Powder coating packaging machine for screening particles

A powder coating and packaging machine technology, applied in packaging, transportation and packaging, filtering and screening, etc., can solve the problems of poor screening effect, low work efficiency, long screening time, etc., achieve good use effect, easy operation, and improve screening efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

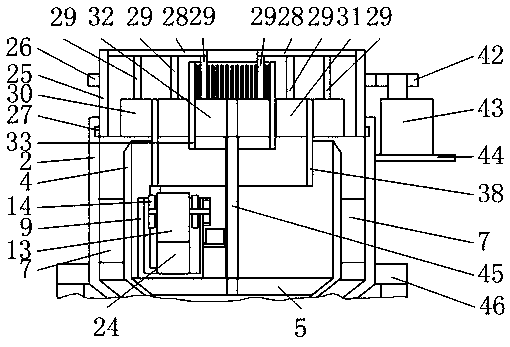

[0048] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

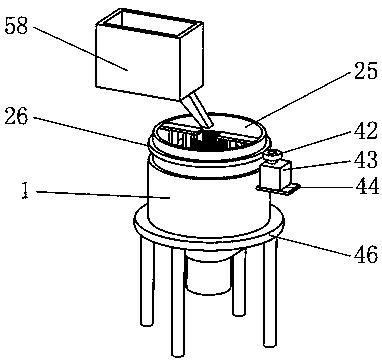

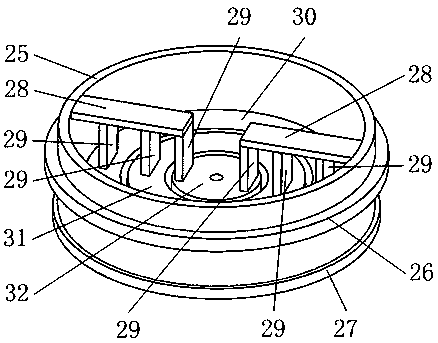

[0049] Such as figure 1 , 2 As shown, it includes the blanking ring cylinder mechanism 1, the transmission mechanism 8, the rotating cylinder 25, the gear ring 26, the rotating positioning ring 27, the first connecting plate 28, the second connecting plate 29, the first rotating ring block 30, the second Rotating ring block 31, rotating round block 32, fine screen drum 33, second rack 35, coarse screen drum 38, first rack 40, third gear 42, electric drive module 43, third fixed base 44, feeding Pipe 45, fixed support 46, wherein as figure 1 , 2 As shown, the blanking ring barrel mechanism 1 with the transmission mechanism 8 installed inside is fixedly installed on the fixed br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com