Screw vibration screening machine

A vibration screening machine and screw technology, applied in the field of mechanical equipment, can solve the problems of low efficiency of manual screening, increase the manufacturing cost of a single screw, poor overall effect, etc., and achieve the effect of efficient screening, perfect function and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

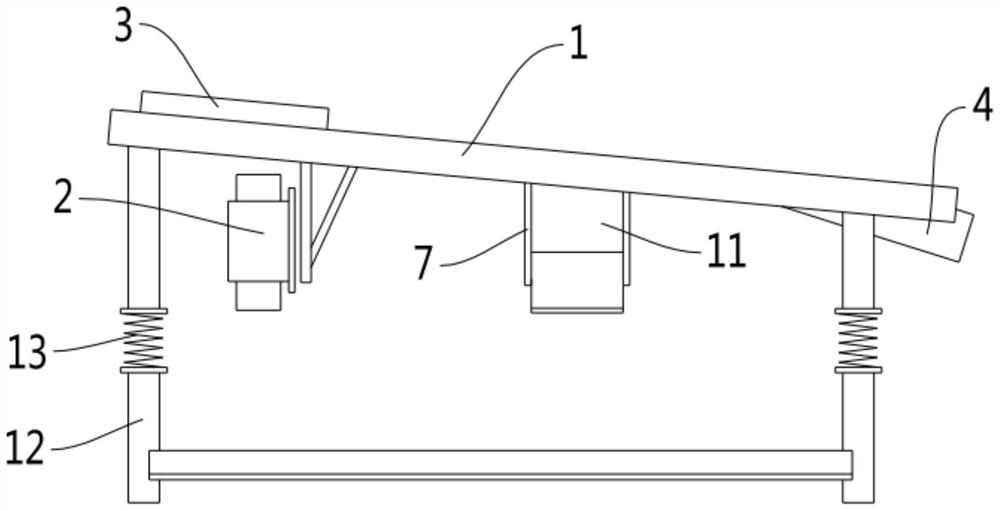

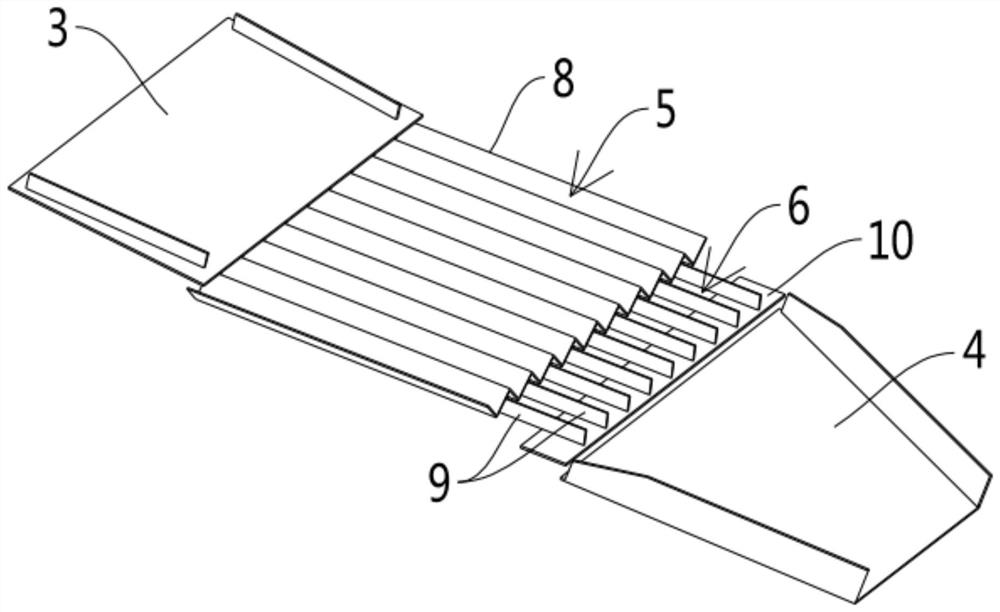

[0014] See figure 1 with figure 2 As shown, the screw vibration screening machine involved in this embodiment includes a frame 1, on which a vibration motor 2 is provided, and the frame 1 is also provided with a feed channel 3 and a discharge channel 4. A number of guide channels 5 arranged parallel to each other are provided between the feeding channel 3 and the discharging channel 4. One end of the guide channel 5 is connected to the feeding channel 3, and the other end is connected to the discharging channel 4. The bottom of the channel 5 is provided with a screening hole 6, and a receiving groove 7 is provided under the screening hole 6.

[0015] In this embodiment, the vibrating motor 2 is turned on, and the mixed long and short screws are placed upside down in the feeding channel 3. After vibration, the screws are fed into the guide channel 5. Because the guide channel 5 is narrow and long, the screws are swung The component slides along its length. When all the screws pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com