Metering device of automatic analysis meter

A technology for automatic analyzers and metering devices, which is applied to the analysis of materials and instruments, and can solve the problems of reducing the working efficiency of automatic analyzers, false detection of dirt photoelectric sensors, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

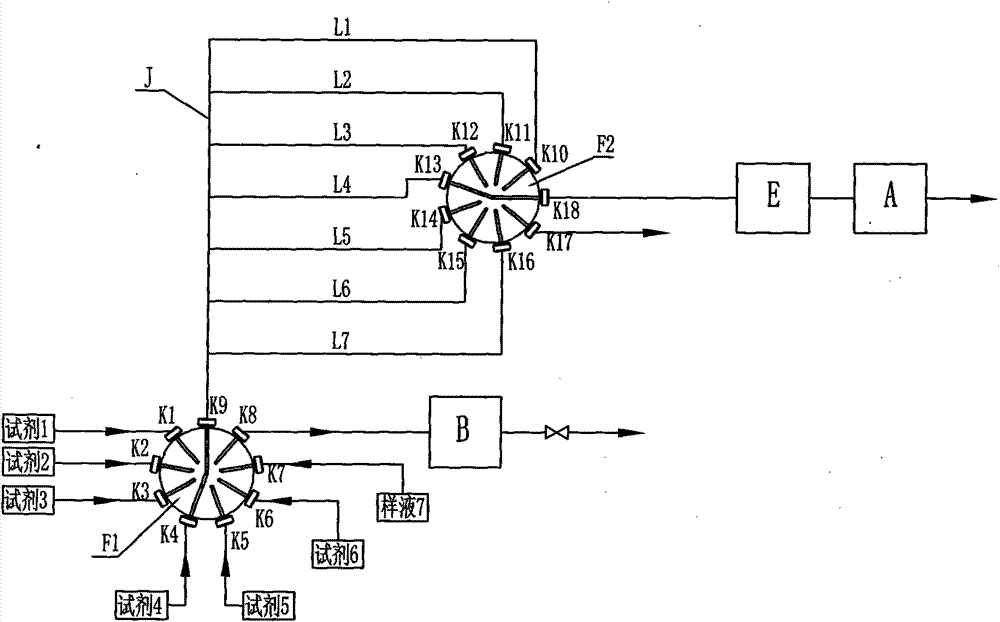

[0040] The automatic analyzer measuring device of the present embodiment is as figure 1 As shown, there are two control valves including a liquid flow driver, a first control valve and a second control valve; the liquid flow driver uses a peristaltic pump A, and the control valve uses a selection valve, that is, the first selection valve F1 and the second selection valve F2. A liquid flow storage and transportation channel is connected between the first selection valve F1 and the second selection valve F2, and the liquid flow storage and transportation channel is the inner pipeline of seven delivery pipes L1, L2, L3, L4, L5, L6, L7. Either hose or tube can be used.

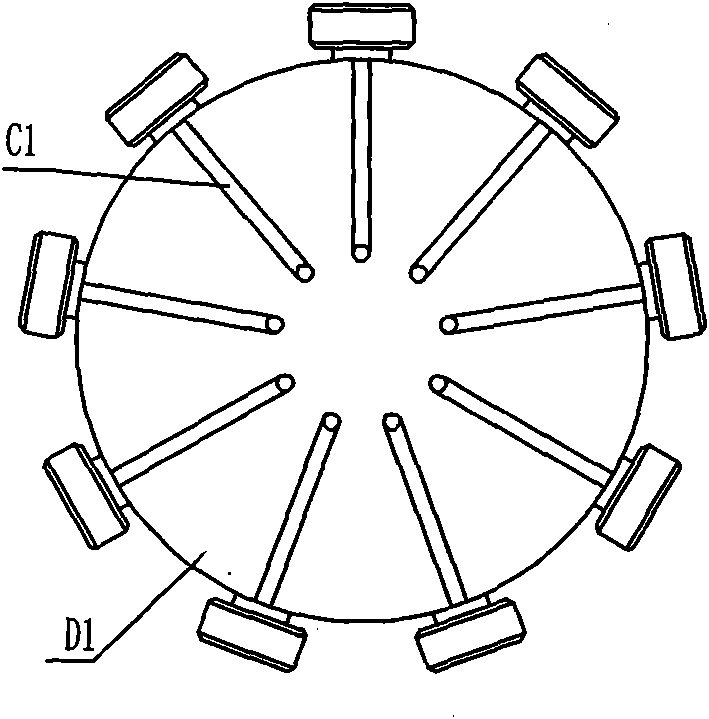

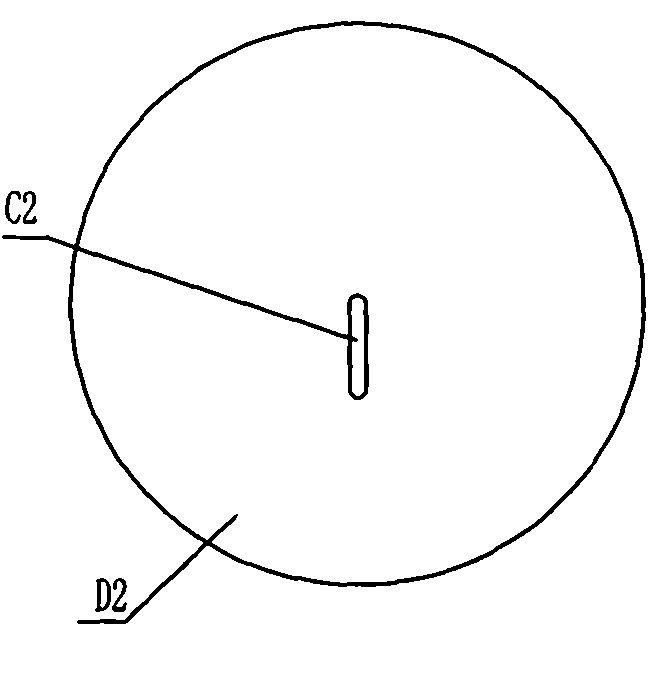

[0041] Such as figure 2 and image 3As shown, the two selector valves F1 and F2 are both composed of the fixed piece D1 and the moving piece D2 pressed against each other, the fixed piece D1 is formed with a channel C1, and the center of the moving piece D2 is formed with a notch C2; When the moving piece rota...

Embodiment 2

[0048] The automatic analyzer metering device of the present embodiment is the transformation on the basis of embodiment one, as Figure 4 As shown, the difference except that it is the same as Example 1 is that the proportions between the seven samples are the same, and the actual different proportions are only four (i.e. L1: L2: L3: L4), so the delivery pipe There are only four (namely L1, L2, L3, L4), and there are only four passages (namely K10, K11, K12, K13) corresponding to the connection between the second selector valve F2 and the delivery pipe. When measuring, samples with the same ratio can reuse the same delivery tube, for example, reagents 1, 2, 3 and sample liquid 7 have the same proportion and the metering volume is the same as delivery tube L1, then the delivery tube L1 can be reused to measure separately Four samples of reagents 1, 2, 3 and sample solution 7. The specific metering process is the same as that in the embodiment, and will not be repeated here. ...

Embodiment 3

[0050] The automatic analyzer metering device of this embodiment is a transformation based on the first embodiment, except that it is the same as the first embodiment: the seven delivery pipes are replaced by the delivery block SK, and the liquid flow storage and transportation channel runs through the whole delivery Seven vias of block SK.

[0051] The first structure of the transport block SK is as Figure 5 , Figure 6 and Figure 7 As shown, the conveying block SK is a cuboid, and there are seven circular through holes L1', L2', L3', L4', L5', L6', L7' spaced from top to bottom in the conveying block SK. , the first common channel J is set on one end surface of the conveying block SK.

[0052] The second structure of the conveying block SK is as Figure 8 , Figure 9 and Figure 10 As shown, the conveying block SK is a cylinder, and seven circular through holes L1", L2", L3", L4", L5", L6", L7" are formed in the conveying block SK along its circumferential section. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com