Ammonia selective catalytic reduction method for diesel injected by assistance of compressed natural gas

A technology for compressing natural gas and selective catalytic conversion, which is applied in chemical instruments and methods, separation methods, climate sustainability, etc. It can solve the problems of environmental and human harm, nitrogen oxide emissions, etc., and achieve the effect of improving the purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Compressed natural gas is mixed with urea solution twice to realize atomization and spraying aid

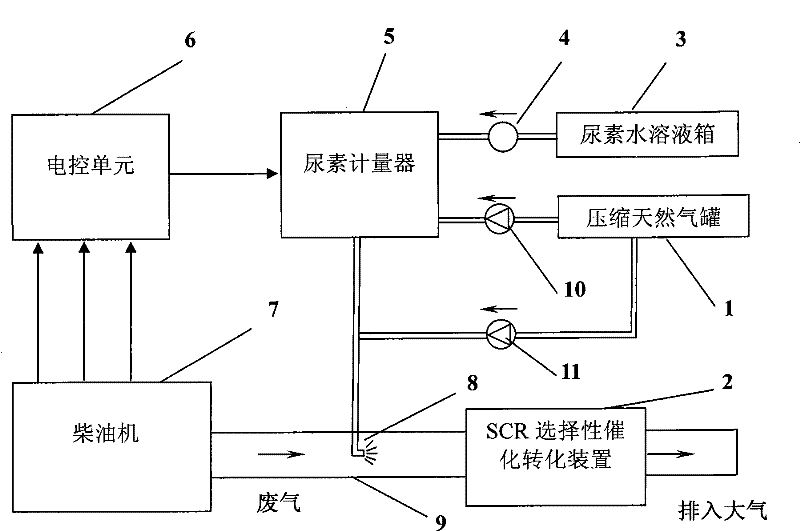

[0033] Press the following parts to figure 1 Connect as shown. Such as figure 1 As shown, the technical device consists of compressed natural gas tank 1, SCR selective catalytic reduction device 2, urea aqueous solution tank 3, urea pump 4, urea meter 5, electronic control unit 6, urea nozzle 8, primary valve 10, secondary valve 11 and pipeline composition.

[0034] When this technical device is working, the urea solution (32.5% urea concentration) in the urea aqueous solution tank 3 is pumped out, pressurized to between 150kPa~300kPa, and sent to the urea meter 5 after filtering. The compressed natural gas in the compressed natural gas tank 1 has a pressure range of 150kPa to 300kPa, wherein the compressed natural gas enters the urea meter 5 through the primary valve 10 and is mixed with the urea solution; the volume mixing ratio of the natural gas and the u...

Embodiment 2

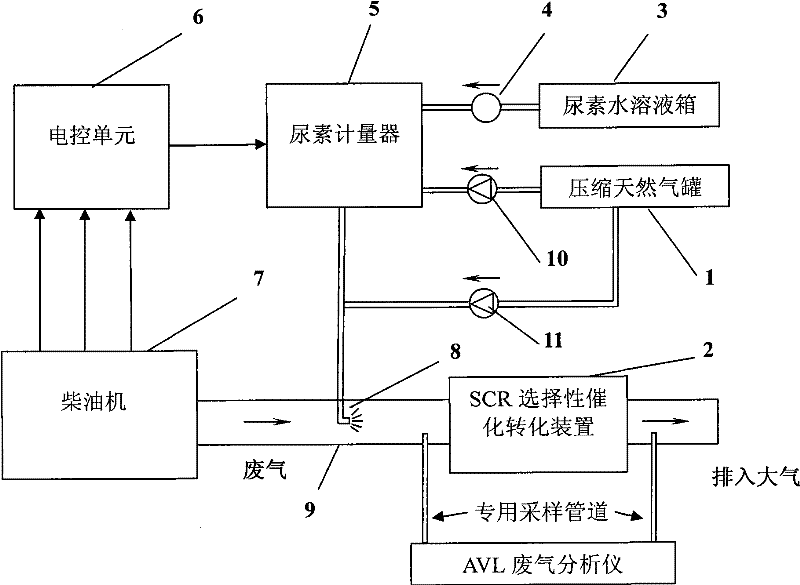

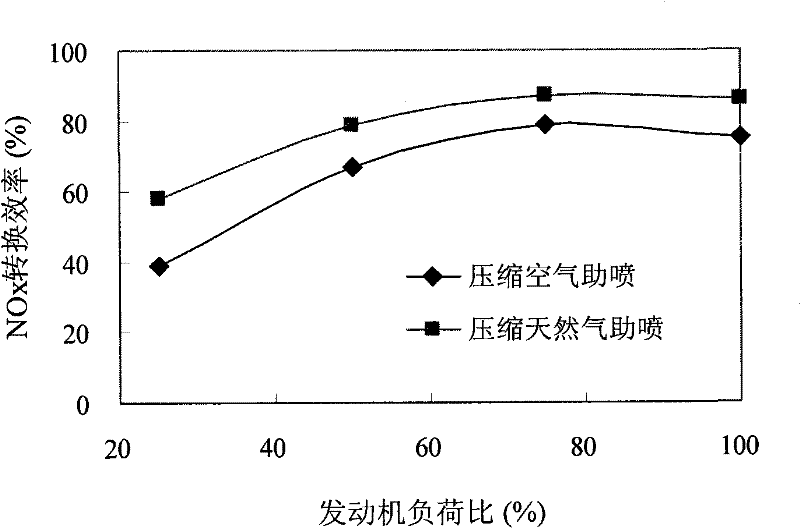

[0035] Example 2: Evaluation of the effect of CNG-assisted injection on reducing NOx emissions

[0036]Using an electronically controlled high-pressure common rail direct injection diesel engine as a prototype, the ammonia selective catalytic reduction method of compressed natural gas assisted injection was used to evaluate the conversion efficiency of NOx, and compressed air assisted injection was used as a comparison. The diesel engine was bench mounted for steady state operation to provide reproducible and stable NOx emissions. The rotating speed of controlling this engine is 2000r / min, and load ratio is respectively 25%, 50%, 75%, 100%, to provide a series of SCR device inlet temperature (the temperature is respectively 243 ℃, 306 ℃, 354 ℃, 422 ℃ ) and NOx concentrations (concentrations are 210ppm, 480ppm, 830ppm, 970ppm, respectively). Use a special AVL exhaust gas analyzer to measure the NOx emissions of diesel engines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com