Method for producing tar, semi-coke and synthetic fuel gas by low-degree of coalification powdered coal

A synthetic fuel, low coalification technology, applied in the production of high-quality tar, semi-coke and synthetic fuel gas, can solve the problems of low comprehensive thermal efficiency, environmental pollution, low yield and quality of synthetic fuel gas and tar, and achieve three wastes Less emissions and less environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] Example 1: Production of tar, semi-coke and synthetic fuel gas using pulverized coal with low degree of coalification

[0109] The coal quality of the pulverized coal with low coalification degree in northern Shaanxi used in this example was analyzed by the methods stipulated in GB212-91 and GB476-91. The coal quality analysis results are listed in Table 1 below.

[0110] Table 1: Coal quality analysis results, expressed in weight %

[0111]

[0112] Use an industrial sieve with a pore size of 12mm to screen the above-mentioned low-coalification pulverized coal in northern Shaanxi that has been crushed, and return the unscreened large-grained coal to the crusher for crushing until it passes through a 12mm industrial sieve, and collect the sieved pulverized coal for processing Utilization, the overall raw material particle size is freely broken distribution.

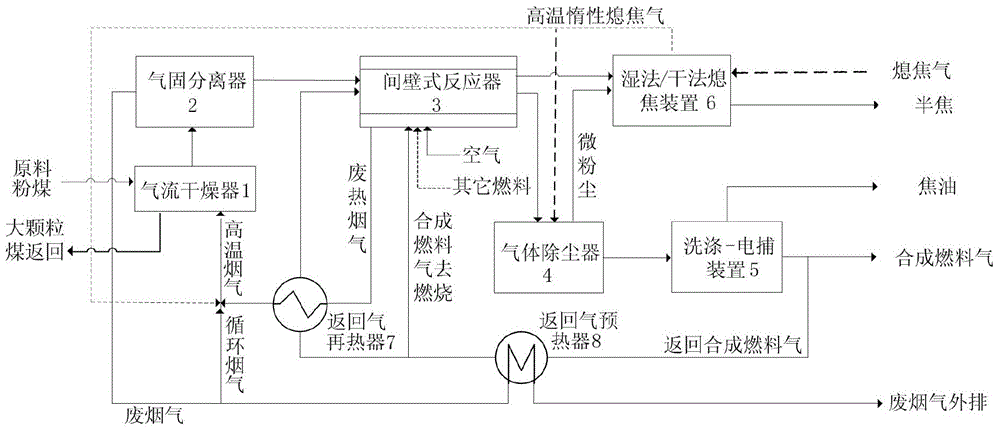

[0113] The implementation steps of this embodiment are as attached figure 1 shown. The specific implement...

Embodiment 2

[0122] Example 2: Production of tar, semi-coke and synthetic fuel gas using pulverized coal with low degree of coalification

[0123] The implementation mode of this embodiment is the same as that of Example 1. The low-coalification degree pulverized coal in northern Shaanxi used in Example 1 is added to the airflow dryer 1 through a conveying device at a rate of about 1150 kg / h, and the air flow into the airflow dryer 1 is adjusted. The circulating flue gas flow rate is 1589.83kg / h, and the high-temperature flue gas flow rate reaches 3432.96kg / h (temperature ~ 510°C). The high-temperature flue gas and the raw pulverized coal contact and exchange heat in the airflow dryer. The temperature of the pulverized coal coming out of the airflow dryer 1 is about 180°C, and the free moisture contained therein is reduced to about 1.5% by weight. The raw coal with large particles of about 23kg / h is automatically screened out by the air dryer 1 and then discharged from the bottom of the ai...

Embodiment 3

[0132] Example 3: Production of tar, semi-coke and synthetic fuel gas using pulverized coal with low degree of coalification

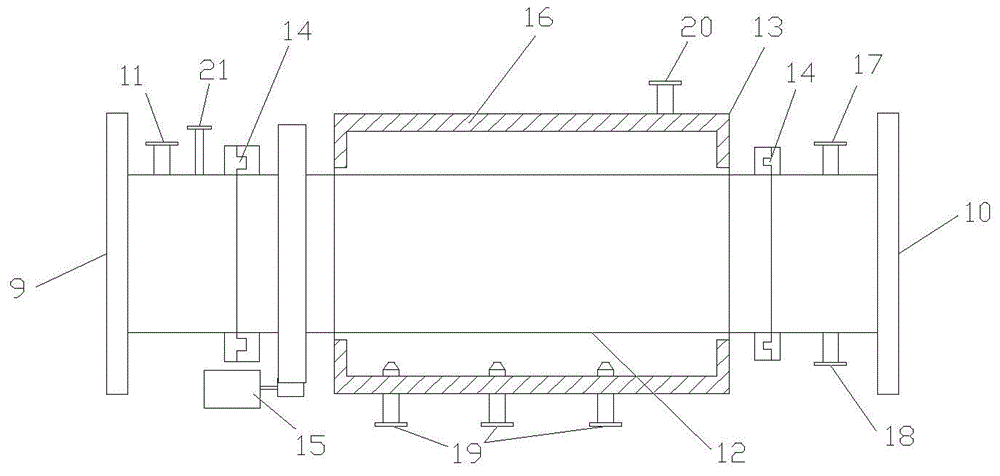

[0133] This embodiment uses the same raw materials as in Example 1, and is carried out in the same manner as in Example 1, except that the return synthetic fuel gas is not introduced into the inner cylinder 12 of the partition wall reactor 3, and the wet / dry coke quenching device adopts dry coke quenching way, the high-temperature flue gas sent to the air flow dryer 1 is part of the high-temperature nitrogen gas produced by the dry coke quenching device, the waste heat flue gas discharged from the partition wall reactor 3 and a part of the waste flue gas discharged from the gas-solid separator 2 ( That is, the mixture composed of circulating flue gas), the gas blowback gas of the gas dust collector 4 in this embodiment adopts the high-temperature nitrogen gas produced by the dry coke quenching device.

[0134]Add the pulverized coal with low coalificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com