Hydraulic pressure braking clamp device

A hydraulic brake and caliper technology, applied in the field of hydraulic brake calipers, can solve problems such as troublesome replacement of brake pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

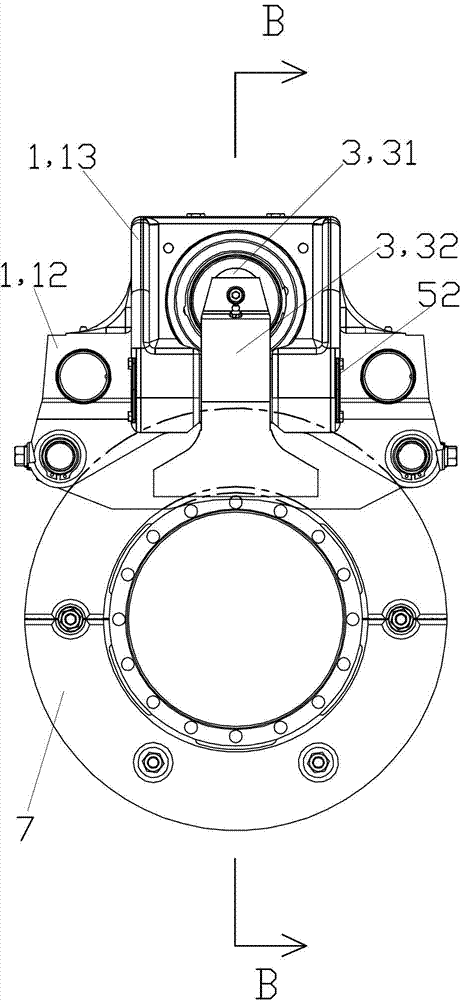

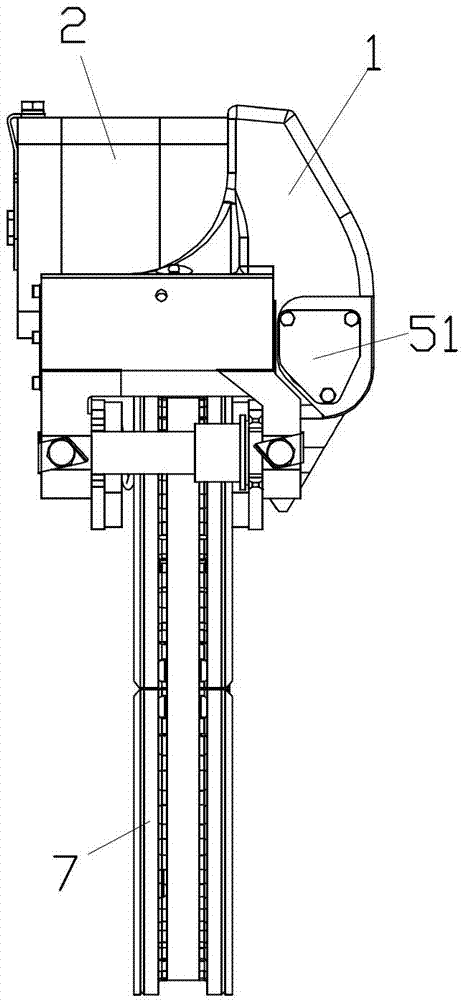

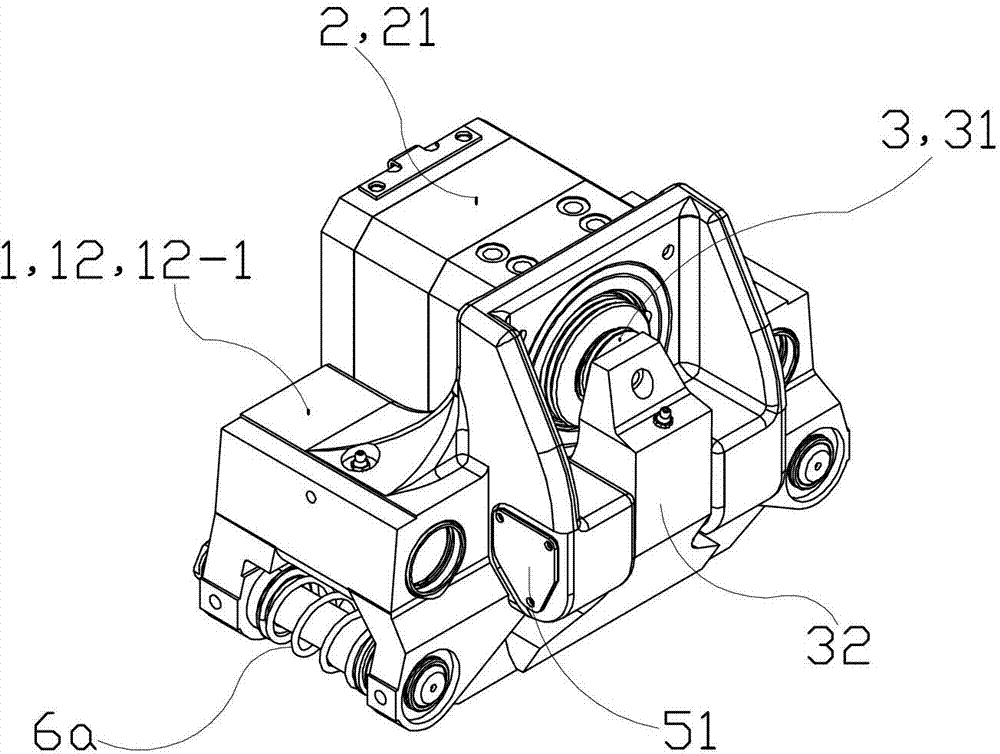

[0132] See Figure 1 to Figure 4 and Figure 7 , The hydraulic brake caliper device of this embodiment is mainly composed of a caliper base 1 , a brake cylinder 2 , a lever member 3 , a lever pin 4 , a left cover 51 , a right cover 52 and a caliper assembly 6 . The lever member 3 is mainly composed of a pressure plate 31 and a lever 32 .

[0133] See Figure 5 and Image 6 , The clamp base 1 is a cast steel integral part, mainly composed of a brake cylinder installation part 11, a brake pin installation part 12, a lever pin left end installation part 13 and a lever pin right end installation part 14.

[0134] The brake cylinder mounting part 11 is mainly composed of a base plate 11-1 and a mounting plate 11-2. The base plate 11-1 is arranged horizontally. The mounting plate 11-2 is arranged vertically, and its body is provided with front and rear through holes as the central hole 11-3 of the brake cylinder installation part 11, and the body of the mounting plate 11-2 is a...

Embodiment 2)

[0233] See Figure 30 and Figure 31 , The remaining parts of this embodiment are the same as those in Embodiment 1, except that the left brake pin 61a and the right brake pin 61b each have only one pin hole 61-1 located at the rear end. Corresponding to the brake pad pin of this structure, in this embodiment, the threaded pins only have left rear threaded pin 67a2 and right rear threaded pin 67b2, but no left front threaded pin 67a1 and right front threaded pin 67b1; the anti-loosening buckle only has left rear anti-loosening Buckle 66a2 and right rear anti-loosening buckle 66b2, but without left front anti-loosening buckle 66a1 and right front anti-loosening buckle 66b1. This embodiment adopts the brake pin of this structure, which makes the replacement of the brake more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com