Device and method for measuring output liquid of coal bed methane well

A coalbed methane well and production fluid technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems that the production fluid cannot be filled, the liquid measurement cannot be performed, and the accuracy of liquid measurement can be solved. And the effect of easy maintenance, good application prospects and wide market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with examples.

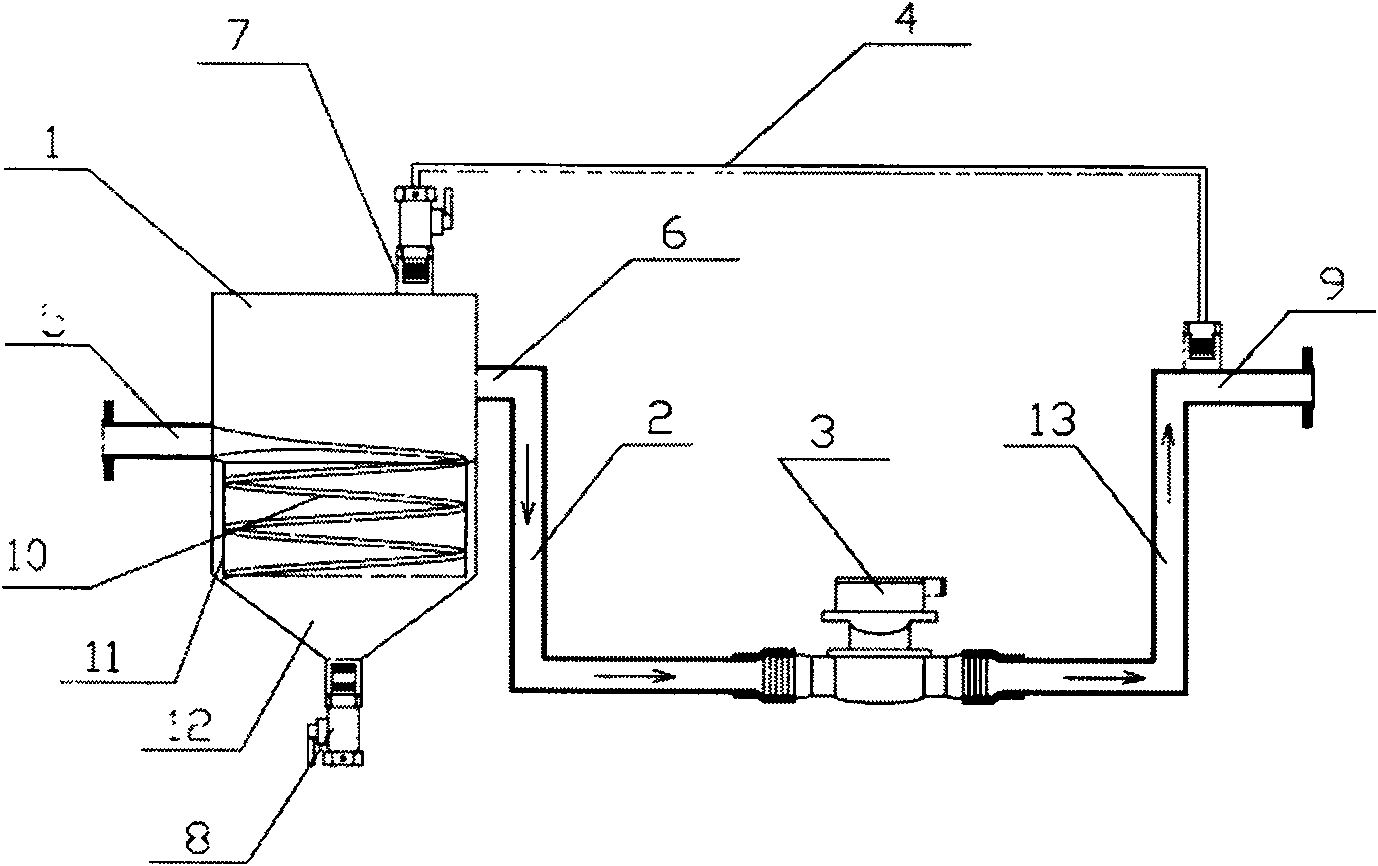

[0028] Such as figure 1 As shown, the device for measuring the produced liquid of a coalbed methane well of the present invention includes a buffer tank 1, a liquid flow meter 3, a first connecting pipe 2 and a second connecting pipe 13. The buffer tank 1 is provided with a buffer tank inlet 5, a buffer tank liquid outlet 6, a gas outlet 7 and a solid phase outlet 8. The upper part of the buffer tank 1 is a cylinder and the bottom part is a cone 12, and the inside of the buffer tank 1 A spiral pipeline 10 is installed. One port of the flow meter 3 is connected to the buffer tank liquid outlet 6 through the first connecting pipe 2, the other port is connected to the second connecting pipe 13, and the other end of the second connecting pipe 13 is the measuring liquid outlet 9. The first connecting pipe 2, the liquid flow meter 3 and the second connecting pipe 13 together form a U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com