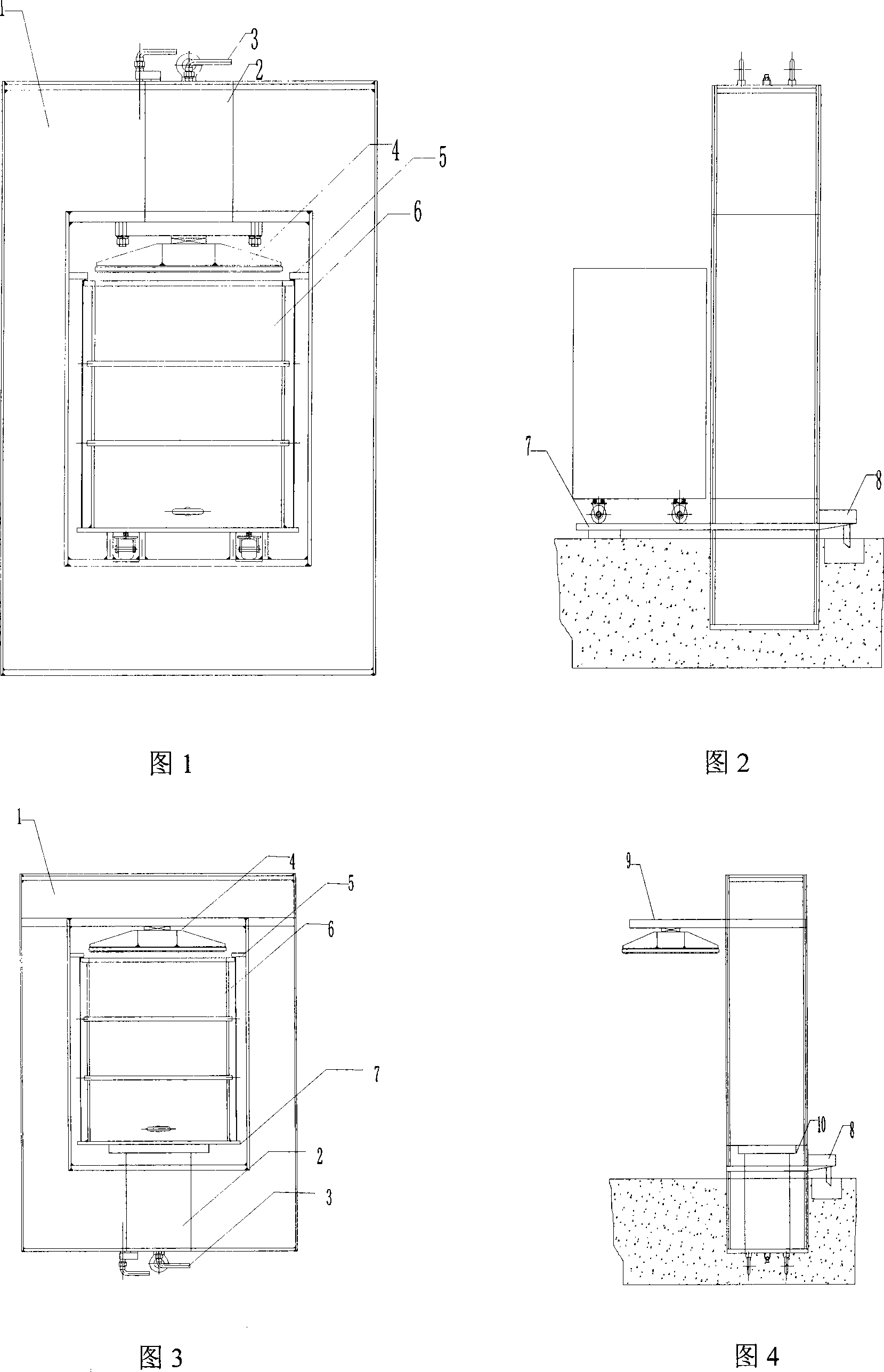

[0023] Structure of the present invention as shown in Figure 1 and Figure 2, comprises frame 1, material cylinder 6 and hydraulic oil cylinder 2, and material cylinder 6 and hydraulic oil cylinder 2 are all installed on the frame, and hydraulic oil cylinder 2 is positioned at above material cylinder 6; The cylinder 6 is a cylindrical material cylinder, the upper end of the material cylinder 6 is open, the lower end is sealed, and the water outlet holes are distributed on the side wall of the material cylinder; the upper end of the material cylinder 6 is provided with a pressure plate 4 that matches the inner diameter of the material cylinder 6, and the back of the pressure plate 4 is connected to the hydraulic pressure. The piston of oil cylinder 2 is fixedly connected.

[0024] The frame 1 is provided with a positioner 5 , and the positioner 5 is located between the material cylinder 6 and the pressing plate 4 .

[0025] The material cylinder 6 is installed on the chassis 7 o...

Embodiment 2

[0035] Structure of the present invention as shown in Figure 3 and Figure 4, comprises frame 1, material cylinder 6 and hydraulic oil cylinder 2, and material cylinder 6 and hydraulic oil cylinder 2 are all installed on the frame, and hydraulic oil cylinder 2 is positioned at material cylinder 6 below; The cylinder 6 is a cylindrical material cylinder, the upper end of the material cylinder 6 is open, the lower end is sealed, and the water outlet holes are distributed on the side wall of the material cylinder; Skateboard 9 links to each other.

[0036] The frame 1 is provided with a positioner 5 , and the positioner 5 is located between the material cylinder 6 and the pressing plate 4 .

[0037] The material cylinder 1 is installed on the chassis 7 of the frame 1, and the material cylinder 6 can move in the horizontal direction of the chassis 7; the upper part of the material cylinder 6 is provided with a feeding port.

[0038] The bottom of the material cylinder 6 is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com