Fitting cutting device

A technology for cutting devices and accessories, which is applied in the direction of sawing machine devices, metal sawing equipment, metal processing, etc., can solve the problems of reducing work efficiency, increasing the labor intensity of operators, and the incision of guide shaft tubular fittings are not neat, etc., to improve work efficiency. Improve efficiency, ensure stability, and reduce work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

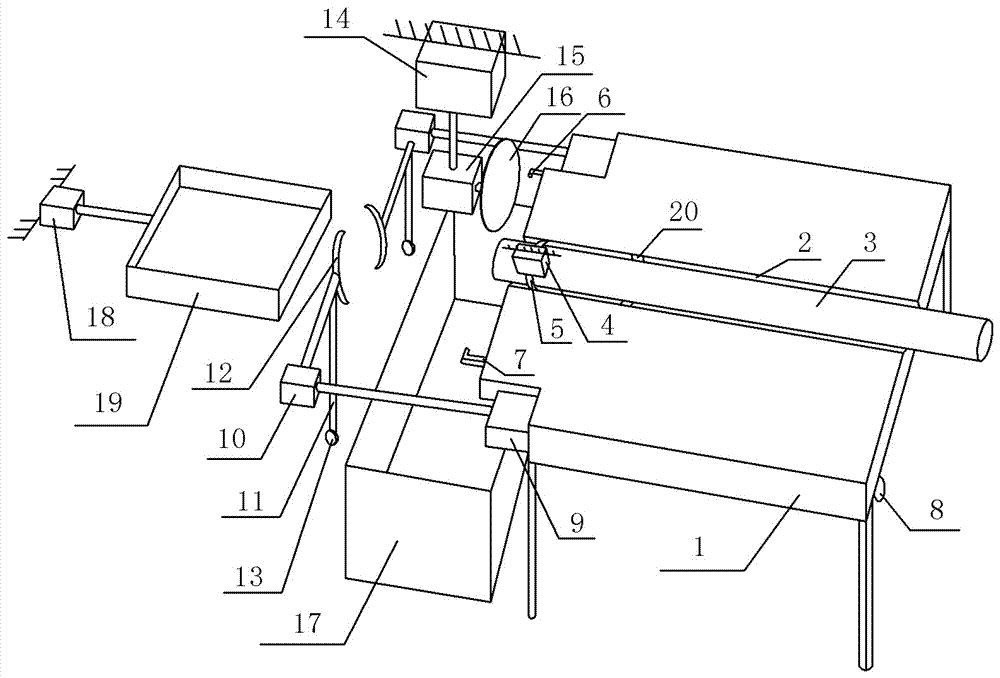

[0014] The reference signs in the accompanying drawings include: support platform 1, through slot 2, tubular fitting 3, No. 5 cylinder 4, auxiliary gripper 5, infrared emitter 6, infrared receiver 7, LED light 8, No. 1 cylinder 9 , No. two cylinder 10, column 11, jaw 12, universal wheel 13, No. three cylinder 14, motor 15, circular saw 16, collection box 17, No. four cylinder 18, collection box 19, pressure sensor 20.

[0015] like figure 1 A cutting device for accessories is shown, which includes a support table 1, a cutting mechanism, a material receiving mechanism and two clamping mechanisms. Fitting 3; No. 5 cylinder 4 is fixed on the frame above the slot 2, and the lower end of the output shaft of No. 5 cylinder 4 is fixed with auxiliary jaw 5, which can be used to compress the tubular fitting 3. An infrared emitter 6 and an infrared receiver 7 are relatively arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com