Method and device for automatic screening of detonator delay body

A technology of delaying body and automatic screening, applied in detonators, attack equipment and other directions, can solve the problems of delayed drug leakage, failure to meet product delaying requirements, ignition delaying body and other problems, so as to avoid hidden dangers of production safety and uncontrollable quality. , the effect of high production safety and efficiency, safety and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

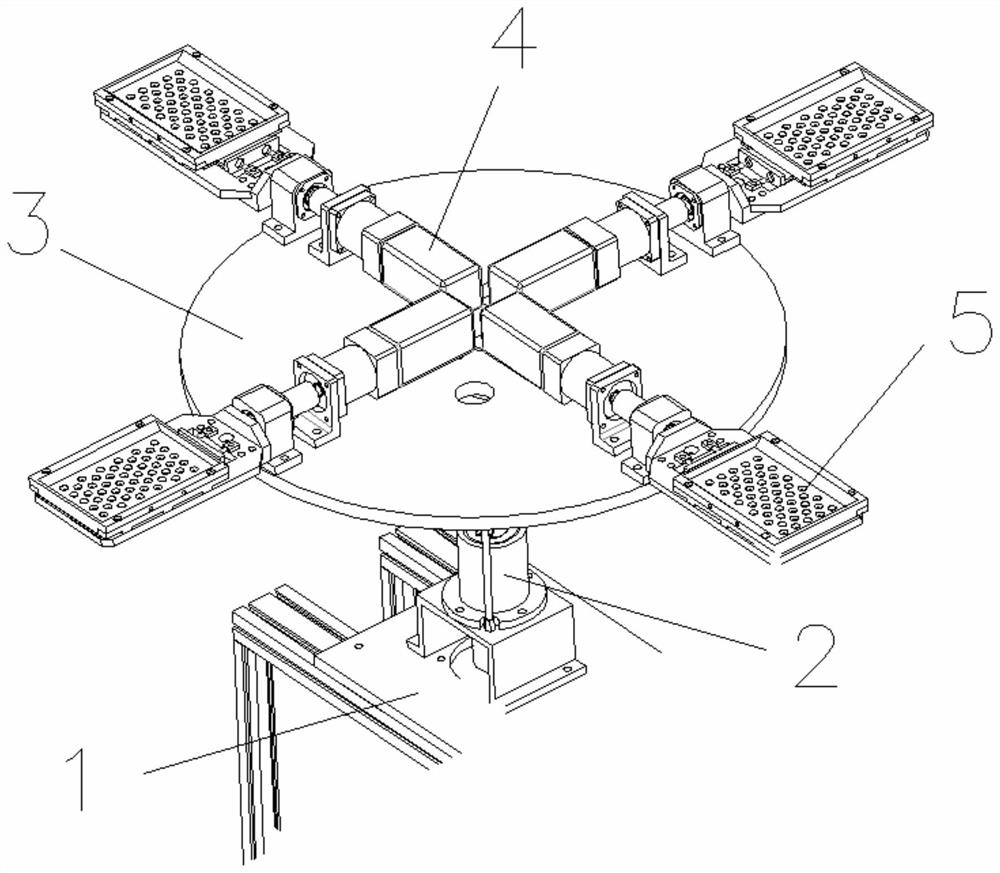

[0010] Embodiment 1 of the present invention: the automatic screening method of the detonator delay body adopts a circular circulation station, and the stations are set in turn as the upper delay body station, the inverted delay body station and the loading station; first the delay body is placed on the upper Put the delay body station into the sieve row mould, and shake it left and right before the screen row mold enters the inverted delay body station, so that the delay body in the screen row mold is sieved into the hole of the screen row mold and reaches the inverted delay body After positioning, the sieve row mold is turned 90° from the horizontal position, and the sieve row mold is turned over again after returning to its position. Pour out the excess extension body in the sieve mould, and enter the filling station after finishing pouring the extension body. At the filling station, the extension body enters the extension body transfer mold from the sieve row mold to comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com