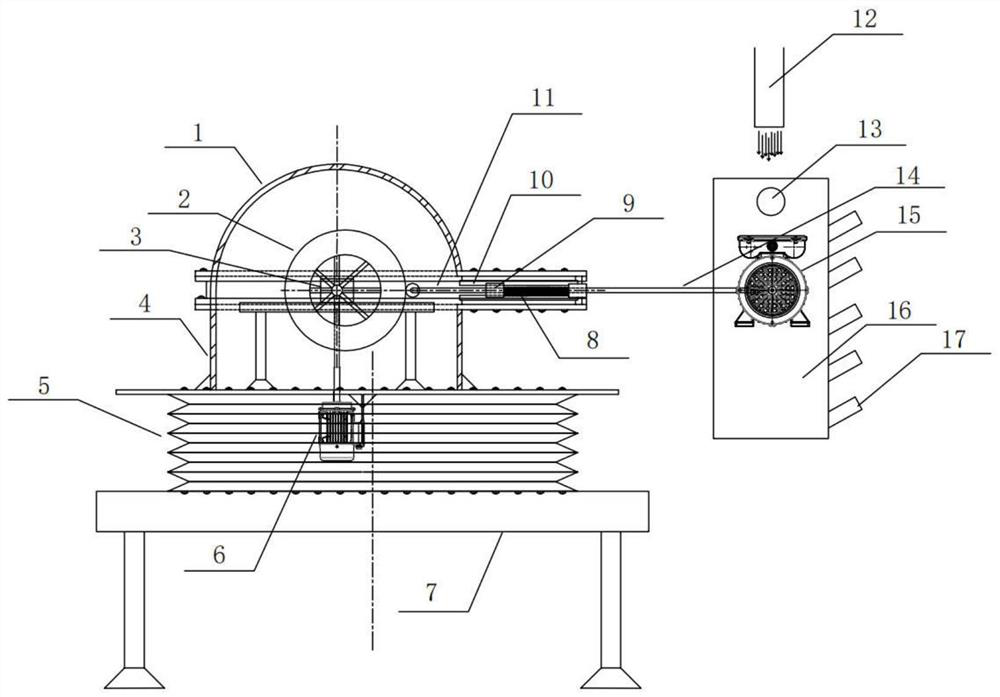

Arm type automatic screening equipment and method for screening granularity of ore pulp in dressing plant through arm type automatic screening equipment

A technology of automatic screening and sorting equipment, applied in chemical instruments and methods, sieving, solid separation, etc., can solve the problems of insufficient depth screening and low efficiency, and achieve the effect of satisfying industrial production, simple process and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Utilize the arm-type automatic screening equipment of the present invention and the method for processing ore pulp in a concentrator to process the ore pulp of a mine in Chenzhou, Hunan, open the pulp inlet, rinse water and start the swing system. The swing process lasts for 15 minutes, and the pulp is discharged after the swing is stopped. and collected, and weighed after drying for each particle size to obtain -800 mesh 417.5g, +800 mesh ~ -400 mesh 51.2g, +400 mesh ~ -200 mesh 33.9g, +200 mesh 225.7g, the proportion of each particle size - 800 mesh 57.3%, +800 mesh to -400 mesh 7.03%, +400 mesh to -200 mesh 4.65%, +200 mesh 30.9%. On-site workers manually sieved 53.9% of the grades at -800 mesh, 7.87% at +800 mesh to -400 mesh, 5.23% at +400 mesh to -200 mesh, and 33% at +200 mesh. The overall screening effect was close.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com