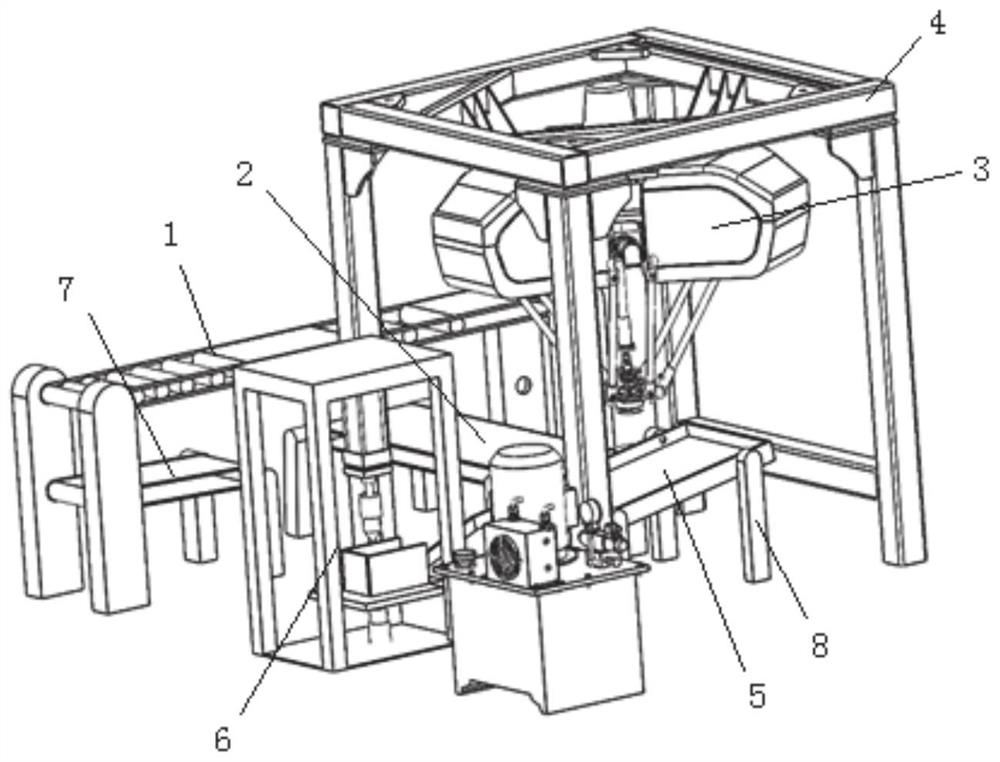

Rock-soil block hardness testing device and working method

A technology of hardness testing and soil blocks, which is applied in the direction of measuring devices, testing material hardness, strength characteristics, etc., can solve the problems of unfavorable working environment for workers, harsh working environment, high labor intensity, etc., and achieve short test time and low labor intensity , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

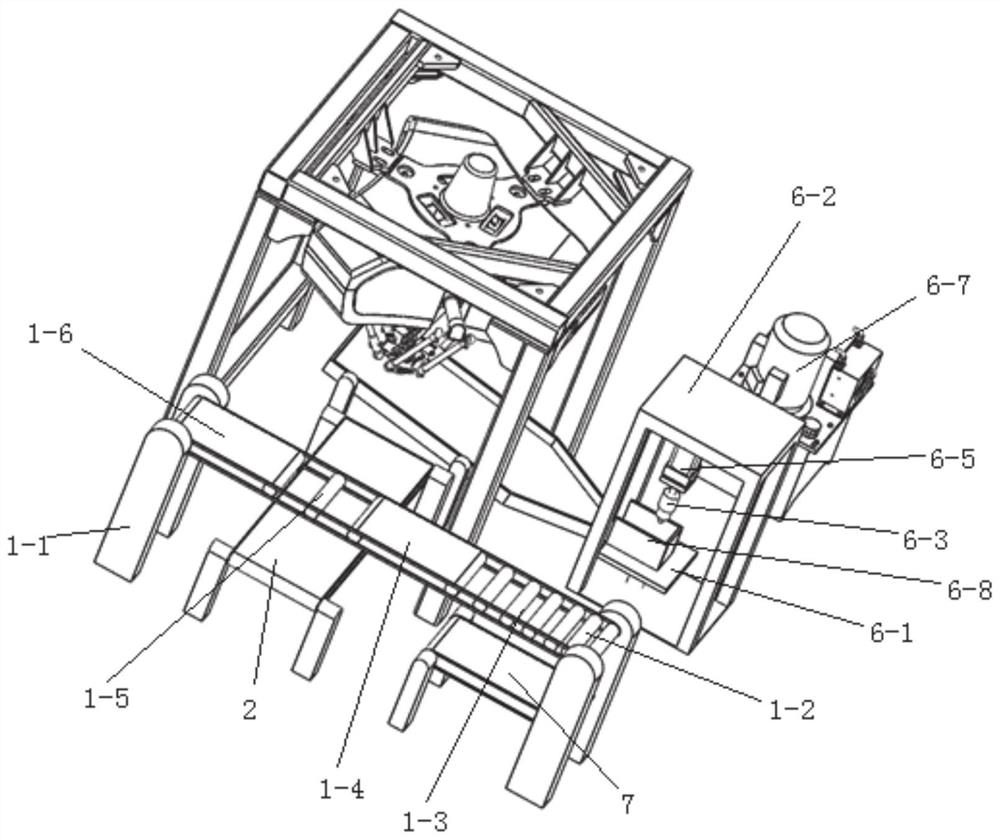

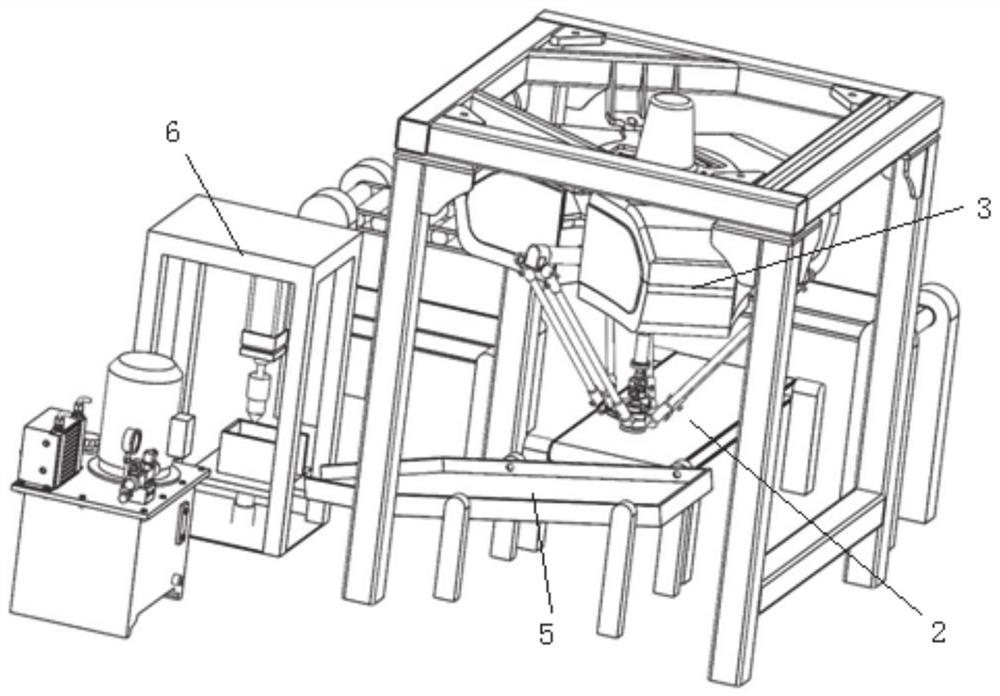

[0053] This embodiment discloses the working method of the rock and soil block hardness testing device described in Example 1: pour the unscreened rock and soil blocks into the screening mechanism, and the rollers in the first area rotate to drive the rock and soil blocks to move. The rock and soil blocks are screened, and the screened rock and soil blocks enter the transition area, and the rest of the rock and soil blocks fall from the space between the two adjacent rollers in the first area and fall into the second conveying mechanism. The soil block is sent into the second area, and the rock soil block falling from the space between two adjacent rollers in the second area is the rock soil block that meets the test particle size requirement, and falls into the first conveying mechanism, and the first conveying mechanism The unfallen rock and soil blocks screened out in the second area enter the third area and are transported by the conveyor belt in the third area. The paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com