Fuel metering system and metering method of pt pump fuel injector

A technology of metering system and metering method, applied in the direction of charging system, instrument, measuring device, etc., can solve the problems of high impact of PT pump injector, non-continuous small flow, difficult accurate detection and measurement, etc. Accurate and effective value, low power consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

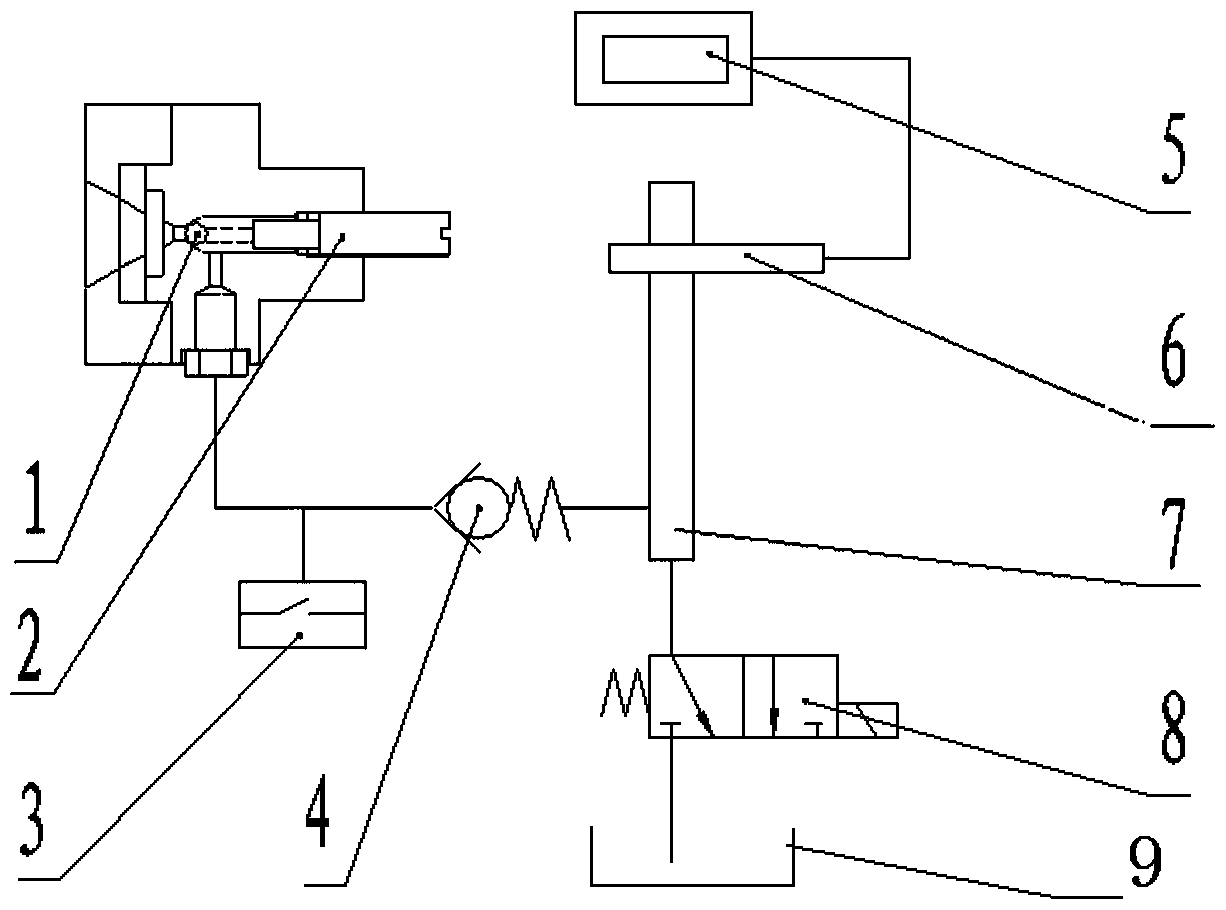

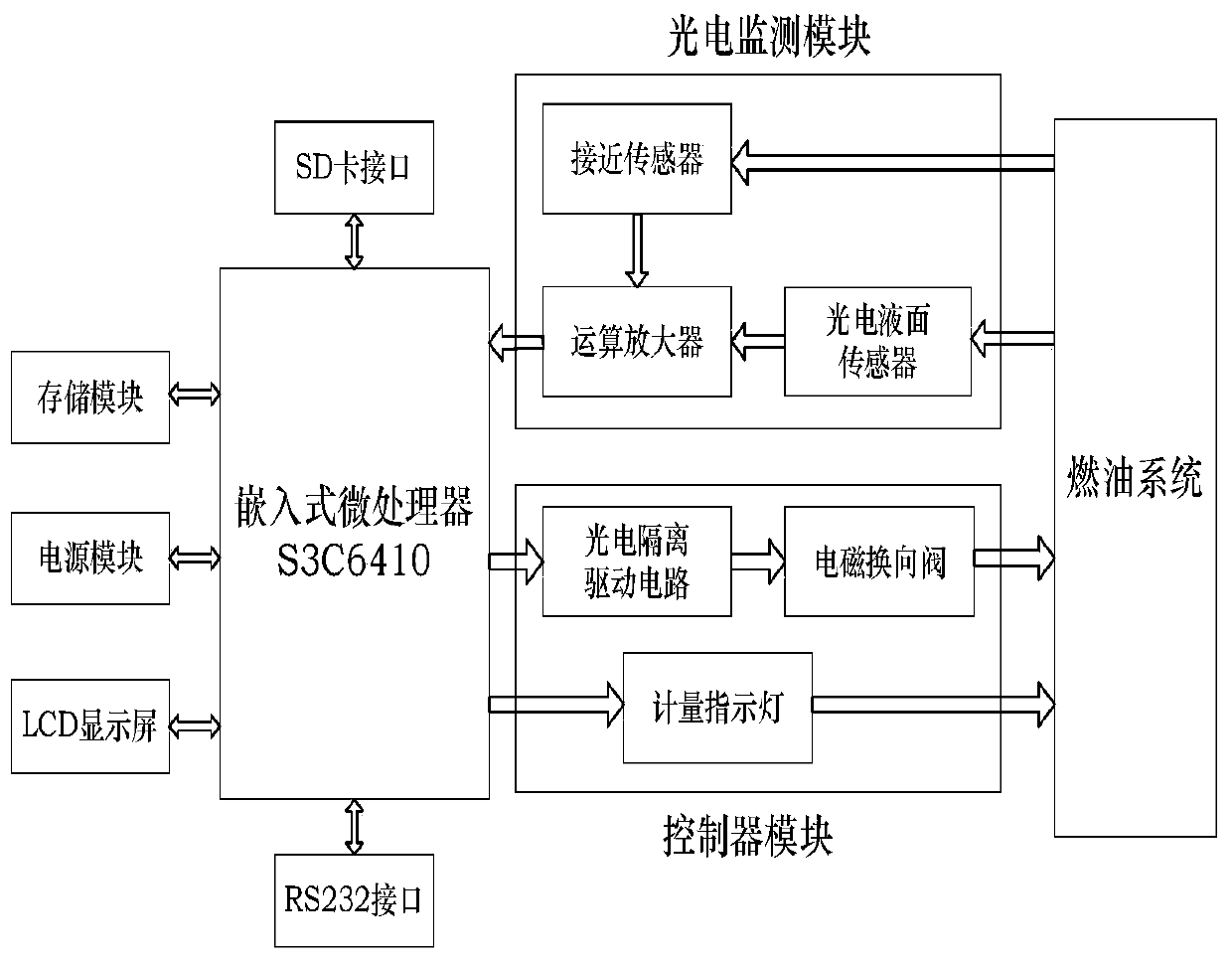

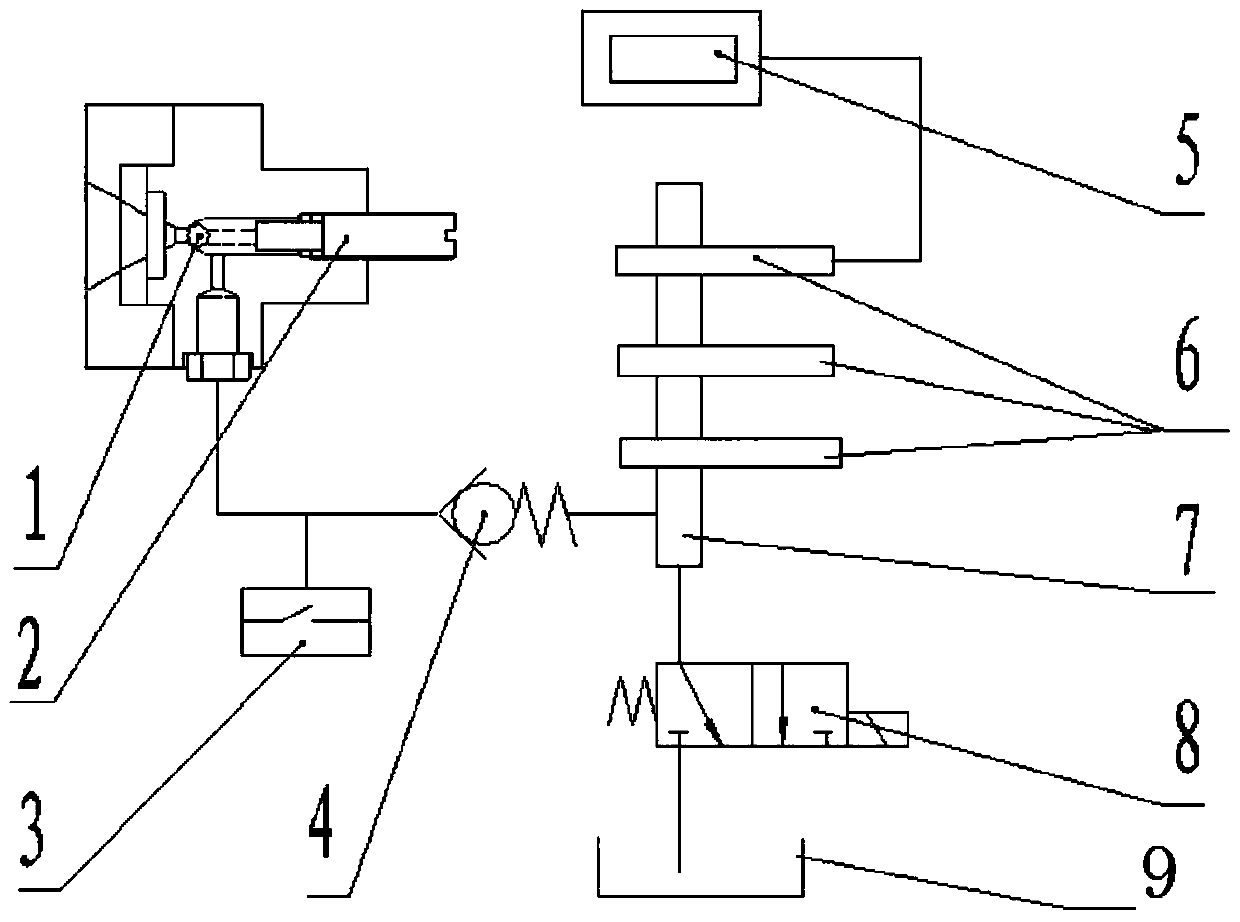

[0035] Such as figure 1 As shown, the metering system includes: a container 7 containing the amount of oil to be measured, a controller, an upper limit liquid level detection device 6 connected to the controller for detecting the upper limit height threshold of the amount of oil to be measured in the container, and a A counting device connected to the controller for counting the number of injections of the fuel injector; this container is connected to the fuel outlet of the fuel injector through a pipe.

[0036] The metering system also includes a fuel tank. After the fuel oil in the container is measured, it is discharged into the fuel tank from the oil outlet of the container through the oil discharge pipe. The oil discharge outlet of the container can be installed at the bottom of the container or installed on the side of the container. An oil discharge valve 8 is also installed on the oil discharge pipeline connected between the container and the fuel tank, and whether th...

Embodiment 2

[0070] The present invention also designs another PT pump fuel injector fuel metering system, the difference between this metering system and the PT pump fuel injector fuel metering system described in the above-mentioned embodiment 1 is that the metering system in embodiment 1 The liquid level detection device in the container is replaced by a fuel quantity detection device that can follow the change of the fuel liquid level in the container and detect the amount of oil in the container in real time. The fuel quantity detection device is connected with the controller to detect the quantity of fuel sprayed into the container by the fuel injector at the set injection times.

[0071] The oil quantity detection device in this embodiment is a float level gauge, which can monitor the liquid level height of the oil quantity in the container in real time with the change of the oil quantity in the container, and the float level gauge has a large measurement range and high sensitivity, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com