Weighing equipment for concrete material

一种计量装置、混凝土的技术,应用在测量装置、控制装置、分析材料等方向,能够解决测定结果精度有限、经济性与时间不现实、精度低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

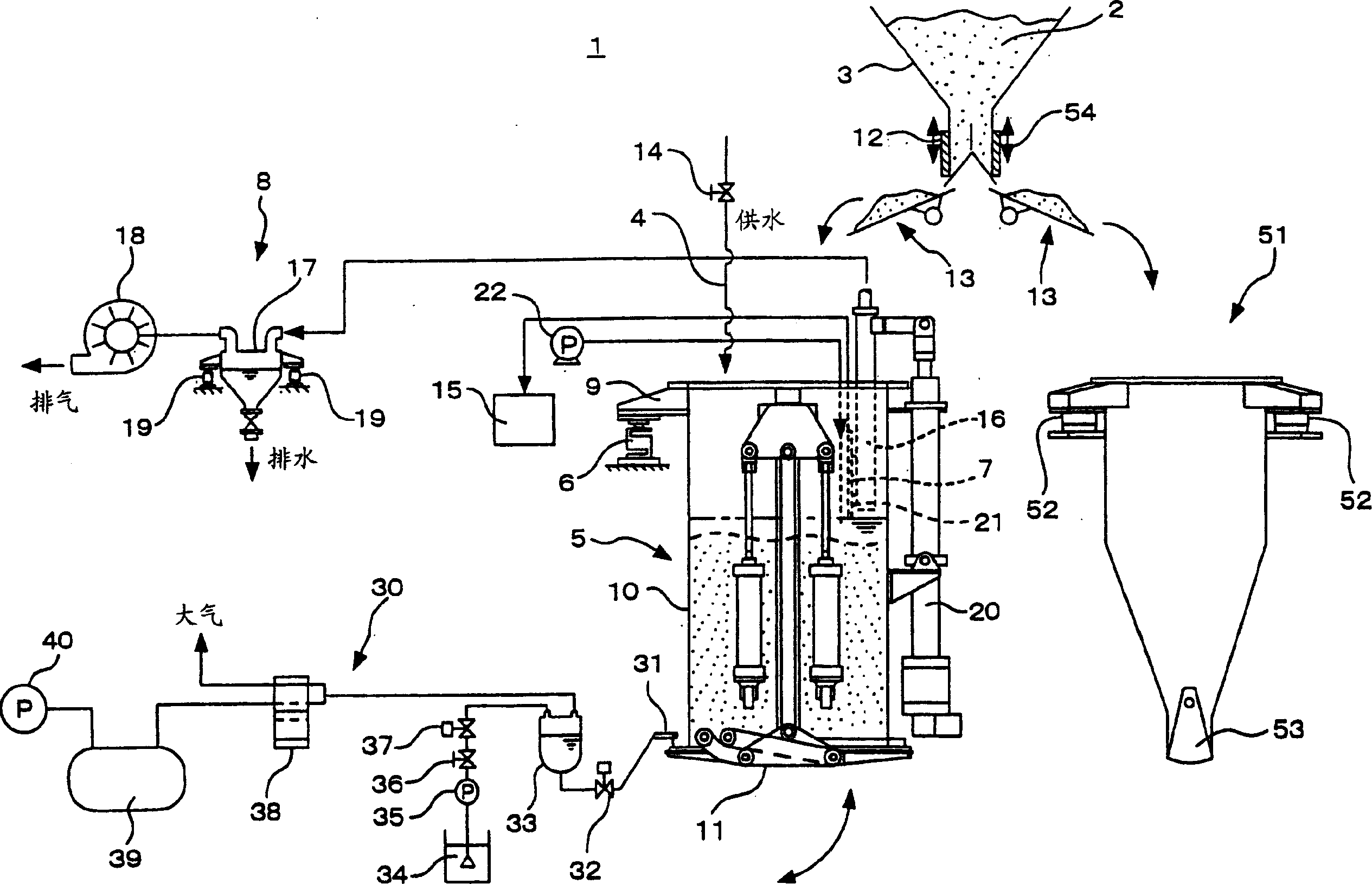

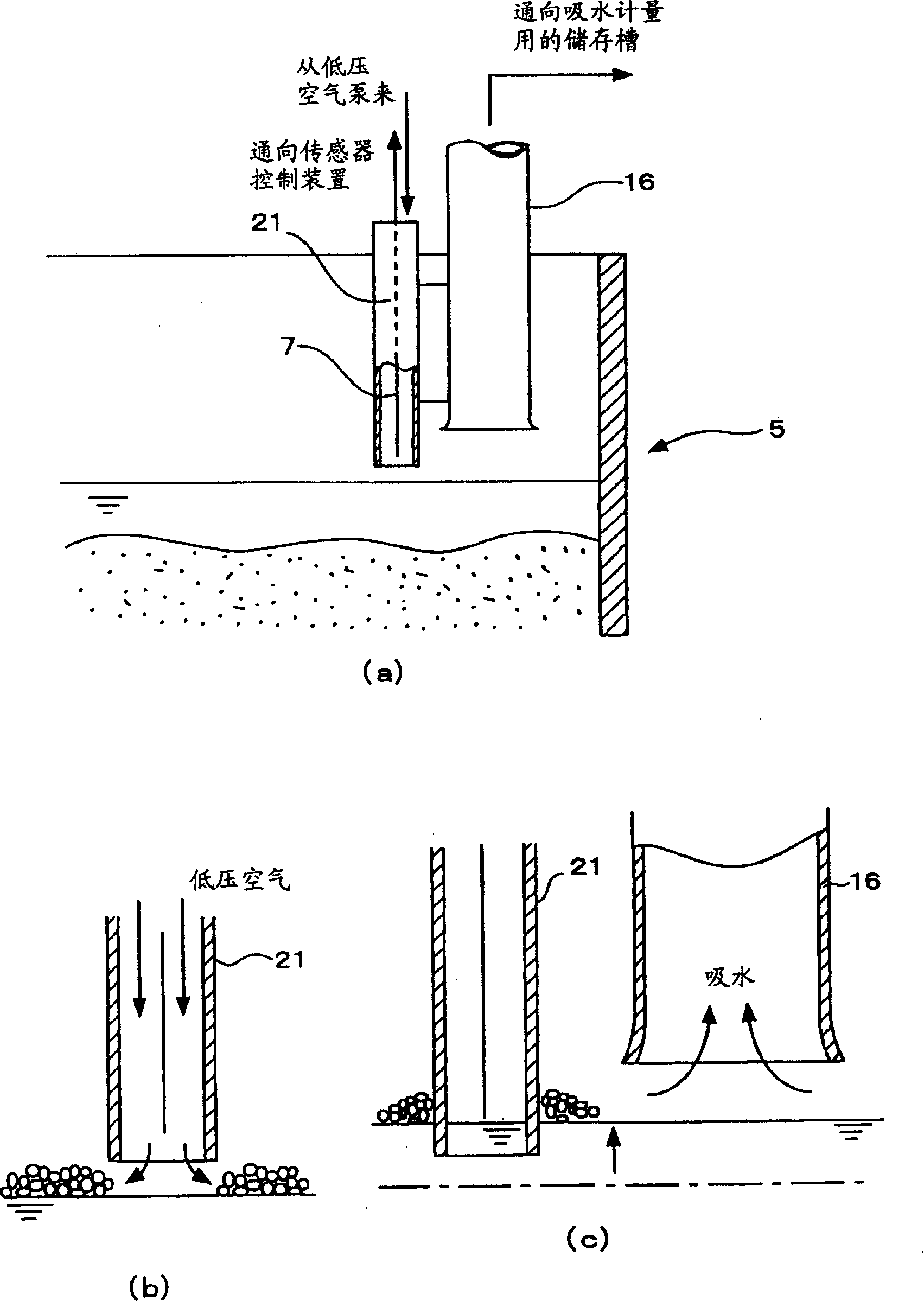

[0086] figure 1 It is the whole schematic diagram of the measuring device of the concrete material of this embodiment. Such as figure 1 As shown, the metering device 1 of the concrete material of the present embodiment basically consists of the following components: an aggregate hopper 3 as an aggregate supply device for supplying fine aggregate 2; a water supply pipe 4 as a water supply device; Aggregate weighing bin 51 that accommodates and measures fine aggregate 2 supplied from aggregate hopper 3; stores fine aggregate 2 supplied from aggregate hopper 3 and water supplied from water supply pipe 4 together as flooded aggregate The metering tank 5 raised up; the load cell 6 as the water-soaked aggregate weight measuring device for measuring the weight of the water-soaked aggregate in the above-mentioned metering tank; the water level as the water-soaked aggregate water level in the metering tank 5 The electrode type sensor 7 of the measuring device; the water level maintai...

no. 2 example

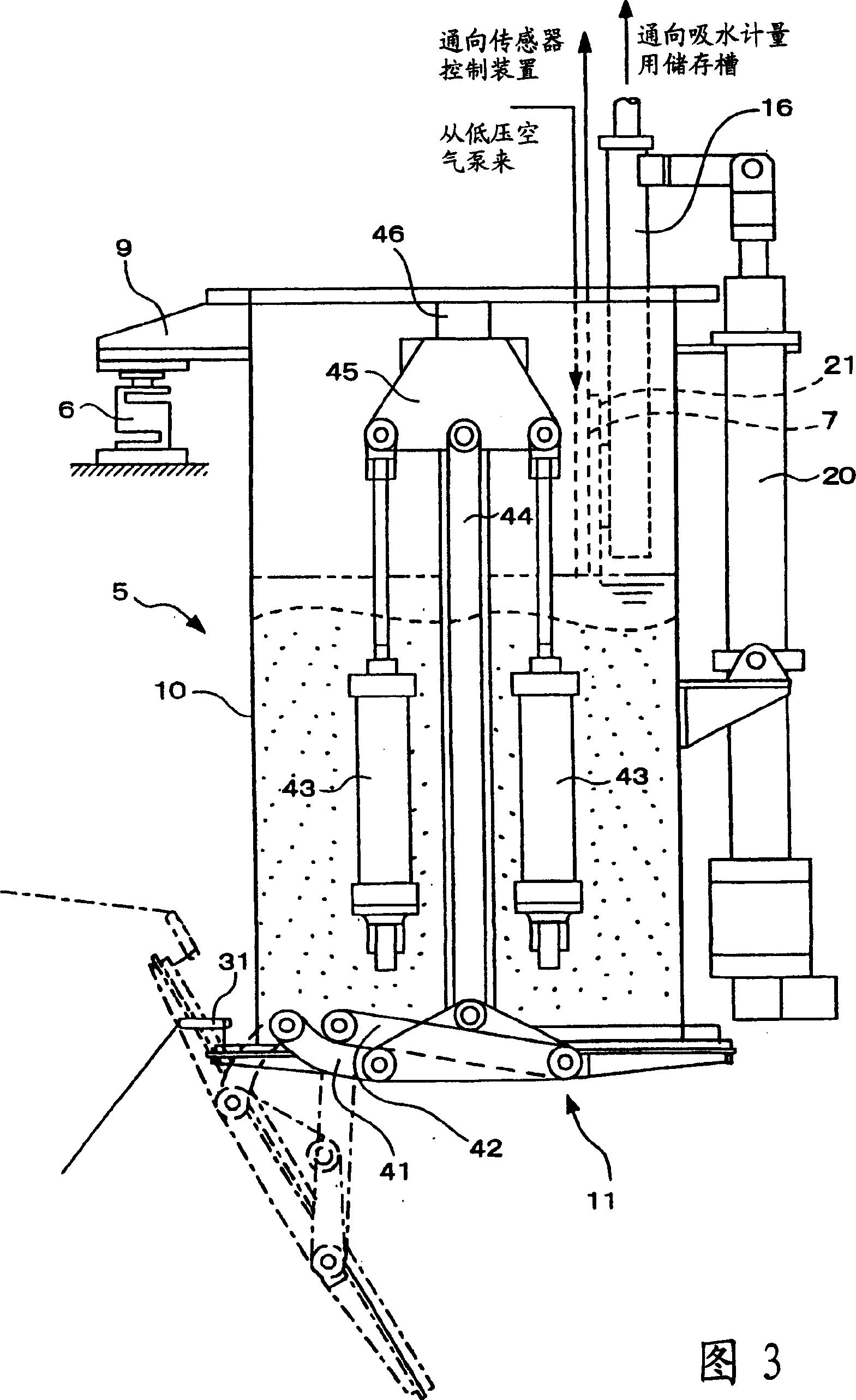

[0171] Next, the measuring device for concrete material of the second embodiment will be described. In addition, all components substantially the same as those of the first embodiment are given the same reference numerals, and description thereof will be omitted.

[0172] Figure 4 It is a figure which shows the whole measuring apparatus of the concrete material of this Example. Such as Figure 4 As shown, the metering device 61 of the concrete material of the present embodiment basically consists of the following components: the aggregate hopper 3 as the aggregate supply device for supplying the fine aggregate 2; the water supply pipe 4 as the water supply device; A measuring tank 5 for storing the fine aggregate 2 supplied from the aggregate hopper 3 and water supplied from the water supply pipe 4 together as the water-soaked aggregate; The load cell 6 of the material weight measuring device; the electrode type sensor 7 as the water level measuring device of the water-imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com