Patents

Literature

44 results about "Volume mixing ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The volume mixing ratio measures the volume of a substance (the solute) contained within the unit volume of a mixture (the solution). It is the ratio of the partial volume of the solute to the volume of the mixture.

Methods for applying sound dampening and/or aesthetic coatings and articles made thereby

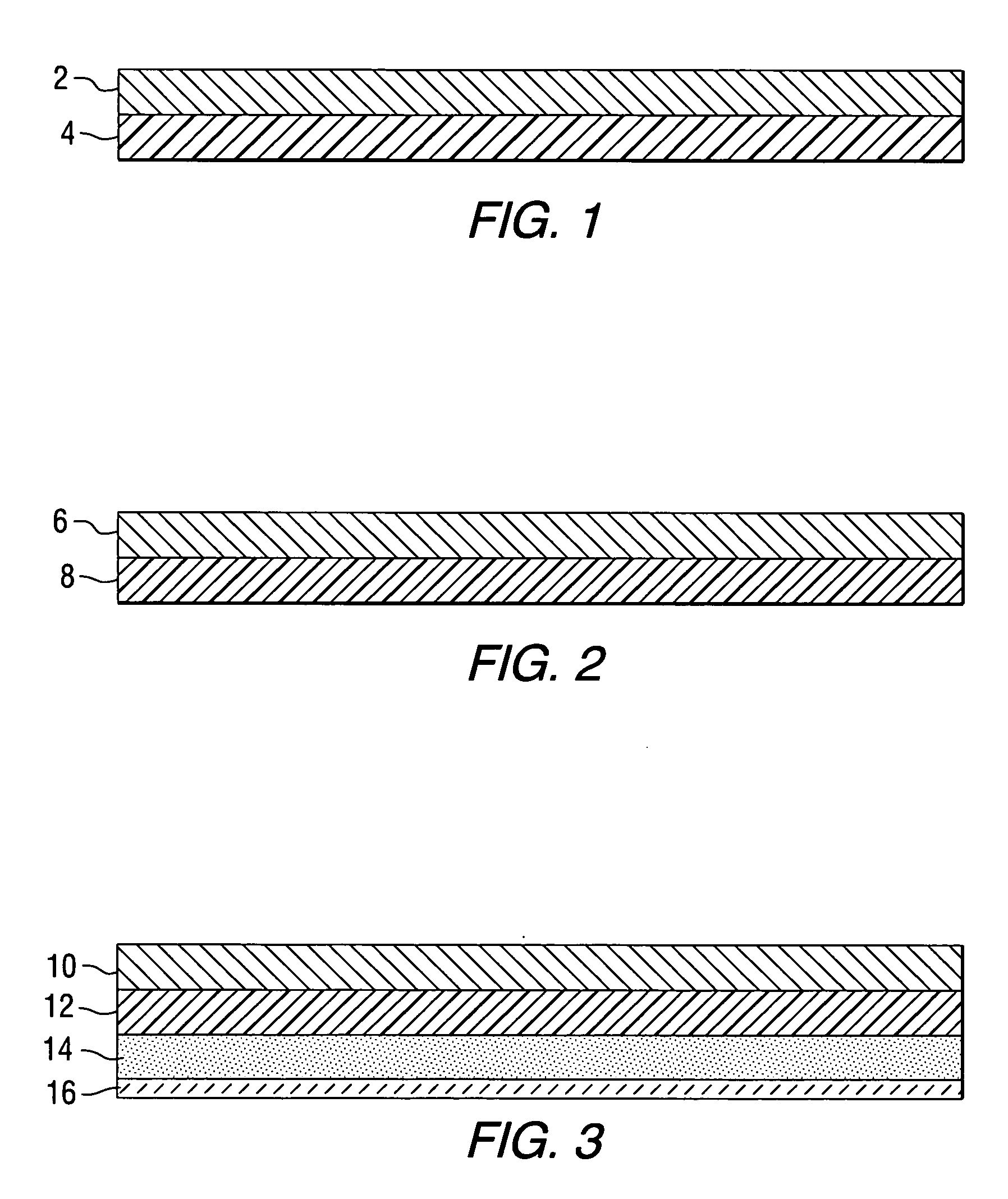

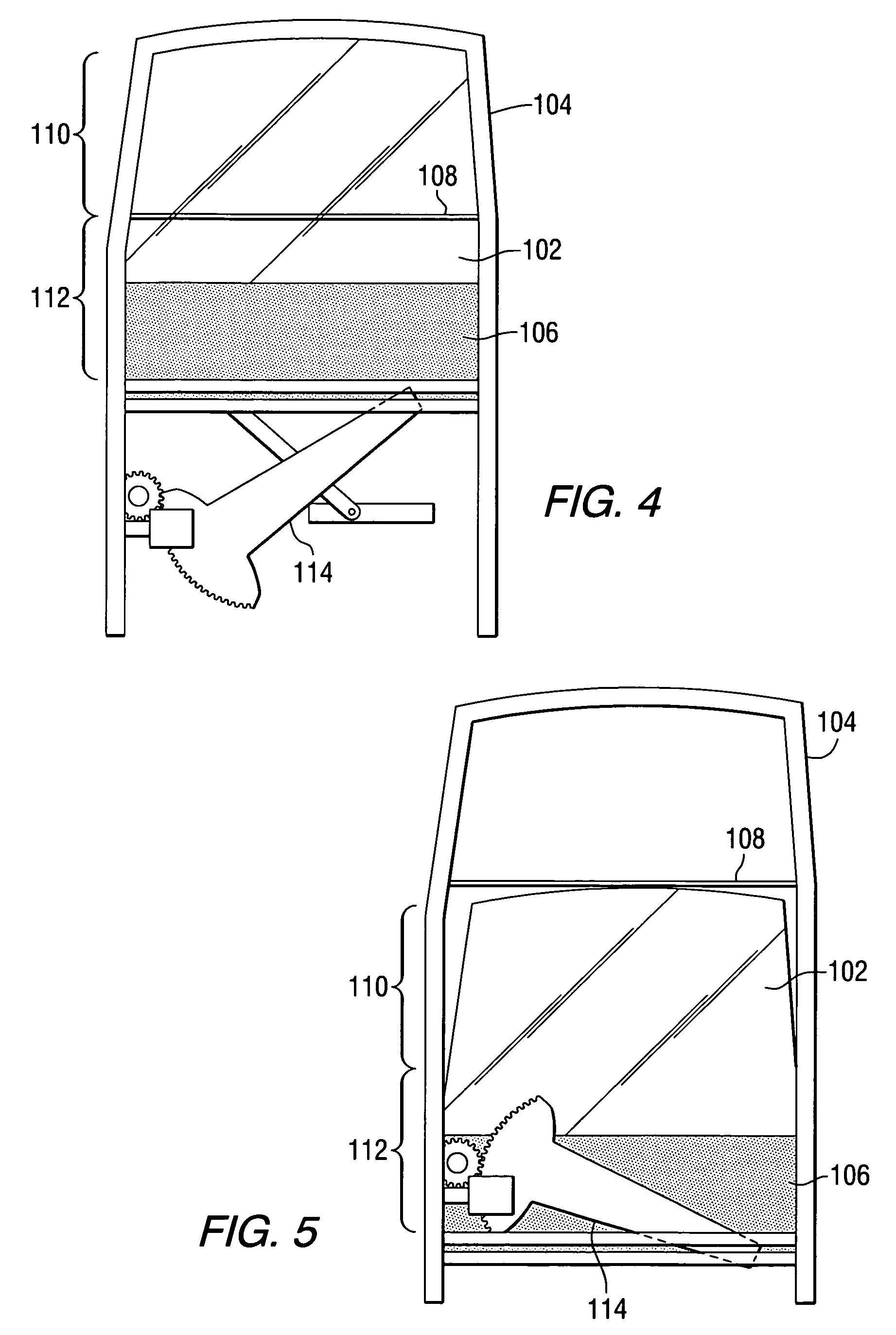

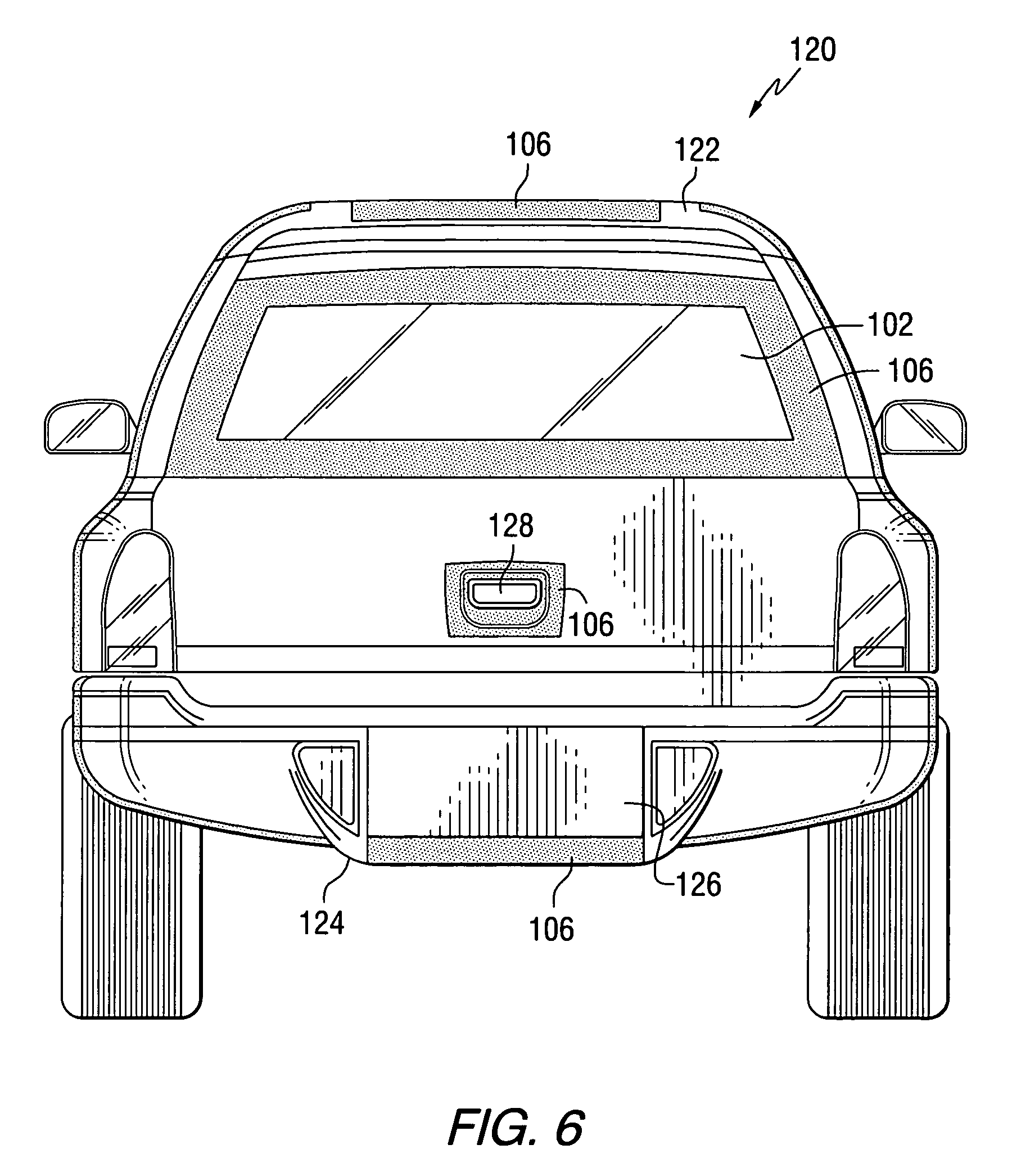

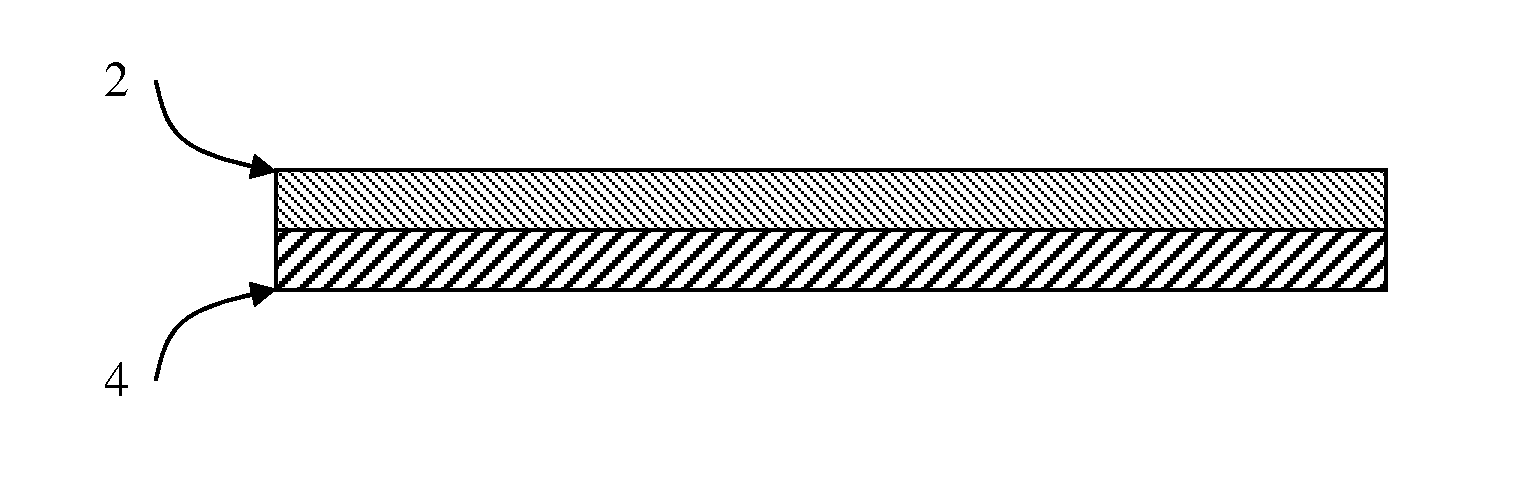

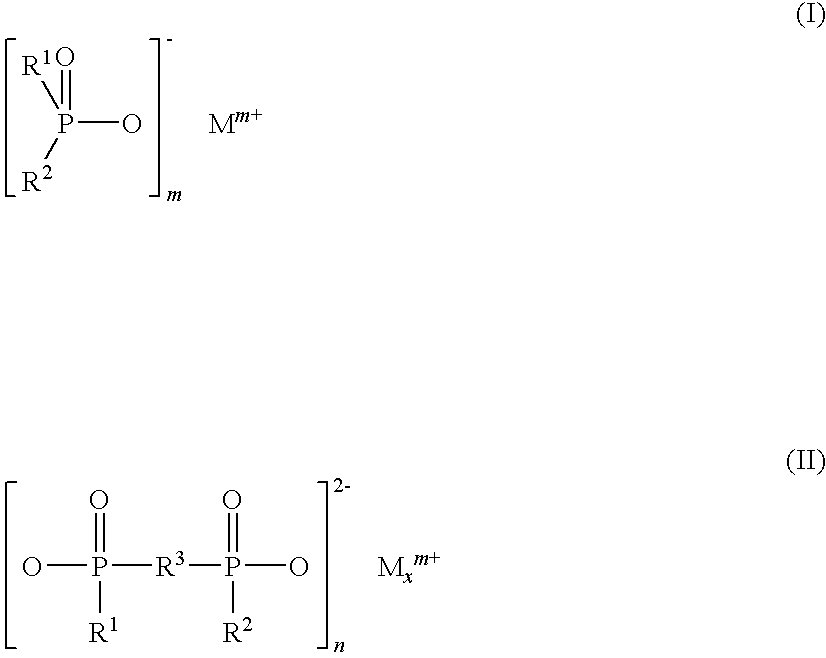

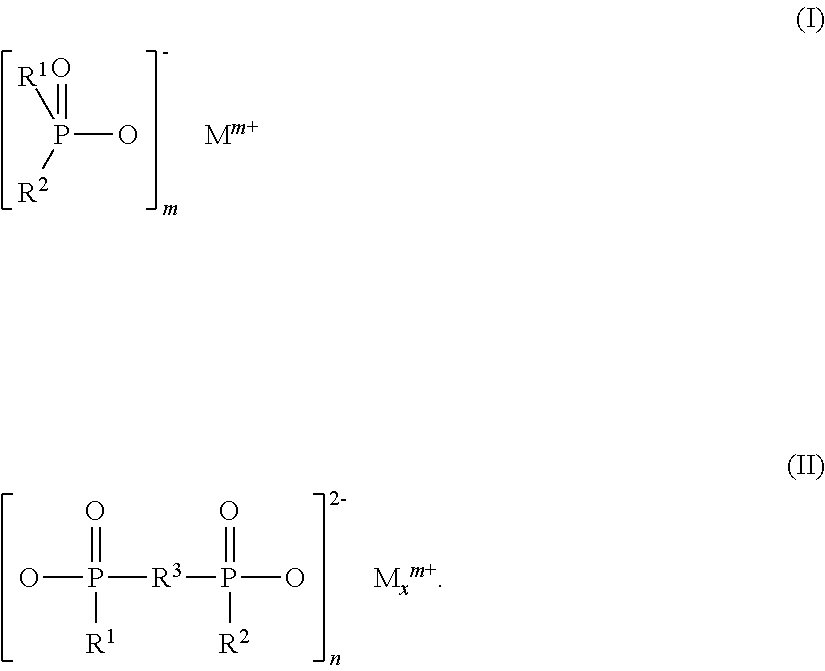

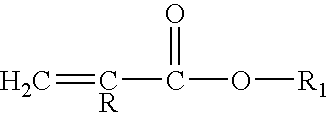

A method for providing a coated transparency, includes the steps of: (a) providing a transparency having a vision area and a non-vision area; and (b) applying a sound dampening coating composition to at least a portion of the non-vision area of the transparency. Where the coating composition is a polyurea coating composition, the coating composition can be formed from a reaction mixture including an isocyanate-functional component and an amine-functional component, wherein the ratio of equivalents of isocyanate groups to equivalents of amine groups is greater than 1, while the volume mixing ratio of the isocyanate-functional component to the amine-functional component is capable of being applied to a substrate at 1:1.

Owner:PITTSBURGH GLASS WORKS

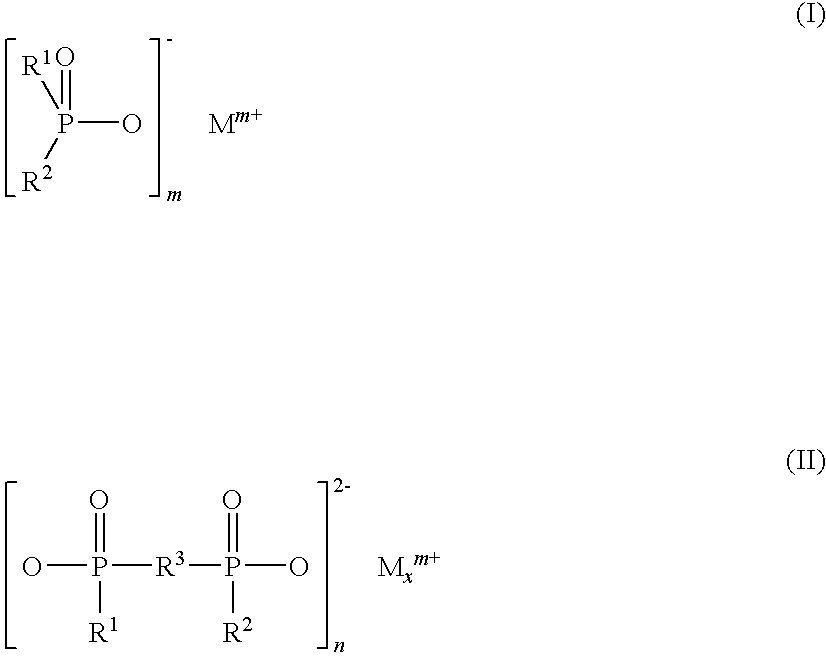

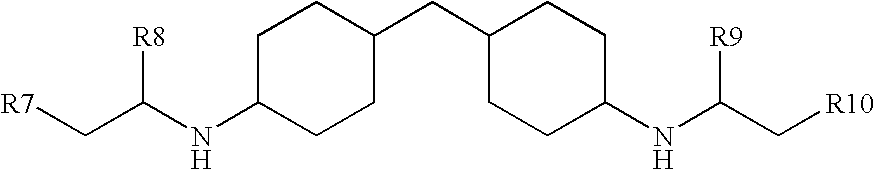

Coating compositions comprising polyurea or polyurea and polyurethane

The present invention is directed to a coating composition comprising polyurea and polyurethane. Further, the present invention is directed to a coating composition comprising polyurea or, polyurea and polyurethane, and flame retardant. The polyurea is formed from a reaction mixture comprising isocyanate and amine wherein the ratio of equivalents of isocyanate groups to equivalents of amine groups is greater than 1 and the isocyanate-functional component and the amine-functional component can be applied to a substrate at a volume mixing ratio of 1:1.

Owner:PPG IND OHIO INC

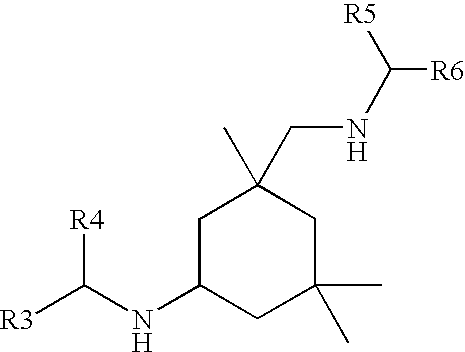

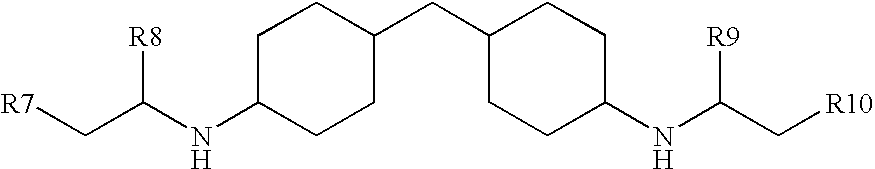

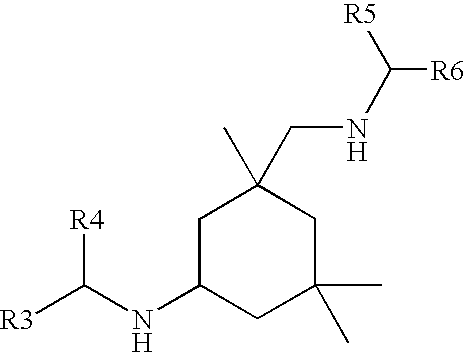

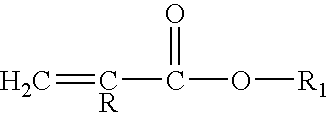

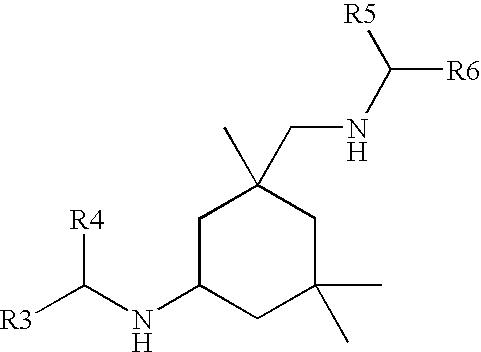

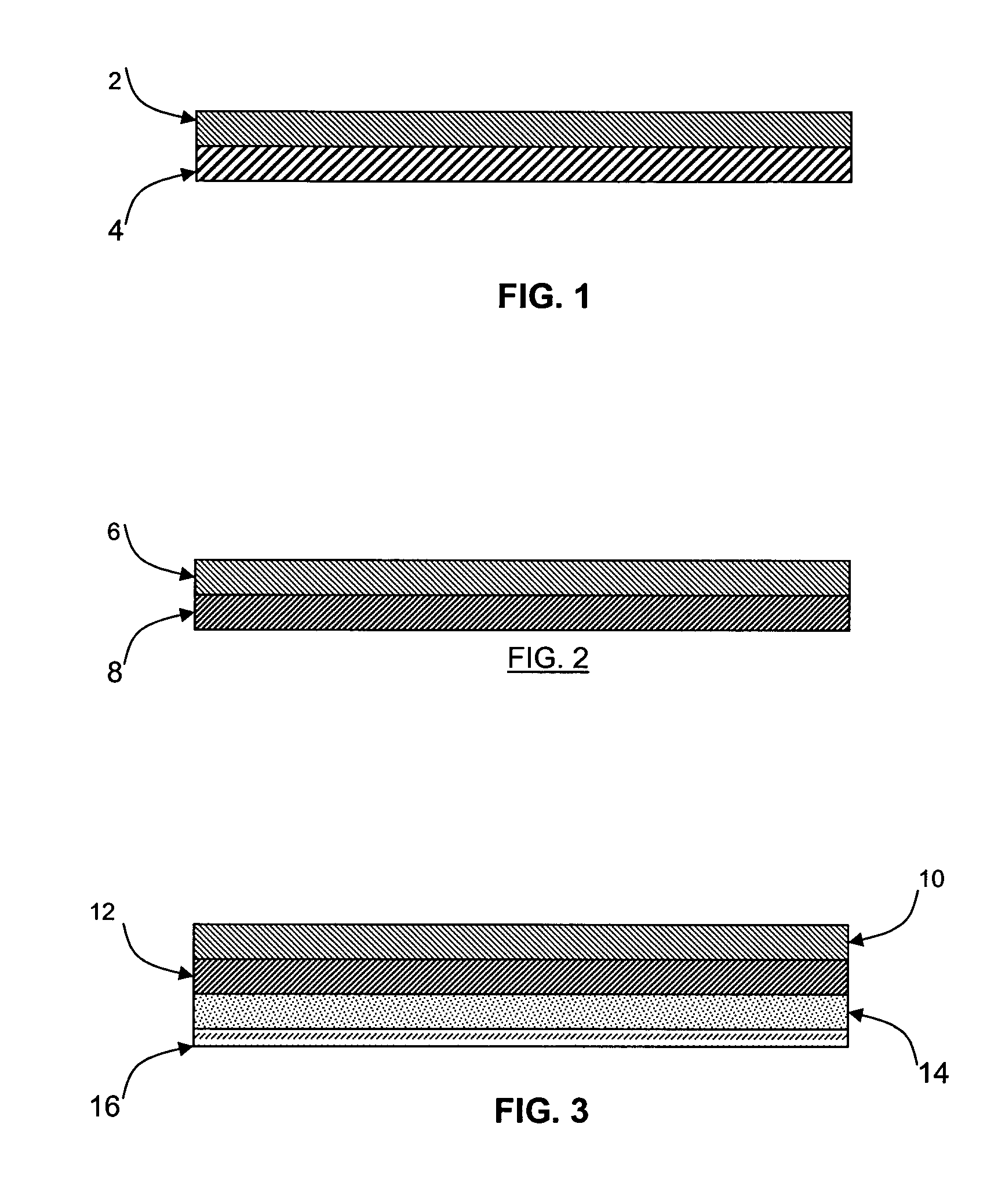

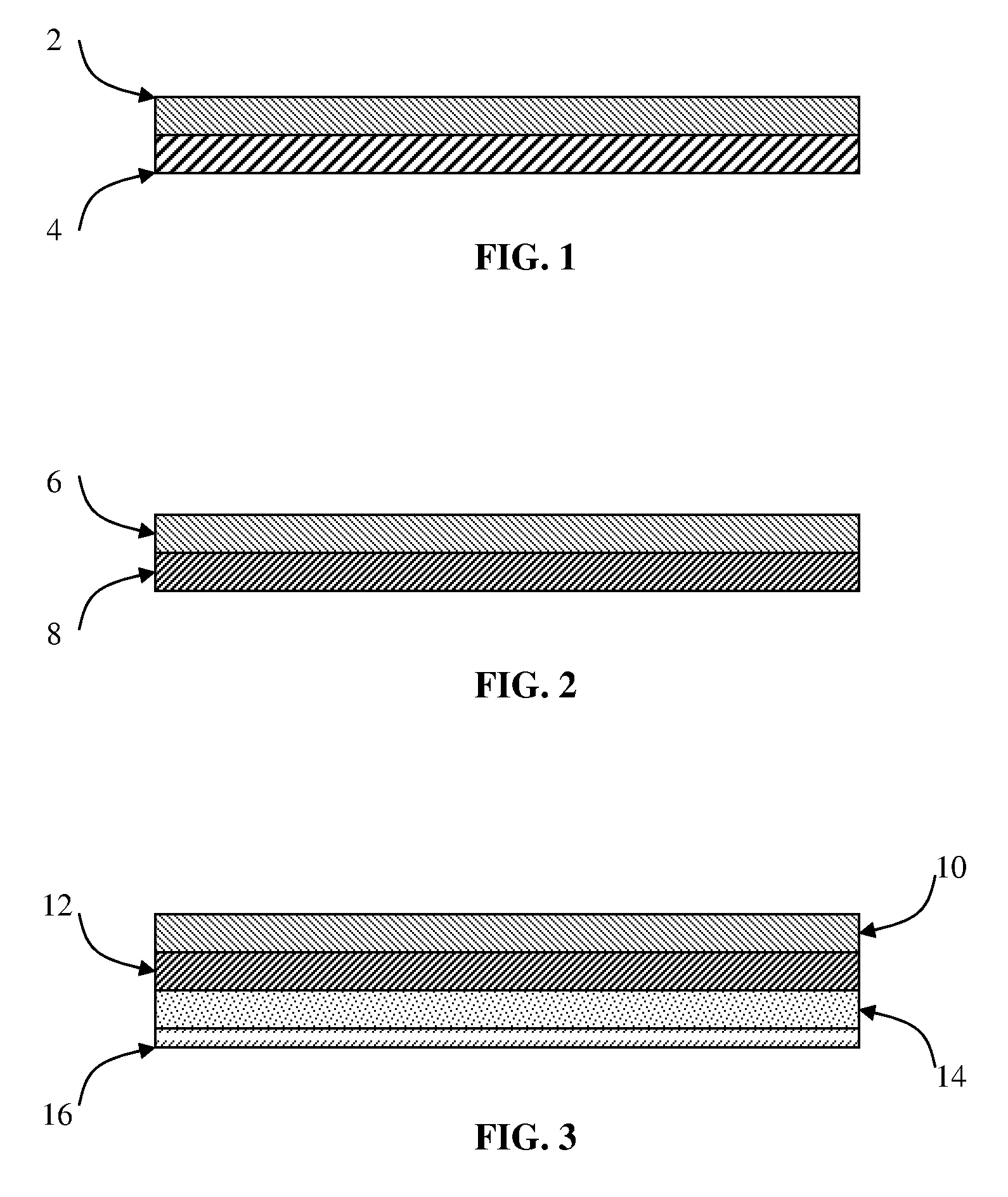

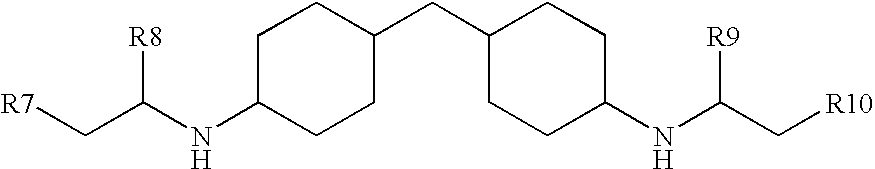

Substrates coated with a polyurea comprising a (METH)acrylated amine reaction product

ActiveUS20070160853A1Liquid surface applicatorsSynthetic resin layered productsMeth-Poly methacrylate

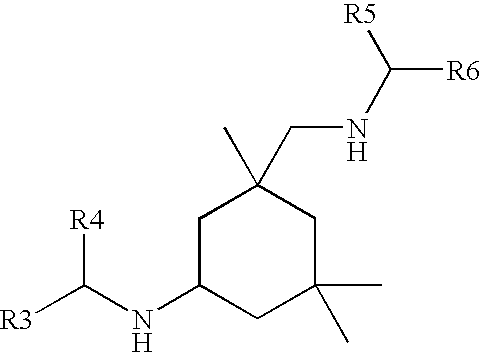

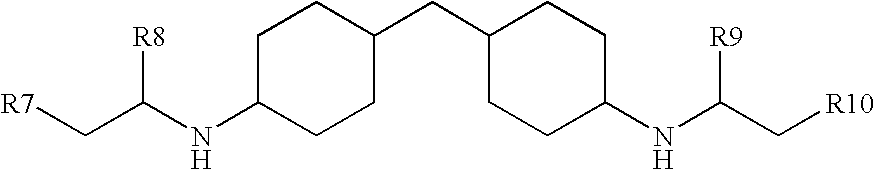

A metallic substrate coated at least in part with a multilayer coating composite, comprising at least one of an electrocoat layer, a base coat layer, and a clearcoat layer; and a polyurea formed from a reaction mixture comprising isocyanate and a (meth)acrylated amine reaction product of a monoamine and a poly(meth)acrylate is disclosed. The ratio of equivalents of isocyanate groups to equivalents of amine groups in the polyurea is greater than 1 and the isocyanate functional component and the (meth)acrylated amine functional component can be applied to the substrate at a volume mixing ratio of 1:1. A building comprising a building component coated at least in part with such a polyurea is also disclosed, as is a substrate coated at least in part with such a polyurea, wherein the ratio of equivalents or isocyanate to equivalents of amine groups is greater than 1.3:1.

Owner:PPG IND OHIO INC

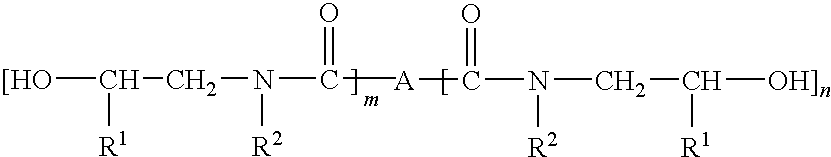

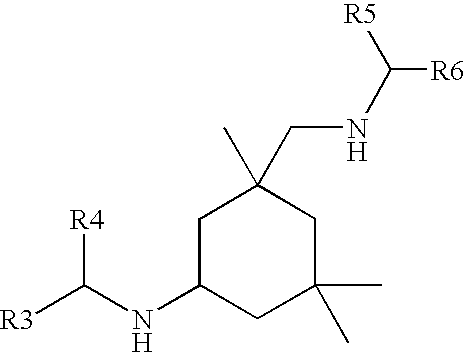

Polyurea coating comprising a polyamine/mono(METH)acrylate reaction product

ActiveUS20100136345A1Synthetic resin layered productsLiquid/solution decomposition chemical coatingMeth-Polyurea

Coating compositions comprising a polyurea formed from a reaction mixture comprising isocyanate and a (meth)acrylated amine are disclosed. The (meth)acrylated amine is the reaction product of a polyamine and a mono(meth)acrylate; the ratio of equivalents of isocyanate groups to equivalents of amine groups is greater than 1 and the isocyanate and the (meth)acrylated amine reaction product can be applied to a substrate at a volume mixing ratio of 1:1. Methods for using the coatings, and substrates coated therewith are also disclosed.

Owner:PPG IND OHIO INC

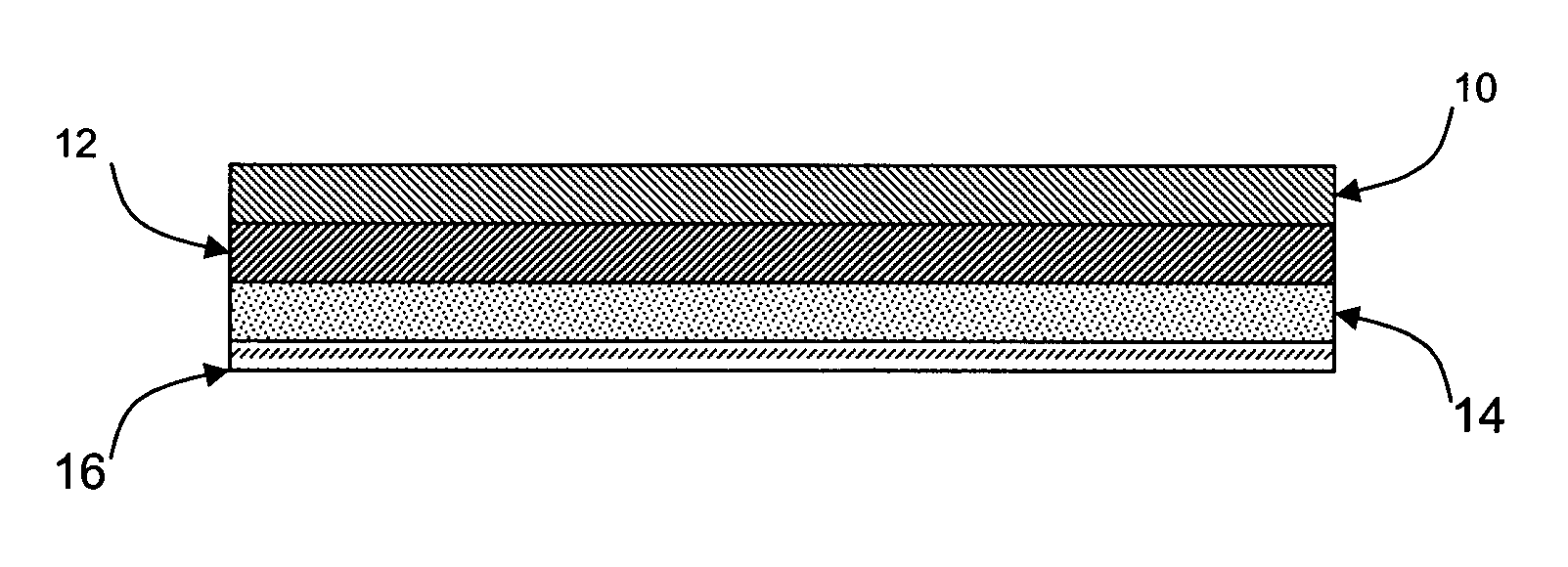

Multi-component coatings that include polyurea coating layers

A polyurea composition, a multi-component composite coating and articles formed therefrom, and methods of forming the same are disclosed. The coating composition is formed from a reaction mixture comprising an isocyanate-functional component and an amine-functional component. The ratio of equivalents of isocyanate groups to equivalents of amine groups is greater than 1 while the volume mixing ratio of the isocyanate-functional component to the amine-functional component is capable of being applied to a substrate at 1:1.

Owner:PPG IND OHIO INC

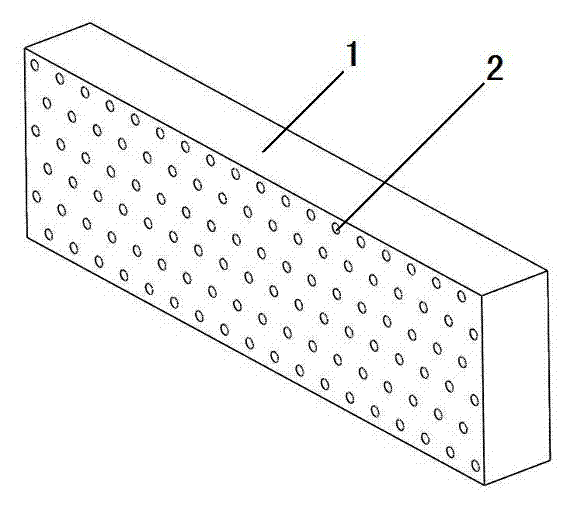

Grinding tool mixed by abrasives

InactiveCN101745875AHigh removal rateImprove surface roughnessAbrasion apparatusSurface finishMaterials science

The present invention relates to a grinding tool mixed by abrasives. The grinding tool is made by mixing a first abrasive, a second abrasive and a binding agent according to the following ratio by volume. The mixed ratio by volume of the first abrasive to the second abrasive to the binding agent is from 1:3:8 to 3:1:3. The present invention has the advantages that satisfactory surface finishing quality can be ensured, and the polishing and grinding processing efficiency is effectively improved.

Owner:XI AN JIAOTONG UNIV

Coating composition of polyurea, polyurethane and flame retardant

The present invention is directed to a coating composition comprising polyurea and polyurethane. Further, the present invention is directed to a coating composition comprising polyurea or, polyurea and polyurethane, and flame retardant. The polyurea is formed from a reaction mixture comprising isocyanate and amine wherein the ratio of equivalents of isocyanate groups to equivalents of amine groups is greater than 1 and the isocyanate-functional component and the amine-functional component can be applied to a substrate at a volume mixing ratio of 1:1.

Owner:PPG IND OHIO INC

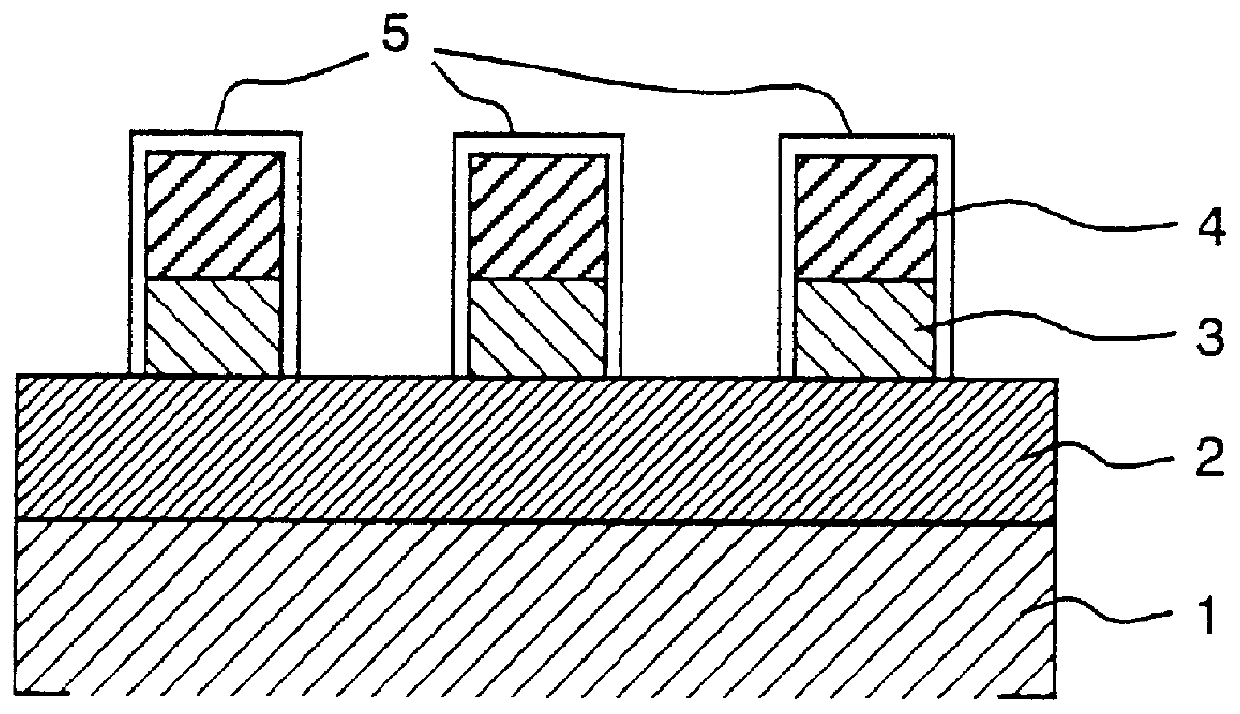

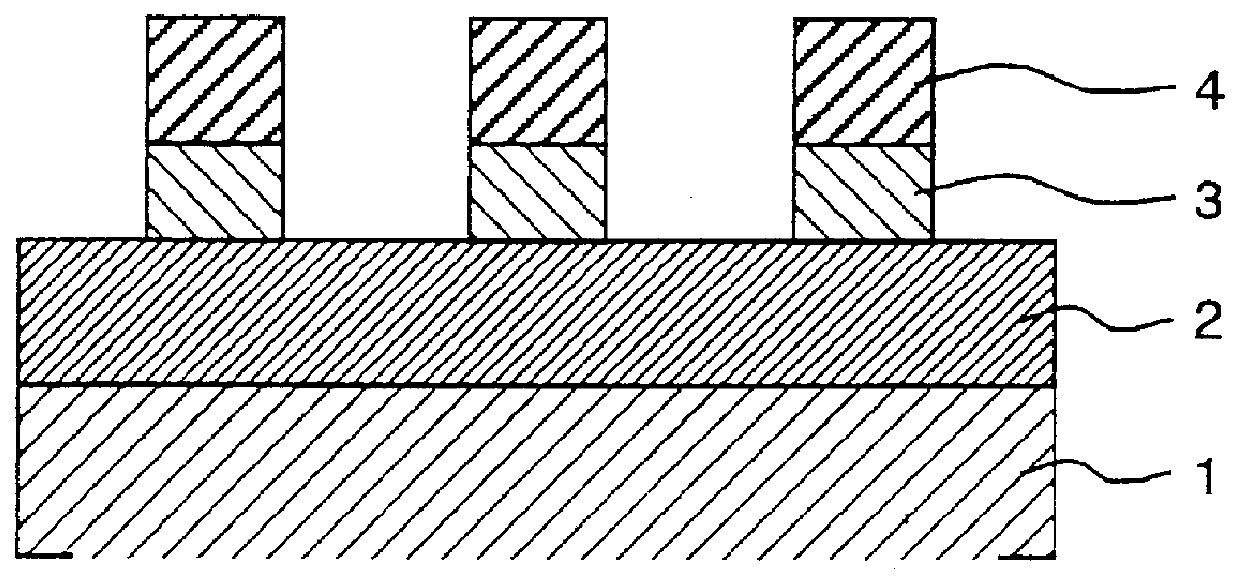

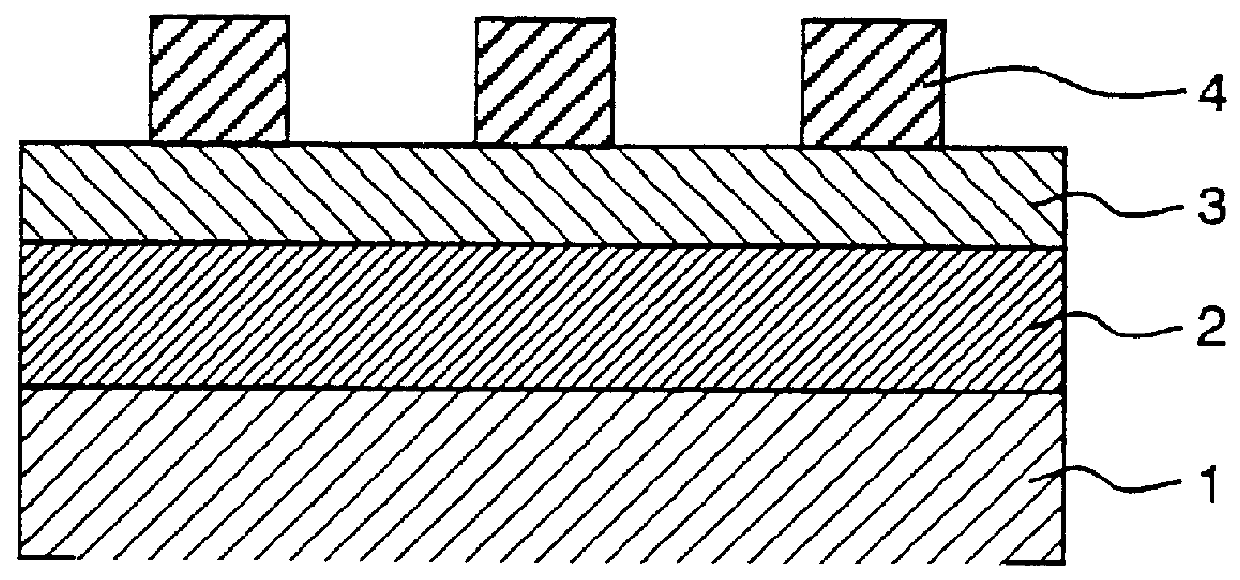

Semiconductor device and manufacturing method thereof for removing reaction products of dry etching

InactiveUS6110834ADecorative surface effectsSemiconductor/solid-state device manufacturingResistHydrofluoric acid

Reaction products due to etching of a semiconductor sample by using a reactive gas are removed by using a liquid chemical that contains sulfuric acid and hydrofluoric acid at a volume mixing ratio of (5 to 7):(1 / 400 to 1 / 1000) and is kept at 25 DEG -70 DEG C. Reaction products and a resist mask are removed simultaneously by using a liquid chemical that contains sulfuric acid, a hydrogen peroxide solution, and hydrofluoric acid at a volume mixing ratio of (5 to 7):1:(1 / 400 to 1 / 1000) and is kept at 70 DEG -100 DEG C.

Owner:RENESAS ELECTRONICS CORP +1

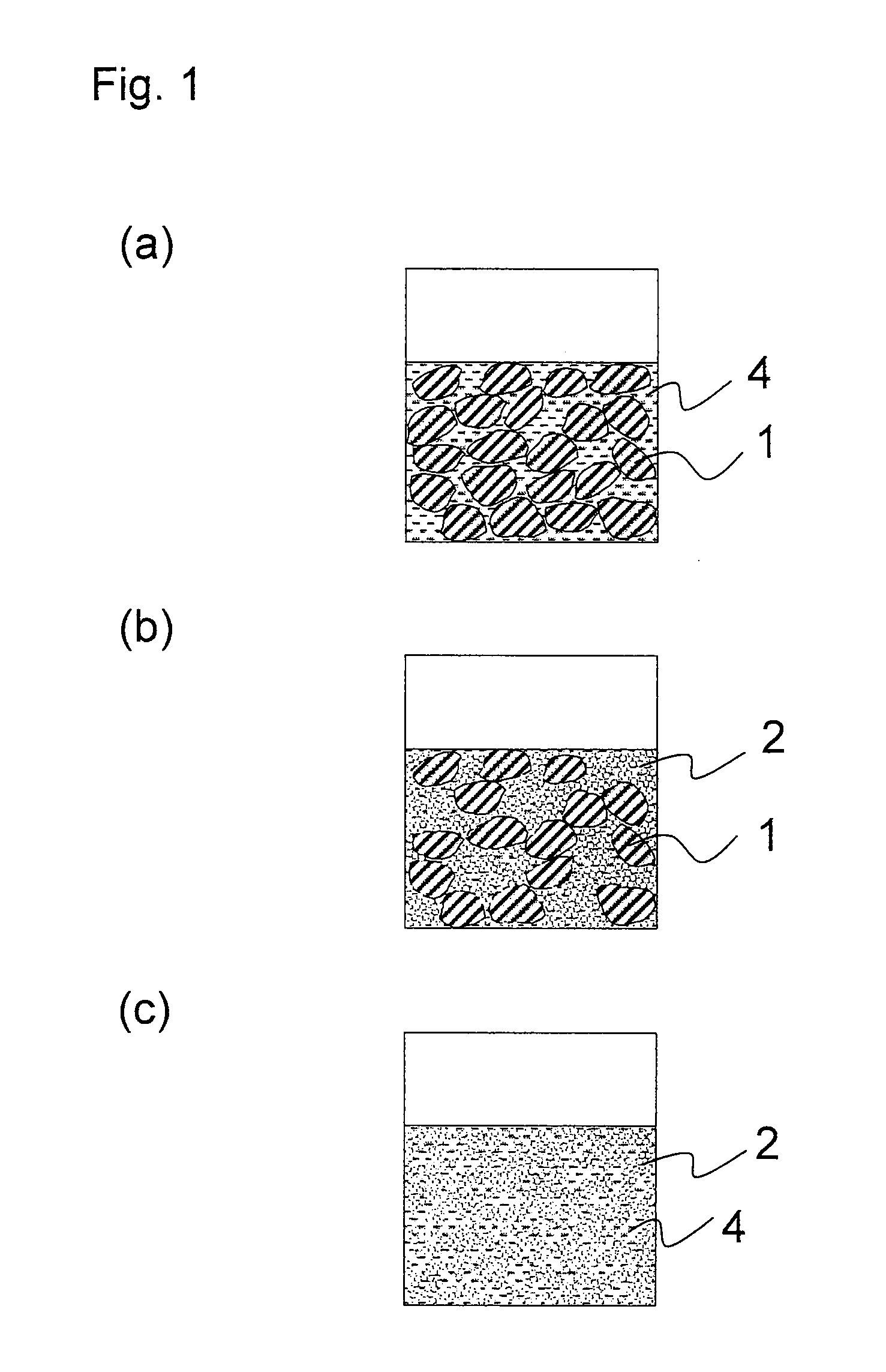

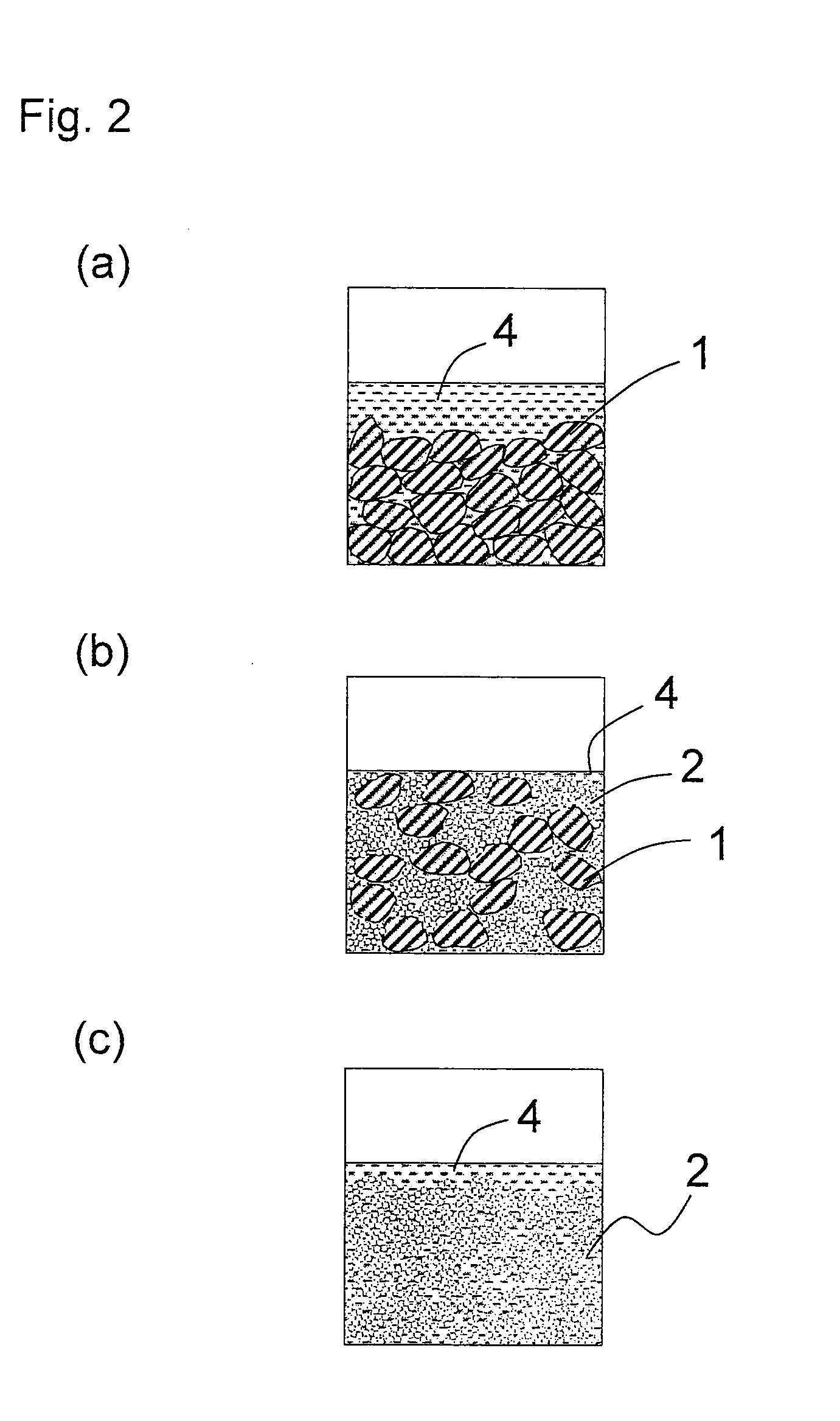

Coating liquid for use in formation of positive electrode for lithium secondary battery, positive electrode for lithium secondary battery, and lithium secondary battery

InactiveUS20100040949A1Good storage stabilityGood coating performancePositive electrodesNanotechnologyHigh energyDiameter ratio

A coating liquid for use in formation of a positive electrode for a lithium secondary battery of the present invention includes a large-particle-size active material having an average particle diameter of 1 to 20 μm and a small-particle-size active material having an average particle diameter of 5 to 100 nm, such that the blending ratio by volume between two materials is 90:10 to 50:50, and the average particle diameter ratio (the average particle diameter of large-particle-size active material / the average particle diameter of small-particle-size active material) is from 50 to 500. The coating liquid is excellent in storage stability over a long period of time and makes dense packing of active material possible, and therefore a positive electrode produced with the use of the coating liquid of the present invention can provide a lithium secondary battery having a high energy density and a high capacity.

Owner:PANASONIC CORP

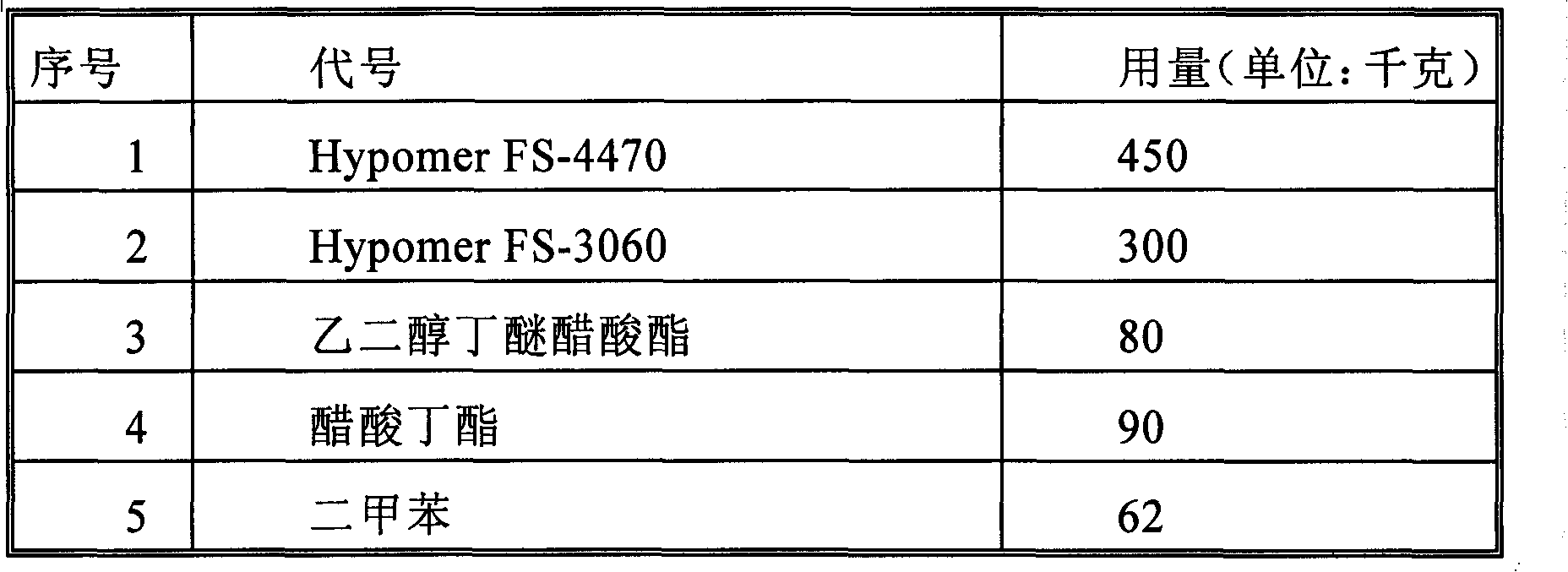

A kind of quick-drying practical varnish and preparation method thereof

Owner:DONGLAI COATING TECH SHANGHAI

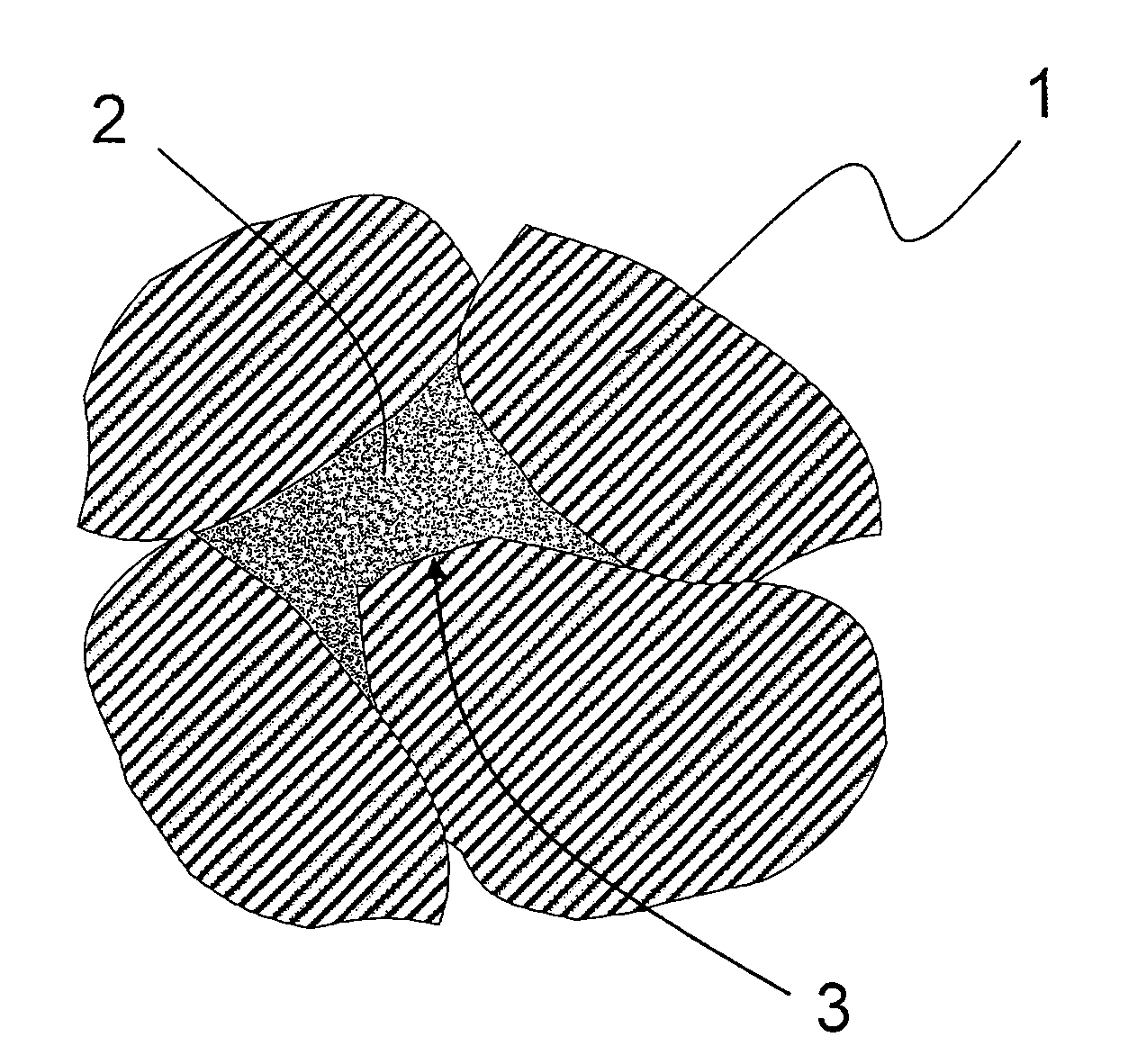

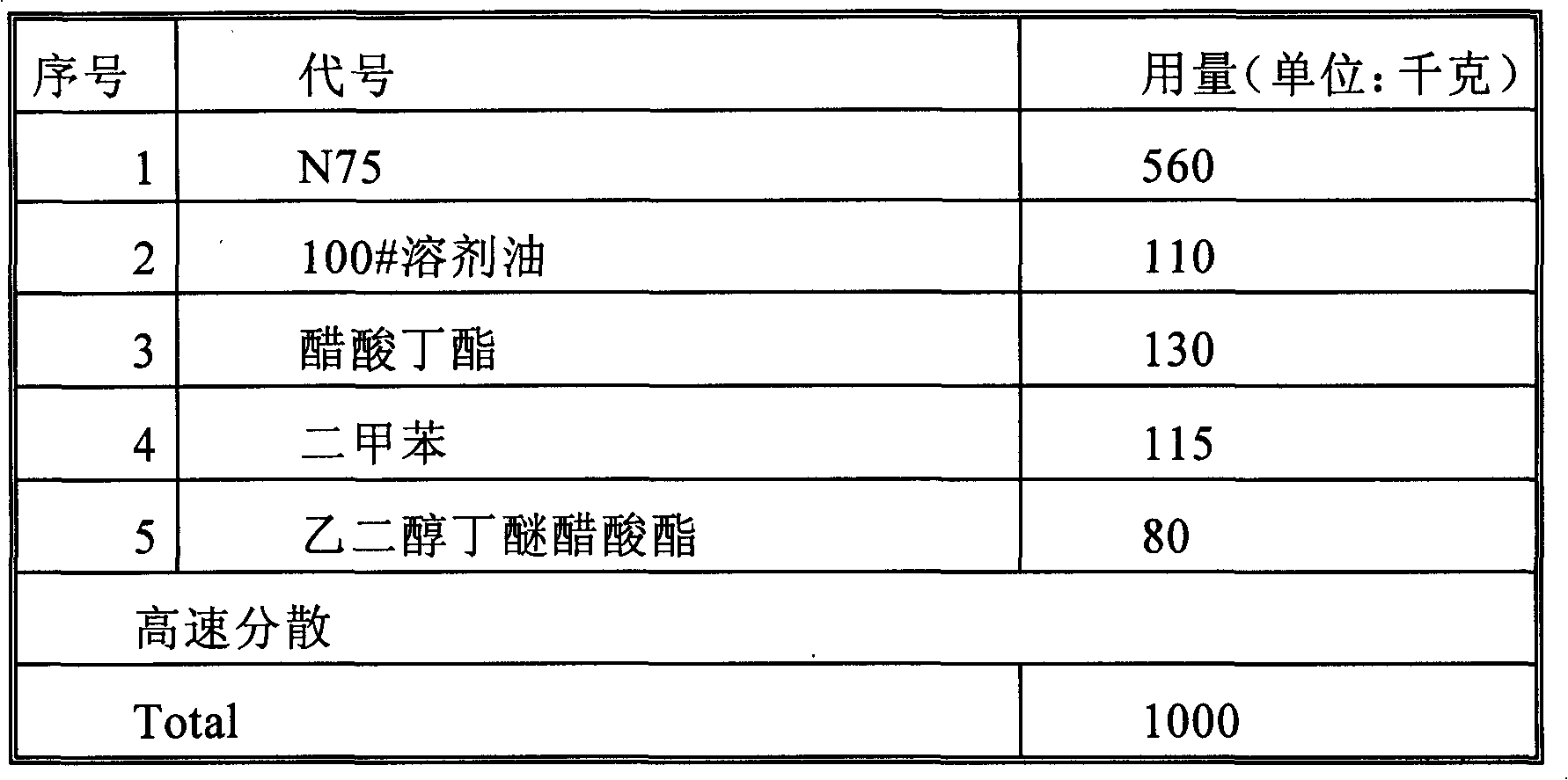

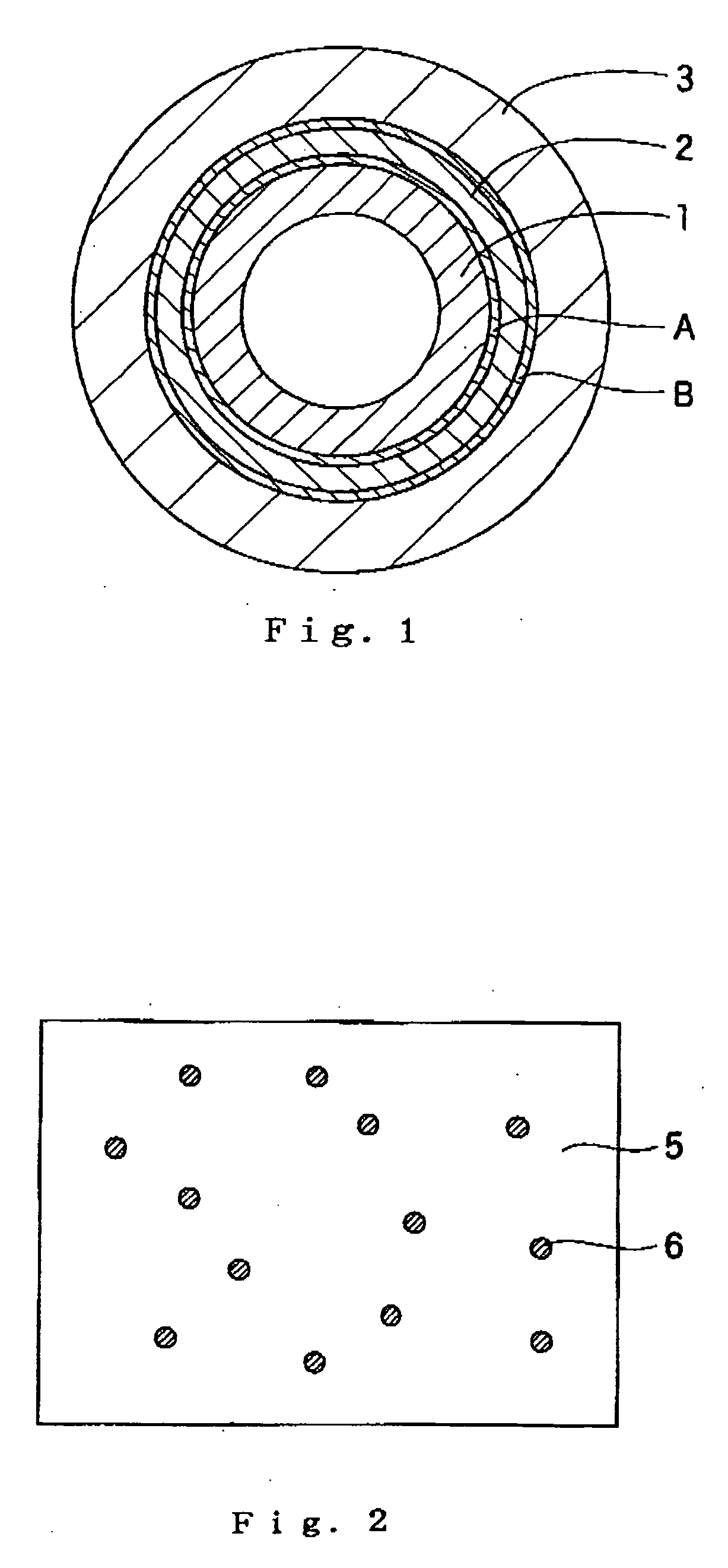

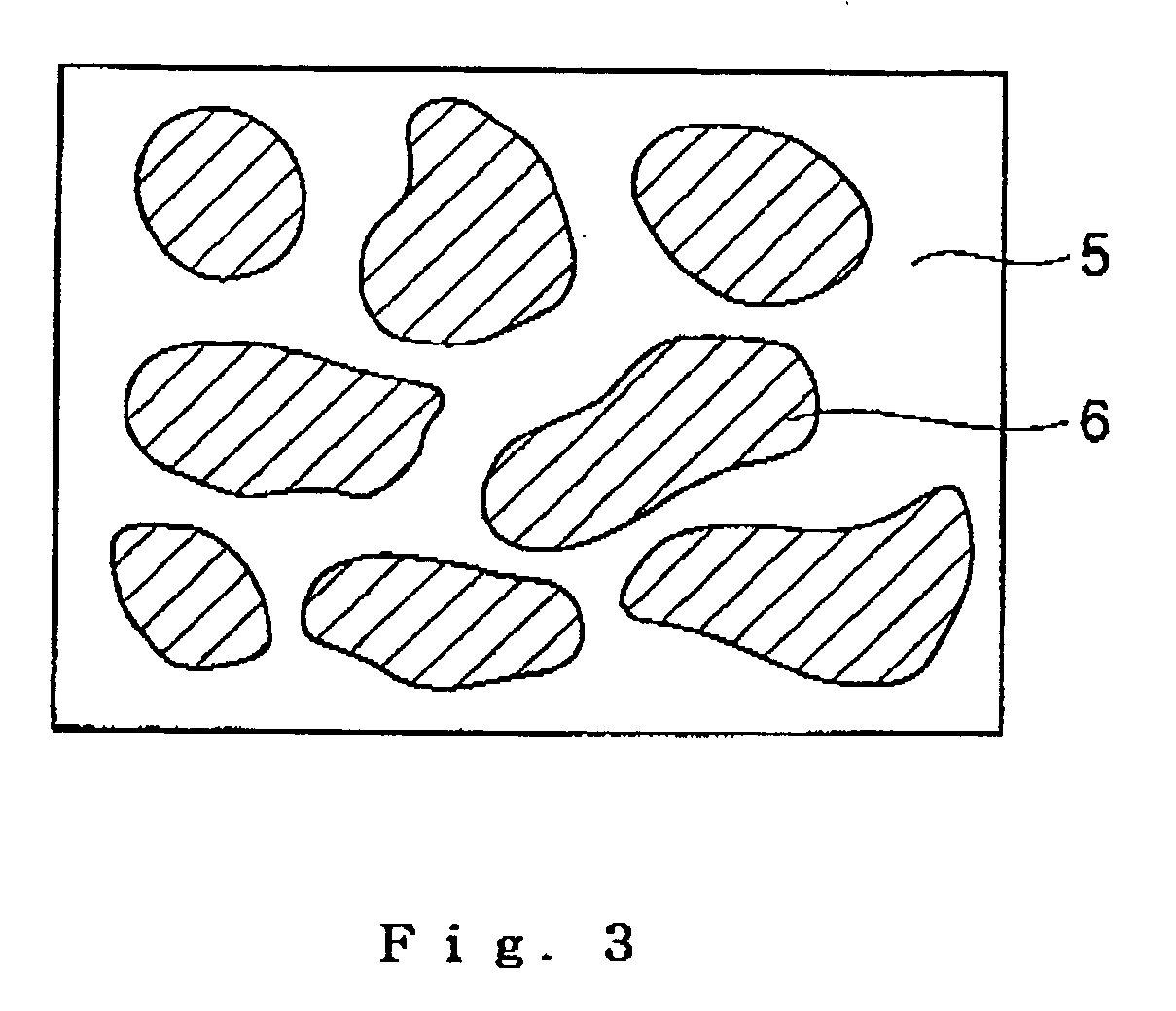

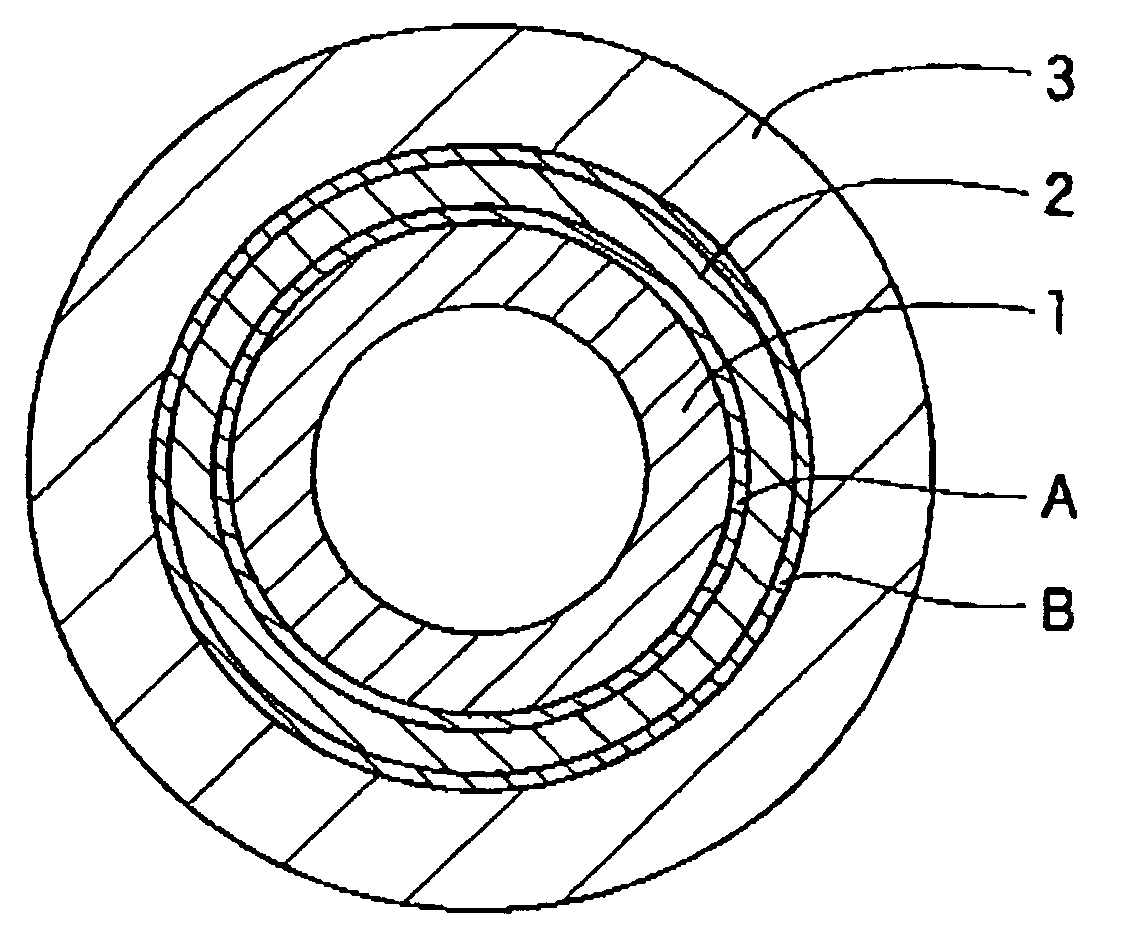

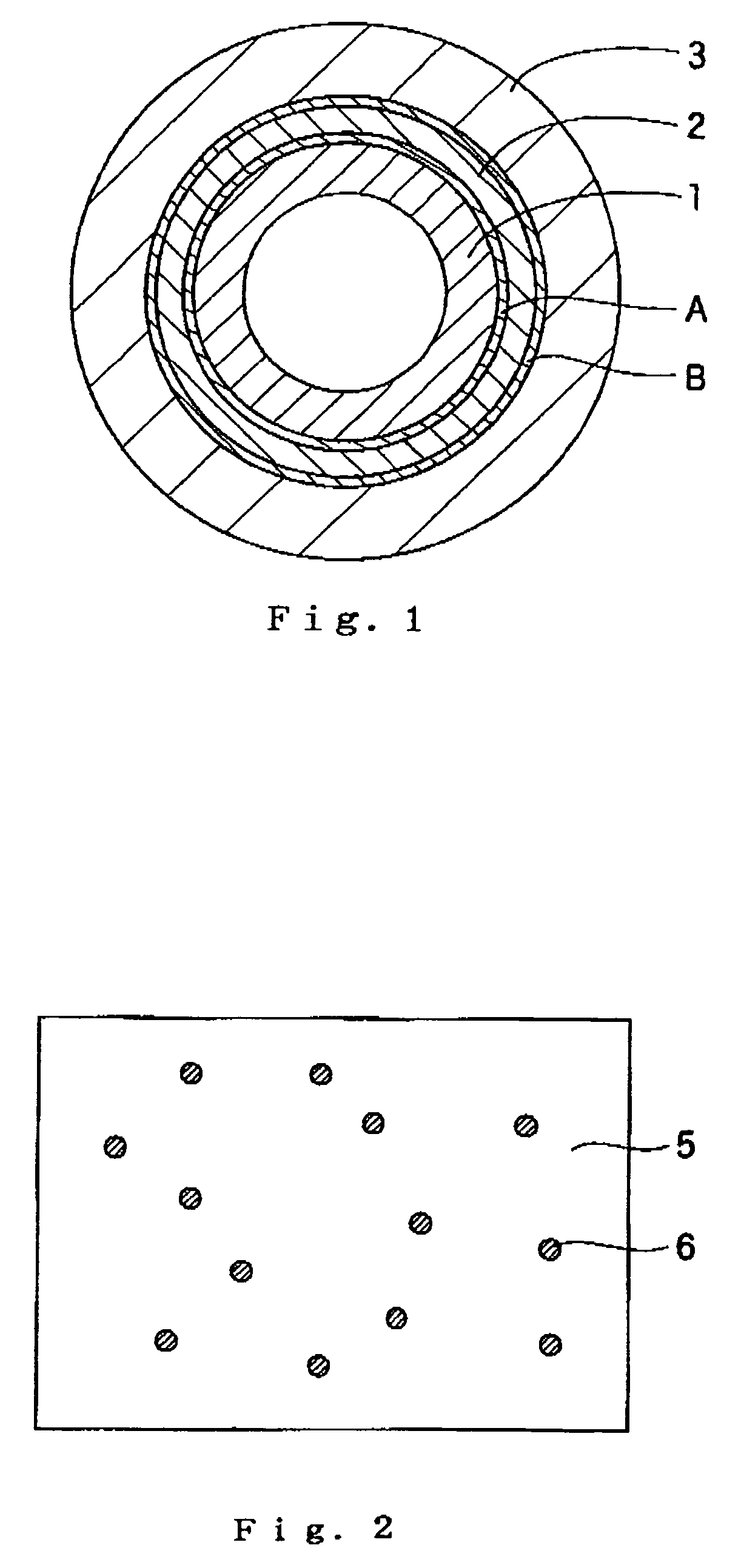

Fuel cell hose

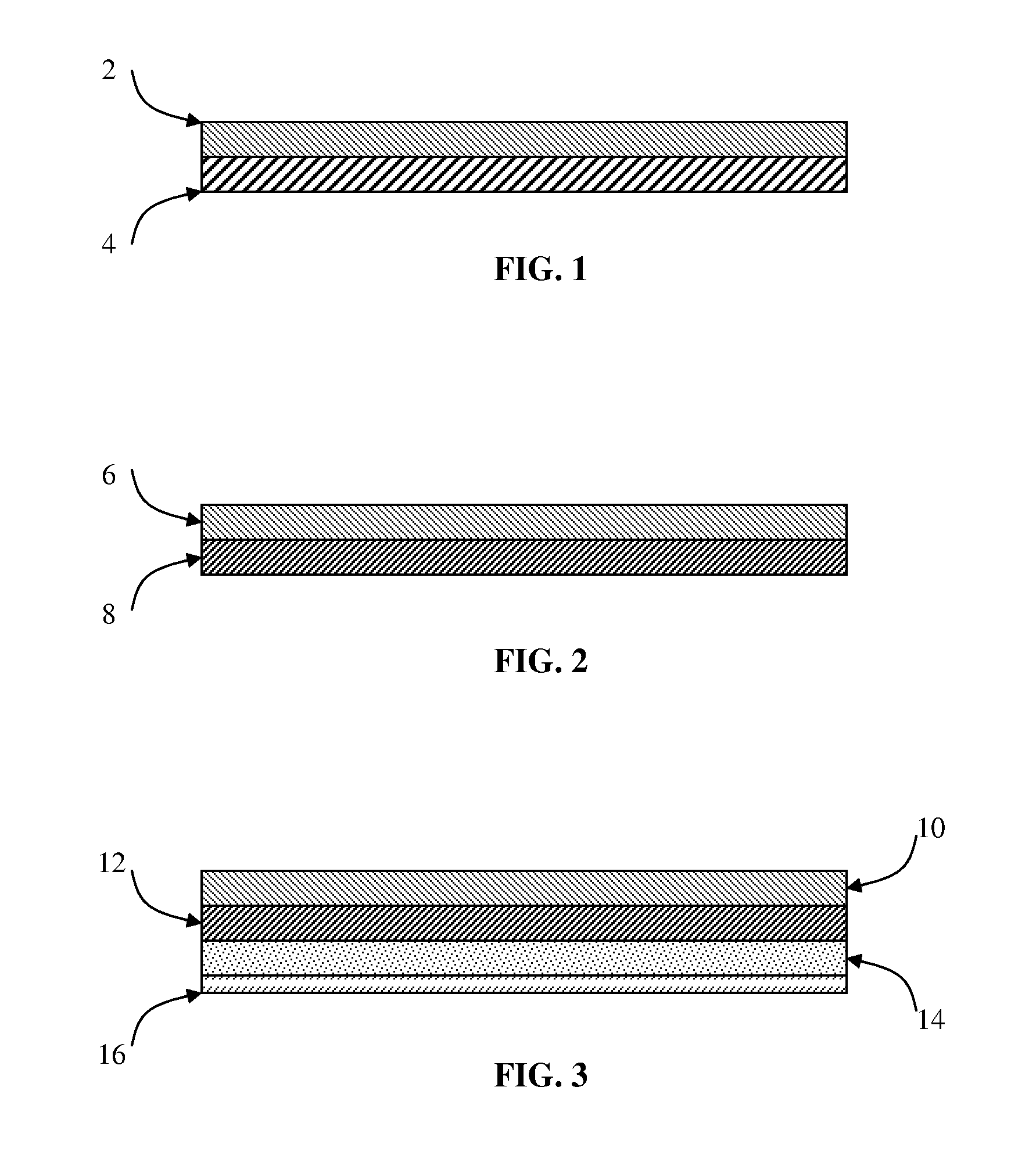

ActiveUS20060191588A1High elongationSynthetic resin layered productsFlexible pipesFuel cellsPolyolefin

A fuel cell hose which is superior in flexibility (low-temperature flexibility) and in barrier performance against hydrogen gas or water without causing a defect such as buckling or cracking at the time of the press-fitting of a connector. The fuel cell hose comprises an inner layer in contact with fluid, a barrier layer formed on an outer peripheral surface of the inner layer and an outer layer formed on an outer peripheral surface of the barrier layer. The inner layer is made of a material (A) containing a polyolefin resin and a styrene-isobutylene block copolymer as essential components, the barrier layer is made of a material (B) containing an ethylene-vinyl alcohol copolymer and a modified polyolefin resin as essential components and the mixing ratio by volume of the ethylene-vinyl alcohol copolymer to the modified polyolefin resin is in the range of 95 / 5 to 30 / 70, and the outer layer is made of a material (C) containing a polyamide resin as an essential component. The barrier layer has an island-sea structure in which island phases composed of the modified polyolefin resin are dispersed in a sea phase composed of the ethylene-vinyl alcohol copolymer.

Owner:SUMITOMO RIKO CO LTD

Fuel cell hose

A fuel cell hose which is superior in flexibility (low-temperature flexibility) and in barrier performance against hydrogen gas or water without causing a defect such as buckling or cracking at the time of the press-fitting of a connector. The fuel cell hose comprises an inner layer in contact with fluid, a barrier layer formed on an outer peripheral surface of the inner layer and an outer layer formed on an outer peripheral surface of the barrier layer. The inner layer is made of a material (A) containing a polyolefin resin and a styrene-isobutylene block copolymer as essential components, the barrier layer is made of a material (B) containing an ethylene-vinyl alcohol copolymer and a modified polyolefin resin as essential components and the mixing ratio by volume of the ethylene-vinyl alcohol copolymer to the modified polyolefin resin is in the range of 95 / 5 to 30 / 70, and the outer layer is made of a material (C) containing a polyamide resin as an essential component. The barrier layer has an island-sea structure in which island phases composed of the modified polyolefin resin are dispersed in a sea phase composed of the ethylene-vinyl alcohol copolymer.

Owner:SUMITOMO RIKO CO LTD

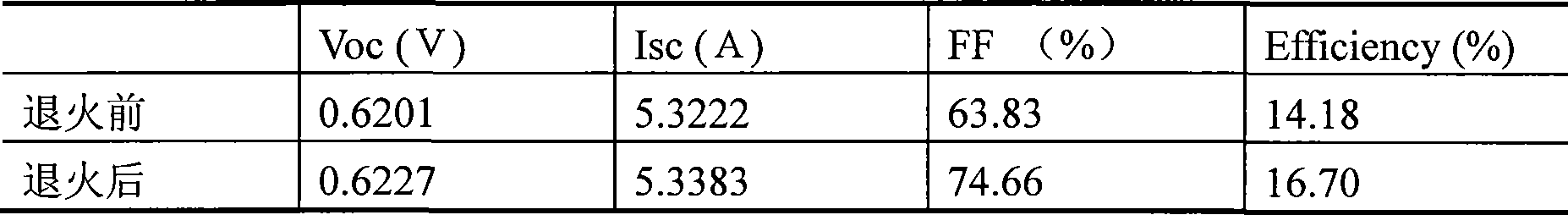

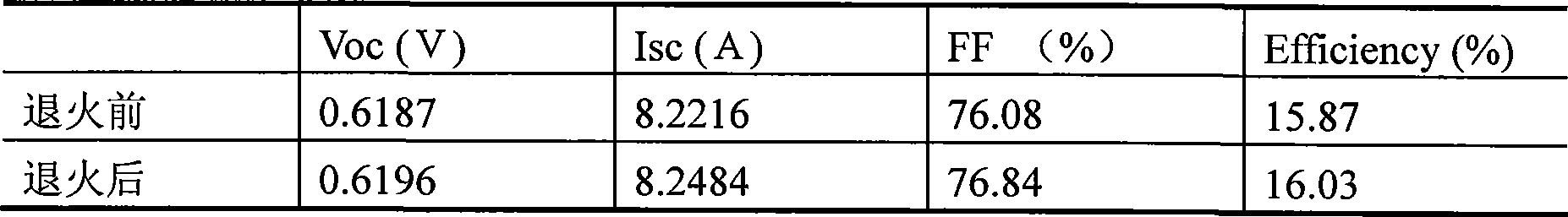

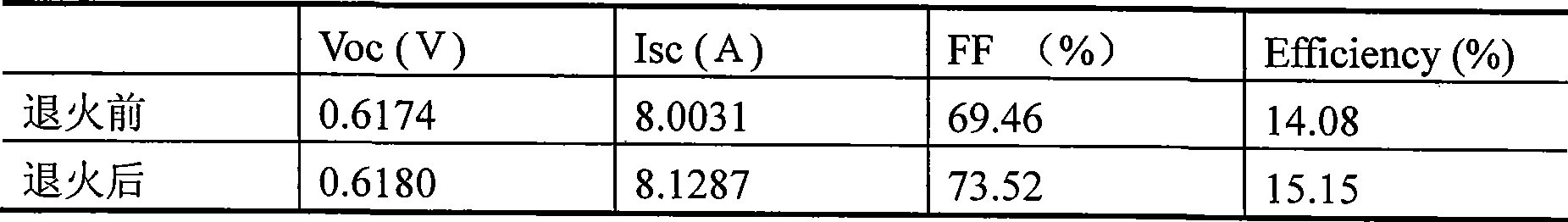

Anneal technique for improving battery electrical property

InactiveCN101465392AImprove electrical performanceLess investmentFinal product manufactureSemiconductor devicesElectricityHydrogen

The invention discloses an annealing process for improving the electric property of a cell, including the step of conducting annealing treatment to a screen printed crystalline silicon solar cell, wherein, inert gases (N2, Ar) are adopted to mix with the reducing gas of hydrogen with different proportions to anneal the crystalline silicon solar cell, and volume mixing proportion of the hydrogen is 5-100%. The annealing process adopts low-temperature special atmosphere to anneal the crystalline silicon solar cell; the process is compatible with the crystalline silicon cell technique; besides, the invention has low equipment investment and high production efficiency, and can effectively improve the electrical property of the cell and has the prospect for large-scale application.

Owner:江苏韩华太阳能电池及应用工程技术研究中心有限公司 +1

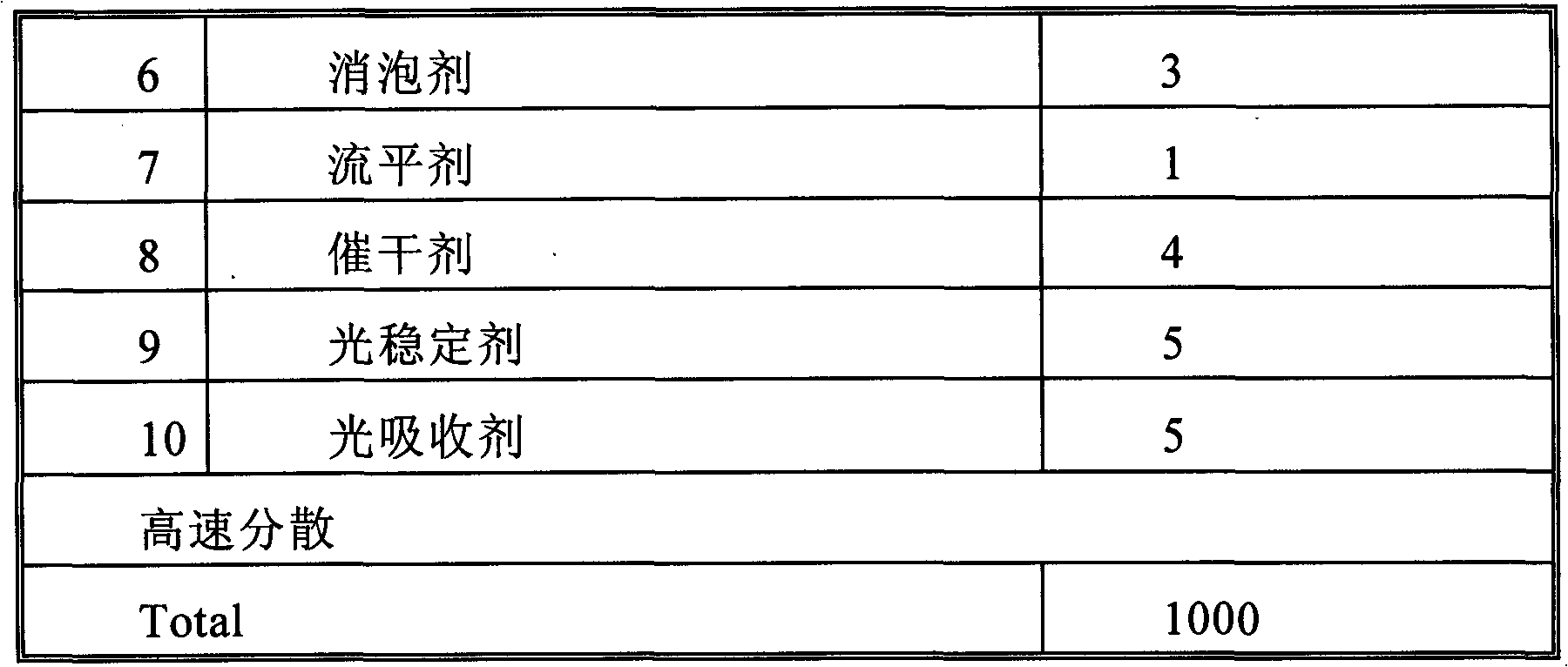

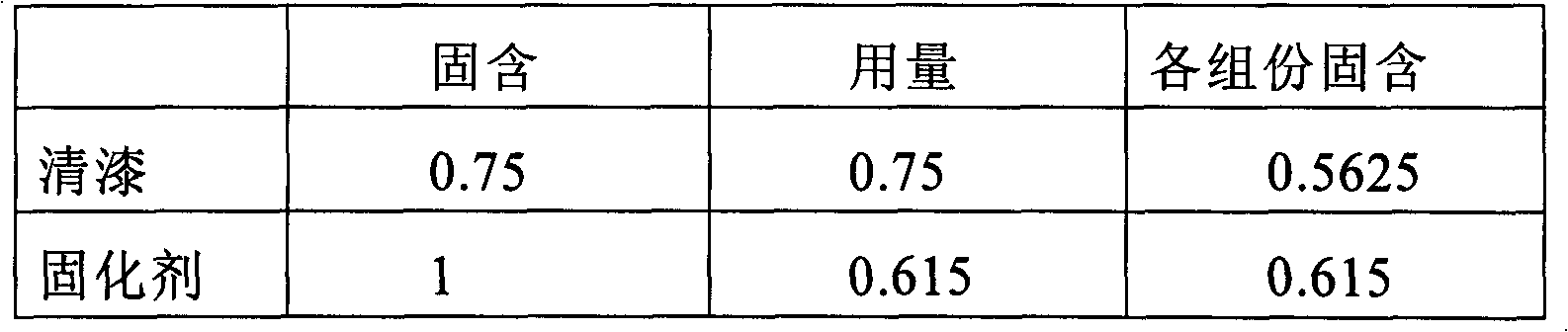

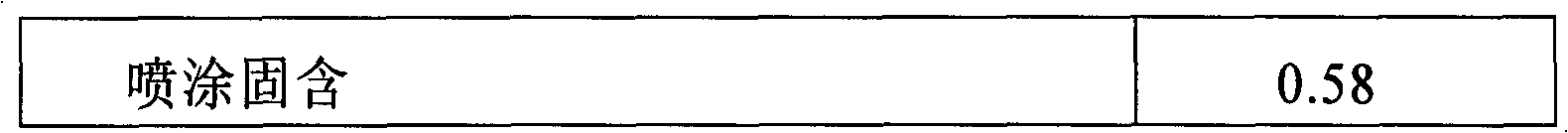

A kind of environment-friendly high-solid varnish and preparation method thereof

The invention relates to an environment-friendly high-solid varnish and a preparation method thereof. The varnish is composed of component A and component B mixed at a volume ratio of 2:1, and component A is composed of the following components and their contents in parts by weight: resin 75-80, solvent a16.55-23.2, defoamer 0.1-0.5, leveling agent 0.1-0.15, drier 0.4-0.8, light stabilizer 0.5-1, light absorber 0.5-1; component B consists of The curing agent and the solvent b are formed in a weight ratio of 61.5-65:35-38.5. Compared with the prior art, the invention has high solid content, the solid content of spraying can reach more than 58%, greatly reduces the volatilization of solvent, effectively improves the plumpness of varnish, and has low cost.

Owner:DONGLAI COATING TECH SHANGHAI

Coloured drawing ornament surface production method

InactiveCN1803475AAvoid deformationSimple preparation processCovering/liningsDecorative surface effectsCement mortarSurface dust

The invention discloses a making method of colored drawing ornament surface, which comprises the following steps: cleaning the ceramic sand paste ground or wall; removing the oil dirt; smoothing the surface of ground or wall; deburring the ground or wall through abrasive cloth or abrasive paper; adsorbing the surface dust on the ground or wall; fixing mould on the ground or wall according to the pattern; filling the mould with sand and glue at 1:1.5-3 bulk ratio to compact; drying the sand and glue; removing the mould; coating transparent resin glue on the surface. The ornament surface is light-quality and high-strength, which possesses abrasive-proof, aging-resistance and deformation-proof property.

Owner:张逢利

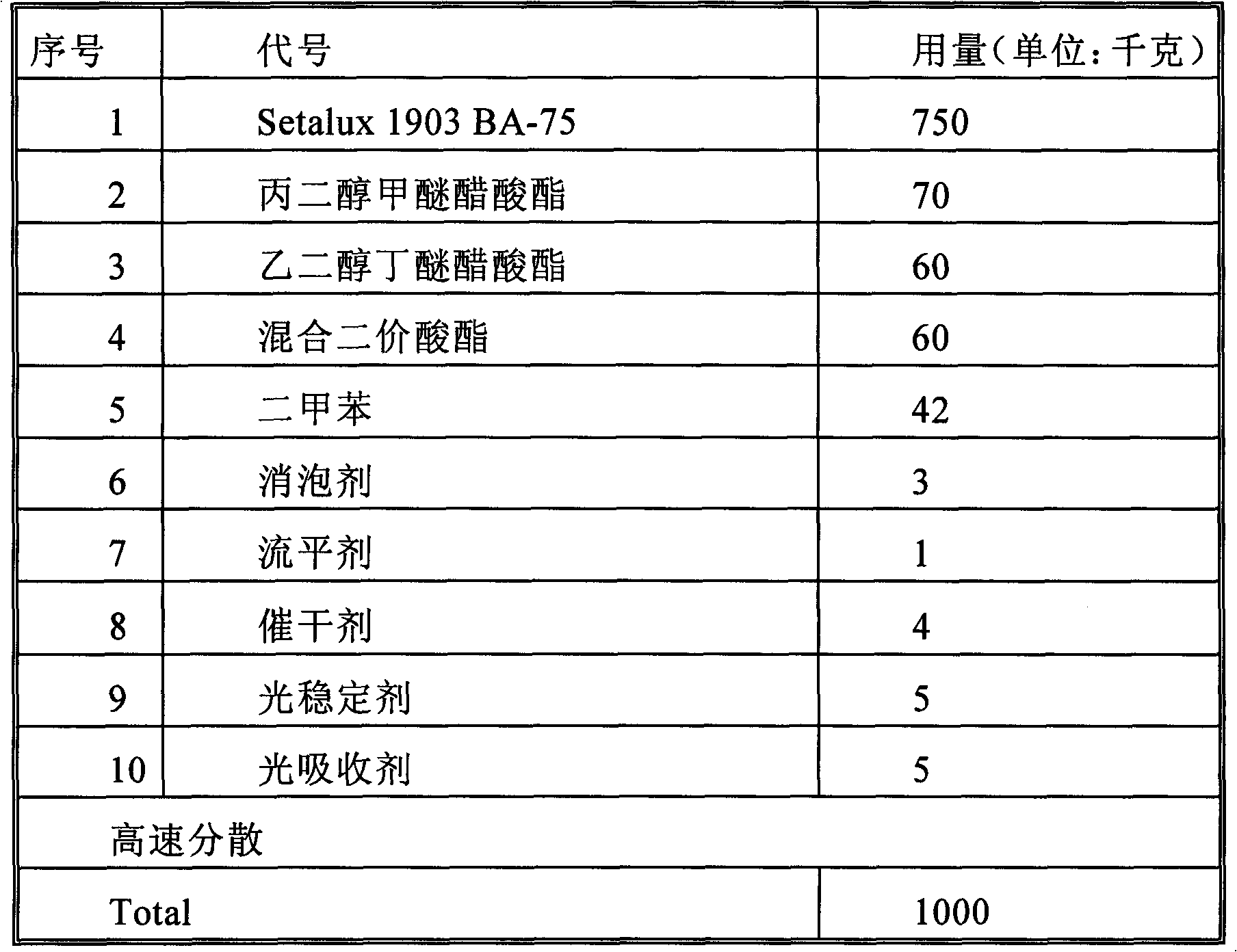

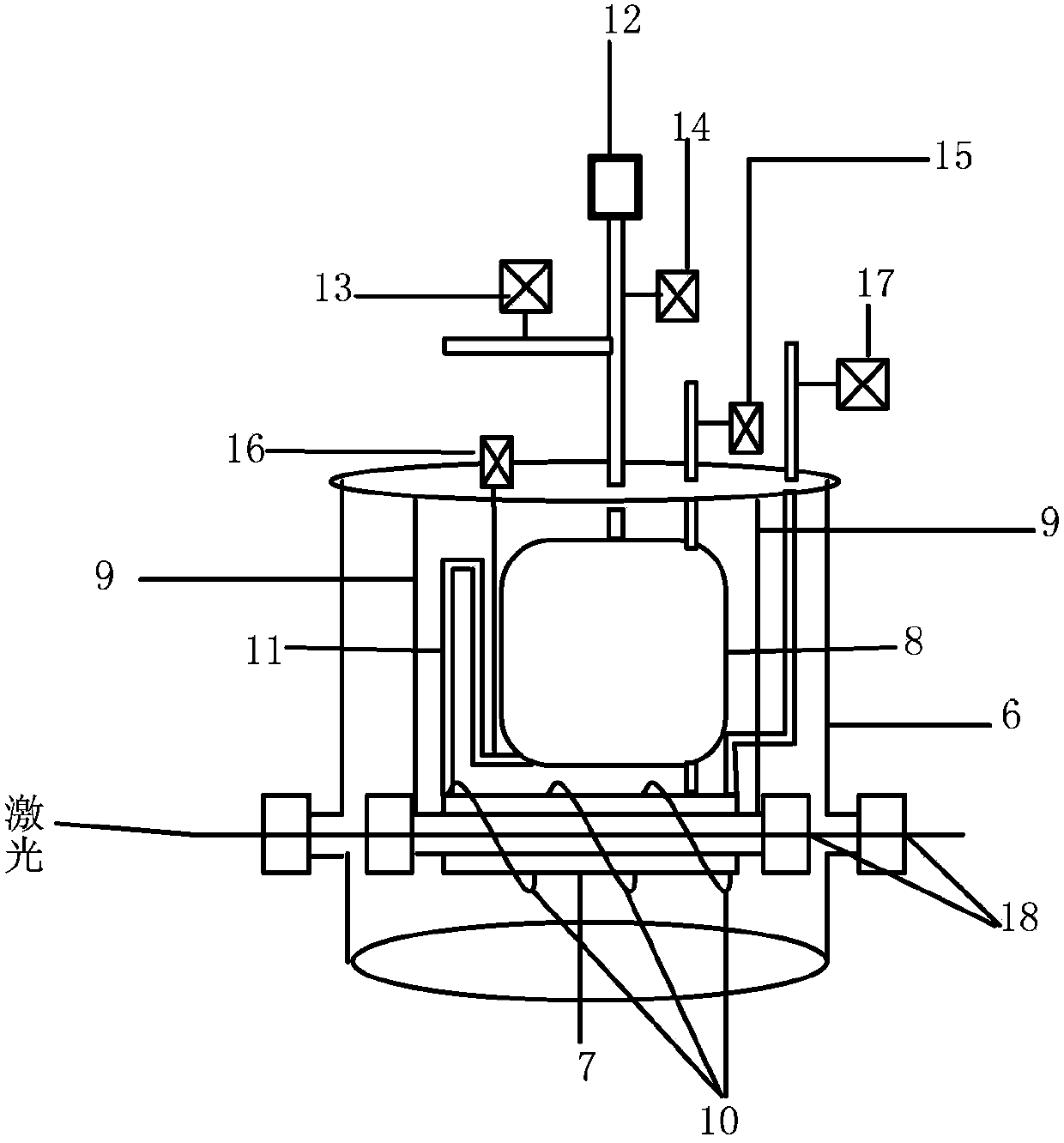

Experiment method and experiment device for decomposing hydrate

ActiveCN104897854APromote decompositionAchieve continuous supplyMaterial analysisDecompositionWater velocity

The invention discloses an experiment method and an experiment device for decomposing hydrate. The method comprises the following steps: loading hydrate sediment particles into a packing pipeline, pushing into a pressure chamber and spraying water into the pipeline, wherein the ratio of the water velocity to the advance velocity of the hydrate sediment particles has to ensure that the volume mixing ratio of water to the hydrate sediment particles is 7 to 3 or above; mixing the hydrate sediment particles in the pressure container with water to promote decomposition of hydrate; simultaneously measuring the temperature and pressure distribution in the pressure chamber; after the hydrate sediment particles in the pressure chamber are decomposed, enabling the gas and water to flow up to the outside through a filter screen; precipitating soil particles to the bottom of the pressure chamber, recording the quantity of the gas, water and soil particles; after decomposing of the hydrate sediment particles is finished, sucking the soil particles out of the pressure chamber; pulling a piston out of the pipeline and refilling the hydrate sediment particles; and repeating the steps to finish the experiment of decomposing the hydrate sediment particles in a way of mixing with water.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

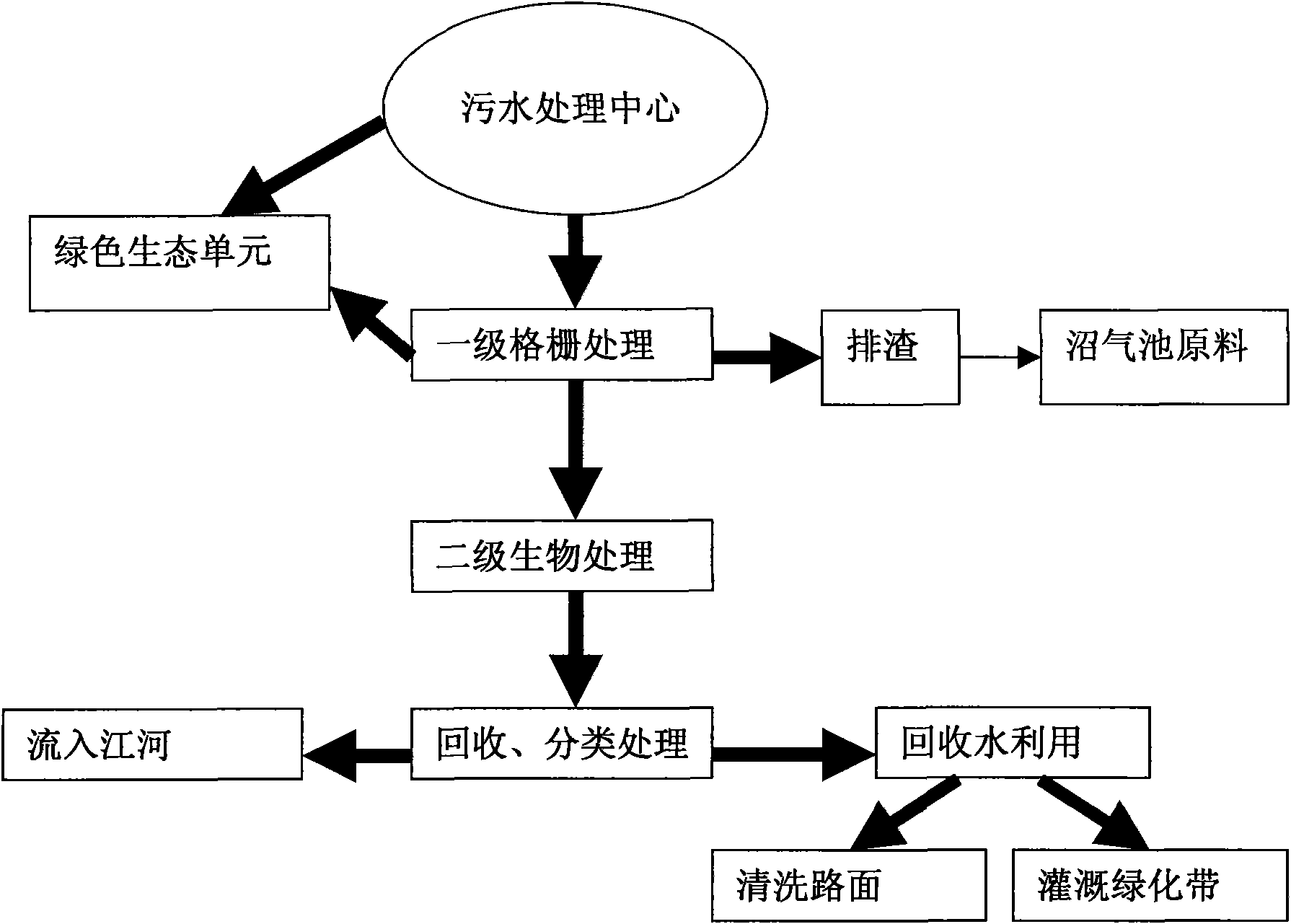

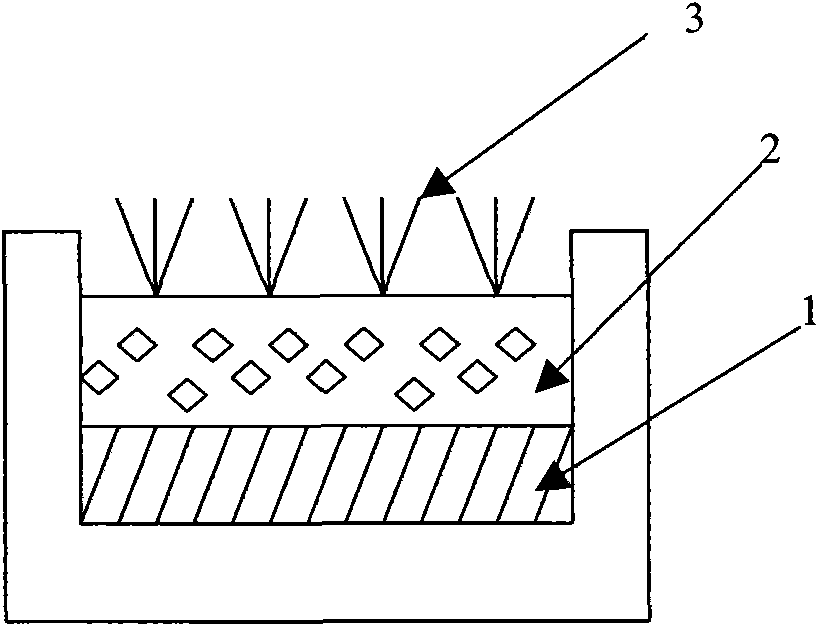

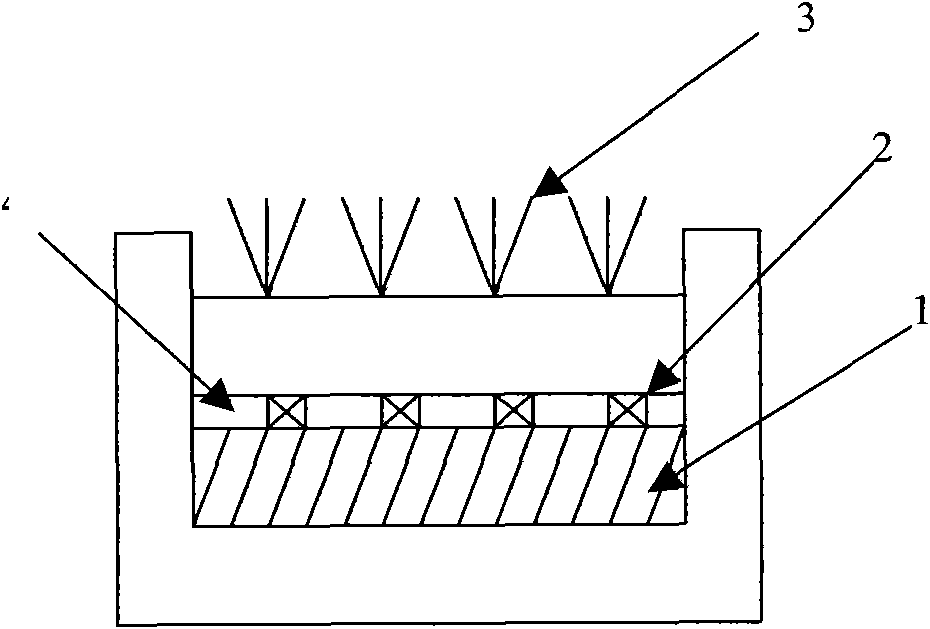

Artificial ecological wastewater treatment unit in expressway service areas

InactiveCN101659501AGood removal effectEfficient removalFatty/oily/floating substances removal devicesWaste based fuelEutrophicationSlag

The invention relates to an artificial ecological wastewater treatment unit in expressway service areas. A layered unit is made from ecological concrete material and is divided into a plant layer, anartificial filler layer and an artificial composite filtering material bedding layer from top to bottom; the thickness of the artificial composite filtering material bedding layer at the bottom part is 4-8 cm, and the artificial composite filtering material bedding layer is formed by mixing crushed stone with the diameter of 1-4 cm, building rubbish, slag and clay particles, and the volume mixingratio is 6:2:1:1; the artificial filler layer is formed by mixing original soil and sawdust, the volume mixing ratio is 6:4, and the thickness is 4-6 cm; and the plant layer comprises black rush, bahia grass (12 clusters / square meter), perennial ryegrass and bulrush (18 clusters / square meter). The artificial ecological wastewater treatment unit can effectively clear the inorganic eutrophic elements, such as nitrogen and phosphorus, in the sewage water, removes various organic pollutant substances such as SS, COD, BOD5, and the like, and conforms to the characteristics of low water quantity andunstable water quality of expressways; in addition, the artificial ecological wastewater treatment unit has wide application range, is not limited by sites, also can be used for treatment of pools, domestic wastewater and industrial wastewater, and is less in construction investment and convenient to operate.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

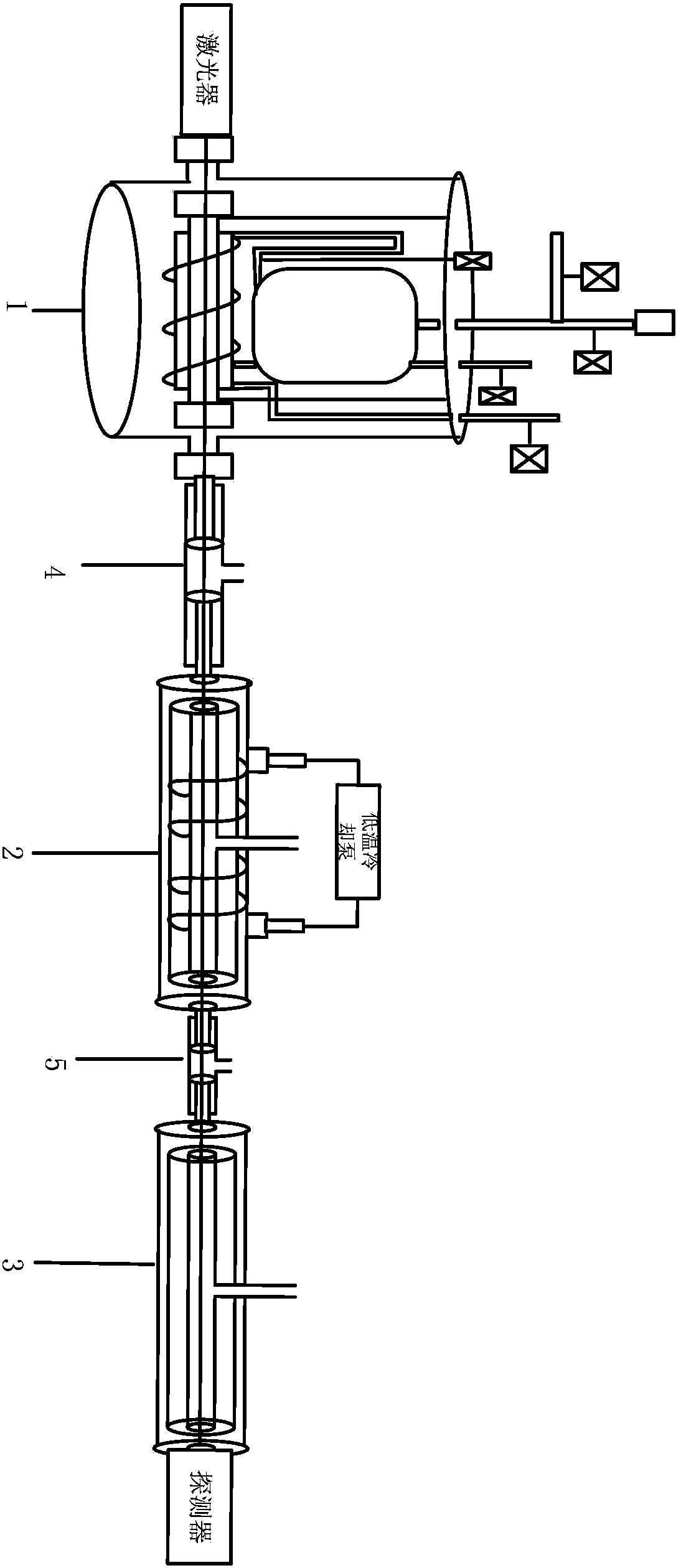

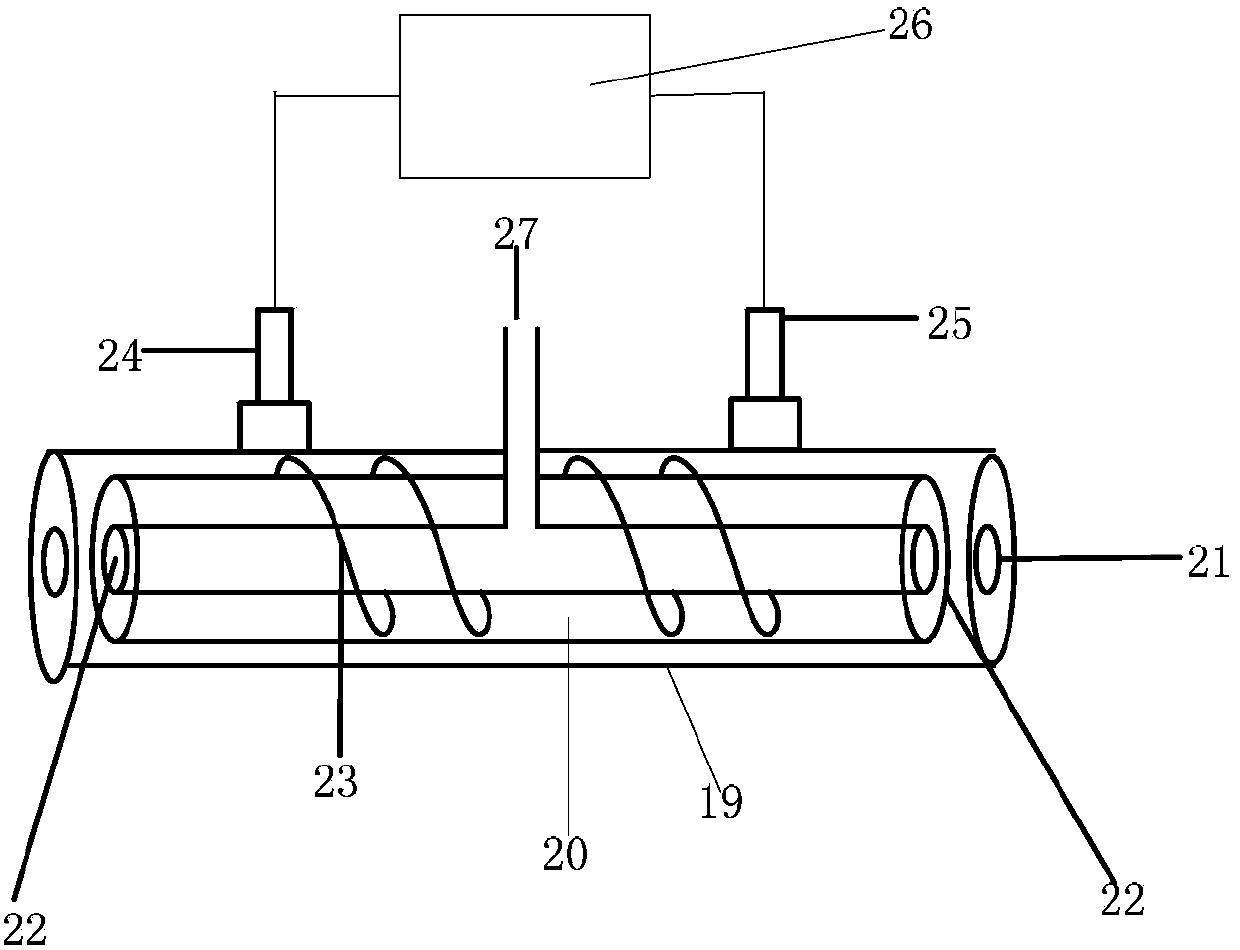

Multi-parameter temperature-controlled absorption cell device capable of simulating vertical atmospheric environment

ActiveCN103424358AReduce temperature stability effectsRapid and uniform coolingMaterial analysis by optical meansAtmospheric layerAtmospheric air

The invention discloses a multi-parameter temperature-controlled absorption cell device capable of simulating the vertical atmospheric environment. The absorption cell device is characterized by comprising a parameter-controllable, single-optical path, single-pass and low-temperature absorption cell, a parameter-controllable, single-optical path, single-pass and moderate-temperature absorption cell and a parameter-controllable, single-optical path, single-pass and ordinary-temperature absorption cell which are connected in series, wherein the low-temperature and the moderate-temperature absorption cell are connected with each other through a first optical path means; the moderate-temperature and the ordinary temperature absorption cell are connected with each other through a second optical path means; through adjusting the temperature of the single absorption cell and the gas volume mixing ratio thereof, the parameters, such as temperature gradient and pressure gradient, of the vertical atmospheric layer can be simulated in a laboratory. The absorption cell device can be used for measuring and analyzing parameters of atmosphere molecule absorption spectrum in direct combination with an absorption spectrum technology, based on which the vertical atmosphere transmittivity can be obtained, and discipline of atmosphere molecule absorption spectrum can be generalized; as the indoor environment is more stable, the device has the advantages of high precision, good stability and the like, and has important meaning for research of atmospheric optics.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

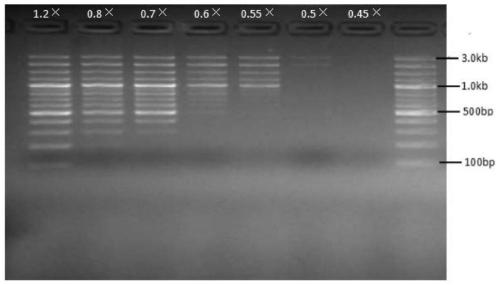

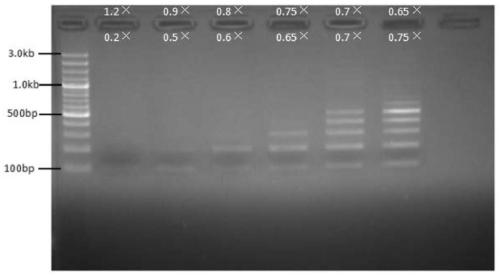

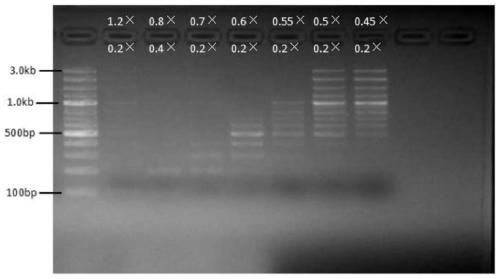

Nucleic acid fragment sorting and purifying reagent and method

ActiveCN110317805AHigh recovery rateHigh purityMicrobiological testing/measurementDNA preparationMagnetic beadRoom temperature

The invention discloses a nucleic acid fragment sorting and purifying reagent and method. The reagent comprises a magnetic bead binding solution, a washing solution and an eluting solution, and can beused for sorting and purifying targeted nucleic acid fragments of different segments in a mixture sample. Sorting of the targeted nucleic acid fragments comprises the following steps that a first nucleic acid mixture containing different segments and the magnetic bead binding solution are mixed uniformly, placed at the room temperature, and then placed on a magnetic stand for standing, supernatant is discarded, and washing and elution are carried out; the volume mixing ratio of the first nucleic acid mixture to the magnetic bead binding solution is 1:(1.2-0.45). In addition, whether or not secondary sorting is performed can be selected according to requirements, that is to say, the first nucleic acid mixture and magnetic beads are combined with the separated supernatant to be taken as a second nucleic acid mixture, and then binding separation, washing and elution are carried out again; the targeted nucleic acid fragments of different segments can be sorted by adjusting the volume of the added magnetic bead binding solution. The provided reagent and method can be used for downstream nucleic acid fragment analysis, second generation sequencing platform library construction and the like.

Owner:杭州千基生物科技有限公司 +1

Substrates coated with a polyurea comprising a (meth)acrylated amine reaction product

ActiveUS7972701B2Liquid surface applicatorsSynthetic resin layered productsMetallic substratePolyurea

A metallic substrate coated at least in part with a multilayer coating composite, comprising at least one of an electrocoat layer, a base coat layer, and a clearcoat layer; and a polyurea formed from a reaction mixture comprising isocyanate and a (meth)acrylated amine reaction product of a monoamine and a poly(meth)acrylate is disclosed. The ratio of equivalents of isocyanate groups to equivalents of amine groups in the polyurea is greater than 1 and the isocyanate functional component and the (meth)acrylated amine functional component can be applied to the substrate at a volume mixing ratio of 1:1. A building comprising a building component coated at least in part with such a polyurea is also disclosed, as is a substrate coated at least in part with such a polyurea, wherein the ratio of equivalents or isocyanate to equivalents of amine groups is greater than 1.3:1.

Owner:PPG IND OHIO INC

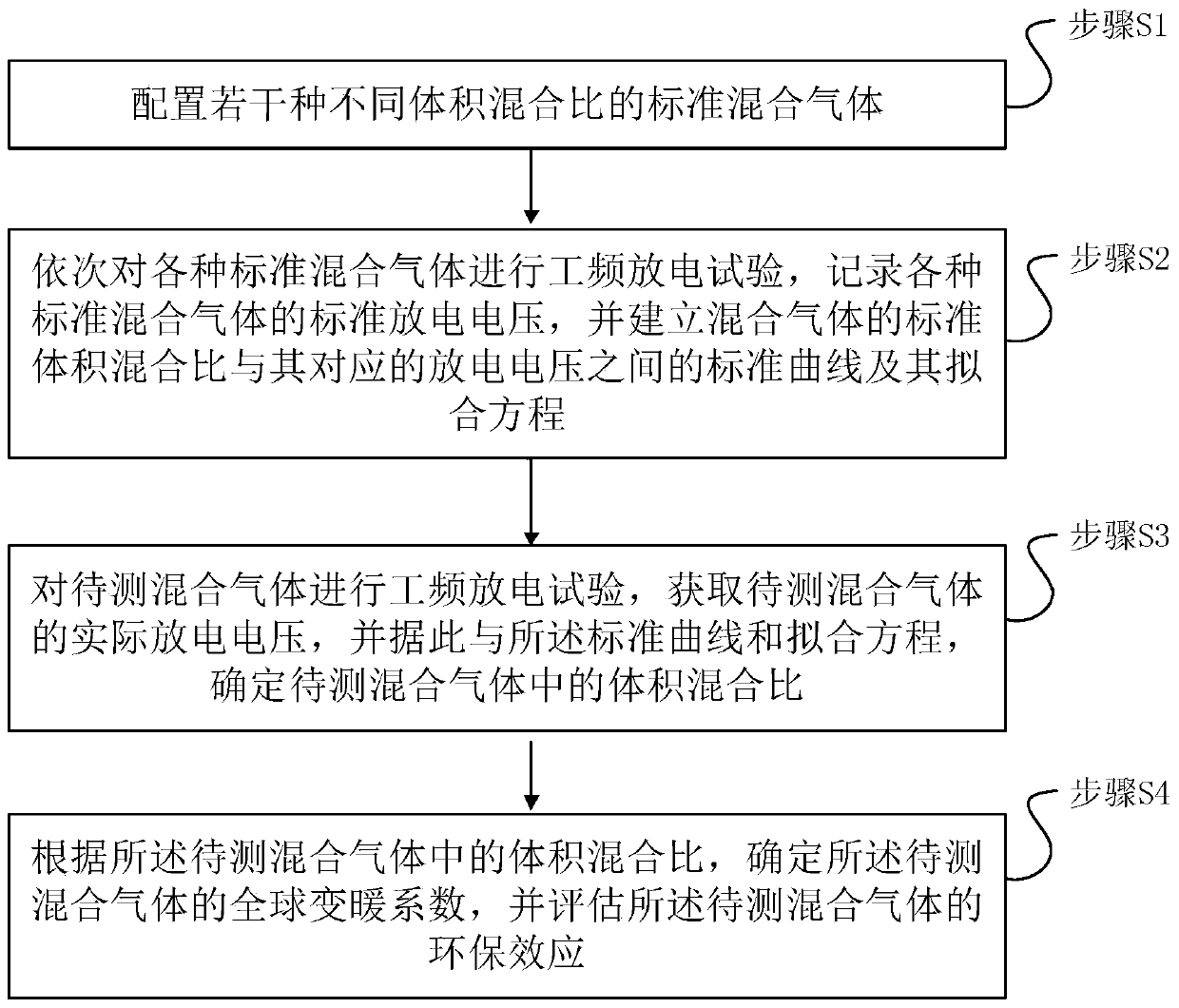

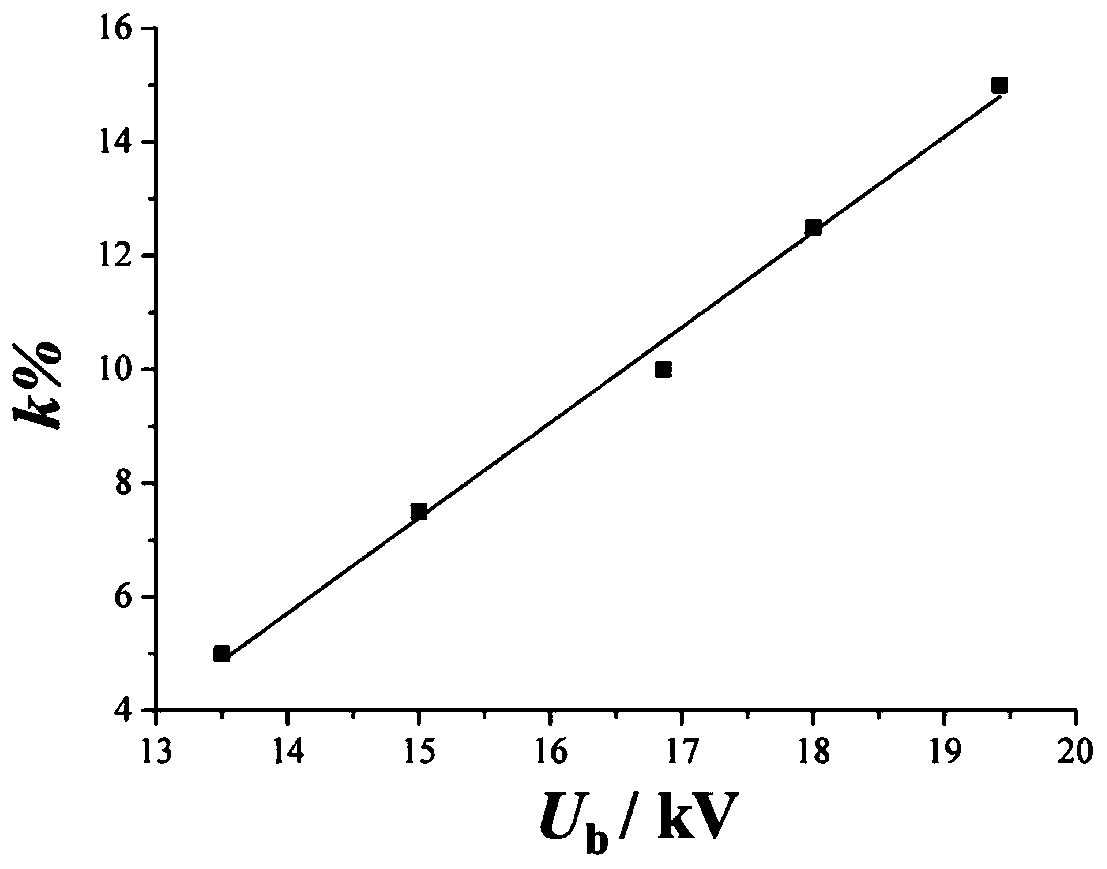

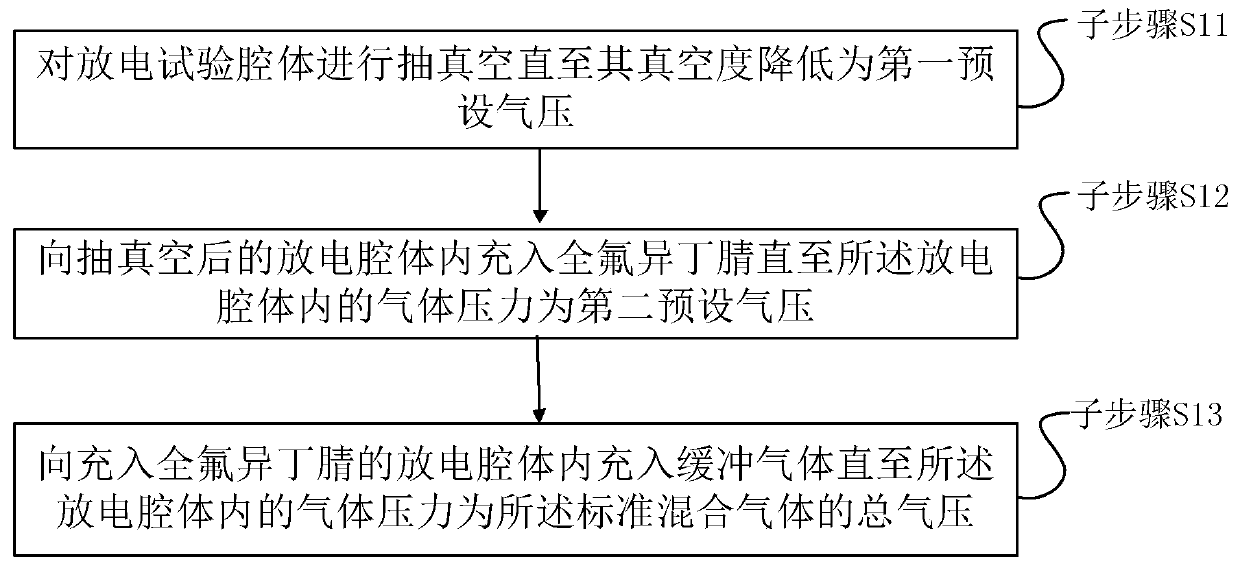

Environmental protection effect assessment method of perfluoroisobutyronitrile mixed gas

PendingCN110095529ALow GWP FeaturesReliable detectionMaterial breakdown voltageEnvironmental resistanceEngineering

The invention provides an environmental protection effect assessment method of a perfluoroisobutyronitrile mixed gas. The assessment method comprises the following steps of configuring standard mixedgases with different volume mixing ratios; carrying out a power frequency discharge test on the various standard mixed gases in sequence, recording a standard discharge voltage, and establishing a standard curve between the standard volume mixing ratio and the corresponding standard discharge voltage and a fitting equation; obtaining an actual discharge voltage of a mixed gas to be tested, and determining a volume mixing ratio in the mixed gas to be tested according to the actual discharge voltage of the mixed gas to be tested; and determining a global warming coefficient of the mixed gas to be tested and evaluating an environmental protection effect of the mixed gas to be tested. Through comparing the global warming coefficient of the perfluoroisobutyronitrile mixed gas to be tested witha preset threshold, the environmental protection effect of the gas to be tested is evaluated to ensure that the configured perfluoroisobutyronitrile mixed gas has a lower GWP characteristic so as to satisfy a current environmental protection replacement requirement to insulation and arc extinguishing media.

Owner:CHINA ELECTRIC POWER RES INST +3

Preparation method for plastic permeable soft foundation layer of artificial turf

InactiveCN110258243AEasy to switchIt also has the function of sponge cityGround pavingsArtificial turfMaterials science

The invention discloses a preparation method for a plastic permeable soft foundation layer of artificial turf, and belongs to the field of artificial turf. The plastic permeable soft foundation layer of the artificial turf comprises the following raw materials in parts by volume: 70-90 parts of sand, 29-7 parts of soil and 1-3 parts of additives. The preparation method comprises the following steps: detecting the particle size grading ratio of the sand to the soil, and calculating the volume mixing ratio of the sand, the soil and the additives according to the particle size grading ratio; sequentially adding the sand, the soil and the additives into a stirrer in a ratio, and stirring for 2-3min at an intermediate speed; and backfilling the mixed mixture of the sand, the soil and the additives into a site, flatly scraping, watering, compacting, drilling and flatly dragging. The raw materials used in the preparation method for the plastic permeable soft foundation layer of the artificial turf are all natural materials, and are more environment-friendly compared with the prior art. The plastic permeable soft foundation layer of the artificial turf is capable of storing water, and has the function of a sponge city to a certain extent. The plastic permeable soft foundation layer of the artificial turf is extremely similar to a material used by a root system layer of natural turf, and simple and convenient switchover between artificial turf and natural turf is achieved. The preparation method for the plastic permeable soft foundation layer of the artificial turf is obvious in cost advantage for achieving the same effect relative to a traditional process.

Owner:广州星卫草业股份有限公司

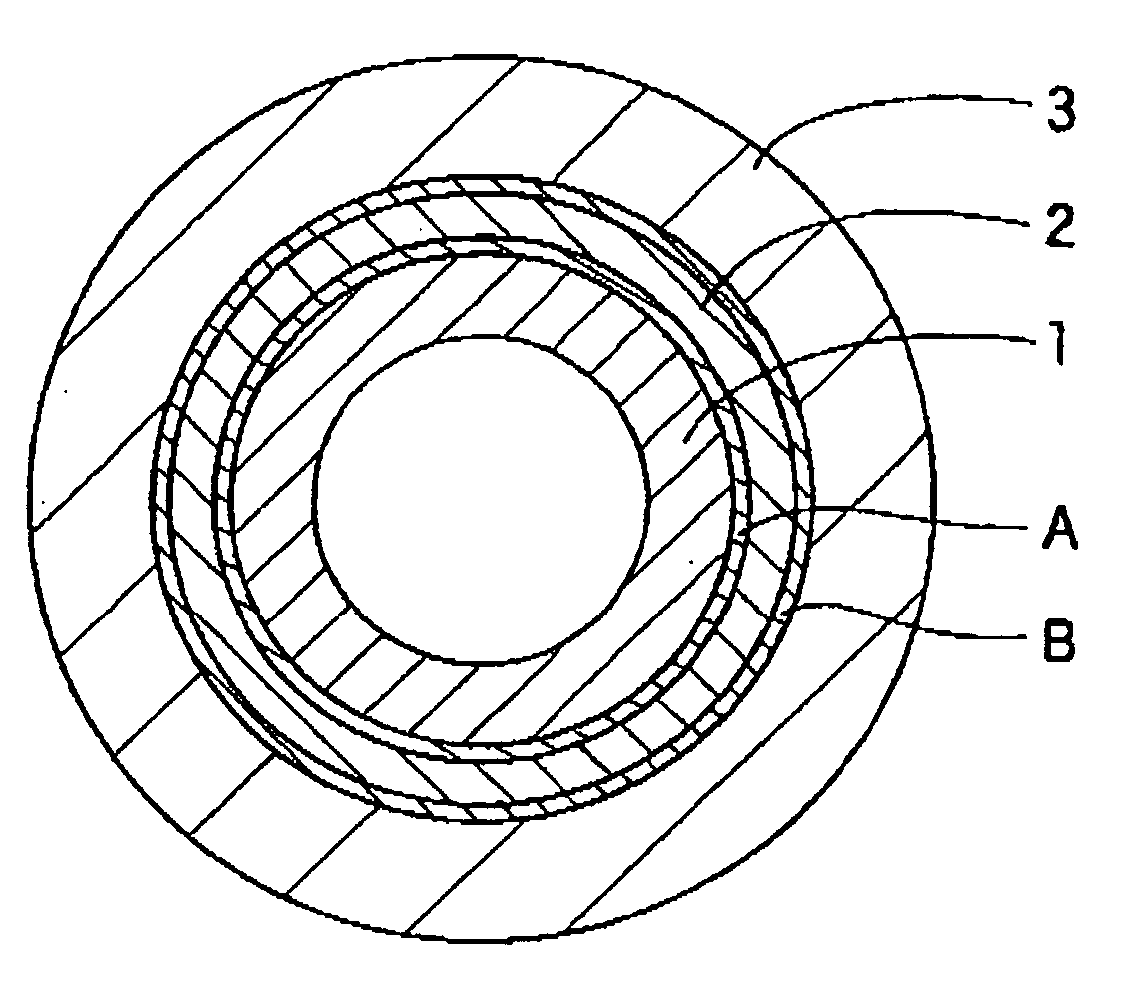

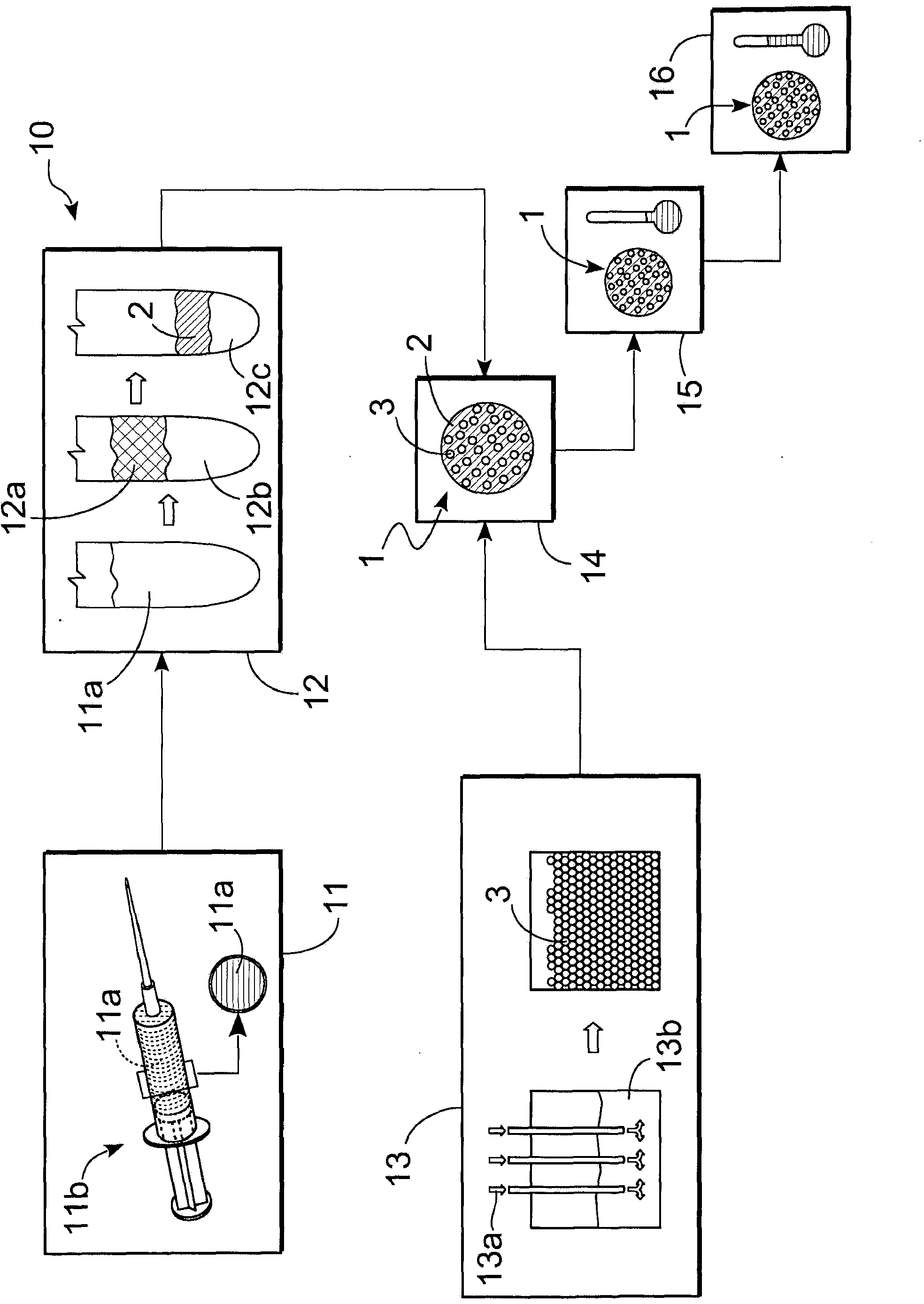

Therapeutic preparation and process for preparing said therapeutic preparation

A therapeutic preparation (1) comprising ozonised oil and a platelet concentrate (2), mixed according to a mixing ratio between the volumes of the platelet concentrate (2) and of the ozonised oil (3) substantially in the range between 2 and 4.

Owner:安德烈亚·比尼奥蒂 +1

Polyurea coating comprising a polyamine/mono(meth)acrylate reaction product

ActiveUS7968198B2Synthetic resin layered productsLiquid/solution decomposition chemical coatingMeth-Polyurea

Coating compositions comprising a polyurea formed from a reaction mixture comprising isocyanate and a (meth)acrylated amine are disclosed. The (meth)acrylated amine is the reaction product of a polyamine and a mono(meth)acrylate; the ratio of equivalents of isocyanate groups to equivalents of amine groups is greater than 1 and the isocyanate and the (meth)acrylated amine reaction product can be applied to a substrate at a volume mixing ratio of 1:1. Methods for using the coatings, and substrates coated therewith are also disclosed.

Owner:PPG IND OHIO INC

Coatings system with common activator and common volumetric mix ratio

A multilayer paint system wherein each layer of paint uses the same activator and the same mixing ratio of film-forming binder to activator. The paint system herein is particularly useful for automotive refinishing applications.

Owner:AXALTA COATING SYST IP CO LLC

Physical Dust Suppression Method of Mine Stockpile

The invention relates to a physical dust suppression method for a mine stockpile, which is characterized in that the high-water quick-setting curing agent is partially modified according to the ultra-high water-curing agent volume percentage, and prepared into a slurry suitable for spraying , use Fengshui mixed duckbill sprayer to atomize and spray this solution on the surface of the stockpile to form a thin hard shell on the surface of the stockpile. The high-water quick-setting curing agent is composed of A curing agent and B curing agent. The volume percentage of high water-curing agent is: water: first curing agent = 94 ~ 96: 6 ~ 4, water: second curing agent = 94 ~ 96: 6 ~ 4, two kinds of slurries are made, and the two kinds of slurries are divided by volume The ratio of 1:1 is mixed into a spray slurry, and the spray slurry is quickly sprayed on the surface of the pile after being atomized by a feng shui mixing duckbill sprayer. The material of the invention is non-toxic, harmless and non-corrosive, has fast setting and solidification speed, can not only suppress dust but also prevent mine damage, has low cost and can be widely popularized and used.

Owner:ANSTEEL GRP MINING CO LTD

Method for enhancing strength of microfiber glass wool

The invention relates to a method for enhancing strength of microfiber glass wool, which is characterized by comprising the following steps: mixing low-heat-value gas, of which the heating value is 2500-4000 KCa / m<3>, with air, and sending the mixture into a gas distribution disk by a fan; and after combustion, blowing flame to glass fiber at a flaming port, thereby obtaining the microfiber glass wool, wherein the flow rate of the low-heat-value gas is 0.035-0.042 m<3> / s; the volume mixing ratio of exhaust to air is 1:1.61; the diameter of the through hole of the gas distribution disk is 3.8-4.2cm; and the temperature of the flame of the gas mixture of the low-heat-value gas and the air is 1200-1500 DEG C. On the premise of keeping the flame temperature, the flow rate of the low-heat-value combustible gas is increased, thereby enhancing the tensile strength of the final microfiber glass wool product. The invention is suitable for processing higher-grade microfiber glass wool downstream products.

Owner:玉门市天鸿化工有限公司

Method for enhancing strength of microfiber glass wool

The invention relates to a method for enhancing strength of microfiber glass wool, which is characterized by comprising the following steps: mixing low-heat-value gas, of which the heating value is 2500-4000 KCa / m<3>, with air, and sending the mixture into a gas distribution disk by a fan; and after combustion, blowing flame to glass fiber at a flaming port, thereby obtaining the microfiber glass wool, wherein the flow rate of the low-heat-value gas is 0.035-0.042 m<3> / s; the volume mixing ratio of exhaust to air is 1:1.61; the diameter of the through hole of the gas distribution disk is 3.8-4.2cm; and the temperature of the flame of the gas mixture of the low-heat-value gas and the air is 1200-1500 DEG C. On the premise of keeping the flame temperature, the flow rate of the low-heat-value combustible gas is increased, thereby enhancing the tensile strength of the final microfiber glass wool product. The invention is suitable for processing higher-grade microfiber glass wool downstream products.

Owner:玉门市天鸿化工有限公司

Oxygen-free copper casting welding technology

ActiveCN103600158AKeep from blowing awayHigh yieldArc welding apparatusWelding/cutting media/materialsAlcoholMass ratio

The invention discloses an oxygen-free copper casting welding technology and relates to the technical field of oxygen-free copper casting welding technology. According to the oxygen-free copper casting welding technology, anhydrous alcohol and CJ 301 scaling powder coat on a welded junction surface of a copper casting after being mixed and then argon-arc welding is performed; the volume mixing ratio of the anhydrous alcohol and the CJ 301 scaling powder is 1 to 2.5 to 3.5; the ingredient and mass ratio of adopted medium during welding process is 25 to 35 % of nitrogen, 25 to 35 % of argon and 35 to 50 % of helium which are served as protective medium; an optimization of the ingredient mass ratio in the protective medium is 30 % of nitrogen, 30 % of argon and 40 % of helium; the environment temperature is maintained to be more than 20 degrees during welding. The oxygen-free copper casting welding technology can improve the welding quality of the oxygen-free copper casting to a large extent.

Owner:DALIPAL PIPE

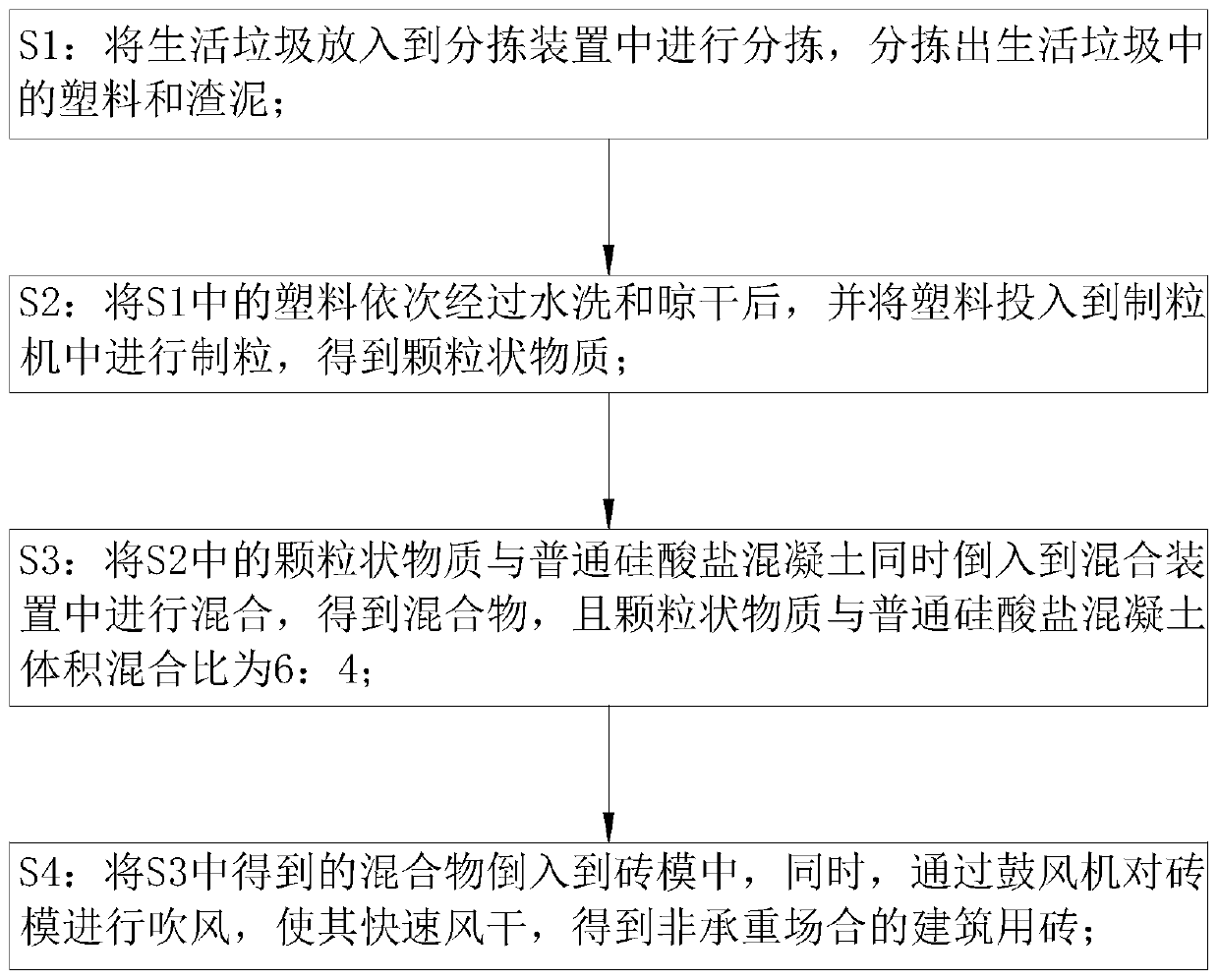

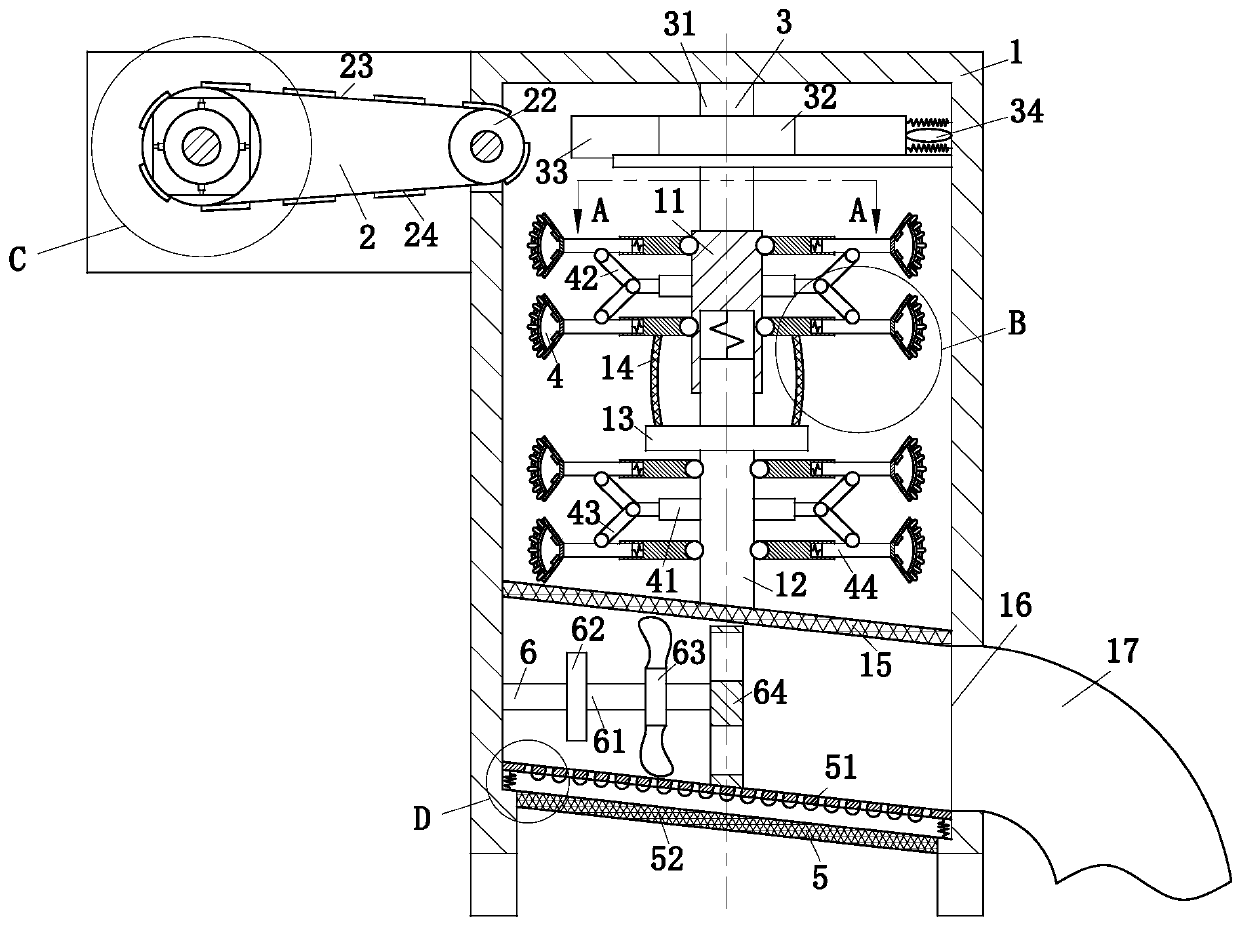

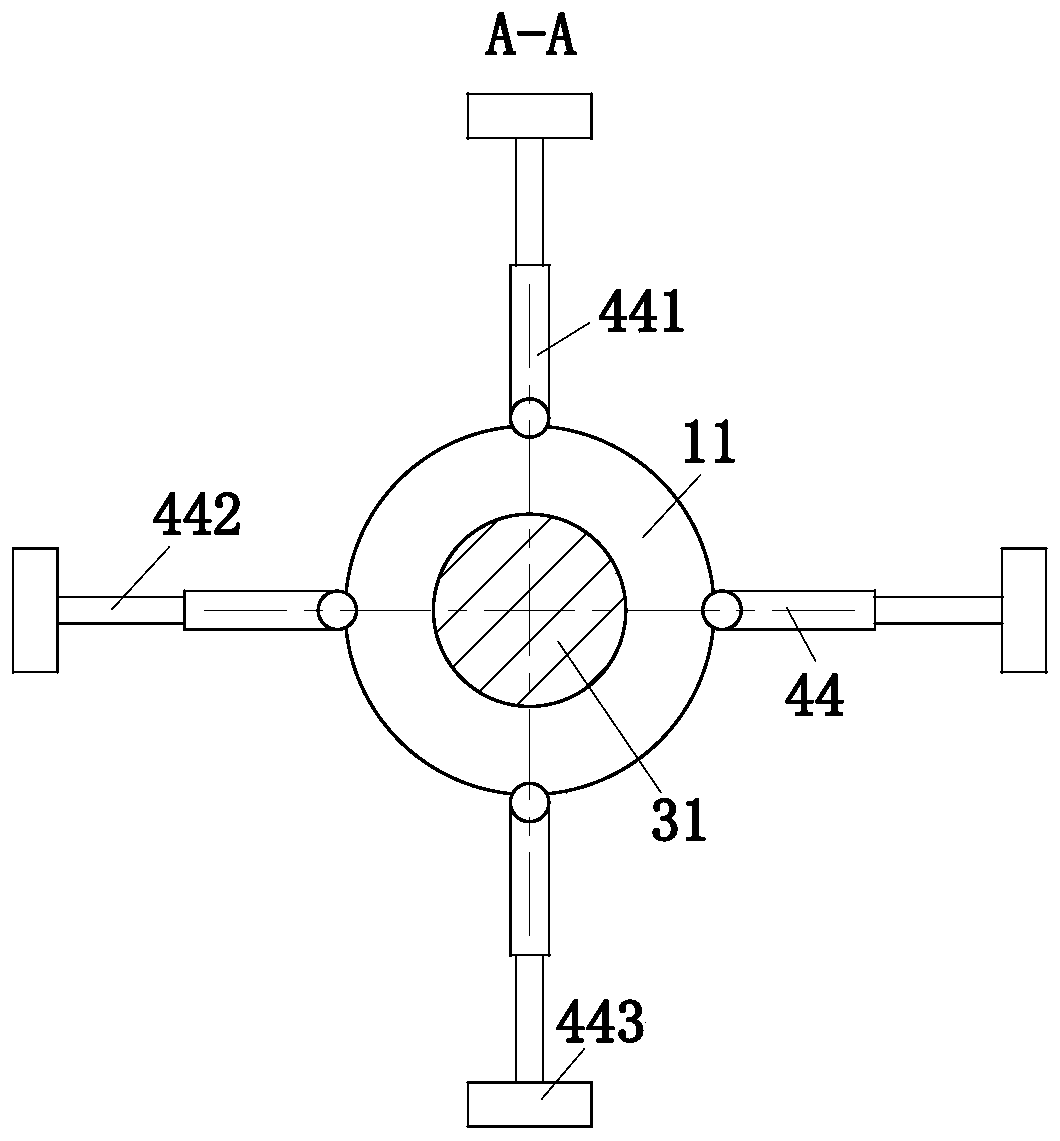

Retreatment process for domestic garbage

The invention belongs to the technical field of garbage treatment, and specifically discloses a retreatment process for domestic garbage. The retreatment process for the domestic garbage comprises thefollowing steps: firstly, placing the domestic garbage into a sorting device and sorting, and sorting out plastic and sludge in the domestic garbage; secondly, sequentially washing and airing the plastic, and then pouring the plastic into a granulator and granulating to obtain granular substances; thirdly, pouring the granular substances and common silicate concrete into a mixing device simultaneously and mixing to obtain a mixture, wherein the volume mixing ratio of the granular substances to the common silicate concrete is 6: 4; and finally, pouring the obtained mixture into a brick die, and meanwhile, carrying out air blowing on the brick die through an air blower, and rapidly air-drying the brick die to obtain a building brick for a non-bearing occasion. According to the retreatment process for the domestic garbage, other chemical raw materials are not needed as adhesives; and the process is simple, low in cost, and beneficial to environment protection.

Owner:江苏贝之元环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com