Patents

Literature

88results about How to "Rapid and uniform cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

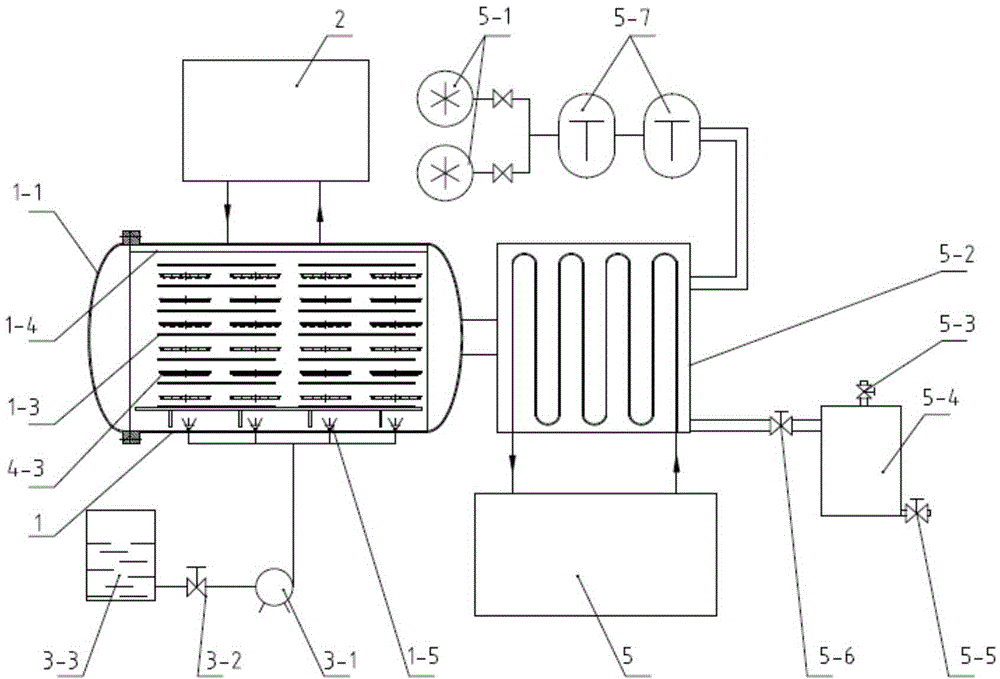

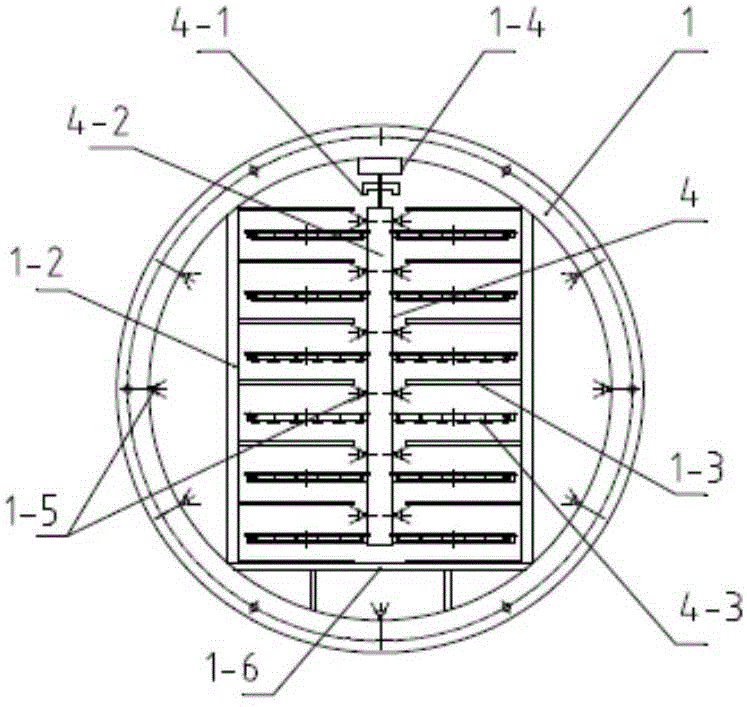

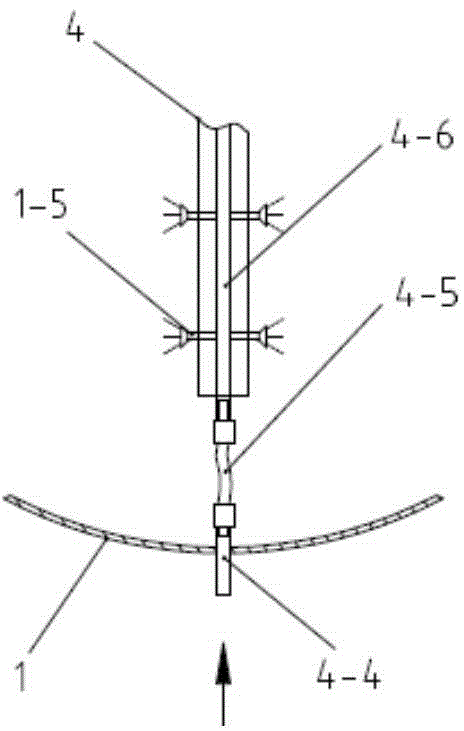

Integrated radiation vacuum freeze-dry device and method

ActiveCN104596206ALow costSimple processFruit and vegetables preservationDrying solid materials without heatWaxFreeze-drying

The invention relates to an integrated radiation vacuum freeze-dry device and method, further relates to a corresponding method, and belongs to the technical field of food devices. The freeze-dry device is characterized in that a vertical side bracket is fixed in a vacuum warehouse body, the side bracket extends out of heating shelves, and the heating shelves and a heat carrying agent heater form a heat exchange cycle system; an accommodating interval of a hanging material vehicle is formed between the two heating shelves on both sides, the hanging material vehicle comprises a vertical suspension which extends out of level trays which are positioned between the two adjacent level hollow heating shelves; spraying nozzles are distributed in the vacuum warehouse body, and are connected to a high pressure water conveying system through a pipeline. Through the adoption of the freeze-dry device disclosed by the invention, the low cost food freezing is realized, and all of the technological processes namely freezing and drying are completed once in the same device, so that the technological processes are simplified, the efficiency is obviously improved, and the freeze-dry device is suitable for various food materials, such as food materials which contain less water, are compact in texture or have wax coat surfaces.

Owner:JIANGSU BOLAIKE FROZEN TECH DEV CO LTD

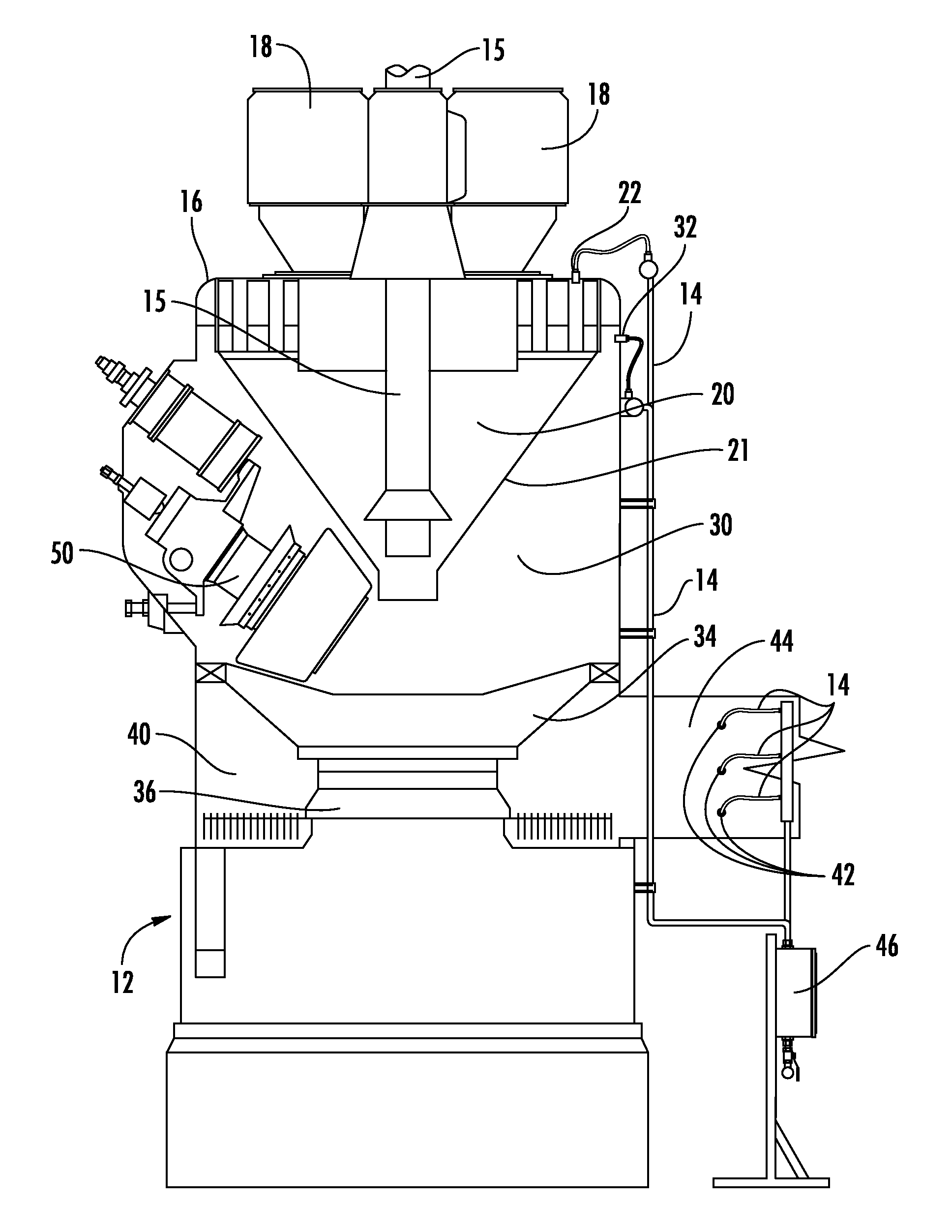

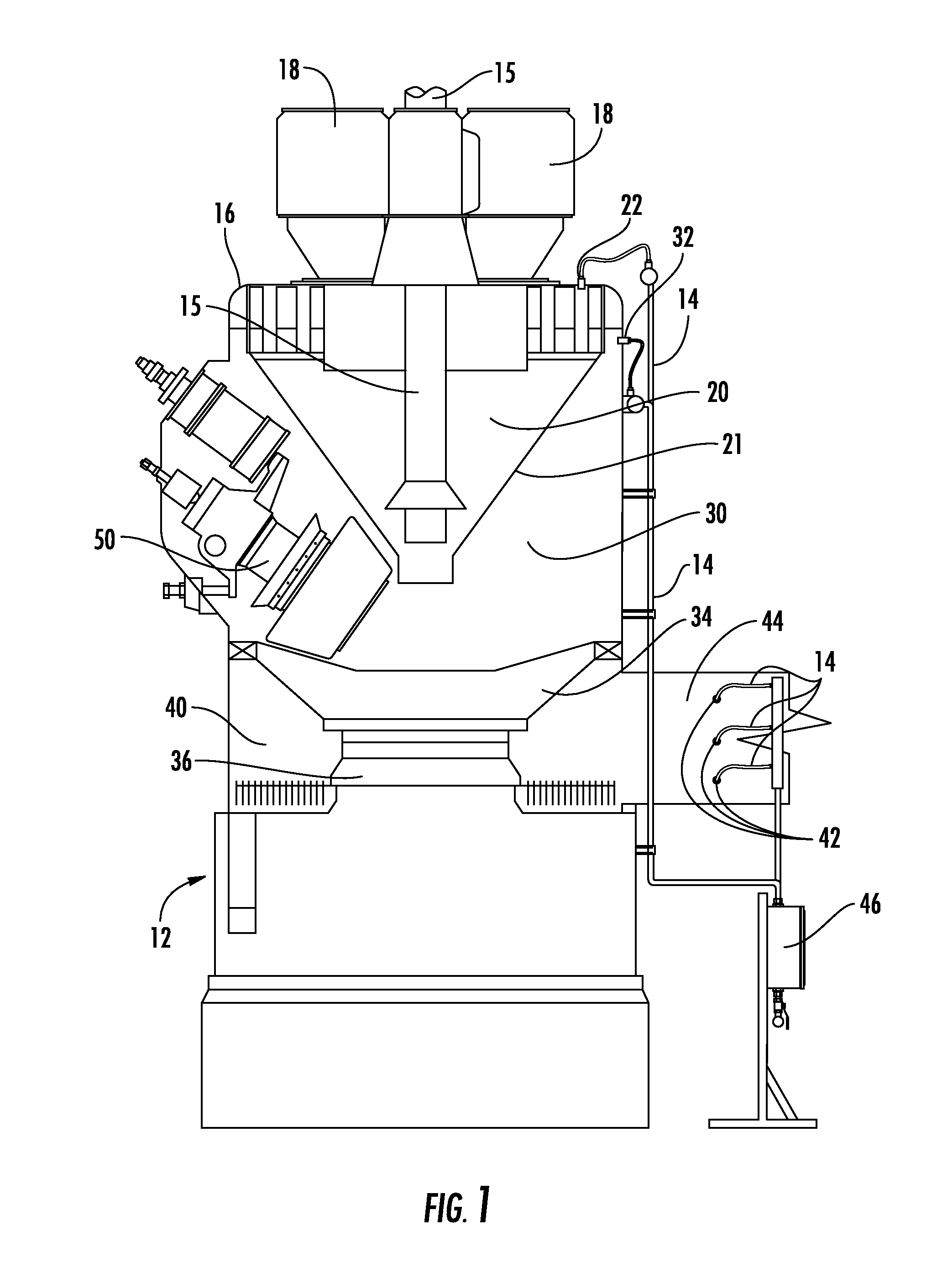

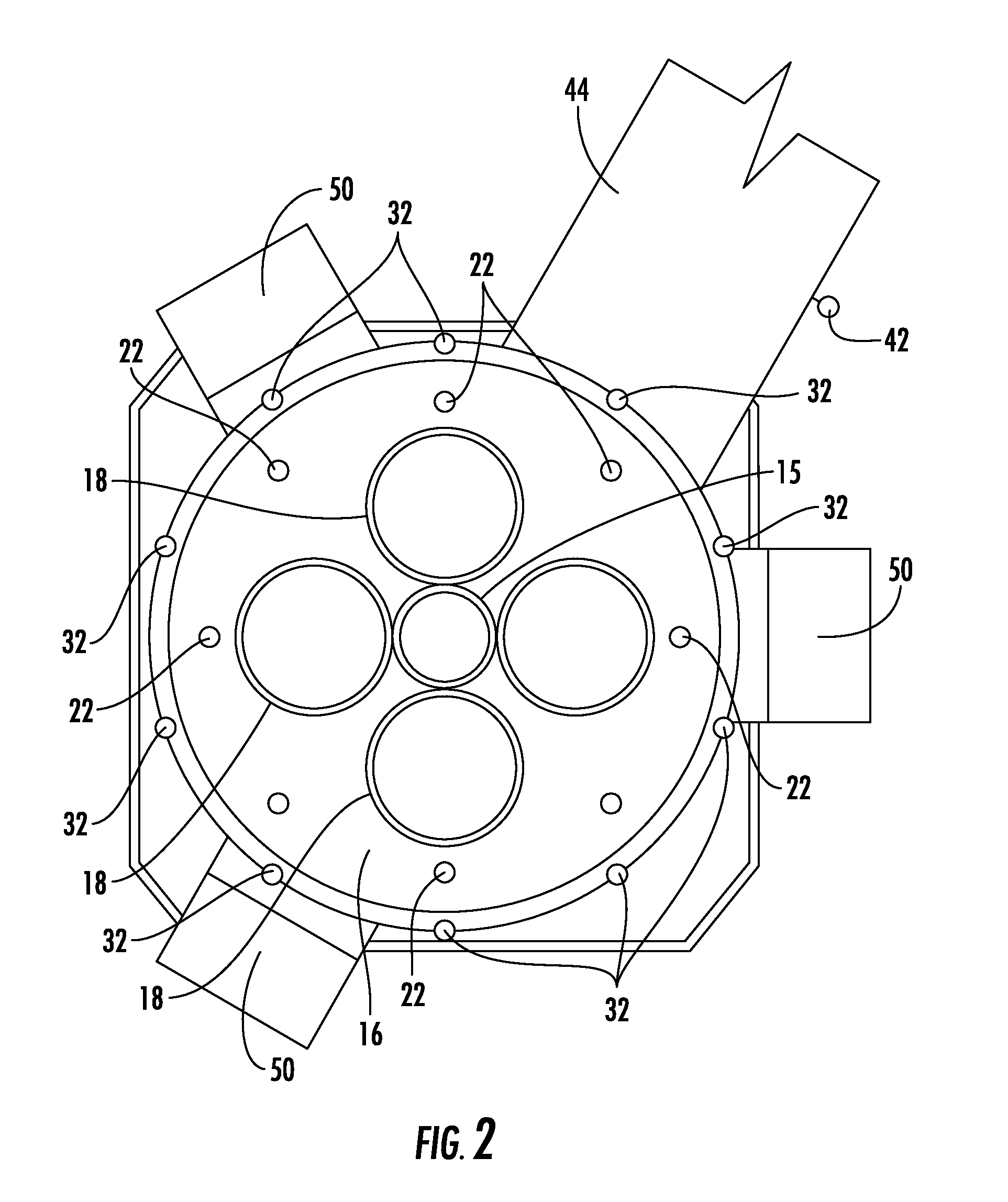

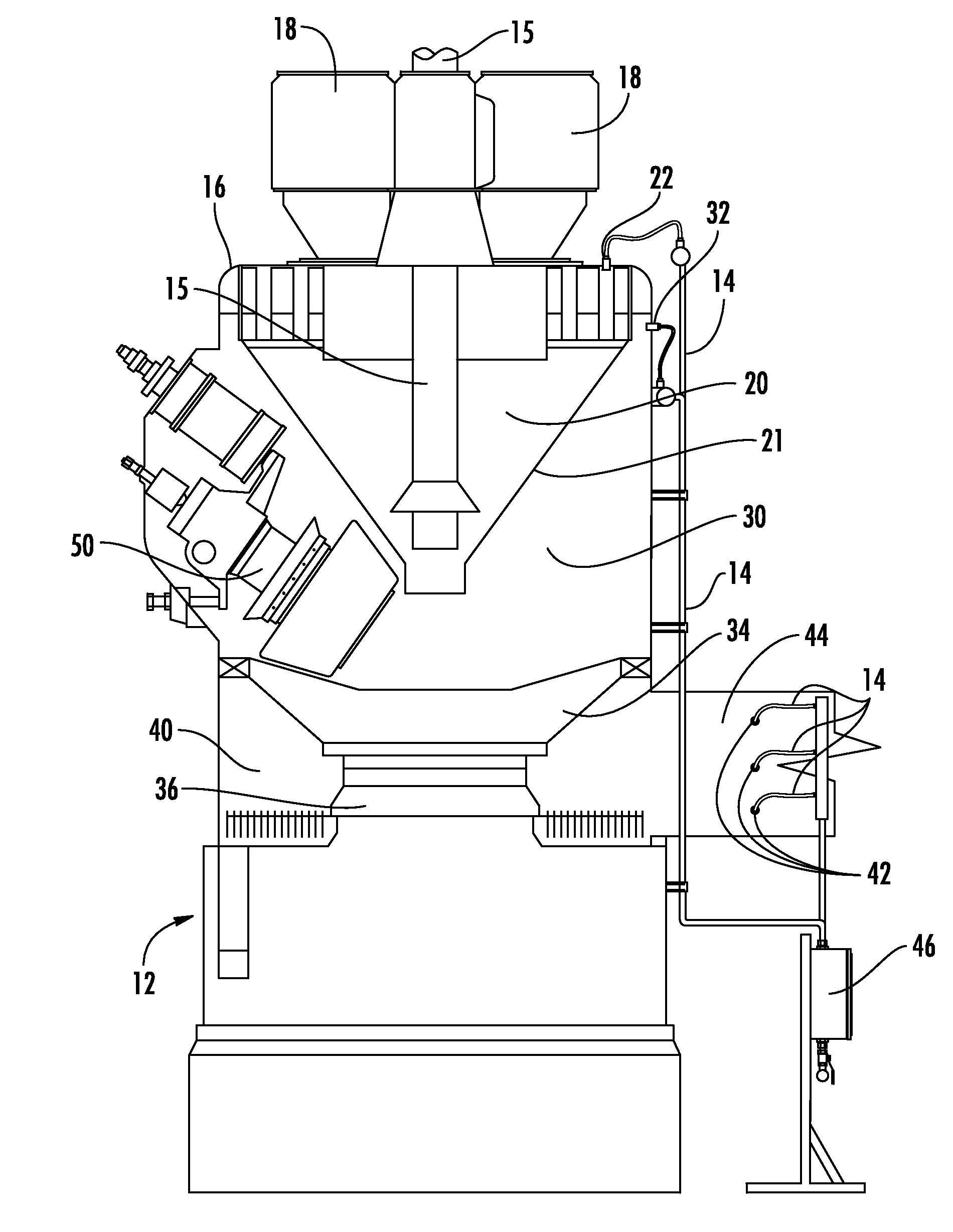

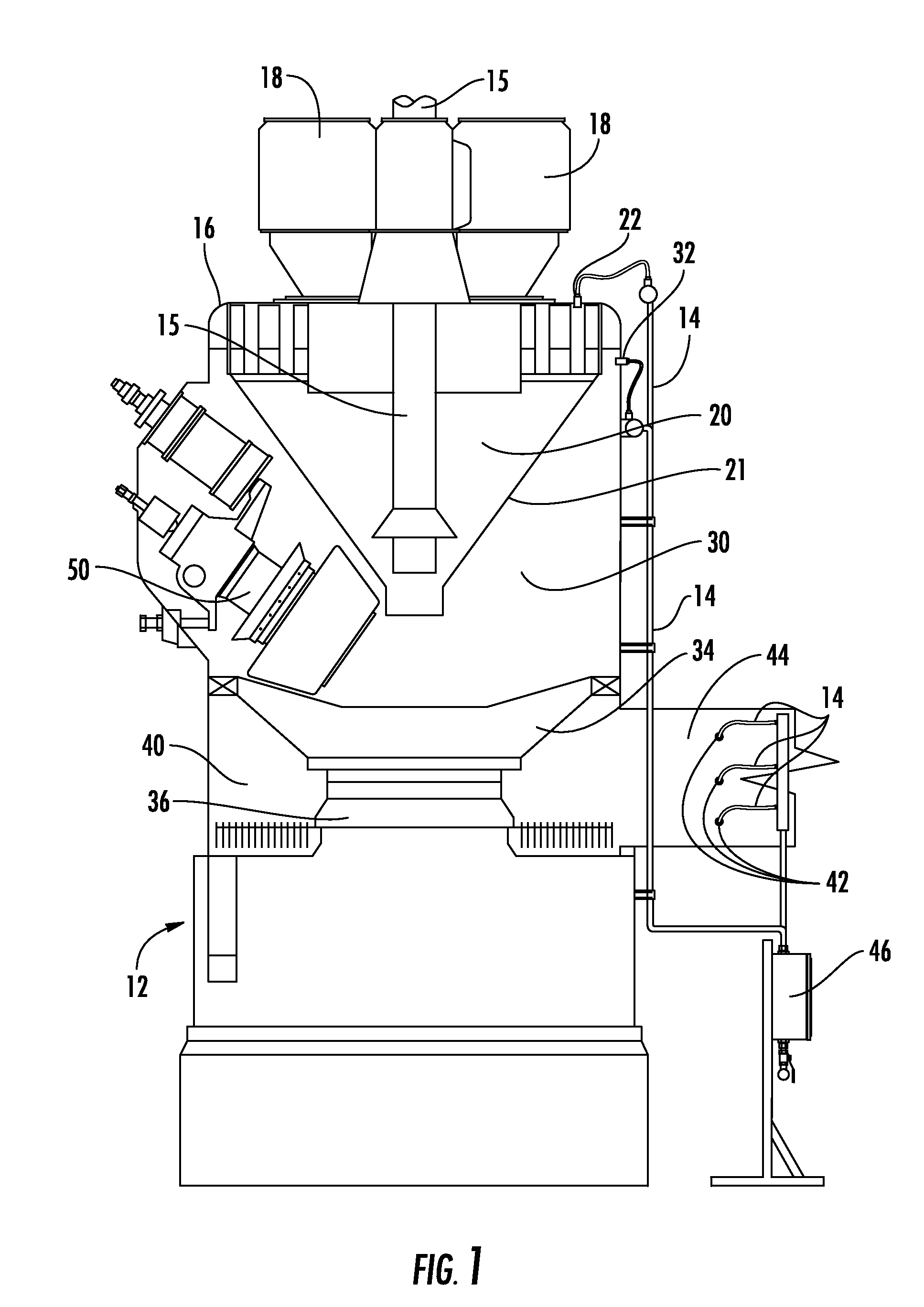

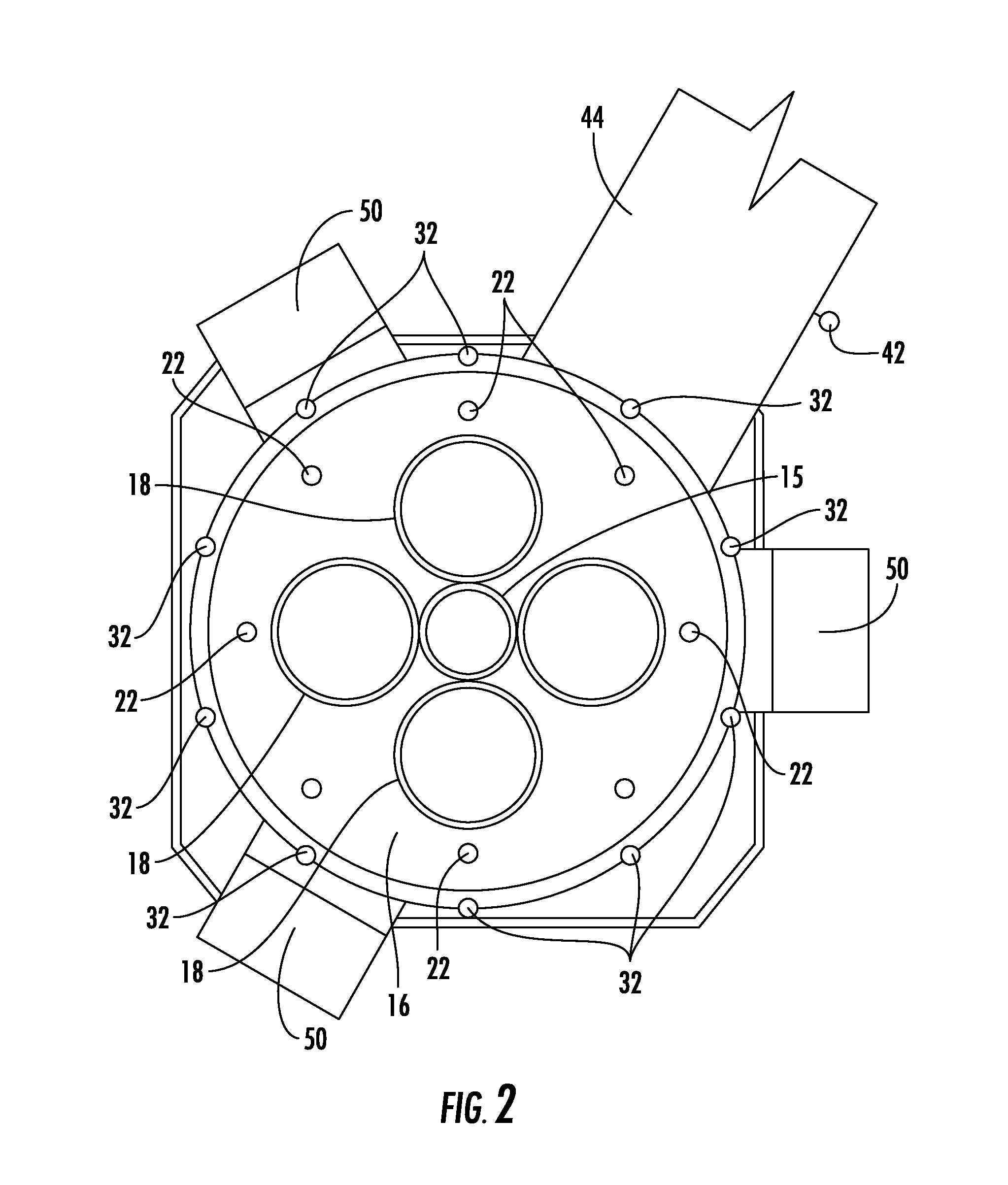

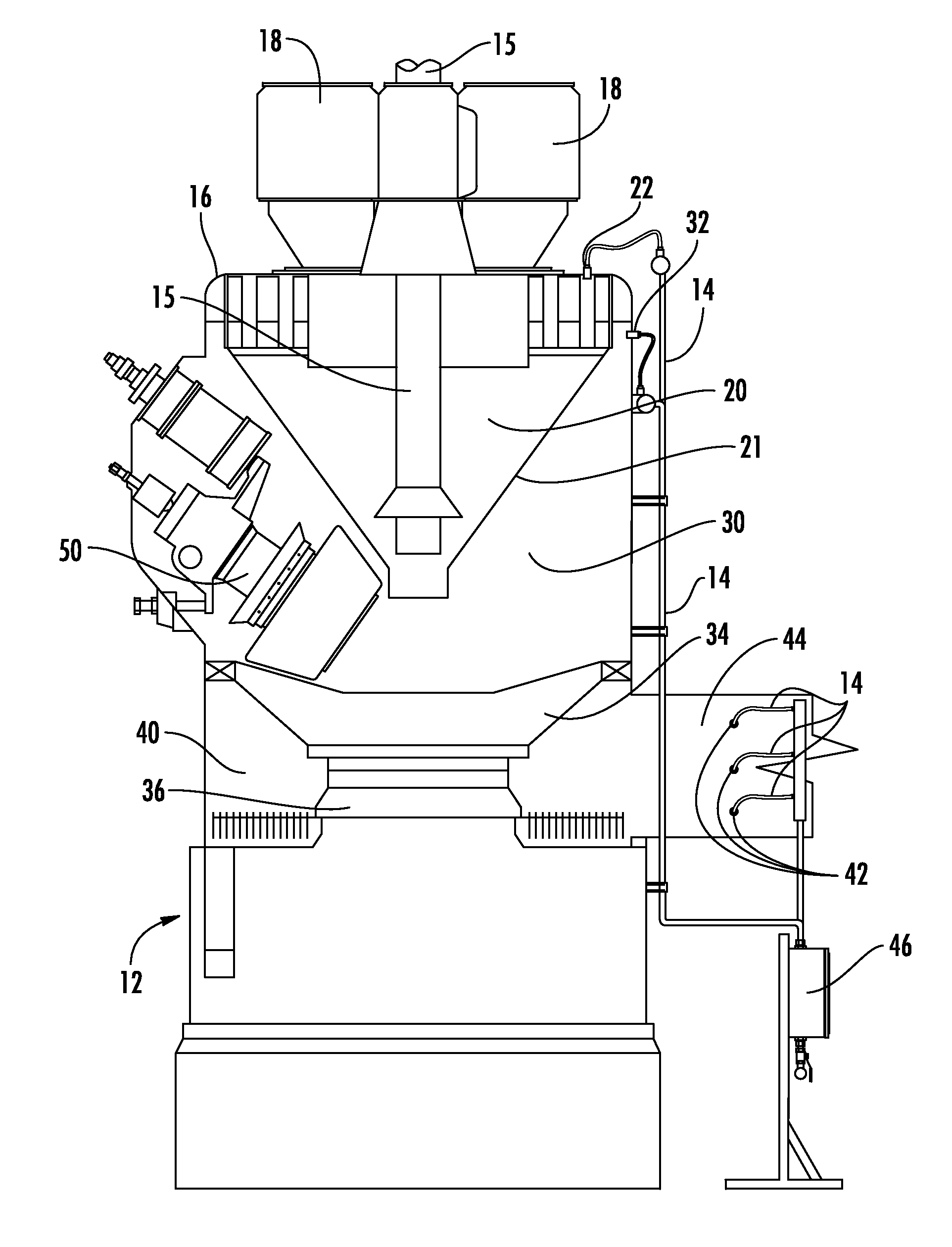

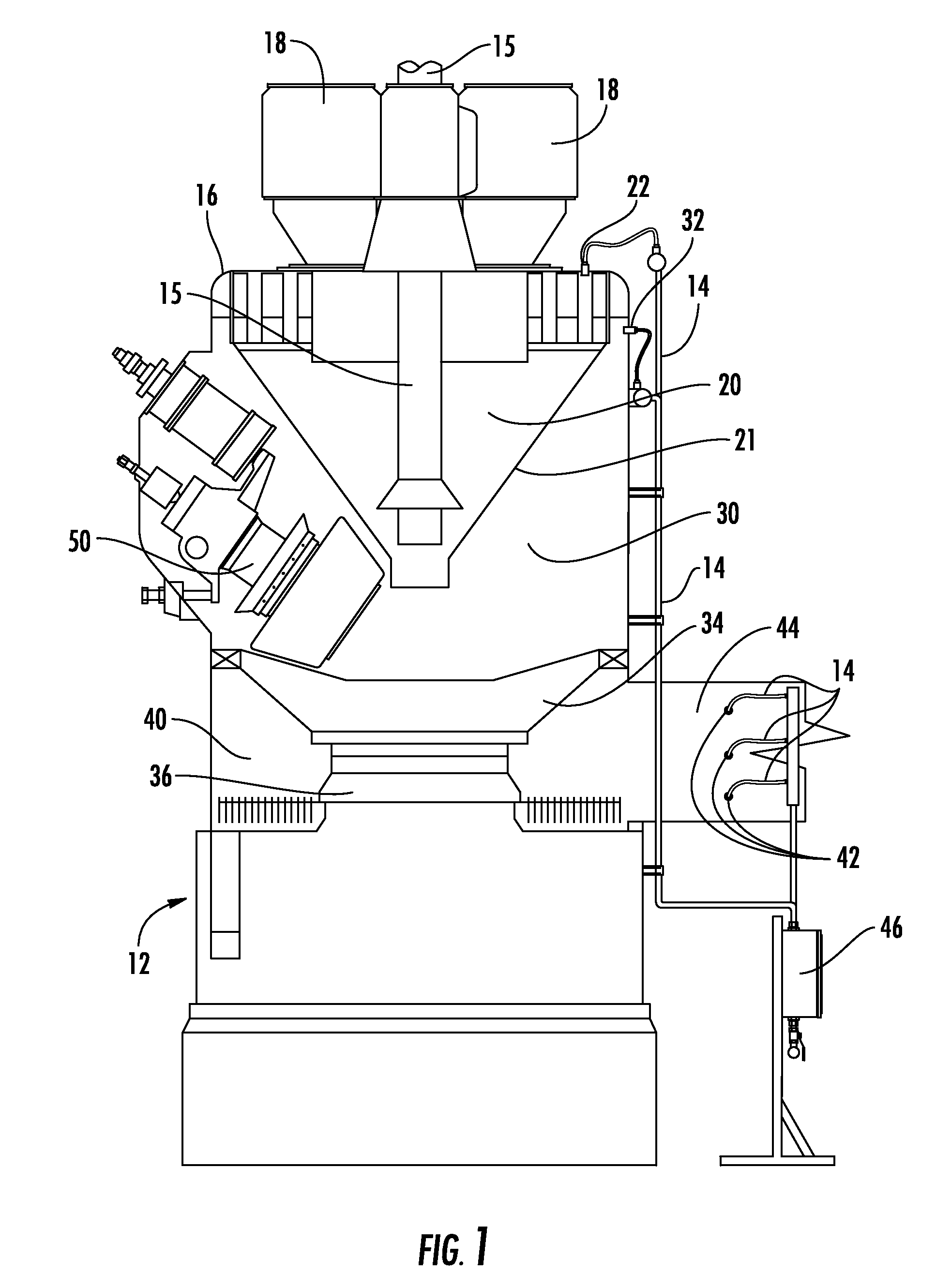

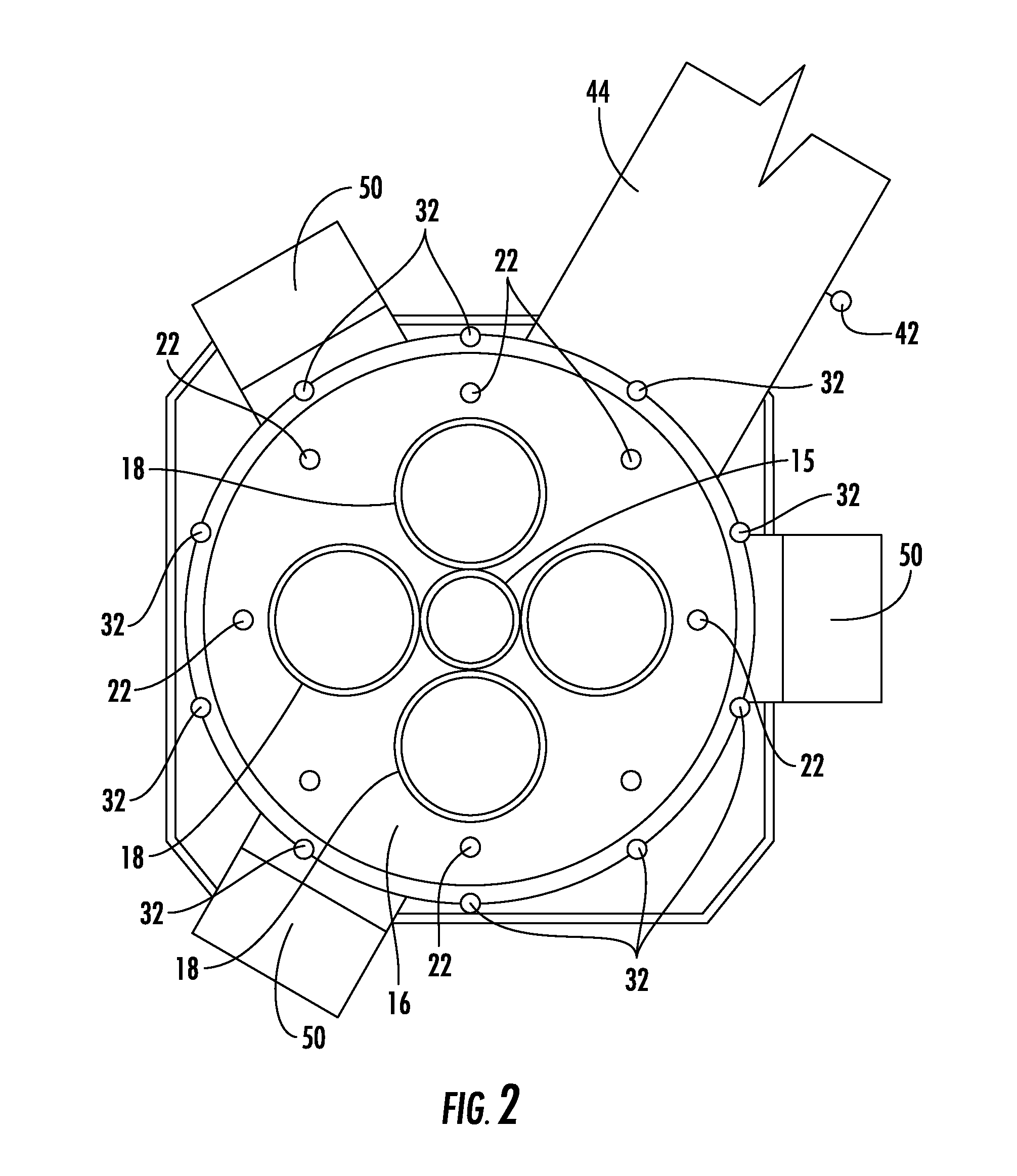

Pulverizer mill protection system

ActiveUS20160096182A1Prevents inhibitsPrevent and inhibit pulverizer mill fireFire rescueGrain treatmentsDistribution systemSpray nozzle

A system for suppressing and inhibiting fires in coal pulverizer mills can include a fire suppression solution storage tank, a flow control cabinet, an equipment control / pumping enclosure, an air distribution system, and injection piping and nozzles installed at various positions in one or more pulverizer mills. A first set of nozzle assemblies in communication with the fire suppression solution can be positioned in the mill to disperse the suppression solution within the classifier zone of the mill. A second set of nozzle assemblies in communication with the suppression solution can be positioned within the mill to disperse the suppression solution within the grinding zone. A third set of nozzle assemblies can be positioned within the primary air duct of the mill.

Owner:INNOVATIVE COMBUSTION TECH

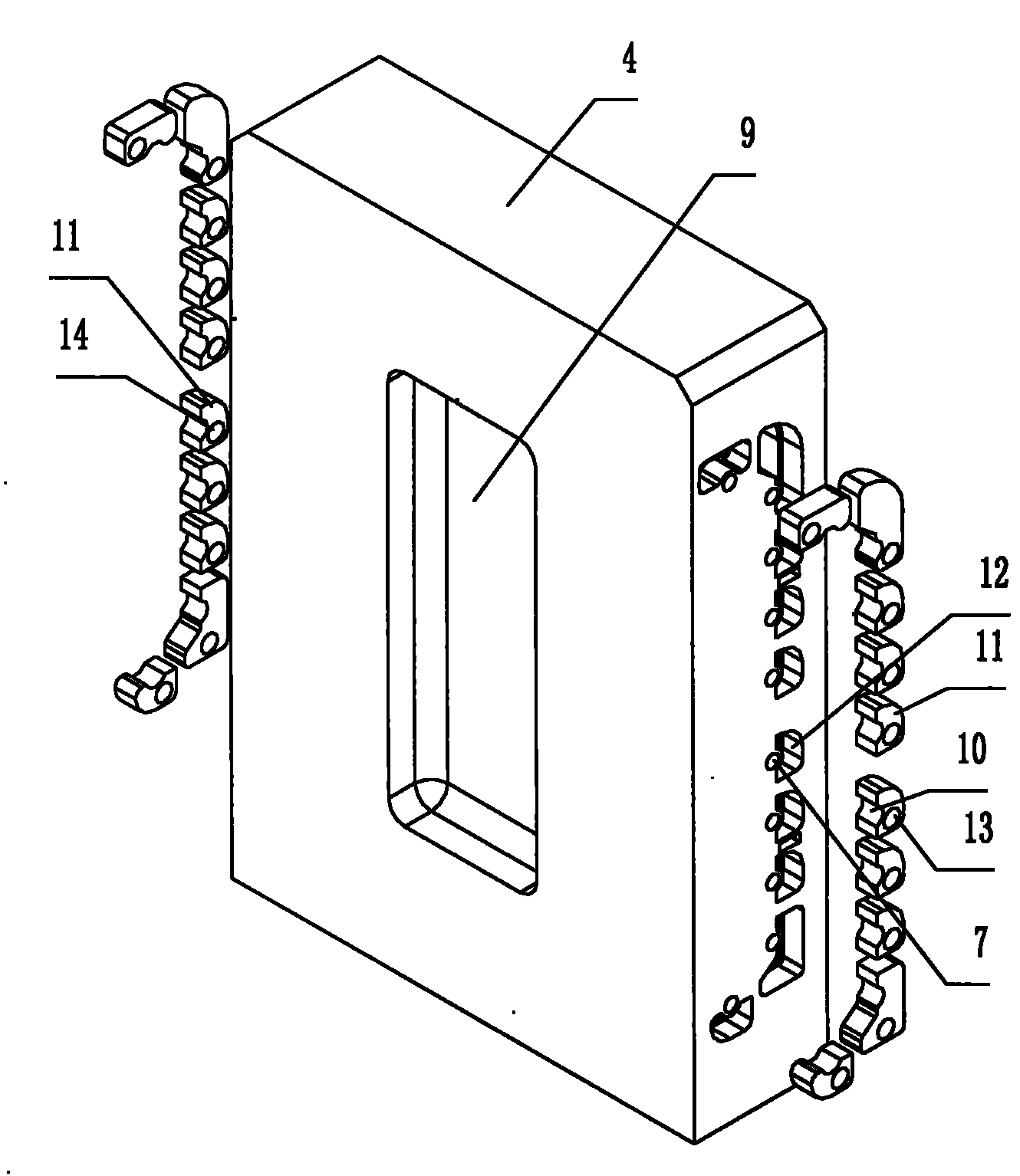

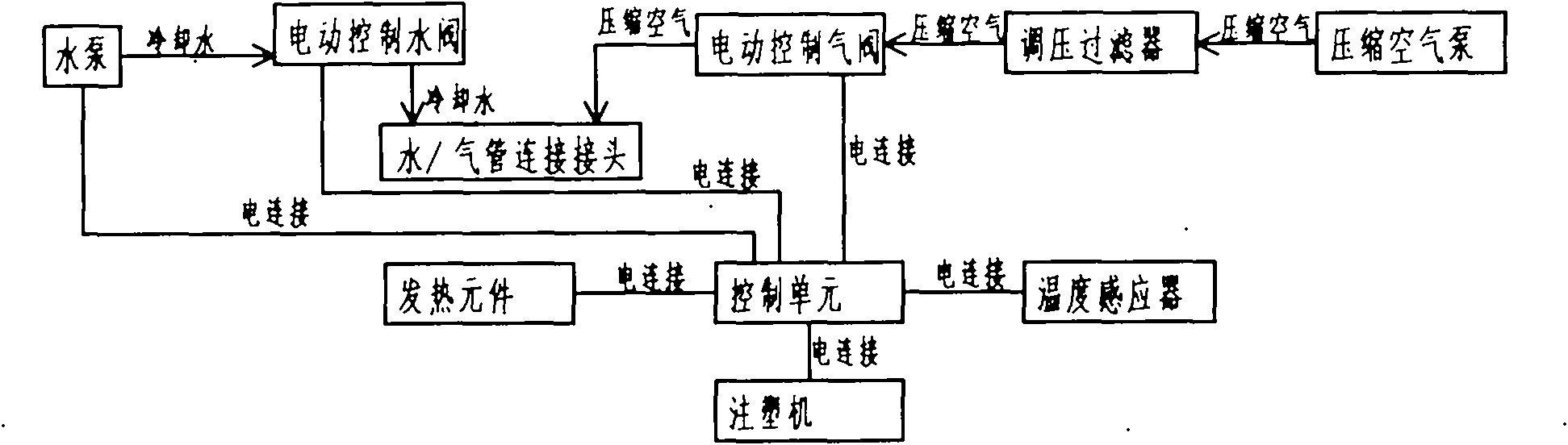

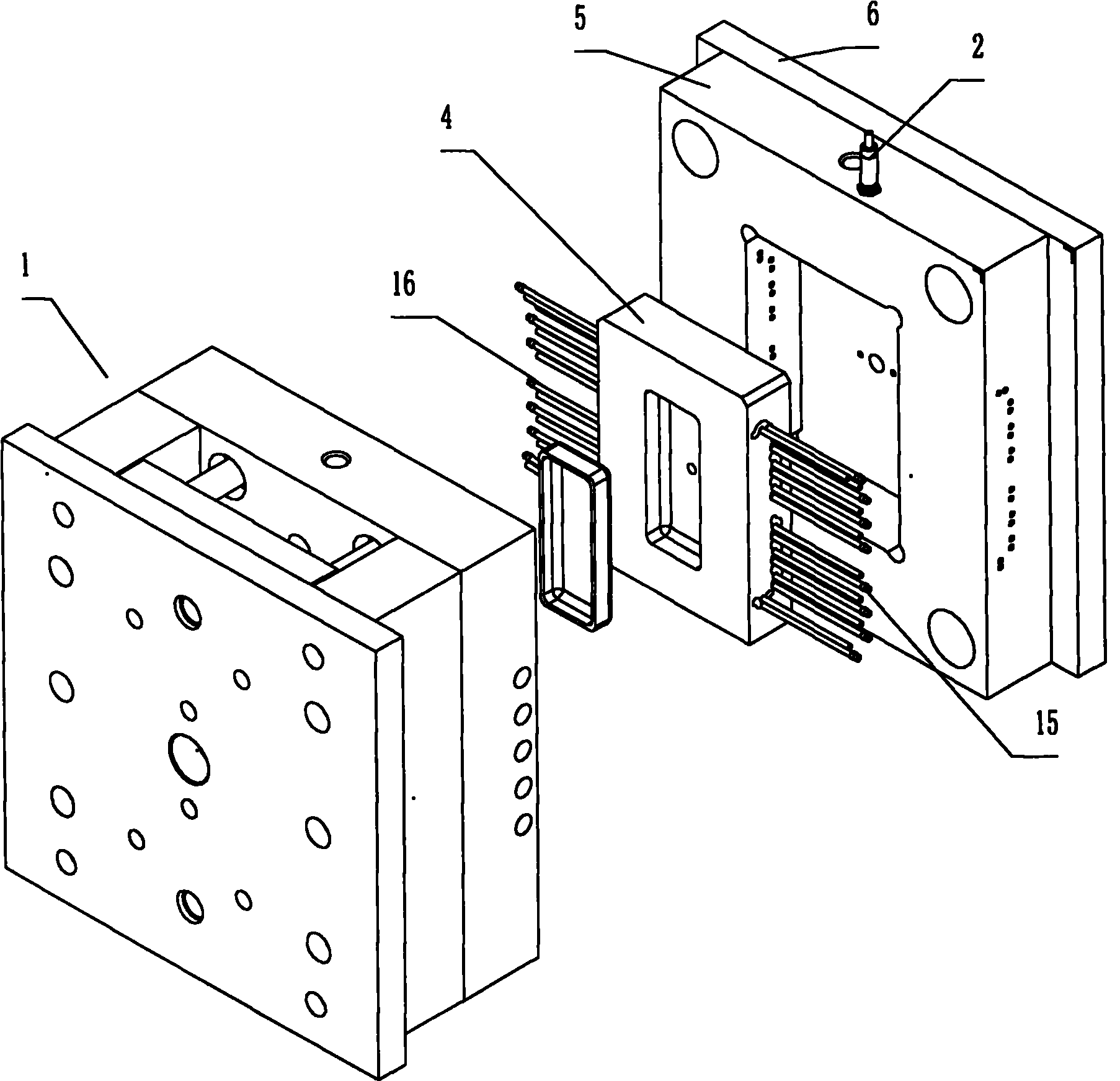

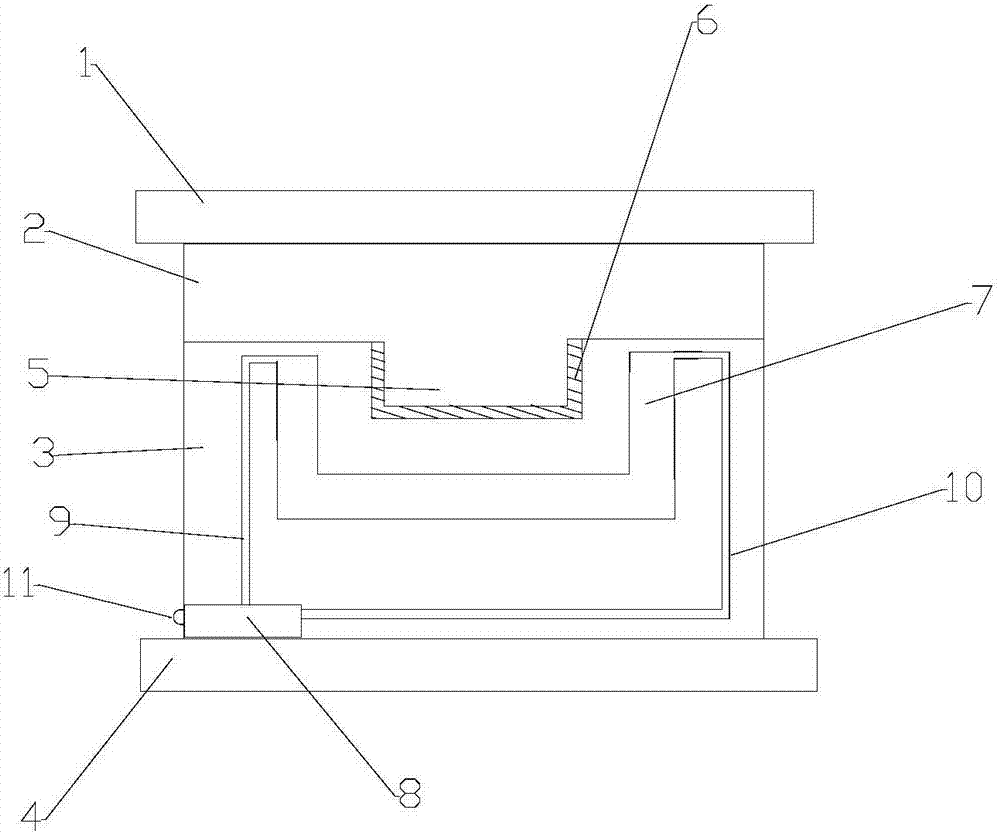

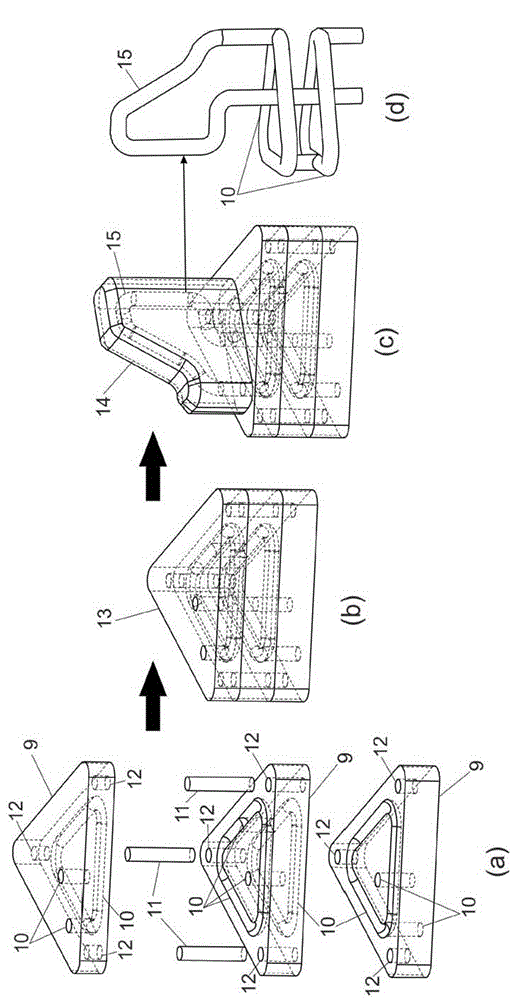

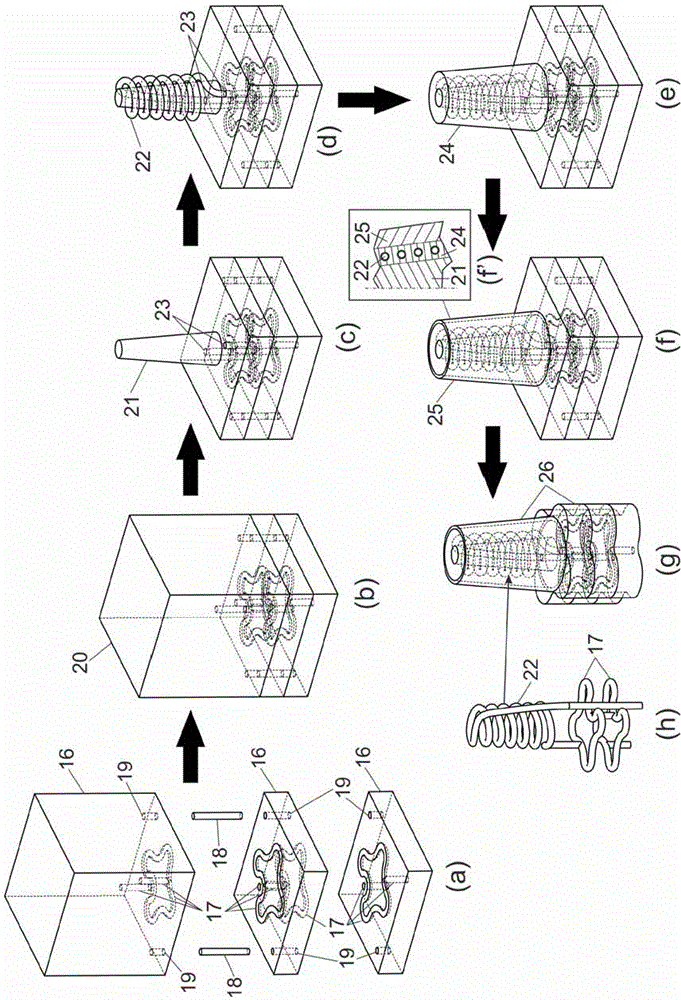

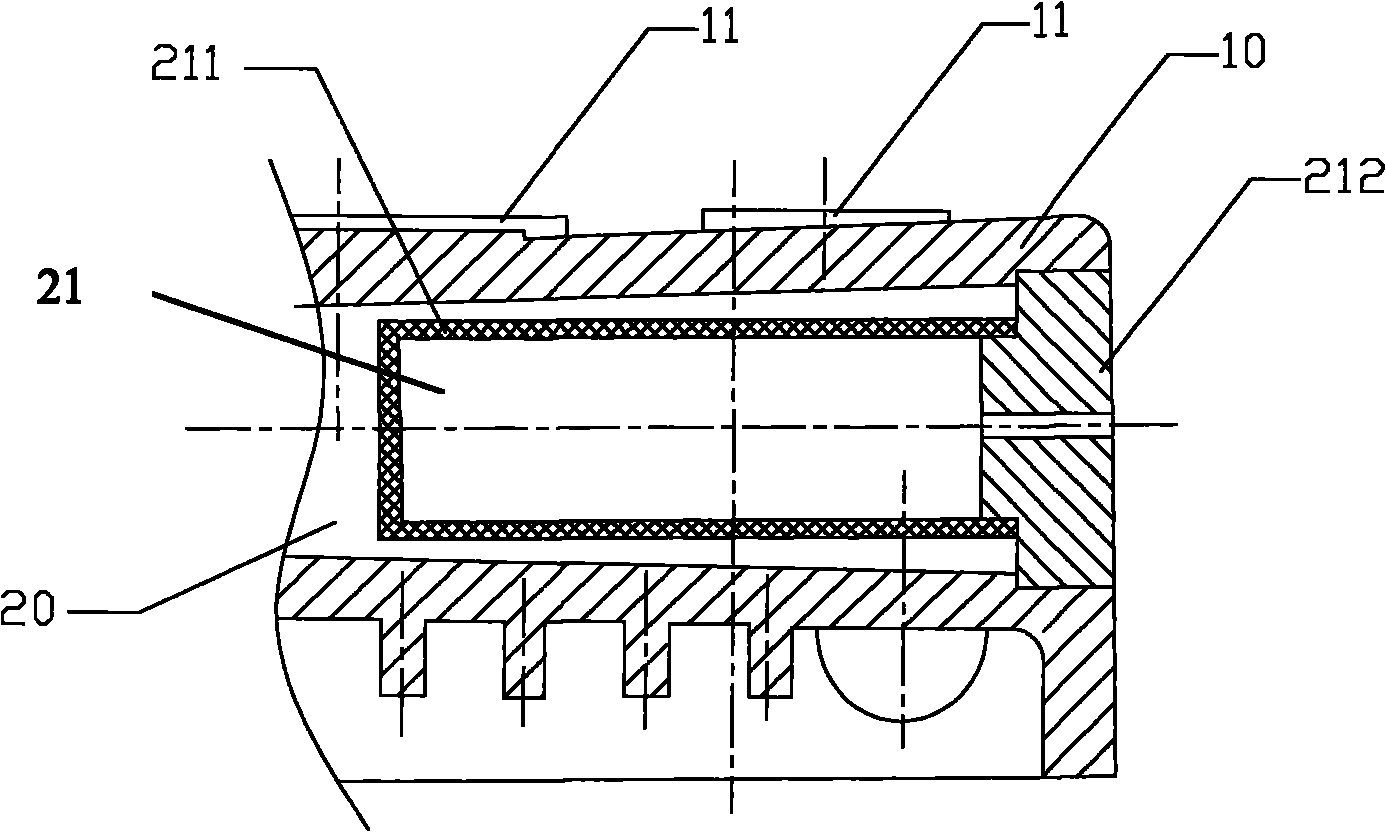

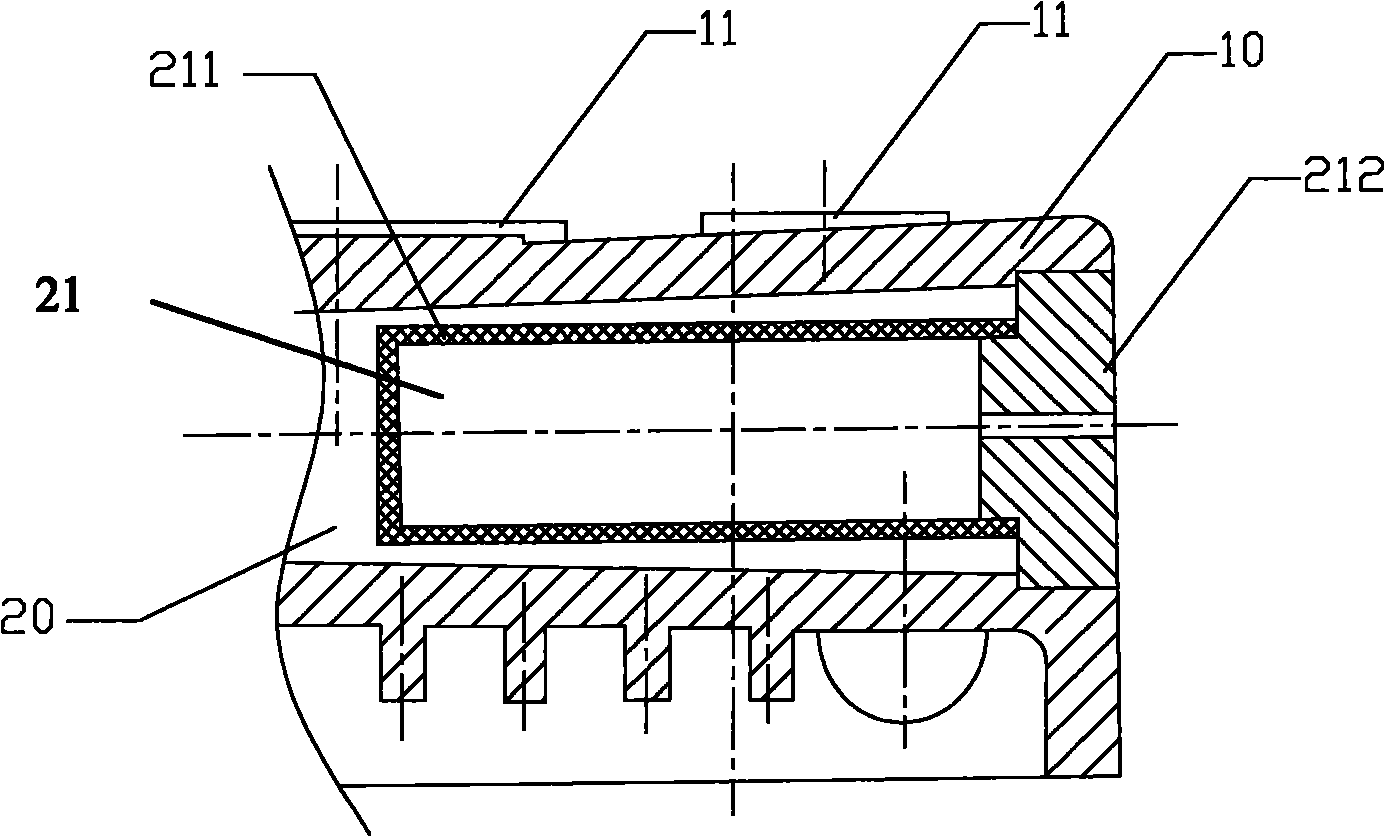

Mould capable of realizing rapid heat cycle

The invention discloses a mould capable of realizing a rapid heat cycle, which comprises a mould core provided with a moulding surface and heating rods with set number. Heating rod accommodating holes are formed at positions close to the moulding surface in the mould core and accommodate the heating rods; cooling insulation holes corresponding to the heating rods are formed at positions close to the heating rods in the mould core provided with the moulding surface, and are positioned on one side of the heating rods far from the moulding surface; the overall outline of the cross section of each cooling insulation hole is a closed curve; and one or more cooling insulation holes enclose corresponding heating rods in three directions. The mould has the advantages that: the moulding surface can be rapidly and uniformly heated and cooled, and can be rapidly heated to the temperature approaching to or equal to the temperature of a fused material, so the moulded products have good quality, weld marks, flow marks, surface bubbles and the like are not generated easily, the products have uniform luster and density and low shrinkage, and injection pressure and product deformation caused by residual stress after the fused material is solidified and moulded are reduced.

Owner:杨东佐

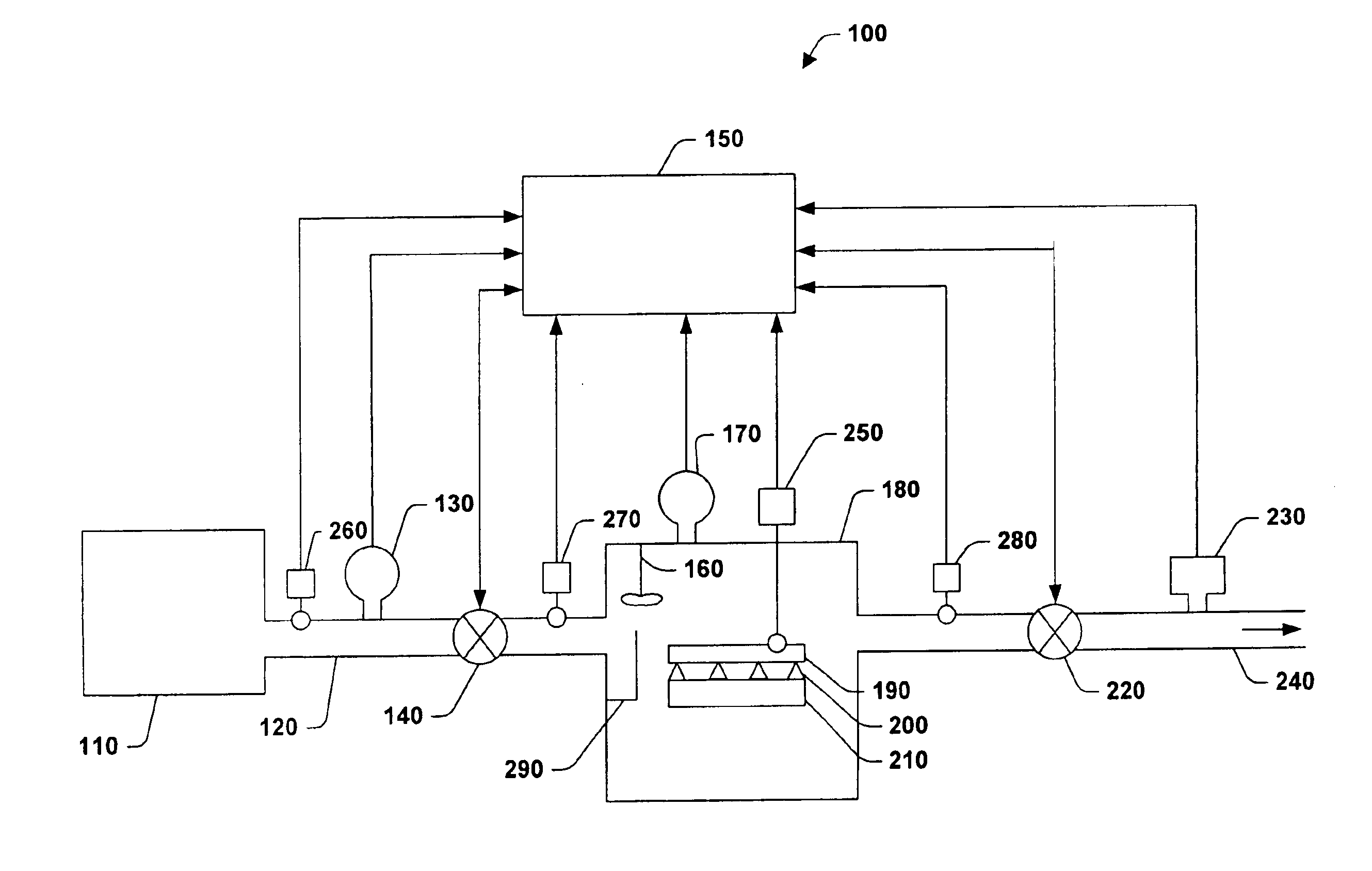

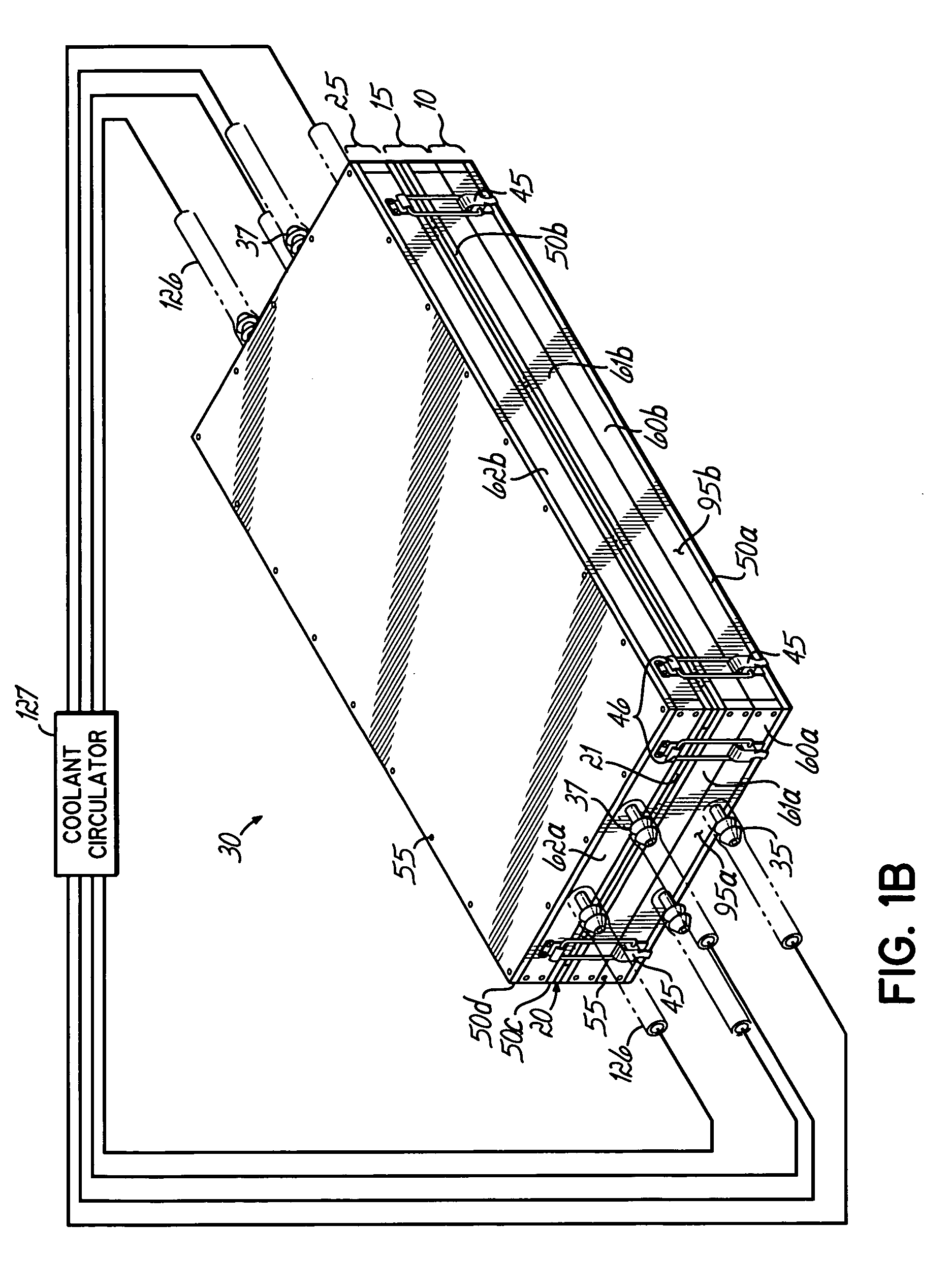

System for rapidly and uniformly cooling resist

InactiveUS6889763B1Temperature differenceCool evenlySpace heating and ventilation safety systemsSpace heating and ventilation control systemsResistAtmospheric air

Resist coated wafers are rapidly and uniformly cooled by a fluid that has been cooled through the Joule-Thompson effect. Fluid from a high pressure reservoir is vented into a chamber that contains the substrates. By varying the pressure difference between the reservoir and the chamber, the temperature of the cooling fluid entering the chamber can be controlled. By also controlling the flow rate through the chamber, the average temperature difference between the fluid in the chamber and the substrates may be limited, whereby more uniform cooling is obtained. While the chamber pressure is lower than that in the high pressure reservoir, the chamber pressure may still be substantially greater than atmospheric. An elevated chamber pressure raises the specific heat and residence time of the fluid in the chamber, which also promotes uniform cooling.

Owner:ADVANCED MICRO DEVICES INC

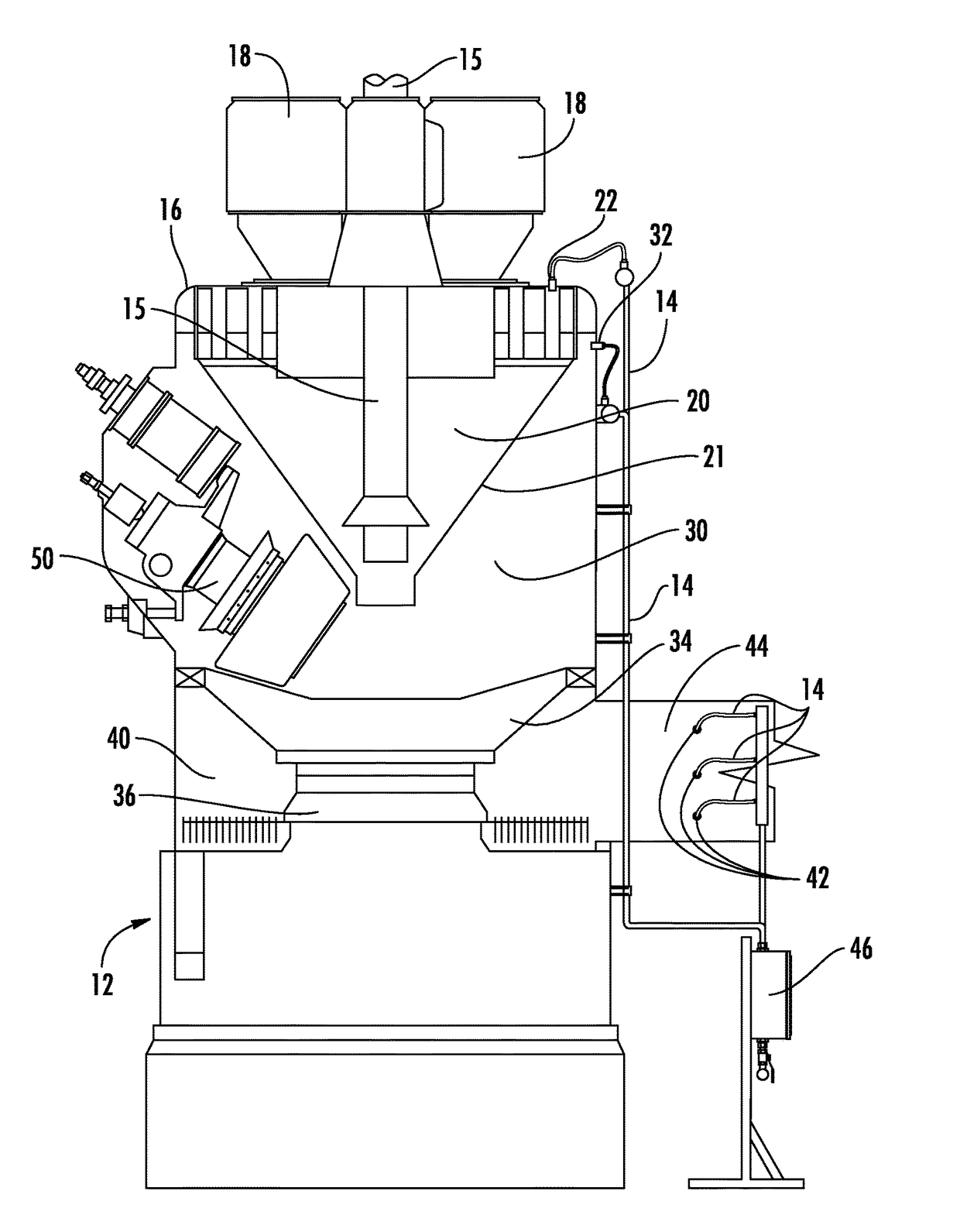

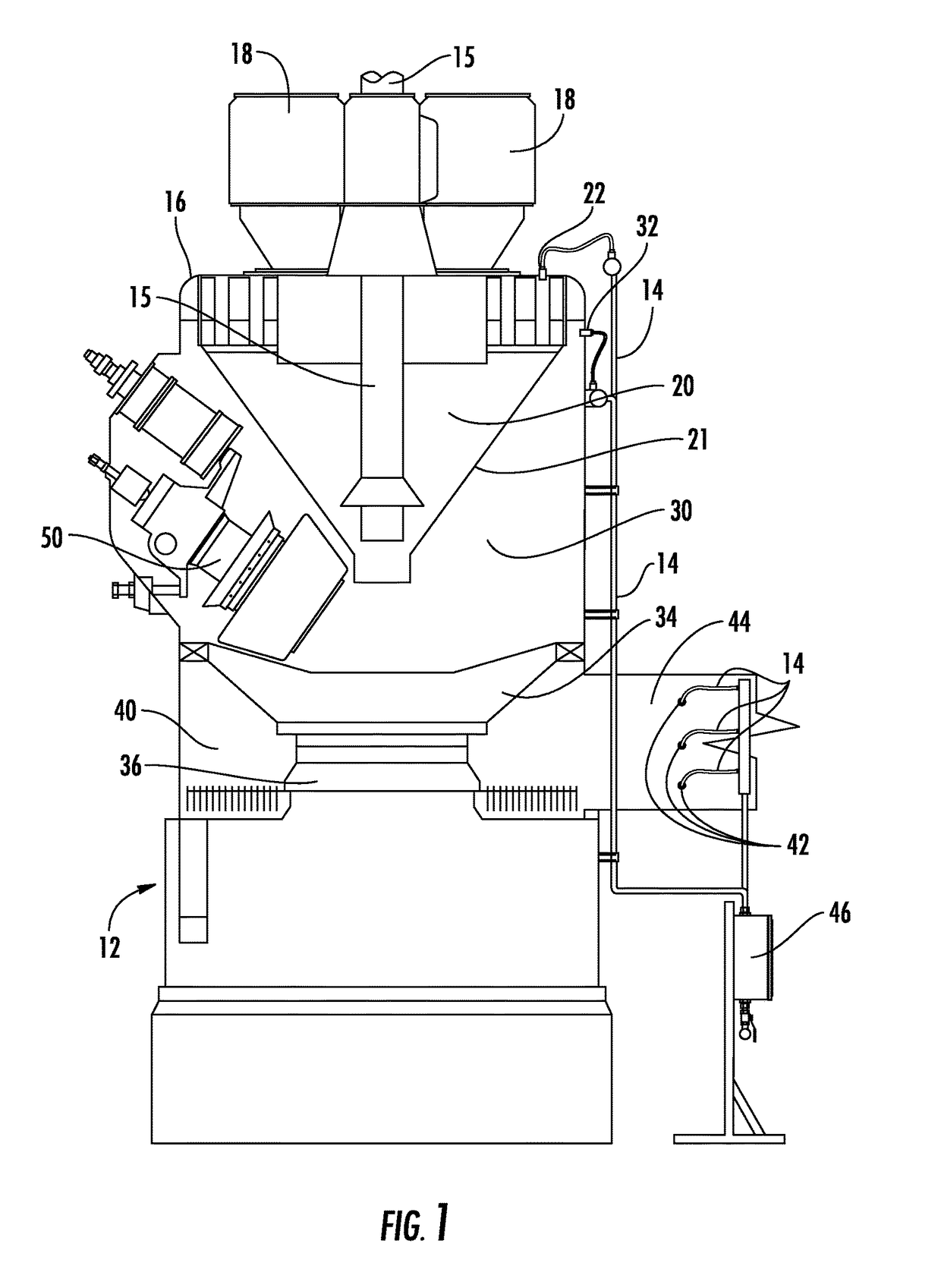

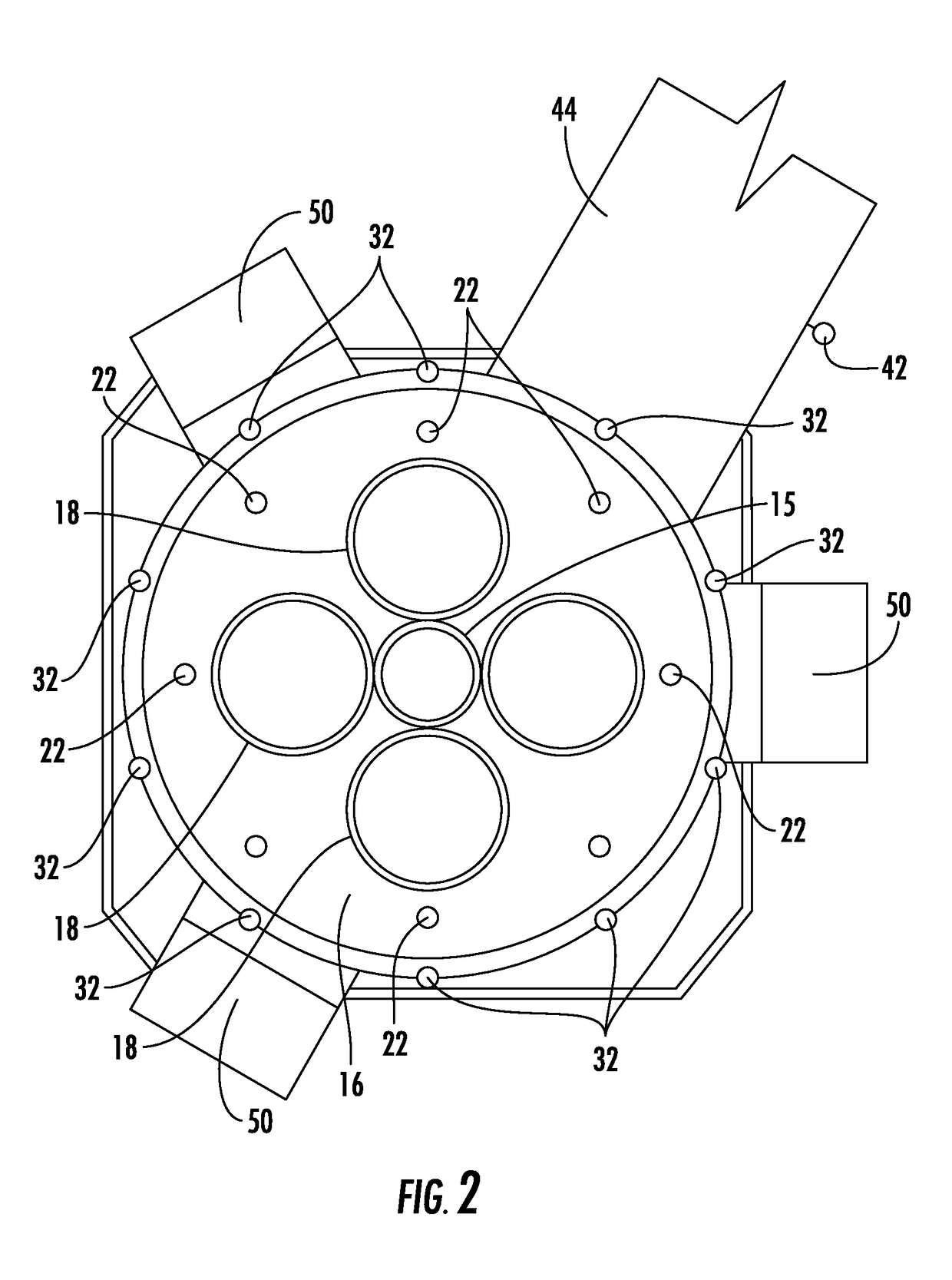

Pulverizer mill protection system

ActiveUS20150053799A1High riskProvide protectionFire rescueGrain treatmentsDistribution systemSpray nozzle

A system for suppressing and inhibiting fires in coal pulverizer mills can include a fire suppression solution storage tank, a flow control cabinet, an equipment control / pumping enclosure, an air distribution system, and injection piping and nozzles installed at various positions in one or more pulverizer mills. A first set of nozzle assemblies in communication with the fire suppression solution are positioned in the mill to disperse the suppression solution within the classifier zone of the mill. A second set of nozzle assemblies in communication with the suppression solution are positioned within the mill to disperse the suppression solution within the grinding zone. A third set of nozzle assemblies are positioned within the primary air duct of the mill.

Owner:INNOVATIVE COMBUSTION TECH

Pulverizer mill protection system

ActiveUS9421551B2Prevents or inhibits pulverizer mill explosions, fires and/orPrevent or inhibit pulverizer mill firesGrain treatmentsDistribution systemProtection system

A system for suppressing and inhibiting fires in coal pulverizer mills can include a fire suppression solution storage tank, a flow control cabinet, an equipment control / pumping enclosure, an air distribution system, and injection piping and nozzles installed at various positions in one or more pulverizer mills. A first set of nozzle assemblies in communication with the fire suppression solution are positioned in the mill to disperse the suppression solution within the classifier zone of the mill. A second set of nozzle assemblies in communication with the suppression solution are positioned within the mill to disperse the suppression solution within the grinding zone. A third set of nozzle assemblies are positioned within the primary air duct of the mill.

Owner:INNOVATIVE COMBUSTION TECH

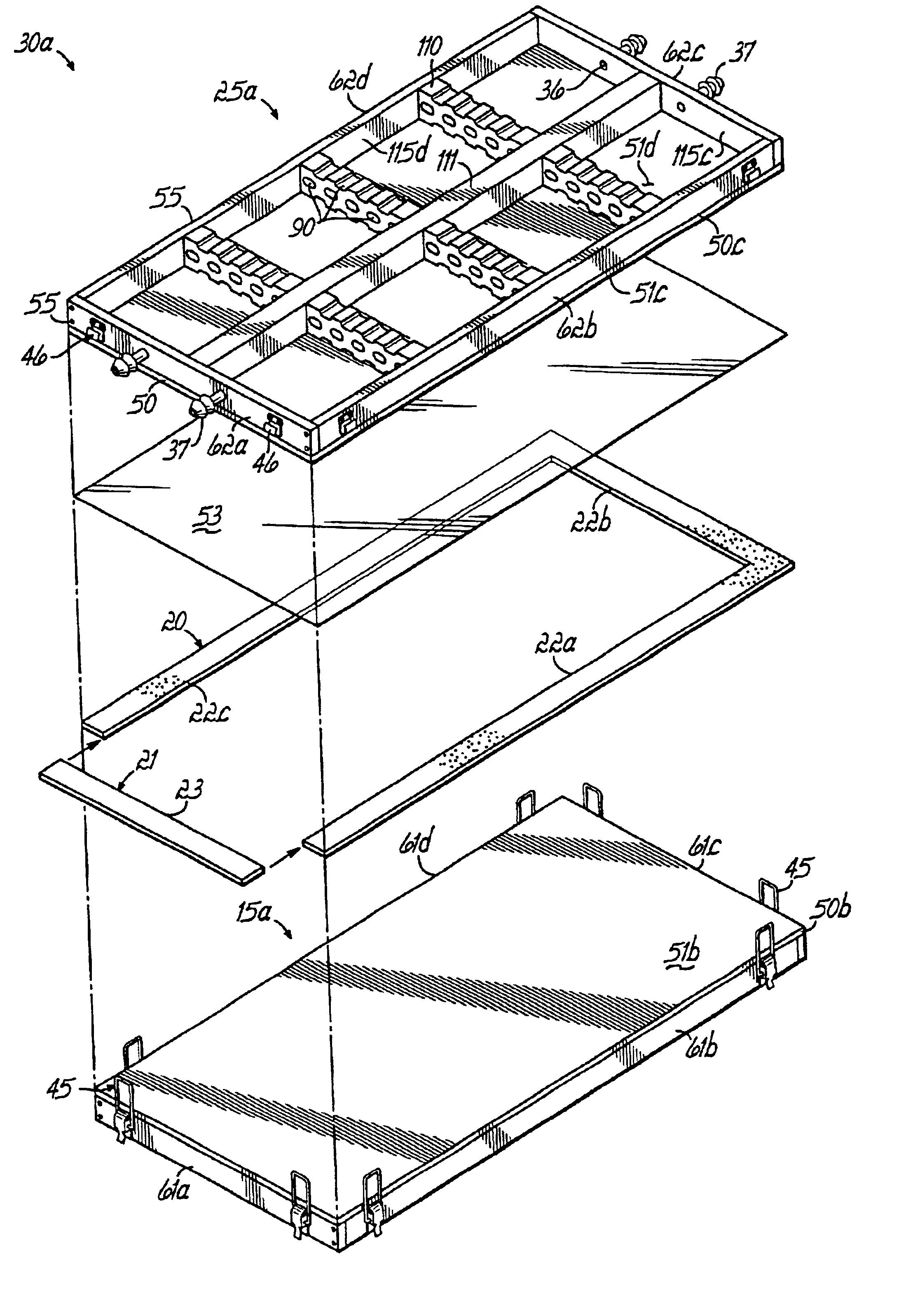

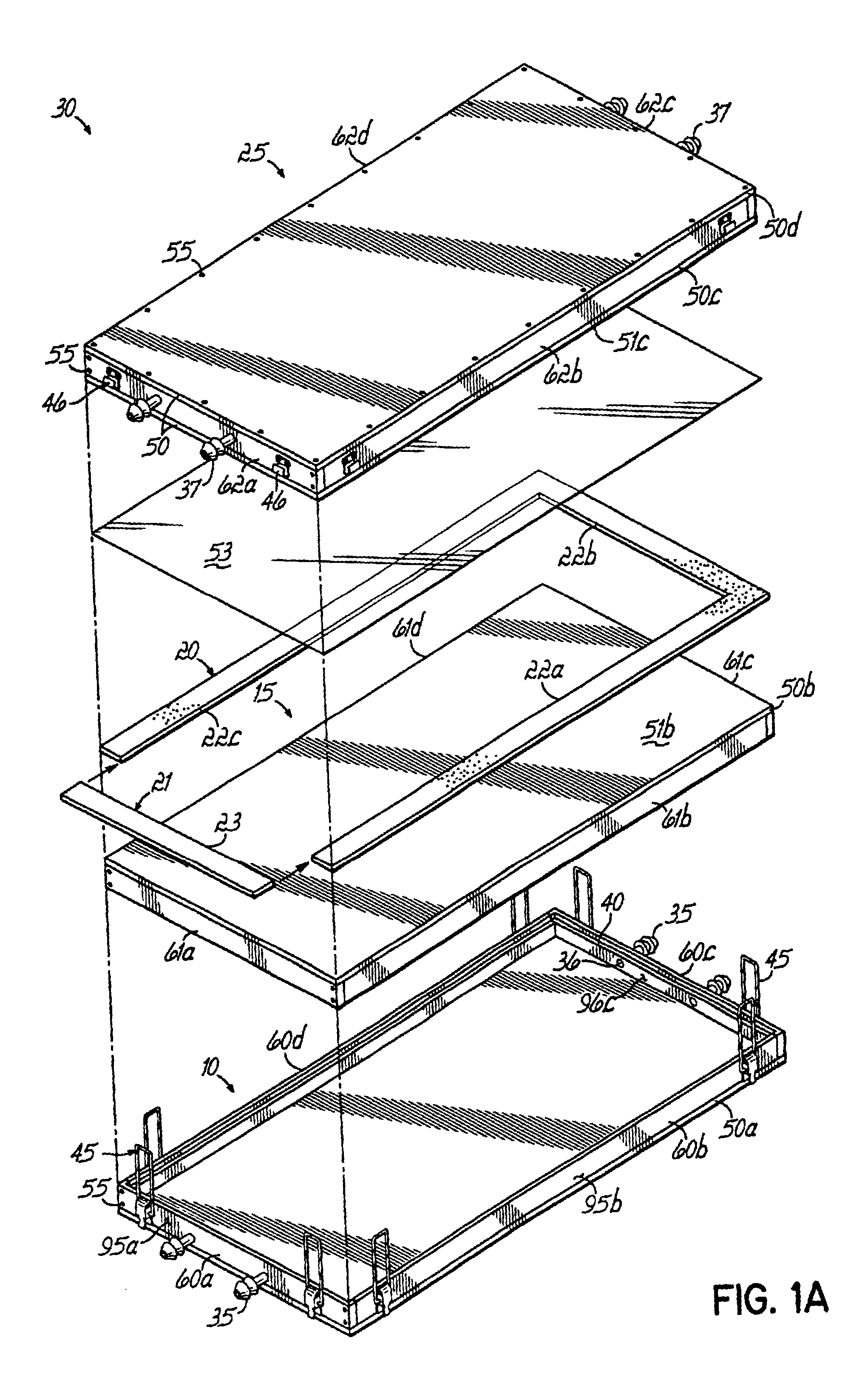

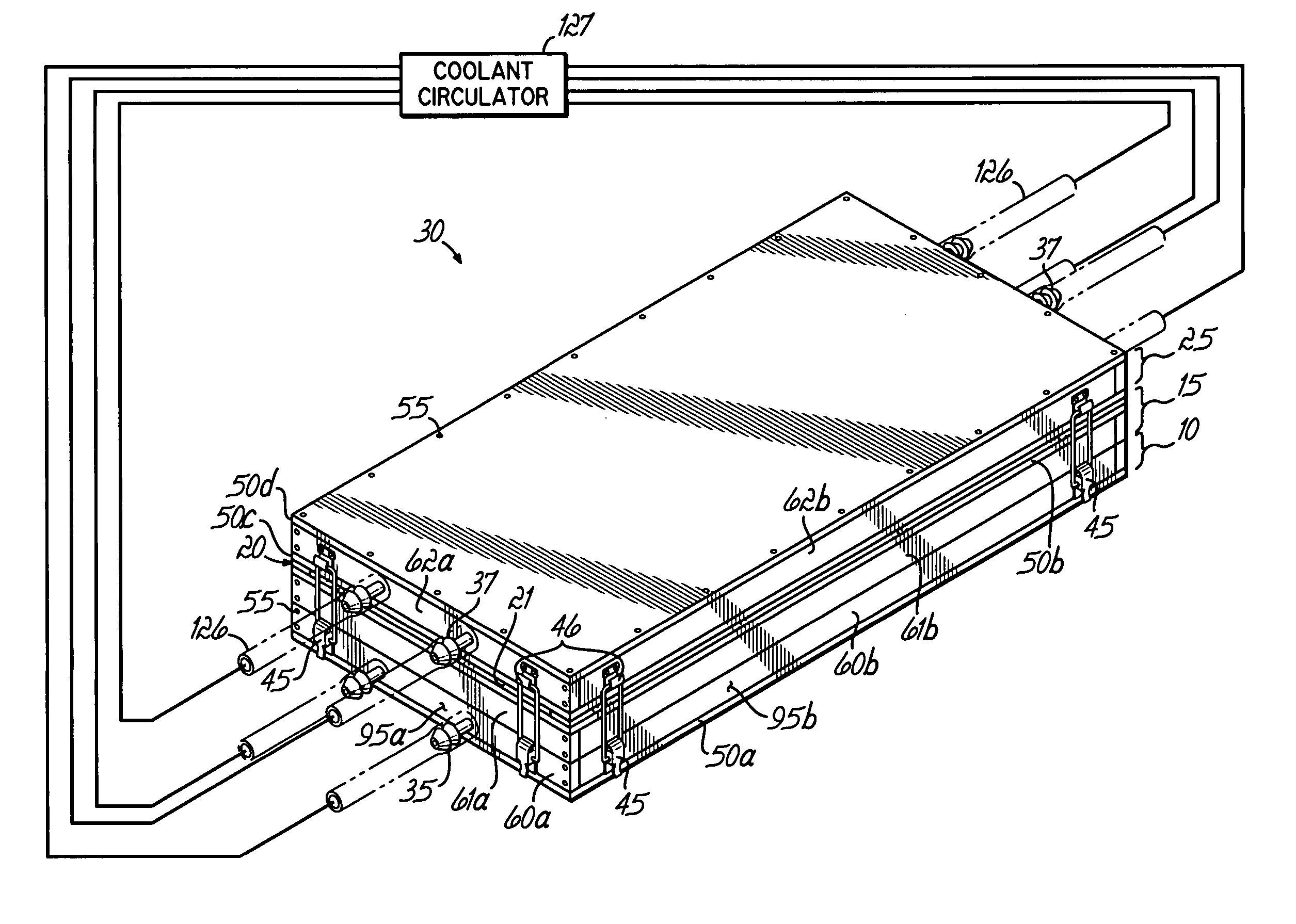

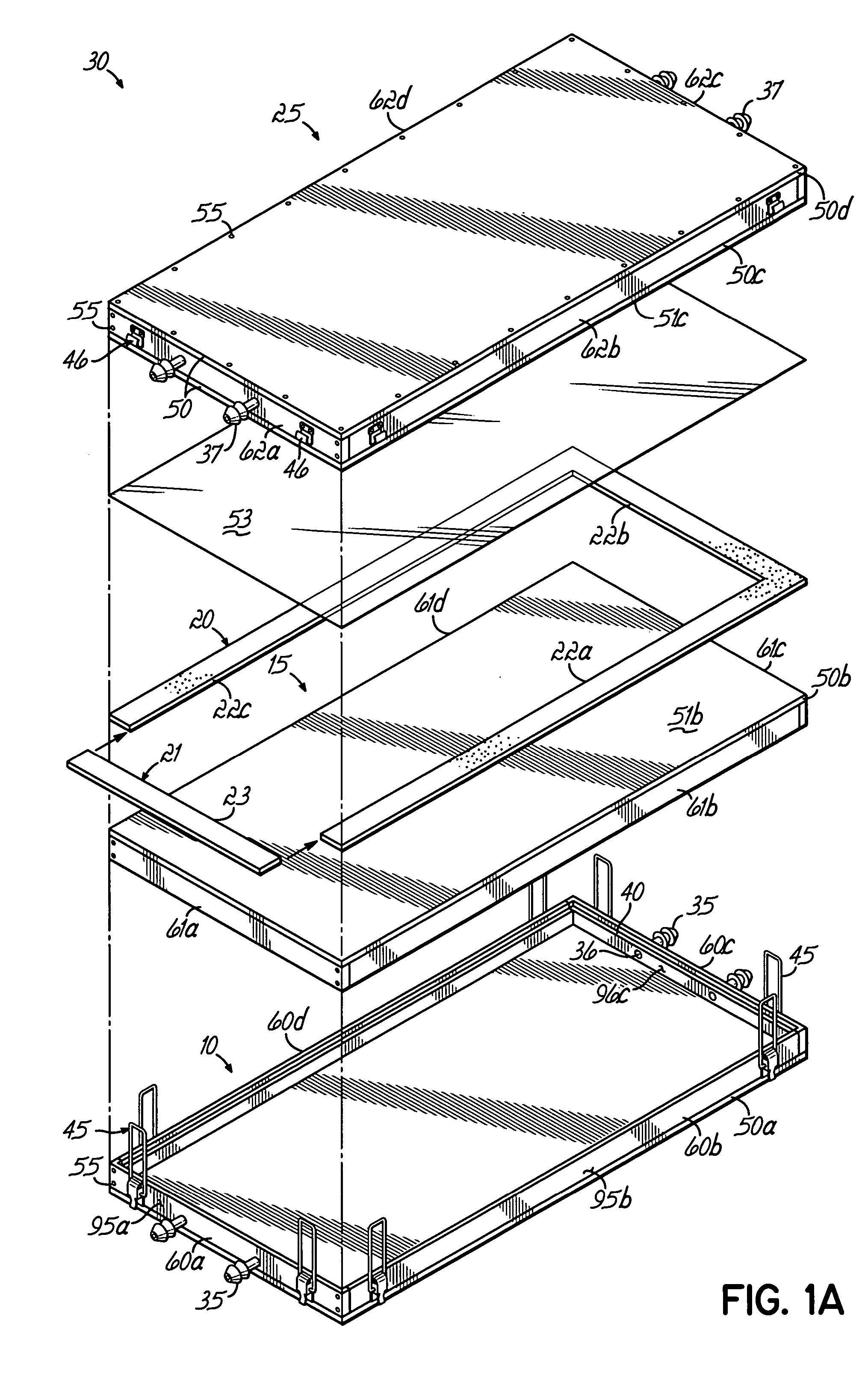

Apparatus for preparing a biocompatible matrix

InactiveUS6905105B2Facilitates rapid transfer of heatRapid and uniform coolingSkin implantsTissue cultureSupporting cellConductive materials

An apparatus and method of using the apparatus to prepare a biocompatible biodegradable matrix capable of supporting cells to form an implantable or engraftable surgical device. A matrix-forming fluid is contained within a chamber defined by top and bottom surfaces of a thermally conductive material and spacers defining the thickness of the matrix. The chamber is then cooled to freeze the solution at a controlled rate, resulting in a matrix with a desired and uniform thickness having symmetric and uniform reticulations. The apparatus and method reproducibly forms such a matrix, which may be populated with cells for transplantation and engraftment into a wound.

Owner:UNIVERSITY OF CINCINNATI +1

Pulverizer mill protection system

ActiveUS9604226B2Prevents or inhibits pulverizer mill explosions, fires and/orPrevent or inhibit pulverizer mill firesFire rescueGrain treatmentsDistribution systemSpray nozzle

Owner:INNOVATIVE COMBUSTION TECH

Method for quenching medium and low carbon alloy structural steel workpieces

ActiveCN101693941AShort holding timeGood energy saving effectHeat treatment process controlQuenchingCarbon alloy

The invention discloses a method for quenching medium and low carbon alloy structural steel workpieces, which comprises the following steps: a, placing medium and low carbon alloy structural steel workpieces to be quenched into a quenching furnace, heating until the furnace temperature is higher than normal austenitizing temperature by 100-200 DEG C for preserving the temperature till the workpieces are sufficiently burnt; b, selecting quenching liquid corresponding to materials of the workpieces, adding the quenching liquid into a quenching groove and intensively stirring; sufficiently burning and then placing the workpieces into the quenching liquid to quench. The quenching method can overcome the defects of large energy consumption, poor environmental protection, and the like in the prior art so as to realize the advantages of low energy consumption, good environmental protection, high toughness and difficult rustiness and can meet the requirement of low-temperature impact toughness of a hoisting rigging industry.

Owner:JULI SLING

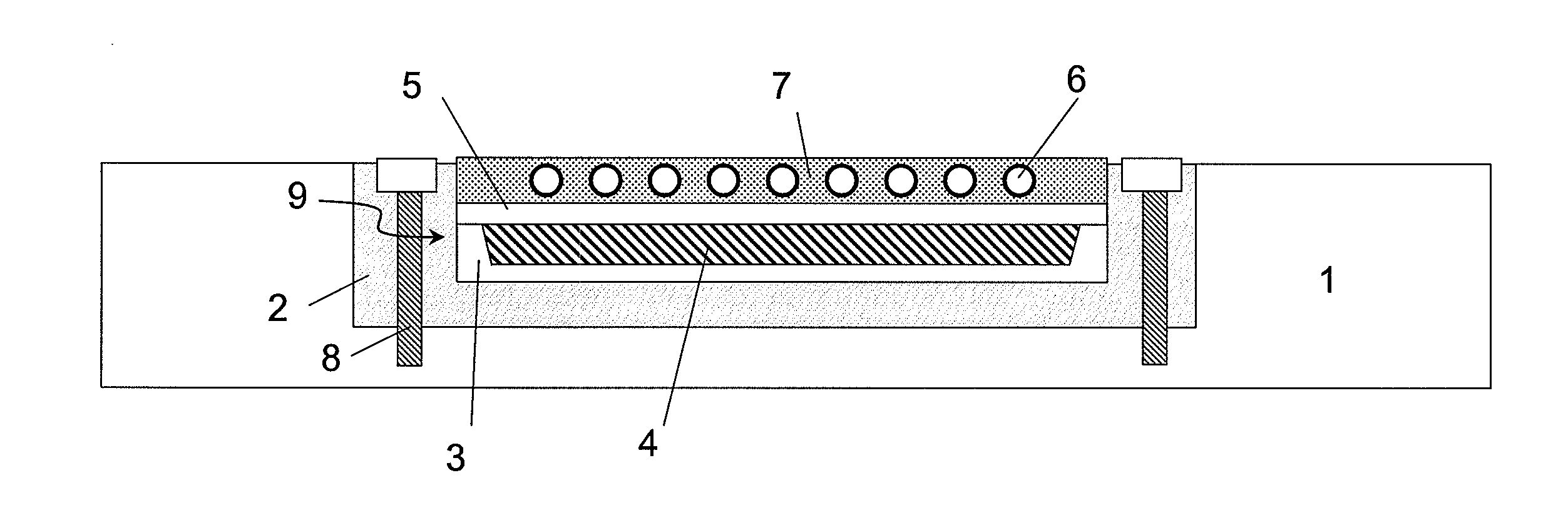

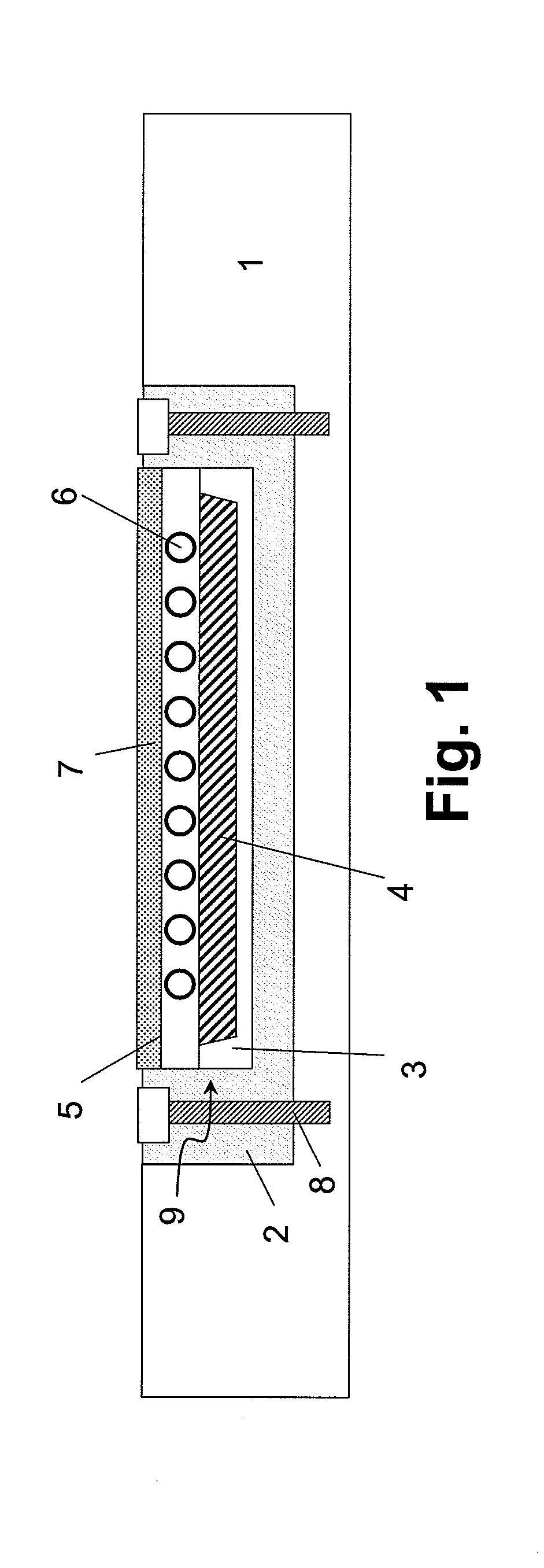

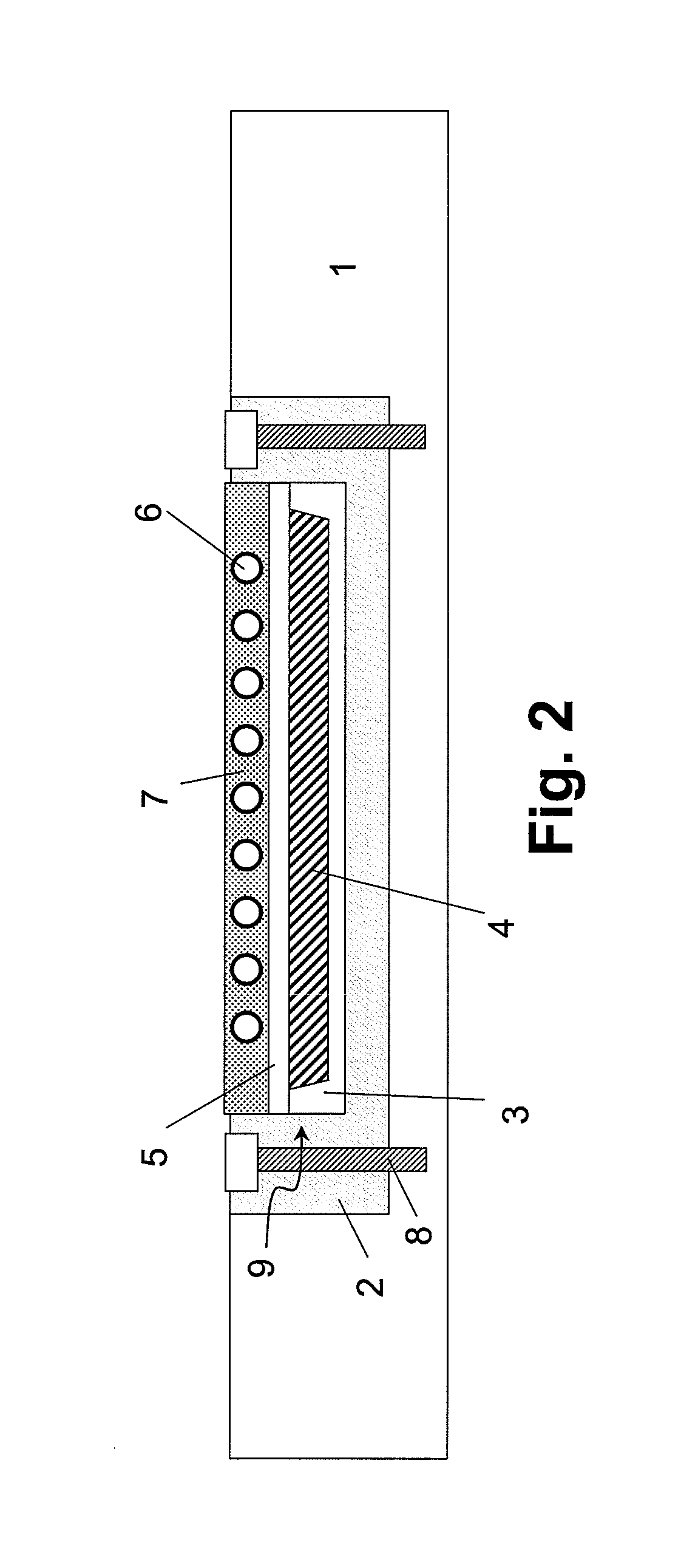

Casting, molding or pressing tool with temperature control medium channels

InactiveUS20110229595A1Improved propertyImprove wear resistance and corrosion resistanceLiquid surface applicatorsMolten spray coatingTemperature controlEngineering

In a method of producing a casting, molding or pressing tool (1) or tool insert (2) with at least one material layer (3, 5, 7) and with temperature control medium channels (6) arranged in the at least one material layer (3, 5, 7), the temperature control medium channels (6) are introduced into the at least one material layer (3, 5, 7) using a thermal spray process (2).

Owner:LINDE AG

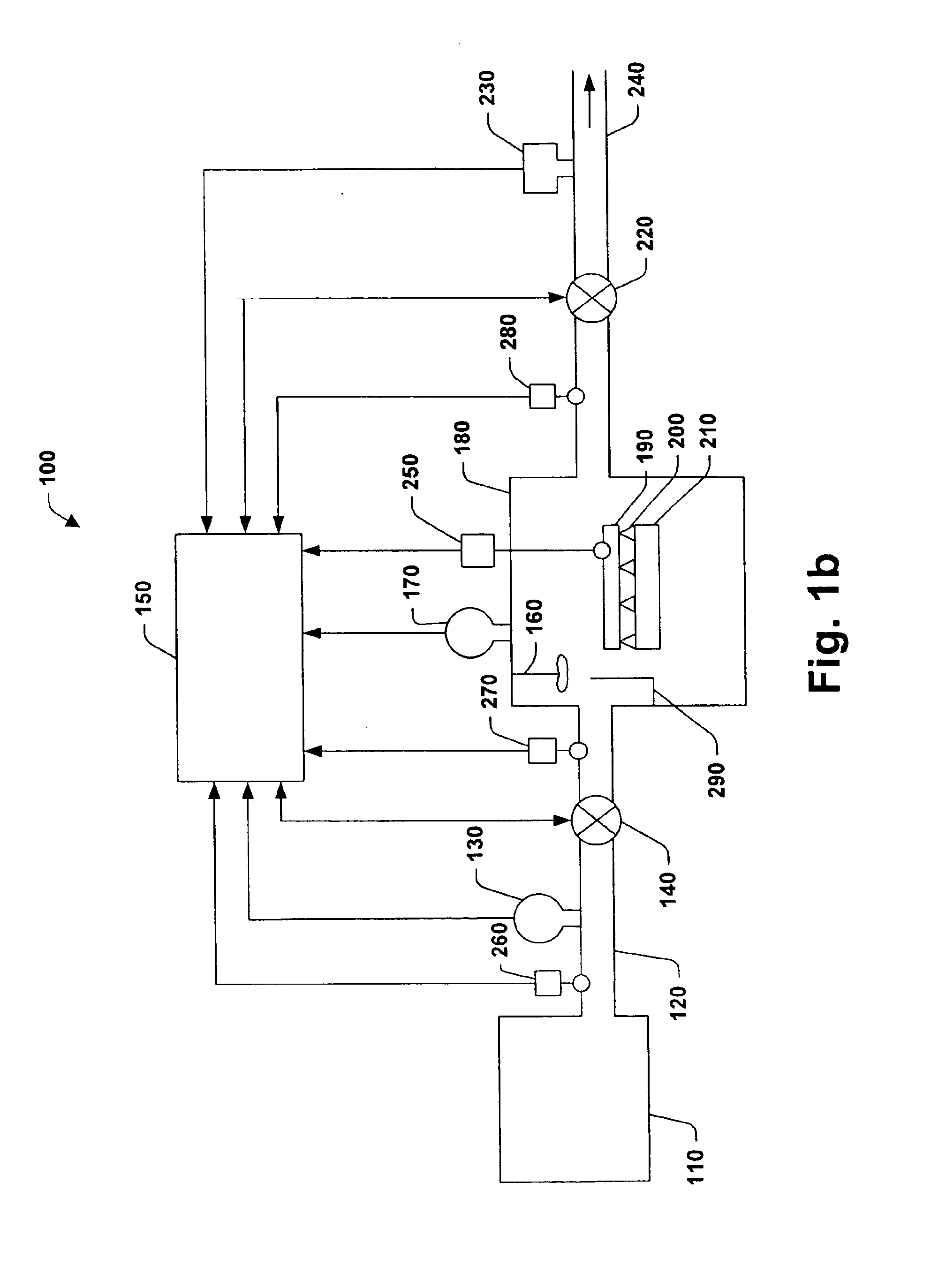

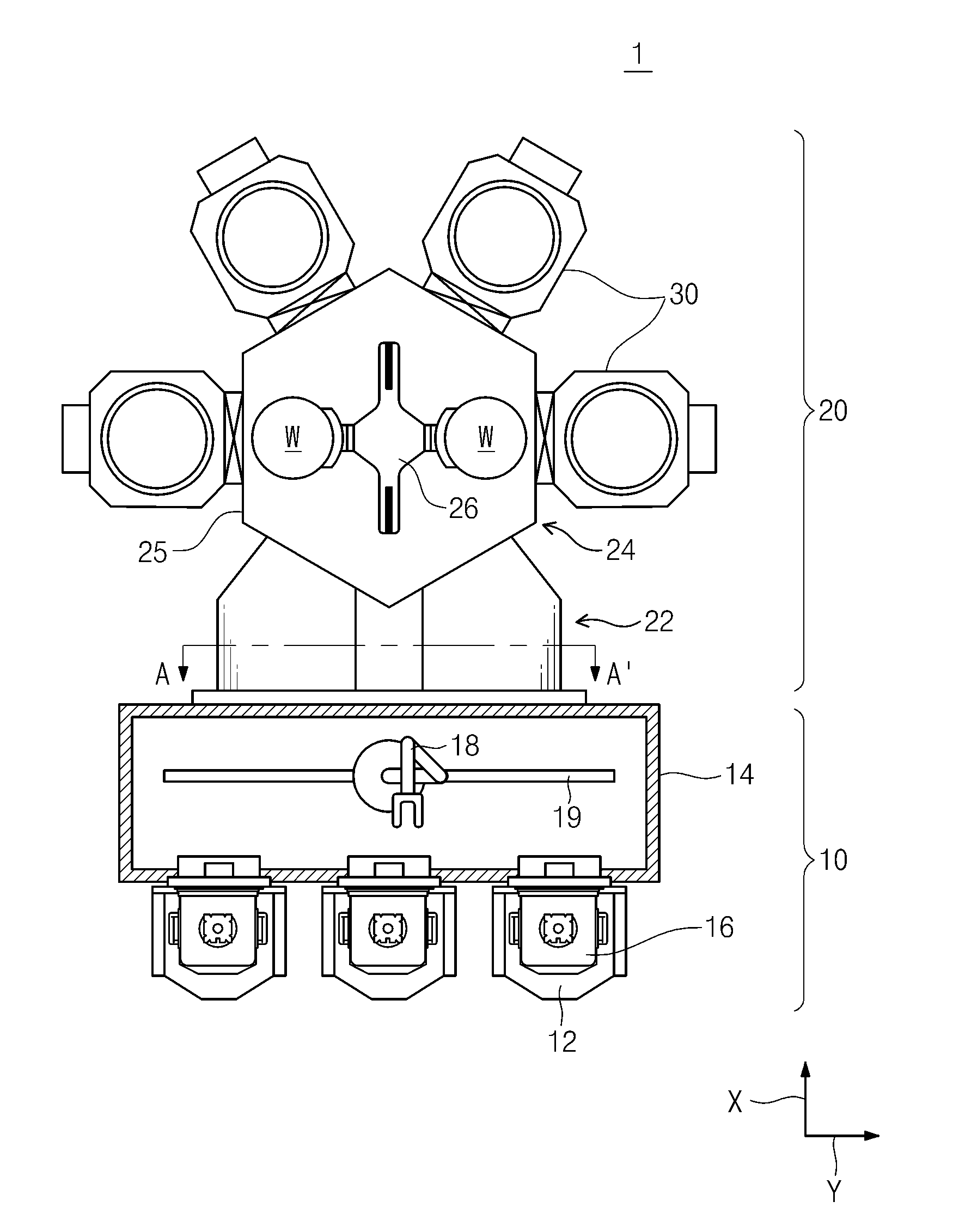

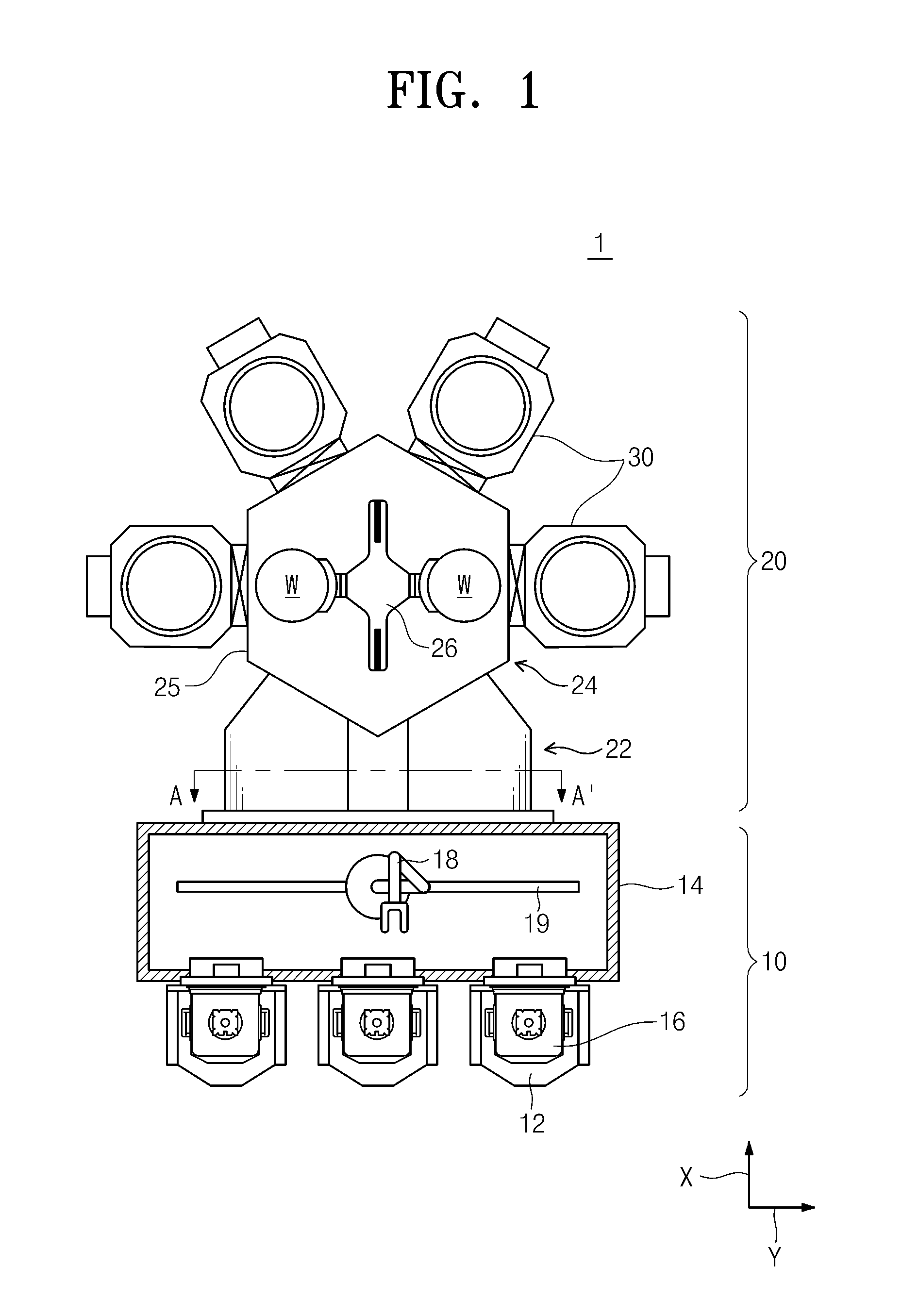

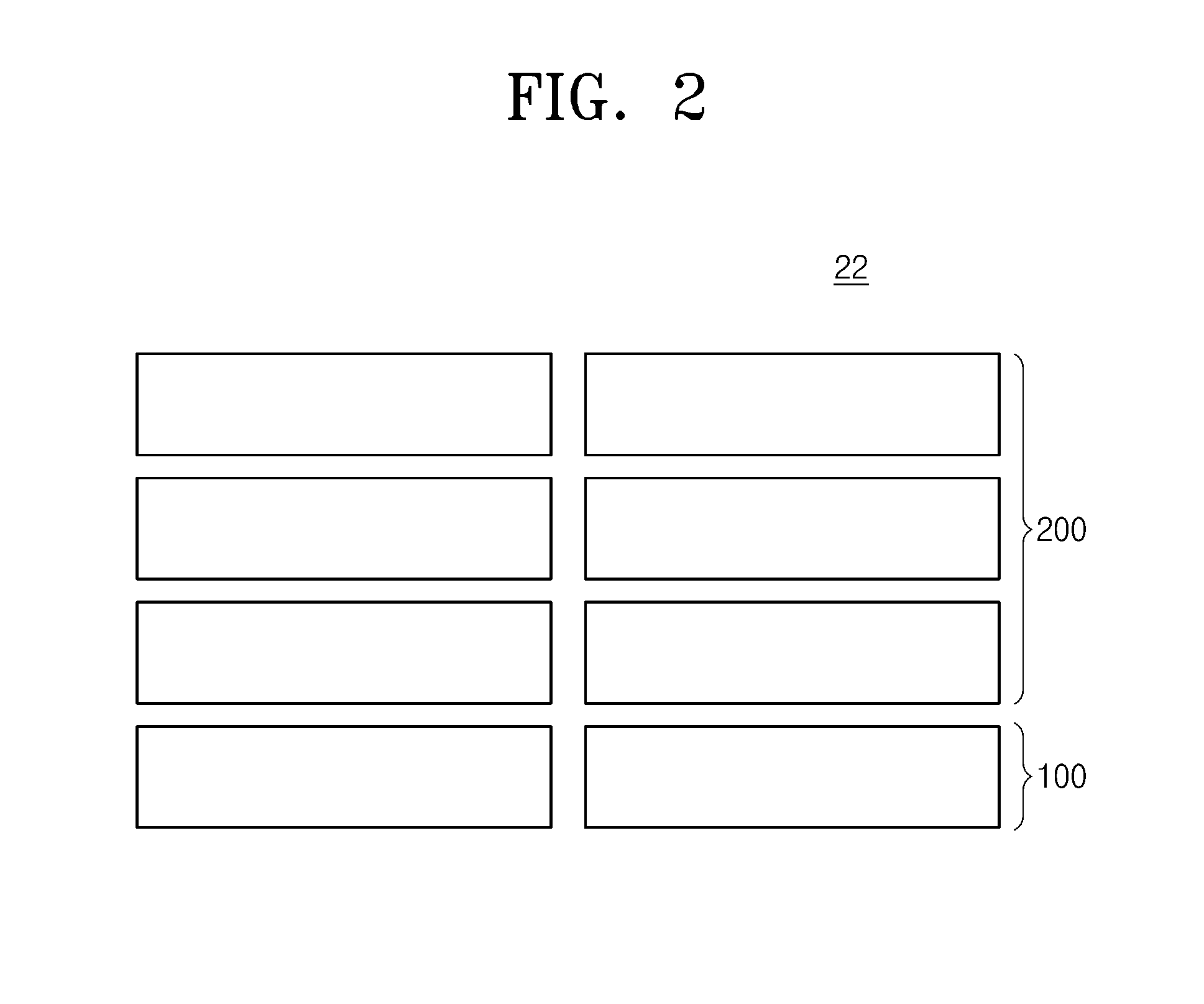

Unit and method for cooling, and apparatus and method for treating substrate

ActiveUS20140377039A1Rapid and uniform coolingMinimizationLighting and heating apparatusSemiconductor/solid-state device manufacturingInterior spaceCooling chamber

Provided is a substrate treating apparatus. The substrate treating apparatus includes an equipment front end module, a loadlock chamber, a transfer chamber, and a plurality of process chambers. The loadlock chamber includes a cooling unit for cooling a substrate treated in the process chambers, and the cooling unit includes a cooling chamber having an inner space, the cooling chamber having a gas inflow hole in one surface thereof, wherein support pins on which the substrate is placed are disposed around a circumference of the gas injection hole, a cooling gas injection part supplying a cooling gas toward the gas inflow hole, and a gas exhaust part exhausting the cooling gas supplied into the cooling chamber and fumes generated from the substrate to the outside of the cooling chamber.

Owner:PSK INC

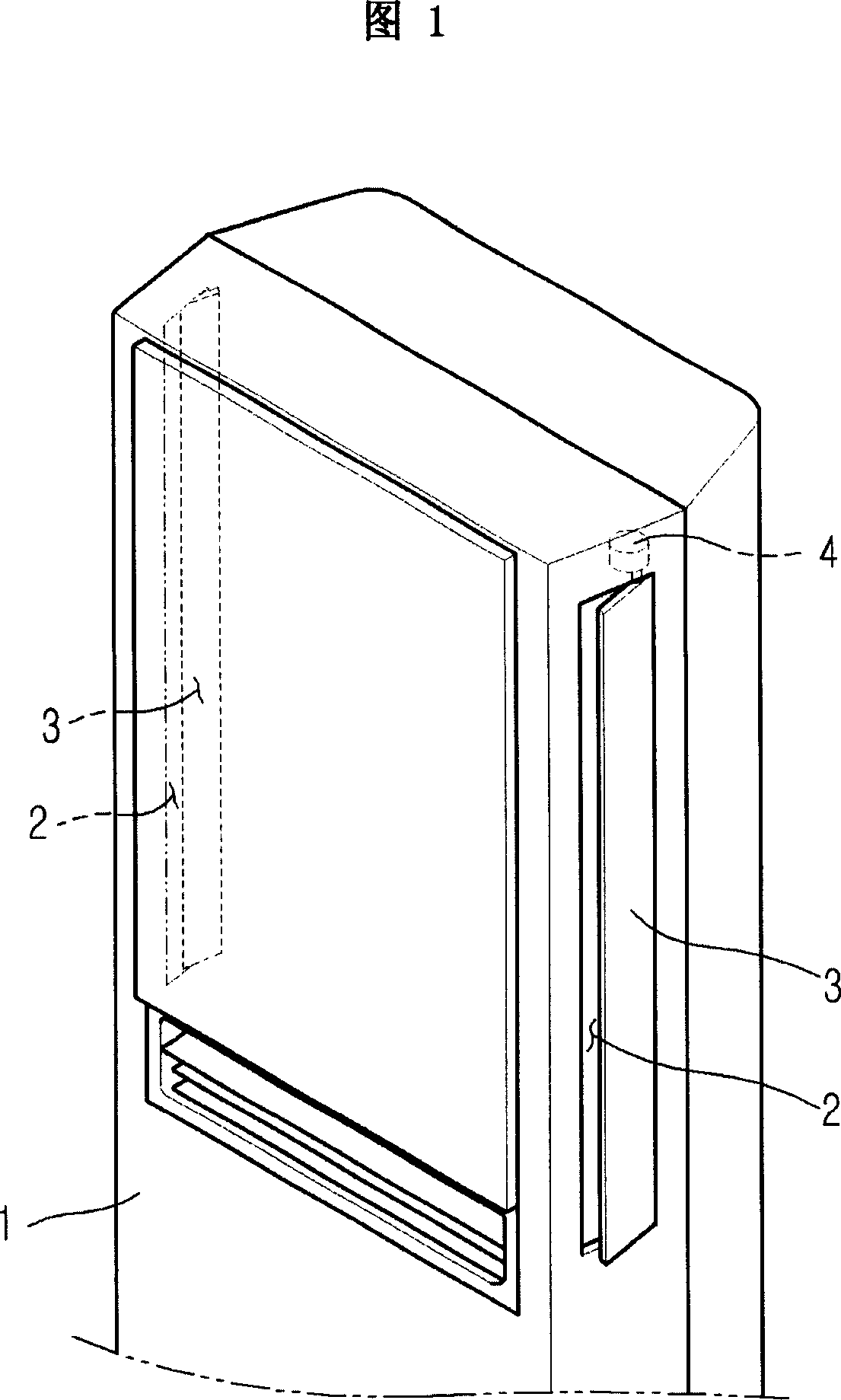

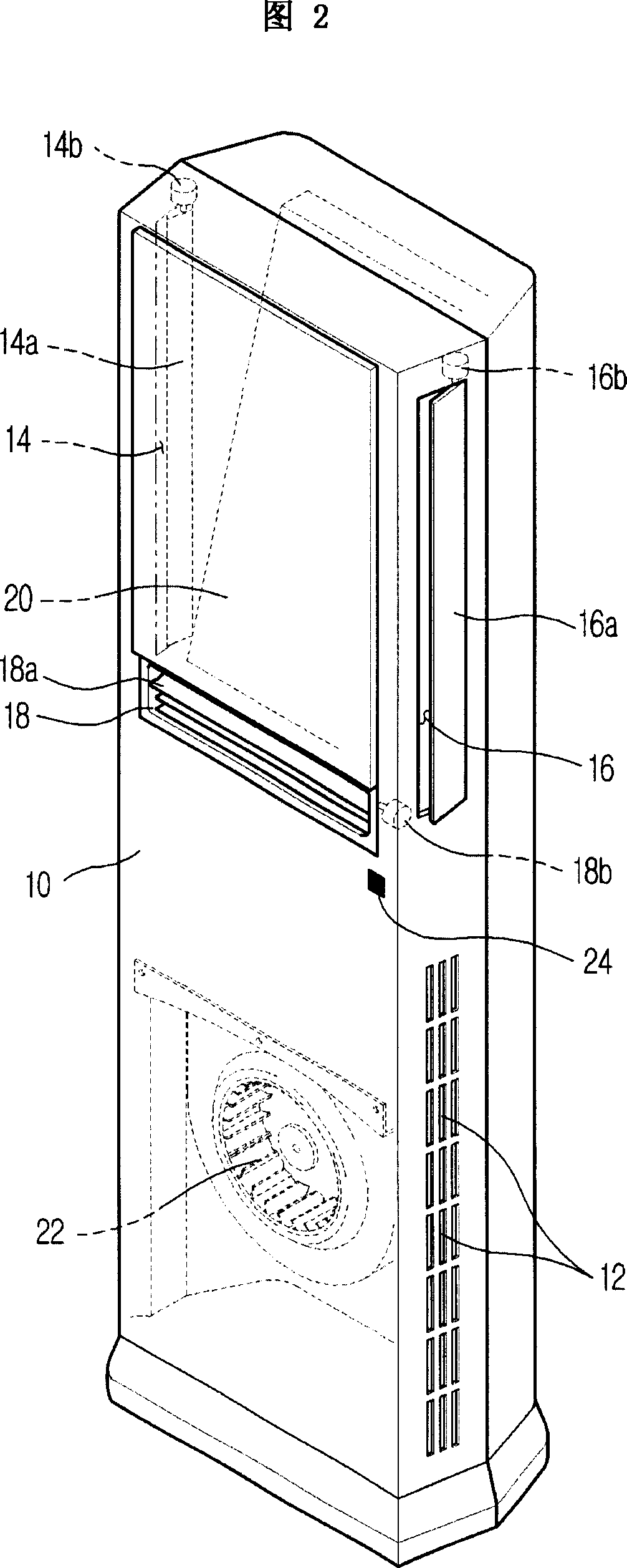

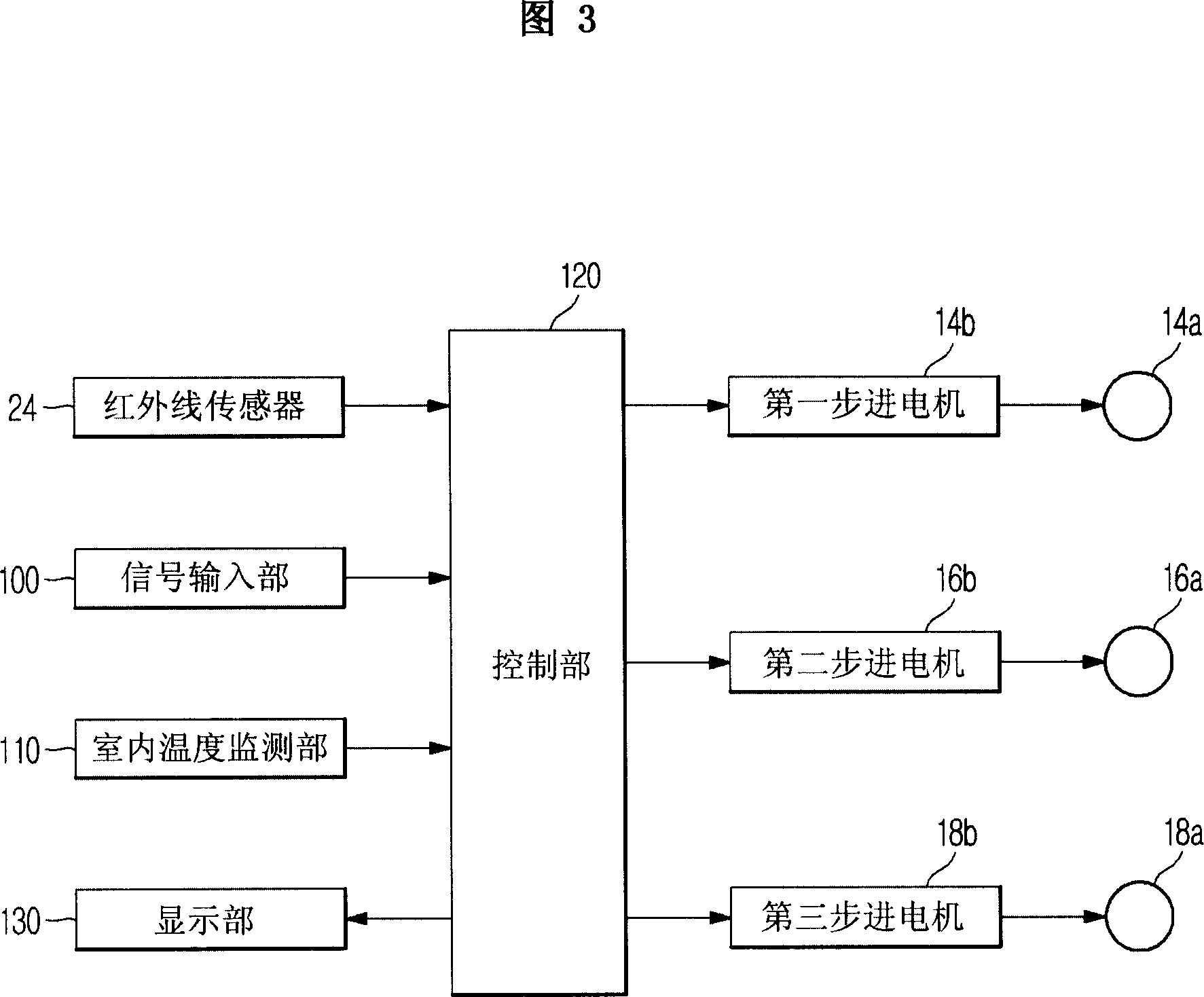

Discharged air flow controller of side discharging type air conditioner and method thereof

InactiveCN101000169ARapid and uniform coolingMechanical apparatusSpace heating and ventilation safety systemsEngineeringStream control

The invention relates to an exhaust stream control device of a side discharge type air conditioner and a method thereof, which is capable of cooling an indoor space rapidly and uniformly by swinging a left and right blades disposed on a side discharge opening for a certain time while in initial operation. Accordingly, the side discharge type air conditioner is provided with the left and the right blades for adjusting wind direction on the side discharge opening of two side face in the body. The control method of the side discharge type air conditioner in the invention includes the following steps: judging whether an operation signal is input based on a user instruction; if the operation signal is input, initial operation is performed by swinging the left and right blades for a predetermined time.

Owner:SAMSUNG ELECTRONICS CO LTD

Injection mold with uniform and quick cooling capability

The invention provides an injection mold for uniform and rapid cooling, comprising a movable mold fixed plate, a movable mold, a fixed mold, and a fixed mold fixed plate, the movable mold is set at the lower end of the movable mold fixed plate, and the fixed mold is set at the fixed mold The upper end of the fixed plate, the lower end of the movable mold is provided with a mold core, and the upper end of the fixed mold is provided with a mold groove. The cooling cavity in the shape of a rotary body, the material of the fixed mold between the mold groove and the cooling cavity is copper, and a refrigerator is embedded in the body of the fixed mold near the bottom edge of its side wall, and the opposite of the cooling cavity An air inlet and an air outlet are respectively arranged on the tops of both sides, an air inlet pipe is arranged between the air inlet and the refrigerator, and an air outlet pipe is arranged between the air outlet and the refrigerator. The invention can quickly and uniformly cool down the product before opening the mold, thereby shortening the production time and improving the precision of the product.

Owner:TIANJIN YONGJU MOLD

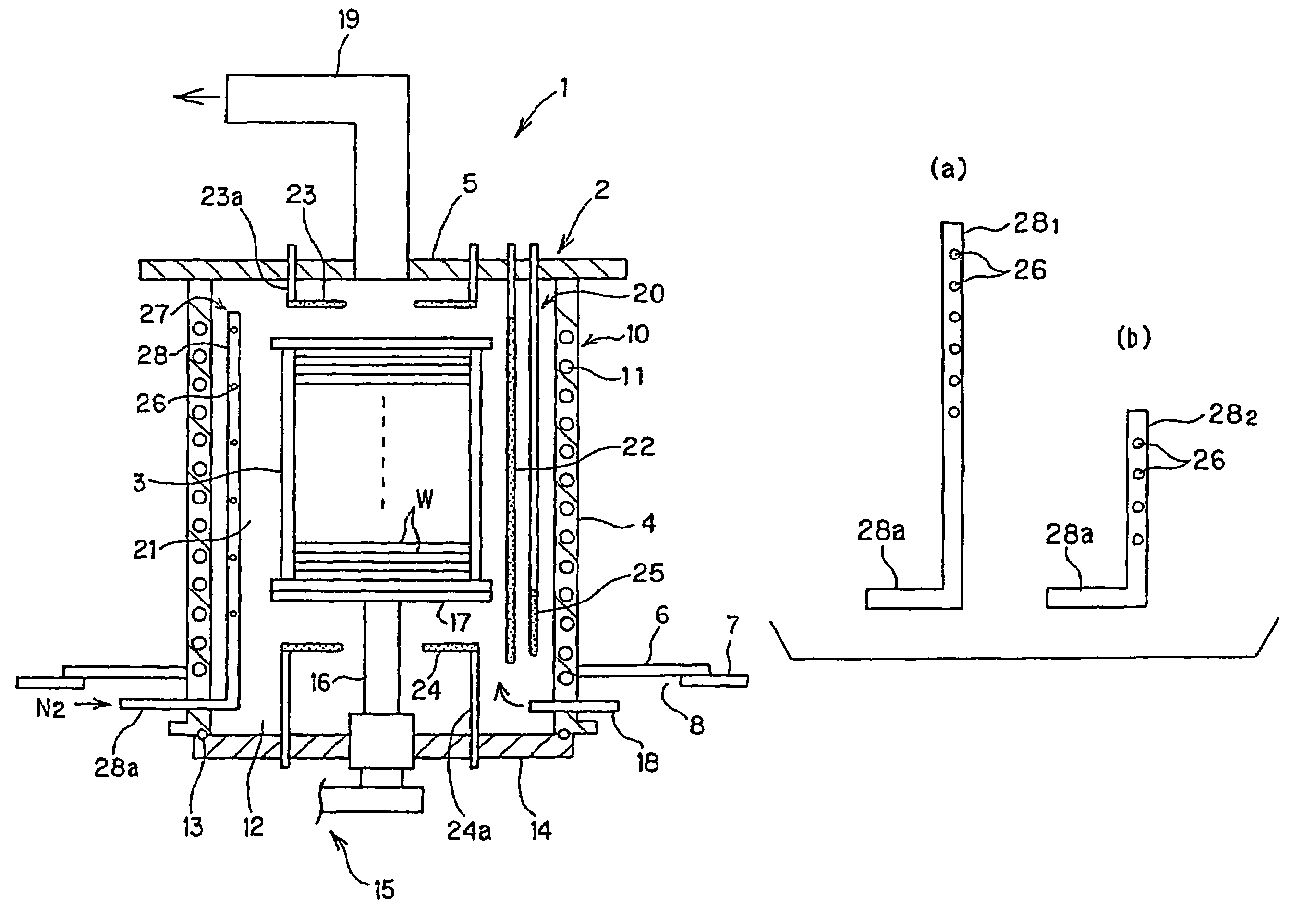

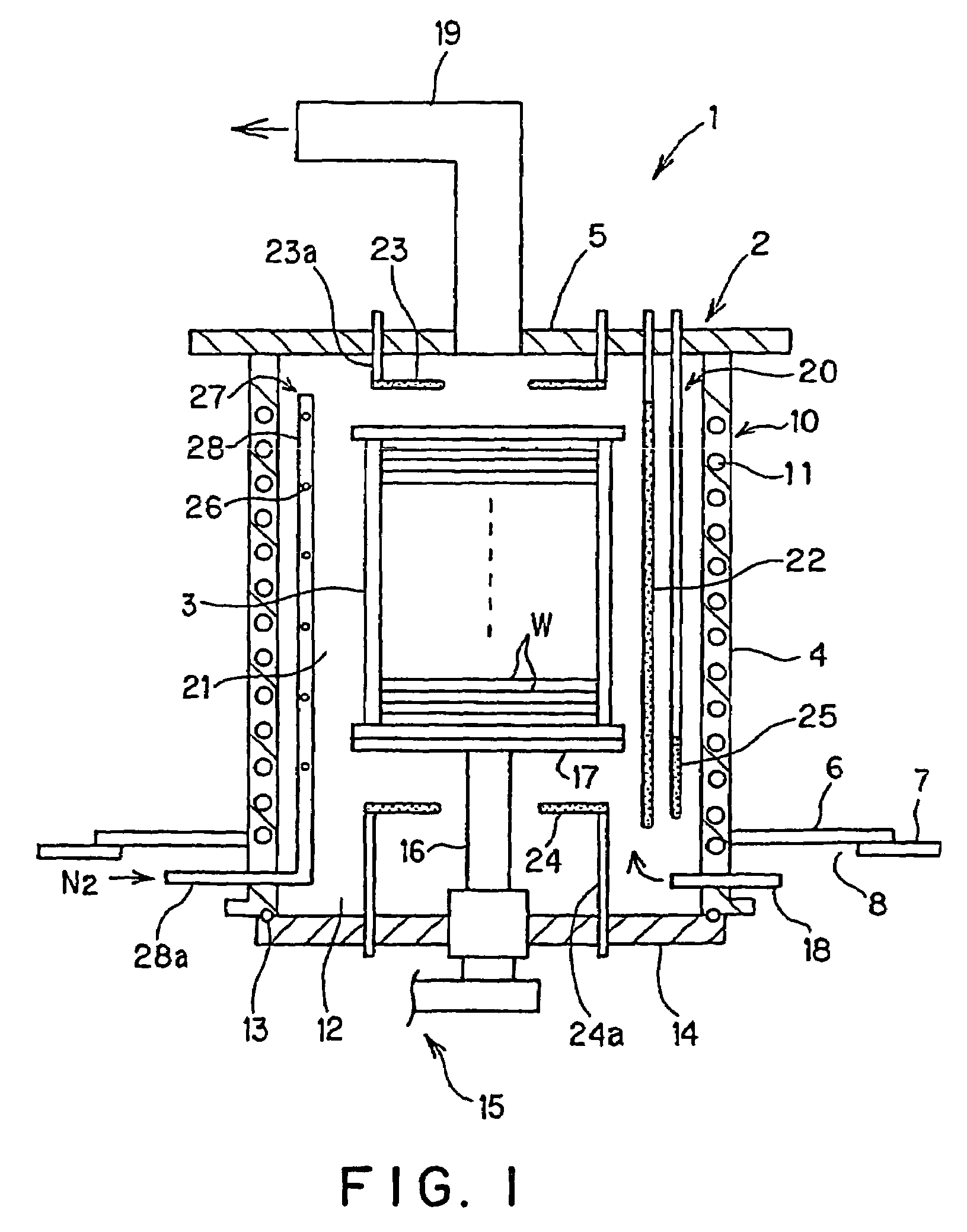

Thermal processing method and thermal processing unit

InactiveUS7537448B2Improve propertiesImprove throughputMuffle furnacesSemiconductor/solid-state device detailsProcess engineeringHeat treated

The present invention is a thermal processing method including: a step of conducting a predetermined thermal process in a low temperature zone to a plurality of objects to be processed held in a tier-like manner by a heating unit, in a processing container that is made of metal and has the heating unit therein, and a step of introducing a cooling gas into respective areas in the processing container divided in a height direction of the objects to be processed.

Owner:TOKYO ELECTRON LTD

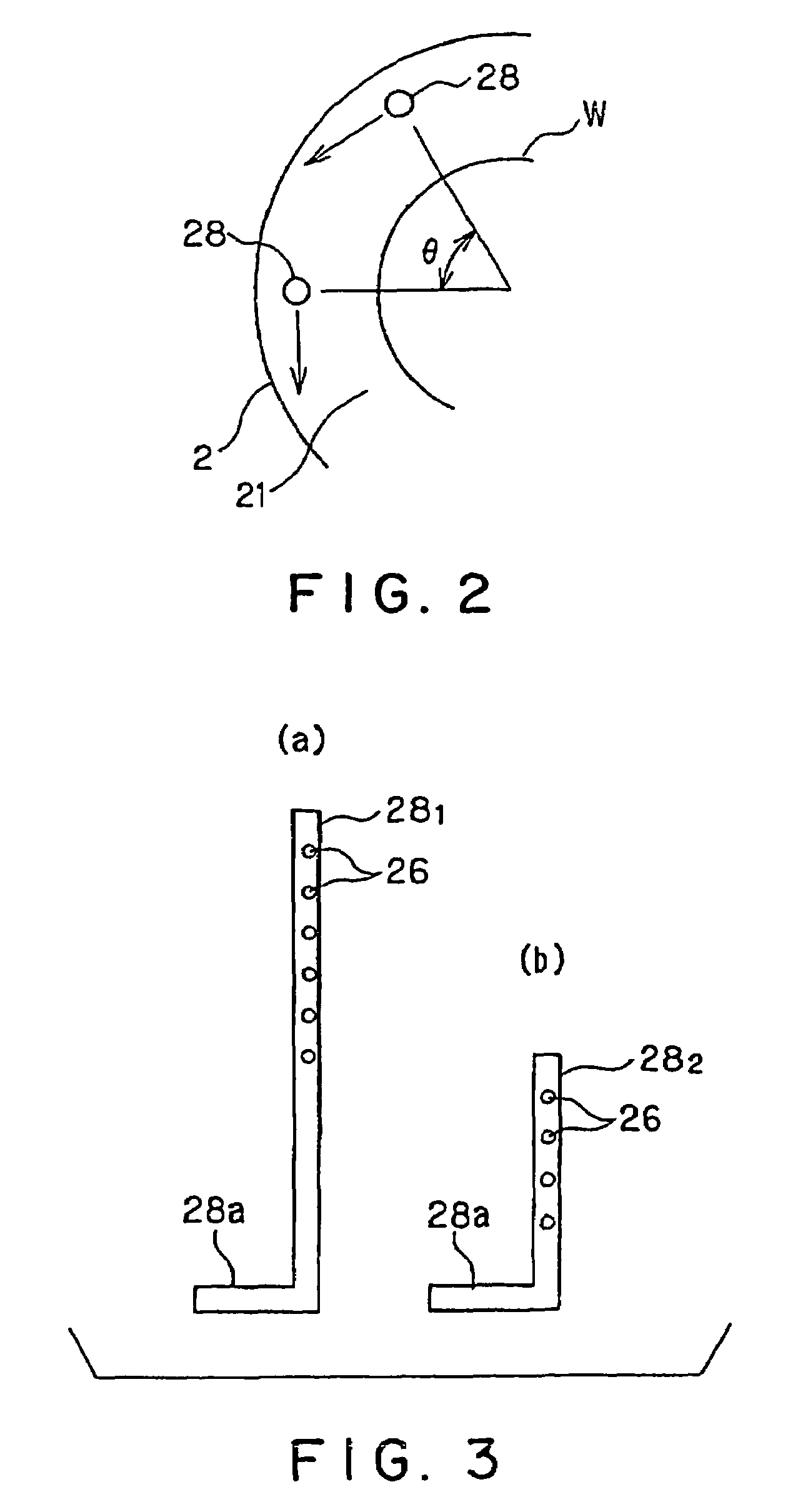

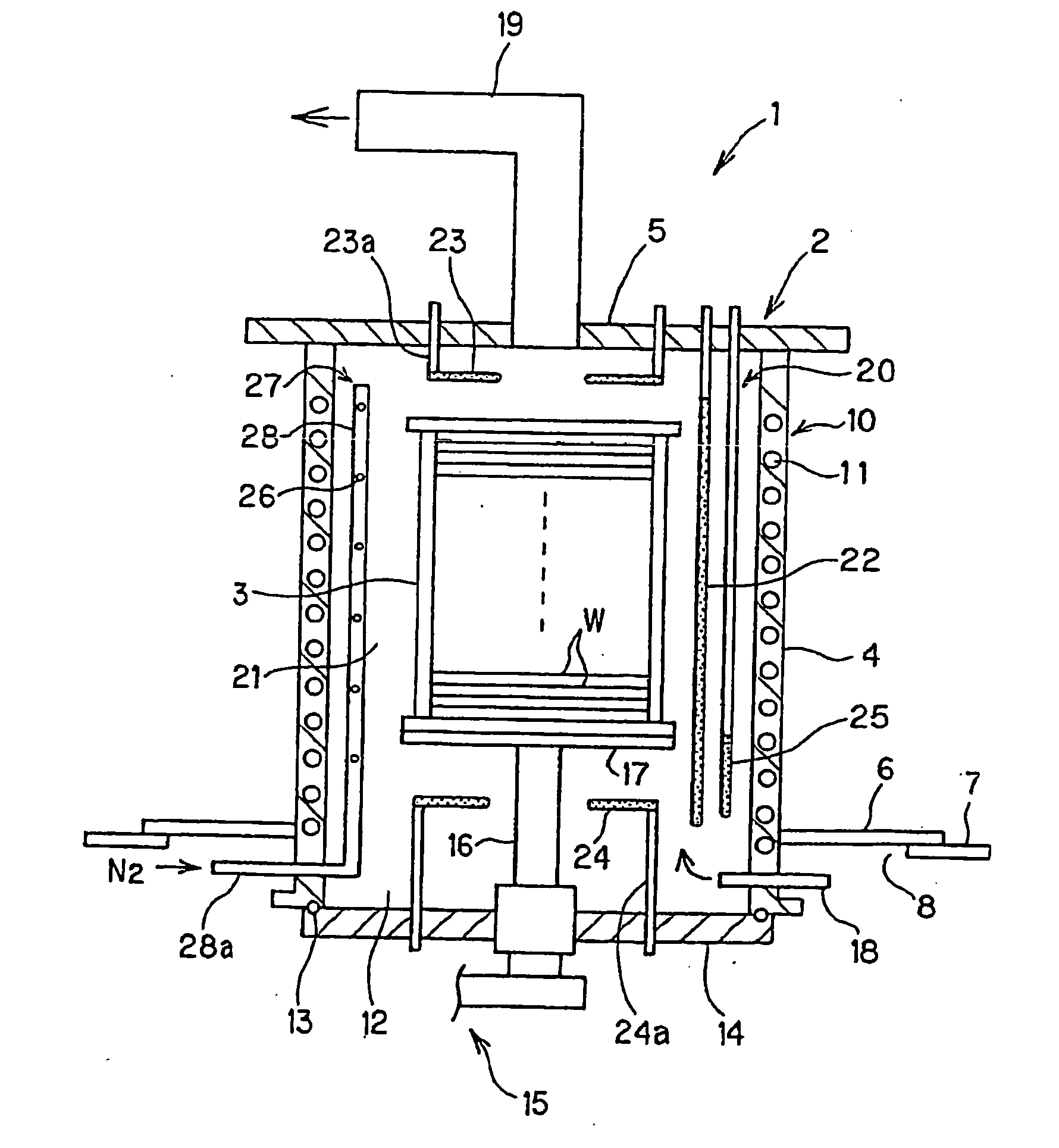

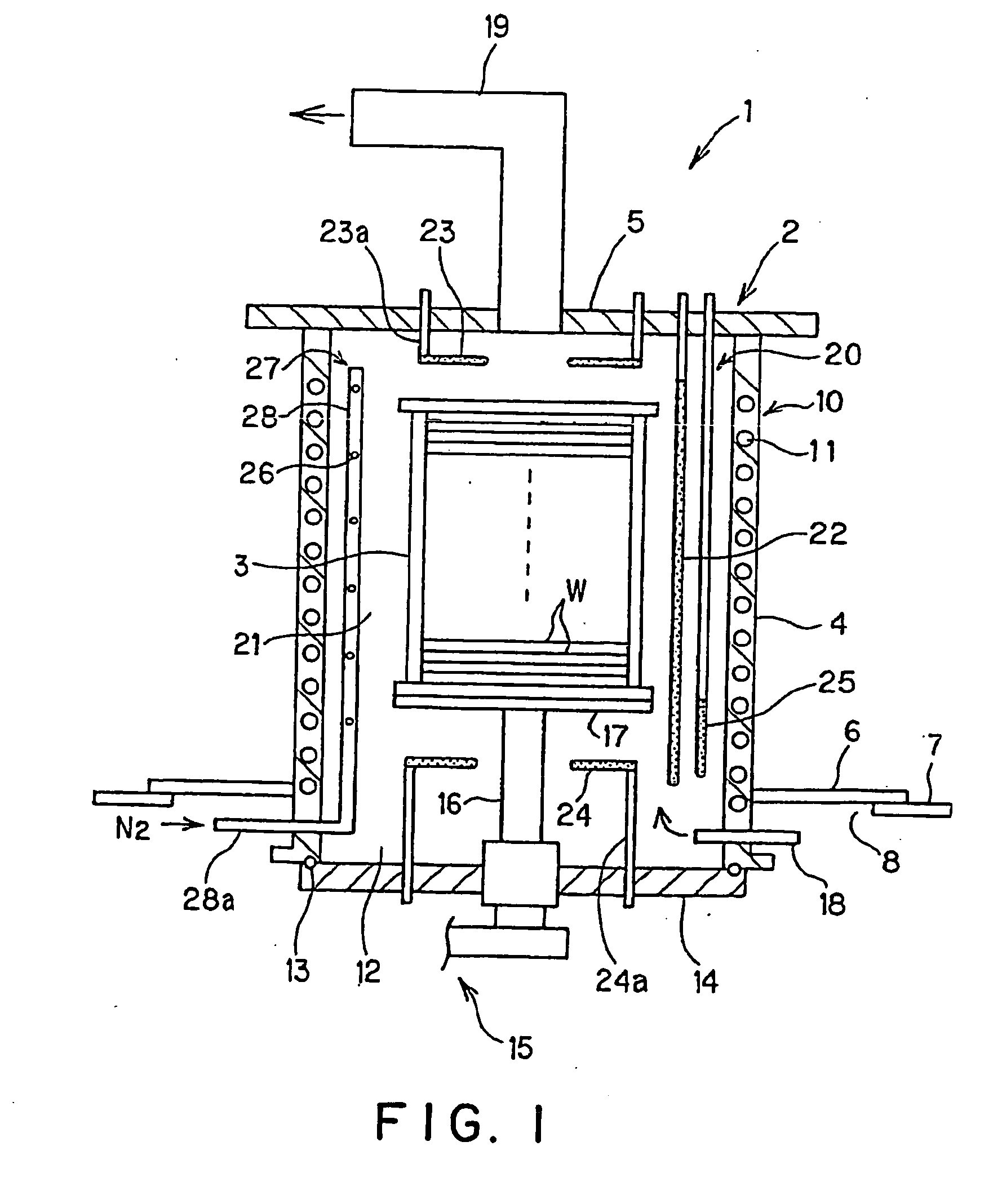

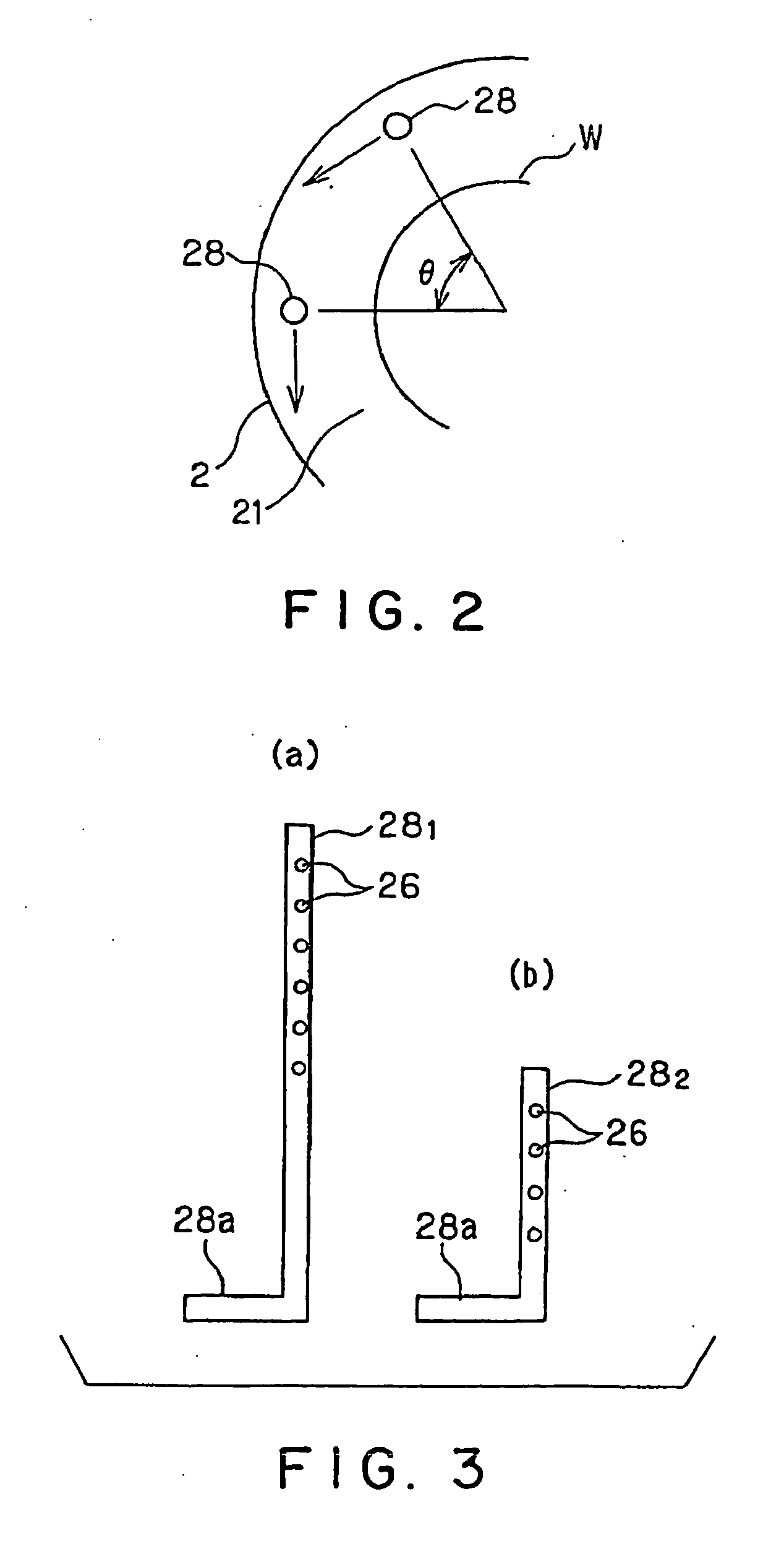

Thermal processing method and thermal processing unit

InactiveUS20070095288A1Simple structureRapid and uniform coolingMuffle furnacesSemiconductor/solid-state device detailsProcess engineeringMetal

The present invention is a thermal processing method including: a step of conducting a predetermined thermal process in a low temperature zone to a plurality of objects to be processed held in a tier-like manner by a heating unit, in a processing container that is made of metal and has the heating unit therein, and a step of introducing a cooling gas into respective areas in the processing container divided in a height direction of the objects to be processed.

Owner:TOKYO ELECTRON LTD

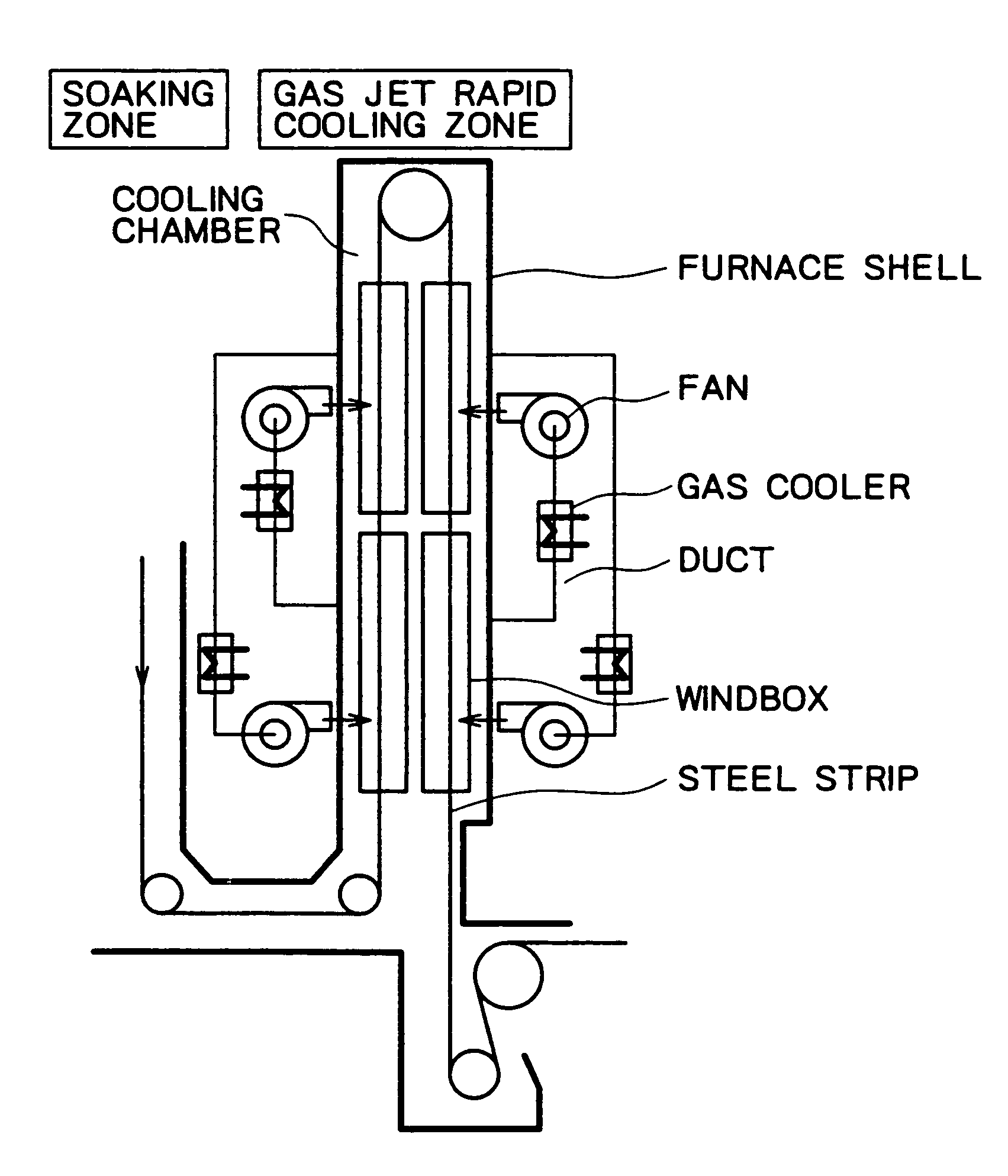

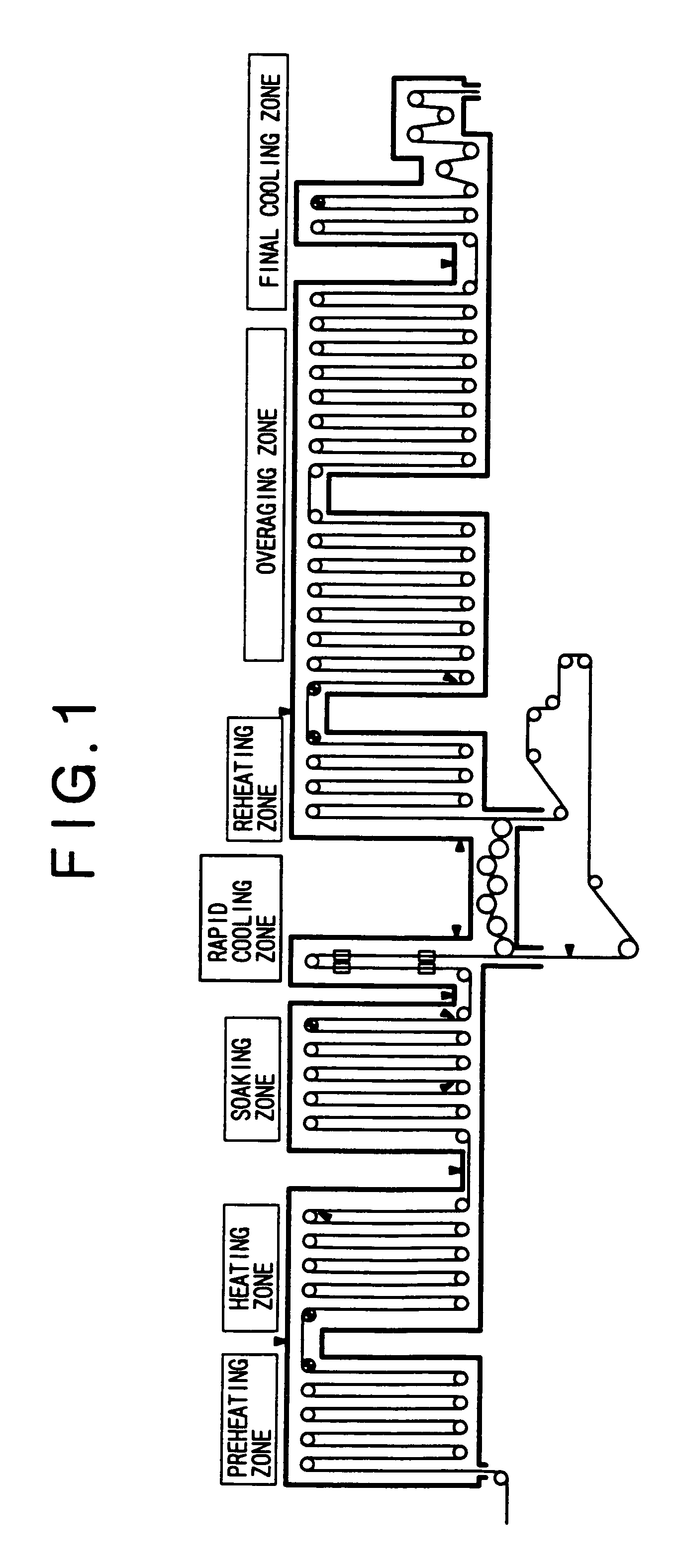

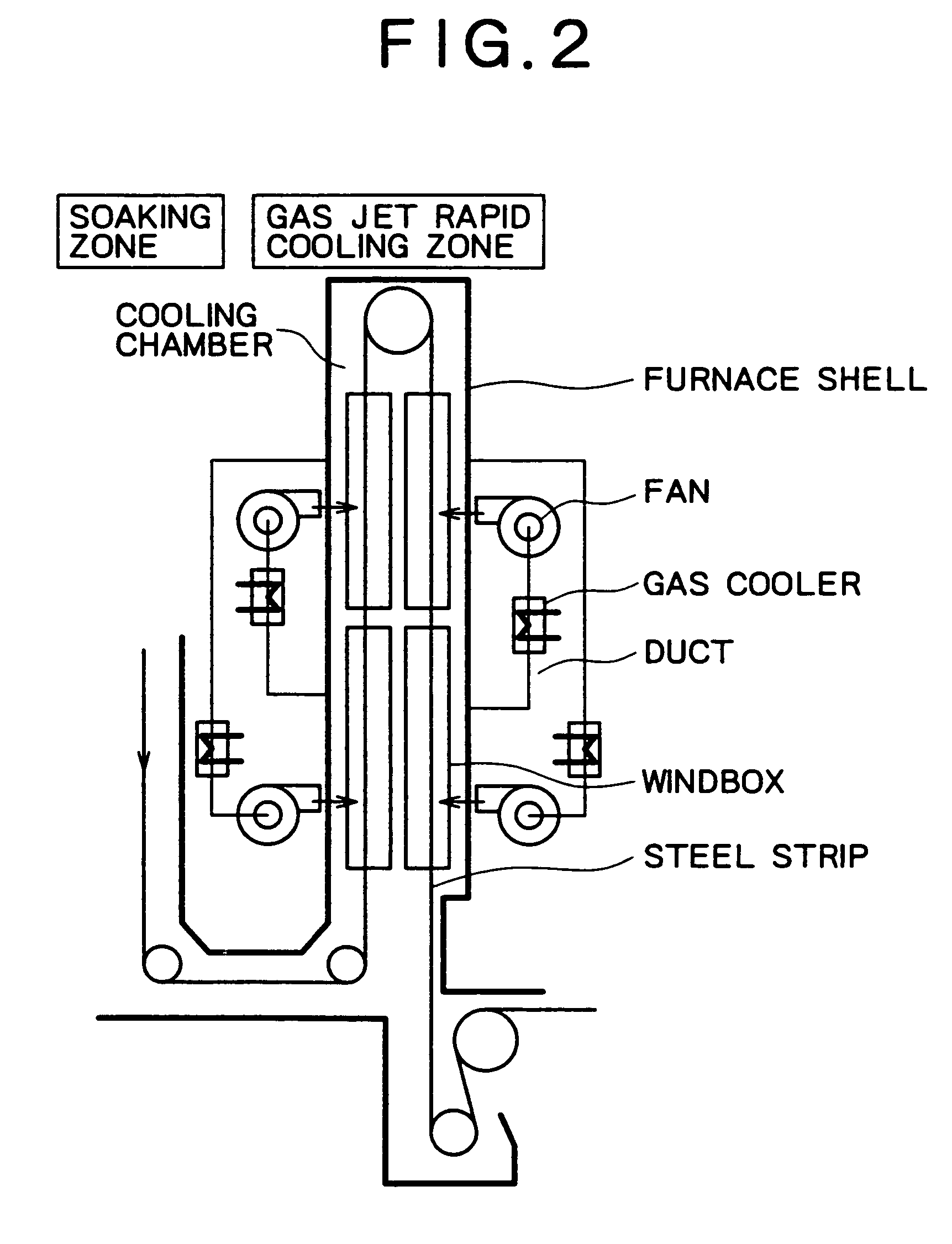

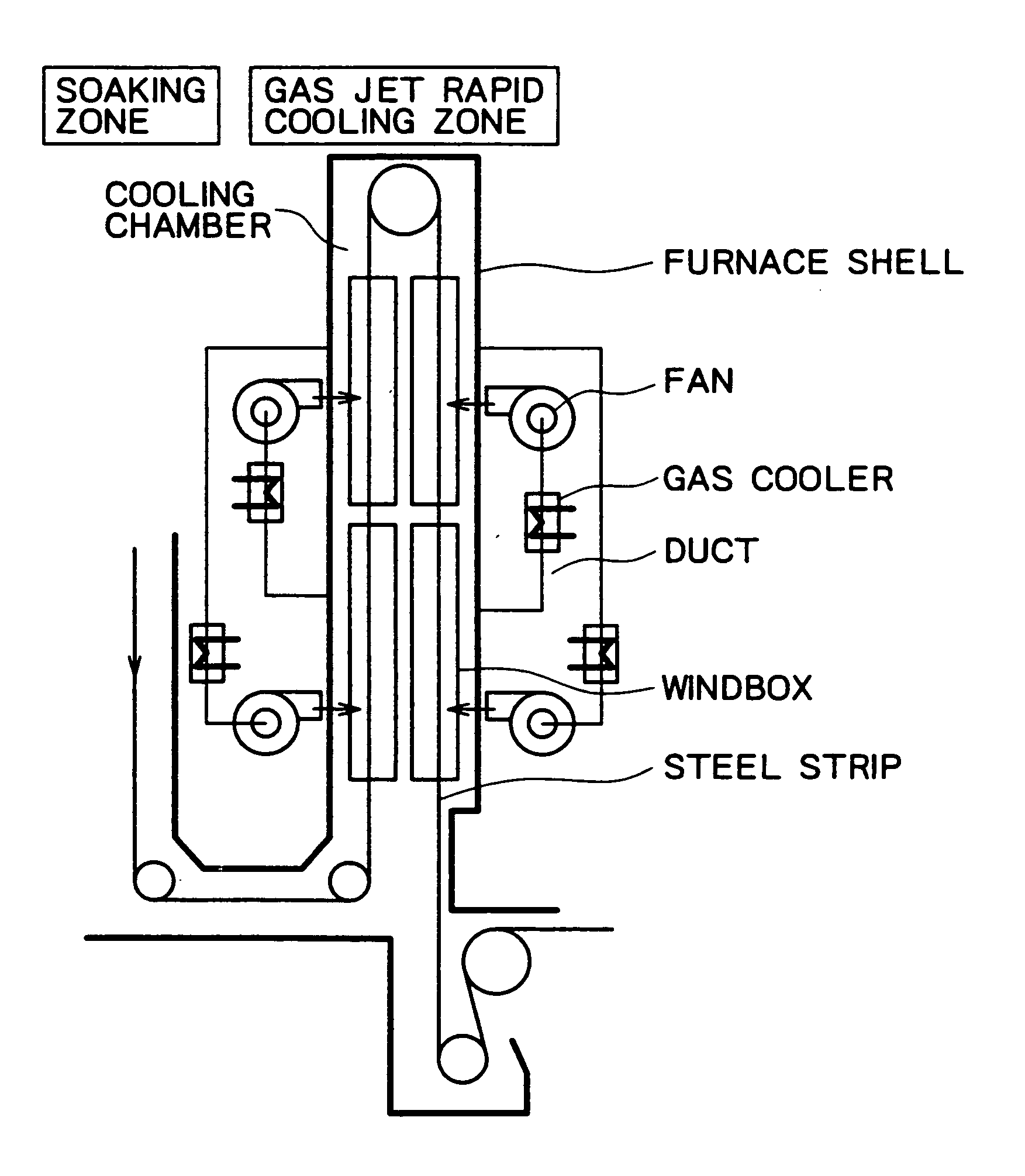

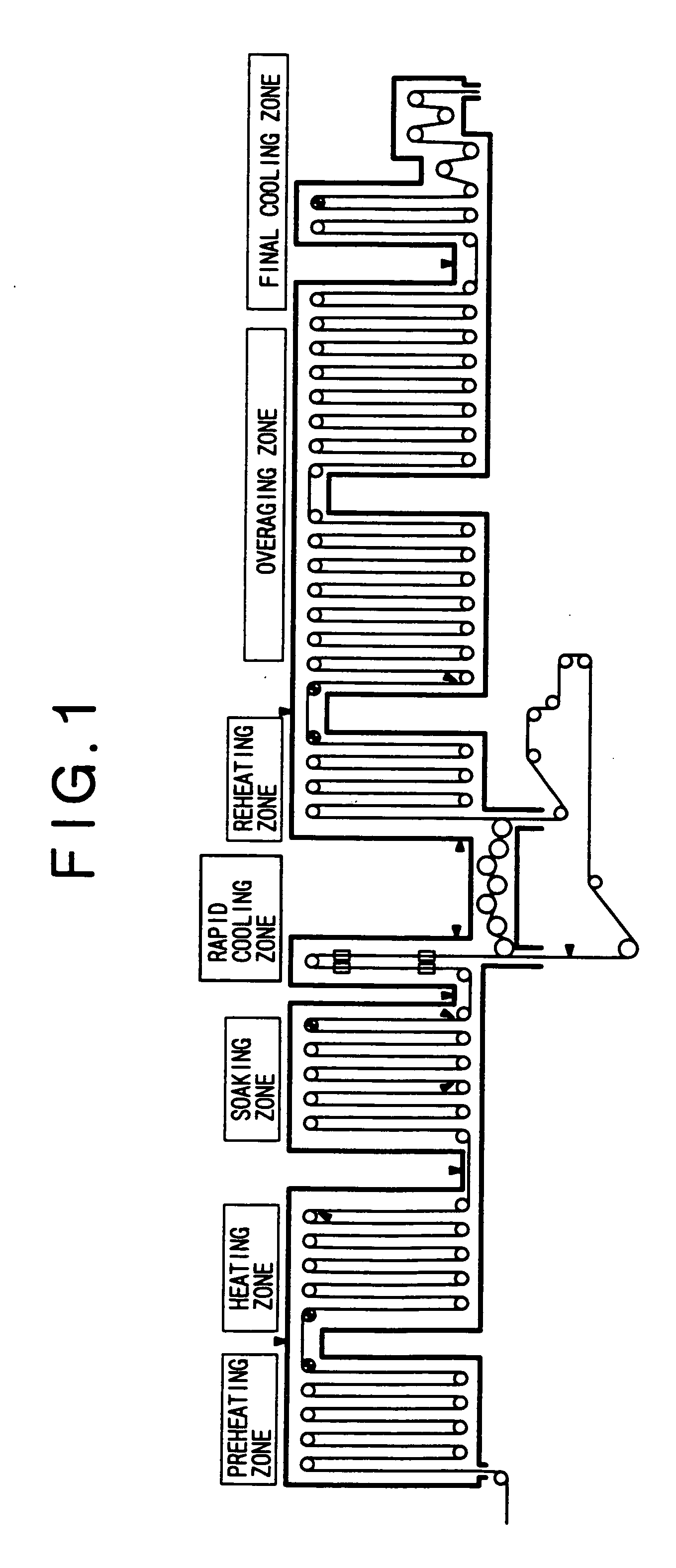

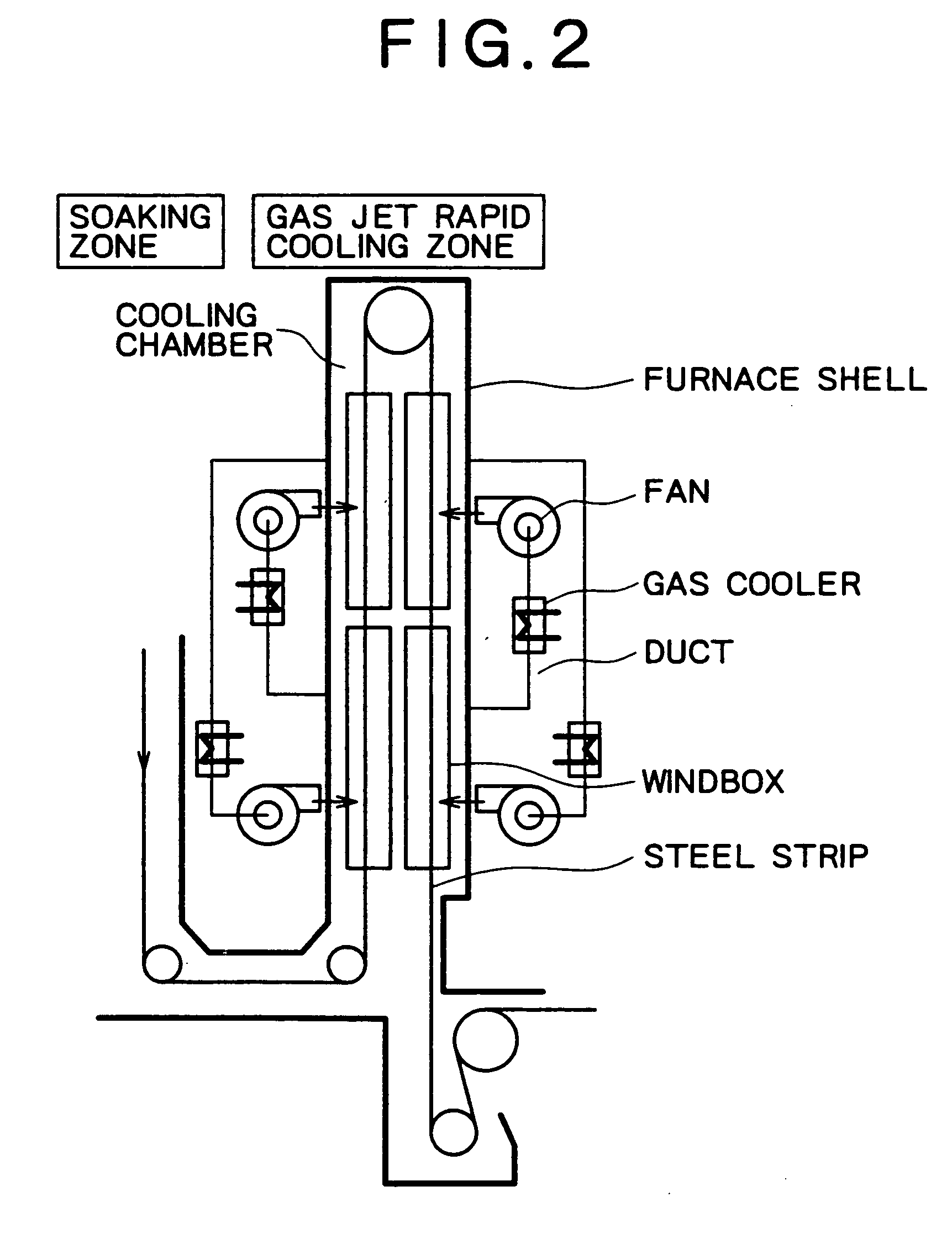

Gas jet cooling device

ActiveUS7381364B2Reduce distanceSmall sizeDrying using combination processesDrying solid materials with heatCooling chamberEngineering

A gas jet cooling device in a continuous annealing furnace is equipped with: windboxes disposed in a cooling chamber on both sides of a steel strip, blowing a cooling gas toward the strip through nozzles to cool it; and a means of cooling the gas introduced from the cooling chamber and then supplying the cooled gas to the windboxes, wherein the distance between the tips of the nozzles and the strip is not more than ten times the diameter of the nozzles; and the length of each of the windboxes in the strip traveling direction is not more than two thirds of the width of the strip. The gas jet cooling device can cool the strip rapidly and uniformly even when the distance between the strip and the front face of each windbox is shorter and the size of a cooling chamber is smaller than the conventional ones.

Owner:KOBE STEEL LTD

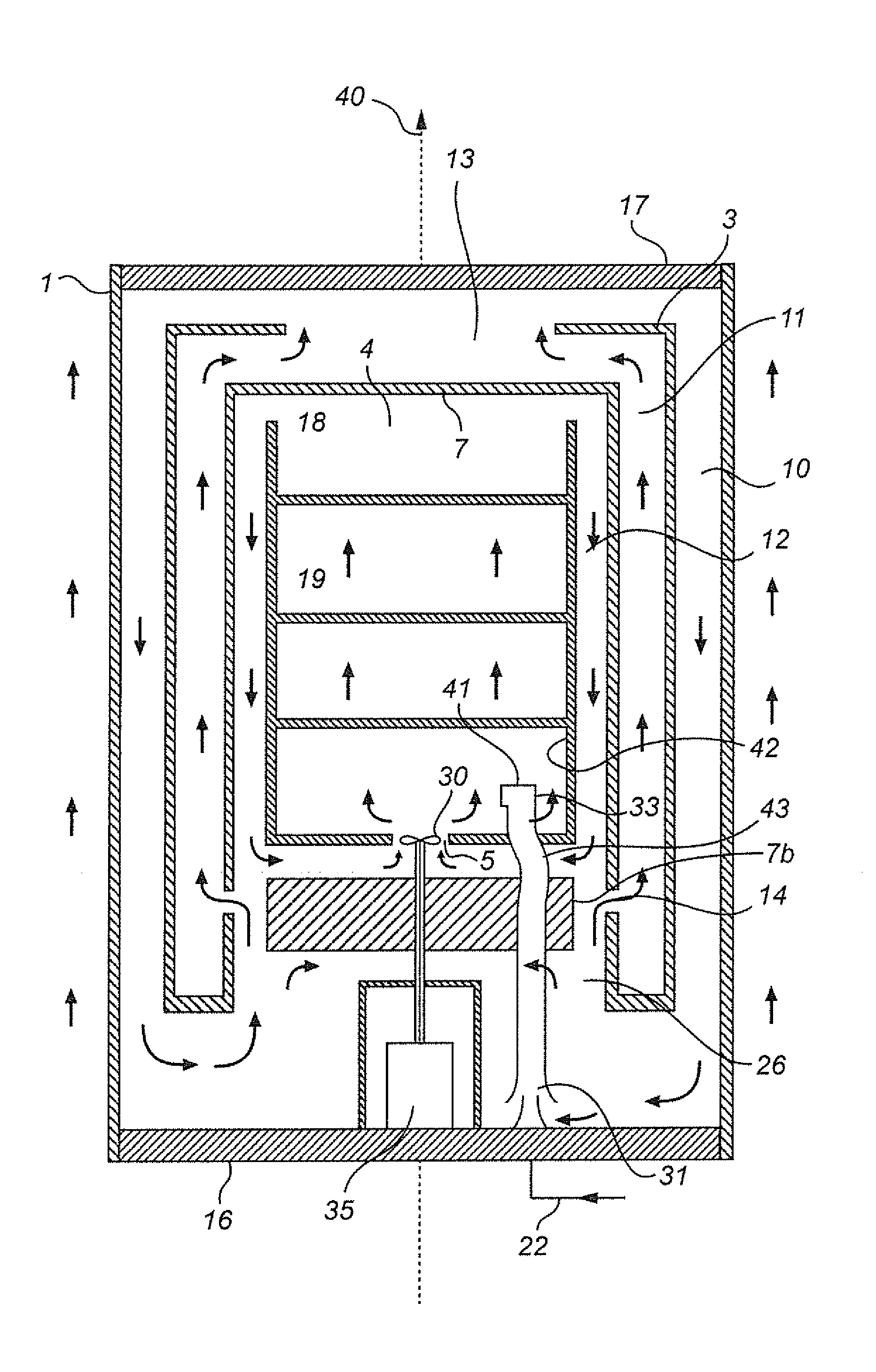

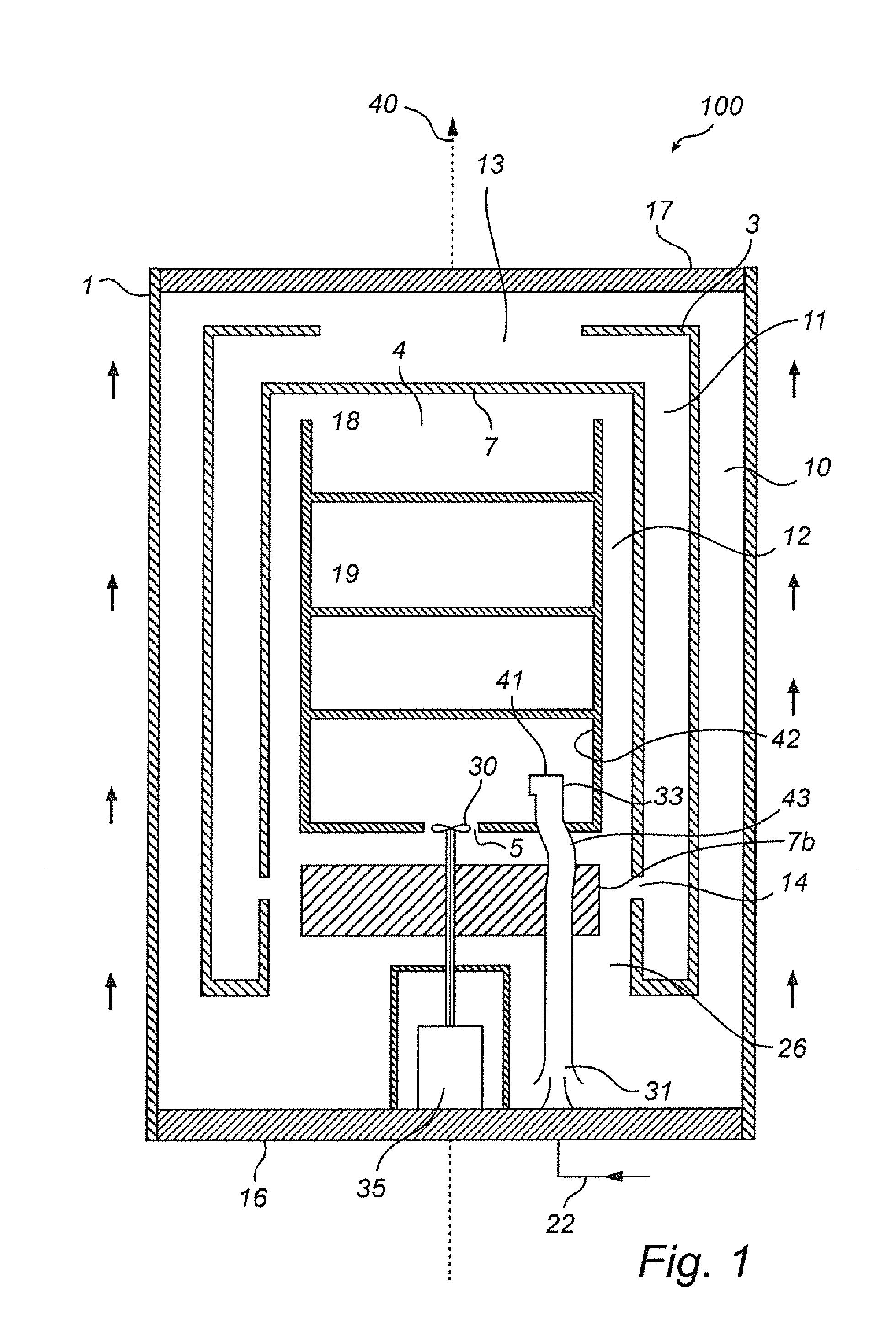

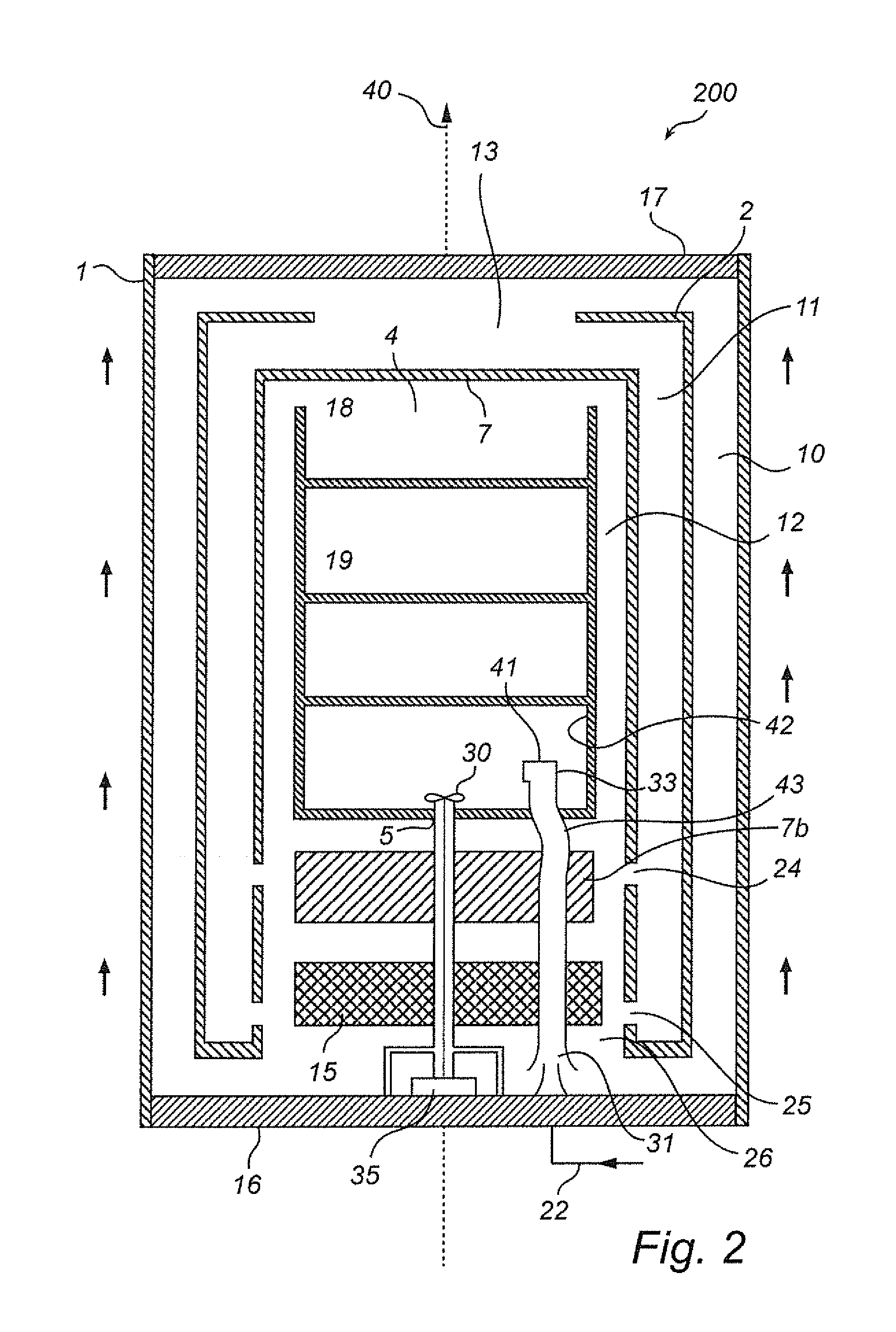

Combined fan and ejector cooling

ActiveUS20140272745A1Rapid and uniform coolingMuffle furnacesMaintainance of heating chambersEngineeringInternal convection

A pressing arrangement for treatment of articles by hot pressing includes a pressure vessel including a furnace chamber and a furnace to hold the articles. A fan circulates a pressure medium within the furnace chamber, and enhances an inner convection loop at a load compartment. The inner convection loop pressure medium has an upward flow through the load compartment, and a downward flow along a peripheral portion of the furnace chamber. A flow generator generates a flow of pressure medium into the load compartment downstream the fan to enhance the inner convection loop. The flow is generated by transporting the pressure medium upwards from a space below a bottom insulating portion and above a bottom end portion, and by injecting the pressure medium into the load compartment downstream the fan to enhance the inner convection loop.

Owner:QUINTUS TECH

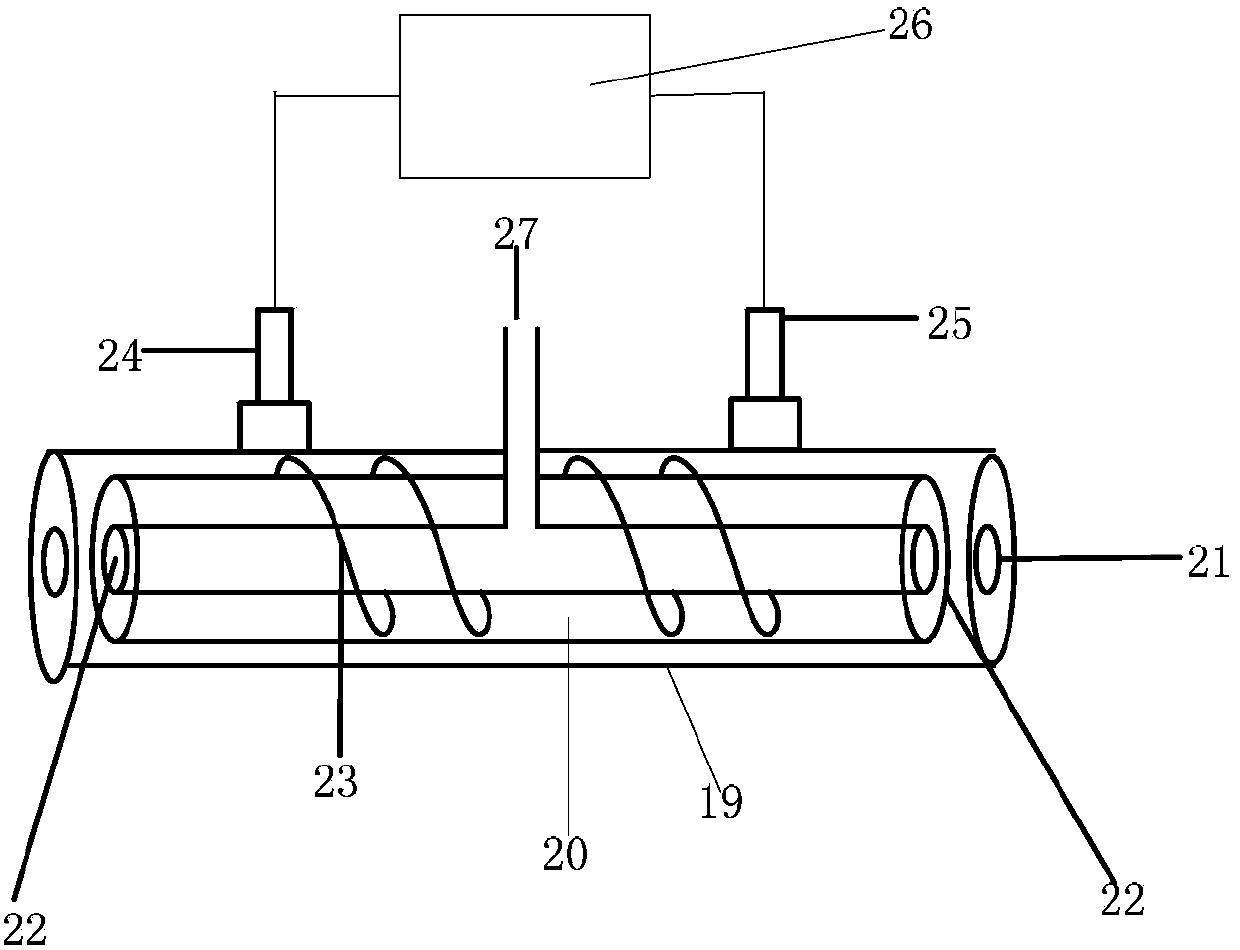

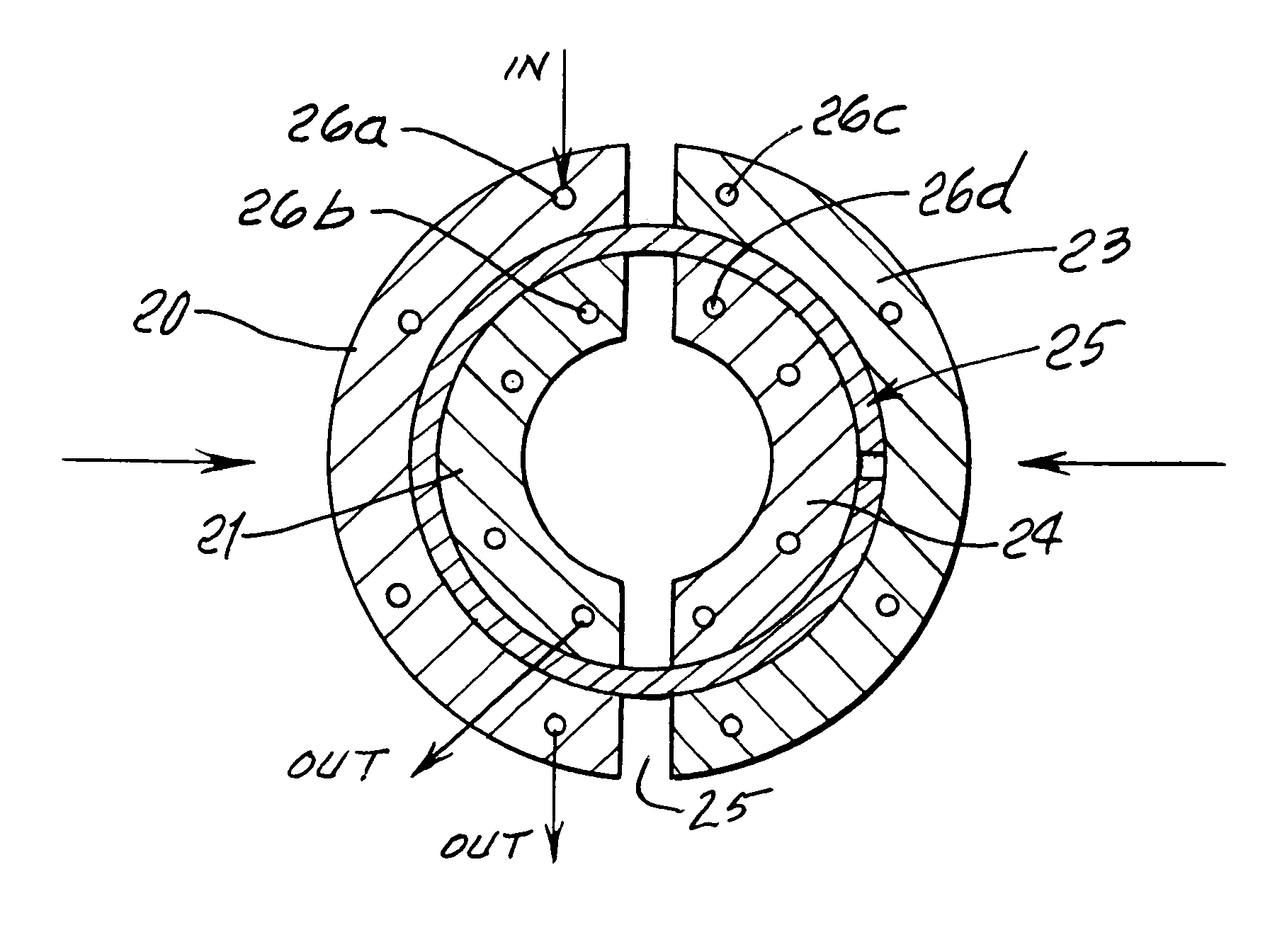

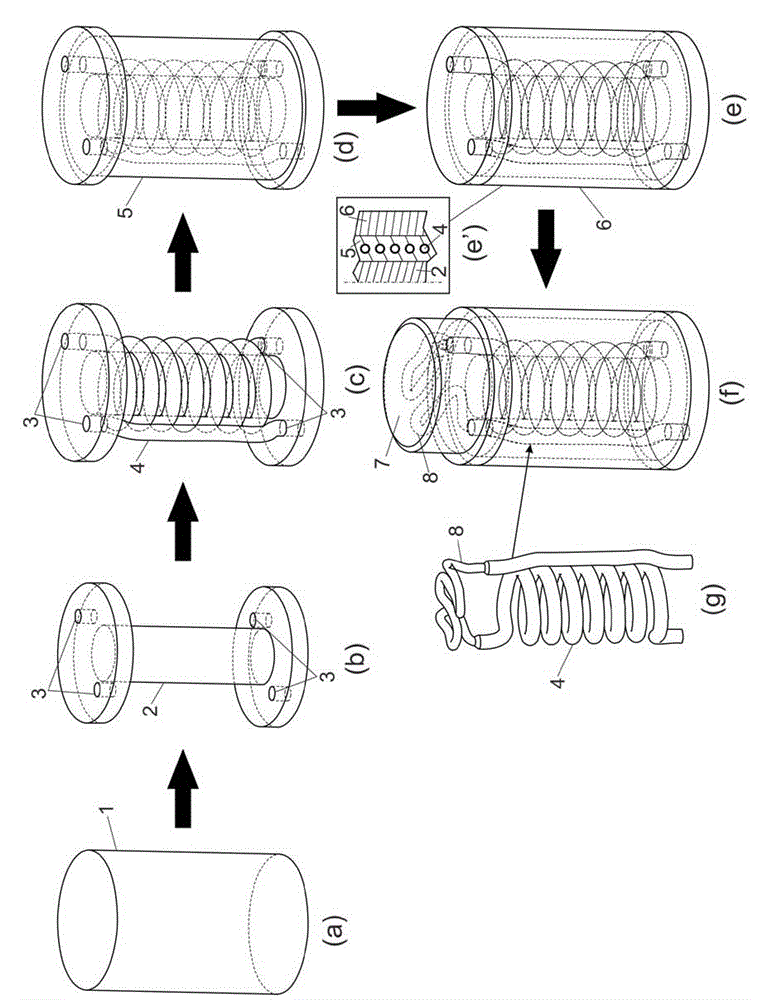

Spraying and quenching device for steel pipe, petroleum well pipe and drill pipe medium frequency heat treatment system

ActiveCN101078045ARapid coolingRapid and uniform coolingFurnace typesHeat treatment process controlSteel tubeQuenching

This invention provides a kind of spray quenching equipment in the frequency treatment system of steel pipe, tube and drill pipe of oil well. The sprinkler is a circle distribution and the inlet pipe is connected with the pump. The spray quenching angle switch equipment is installed onto the sprinkler. Several muzzles are fixed to the sprinkler, which are distributed in taper or sector shape. All of the muzzles are symmetric set, the diameter of which is from 1.2mm to 4mm. The center line of the spray quenching equipment is coinciding with that of the steel pipe , tube and drill pipe. The advantages are: the continuum spray quenching process with product line can make the work pieces quenched properly. The average flatness of a 10-meters long work piece can come up to the US standard API, which is 0.2% of the total length from one end to the other. It couldn' t exceed 3.175 mm within 1524mm long. The spray pressure is controllable, the equipment can cool down quickly and the jam can be removed quickly. The angle of the muzzle is adjustable, which can reduce the backwater when the work pieces pass the spray quenching area.

Owner:朱兴发

Gas jet cooling device

ActiveUS20050262723A1Reduce distanceSmall sizeDrying using combination processesDrying solid materials with heatCooling chamberEngineering

A gas jet cooling device in a continuous annealing furnace is equipped with: windboxes disposed in a cooling chamber on both sides of a steel strip, blowing a cooling gas toward the strip through nozzles to cool it; and a means of cooling the gas introduced from the cooling chamber and then supplying the cooled gas to the windboxes, wherein the distance between the tips of the nozzles and the strip is not more than ten times the diameter of the nozzles; and the length of each of the windboxes in the strip traveling direction is not more than two thirds of the width of the strip. The gas jet cooling device can cool the strip rapidly and uniformly even when the distance between the strip and the front face of each windbox is shorter and the size of a cooling chamber is smaller than the conventional ones.

Owner:KOBE STEEL LTD

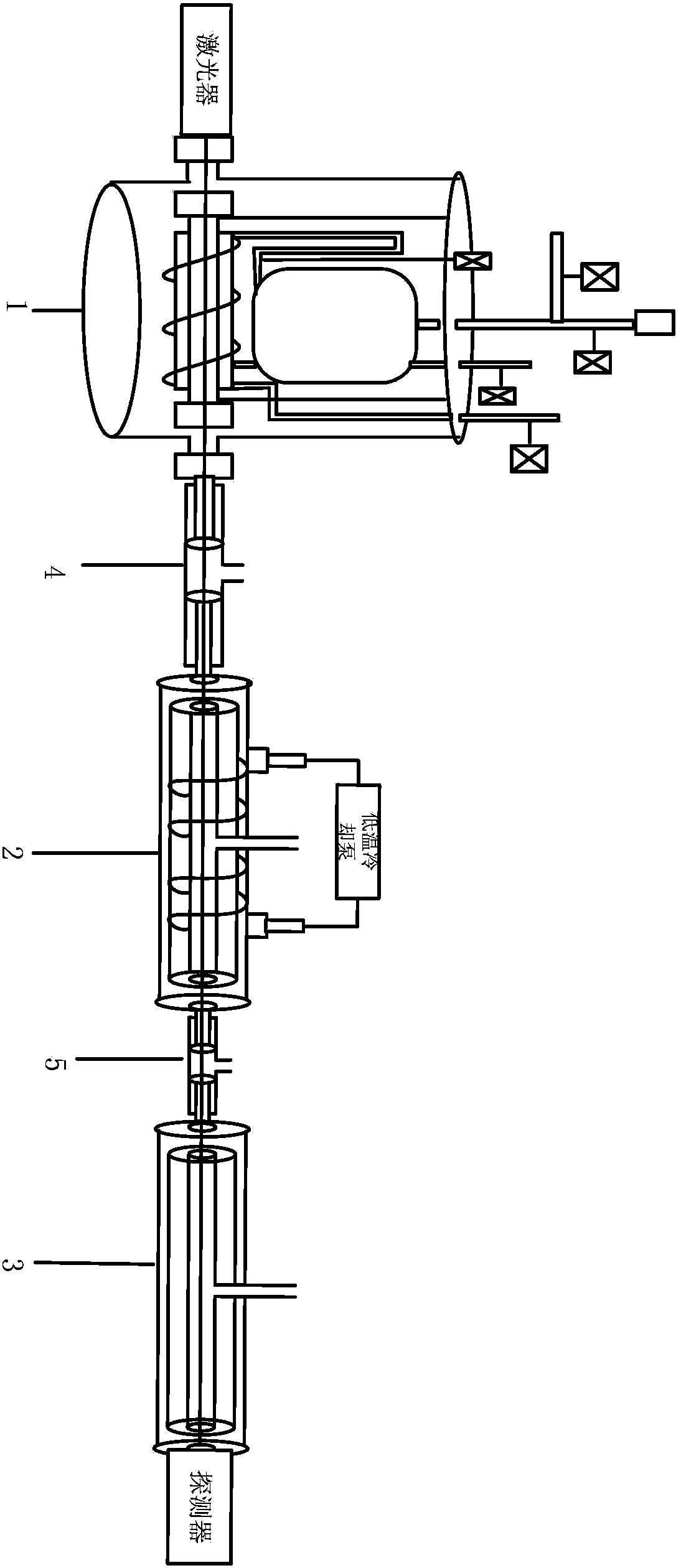

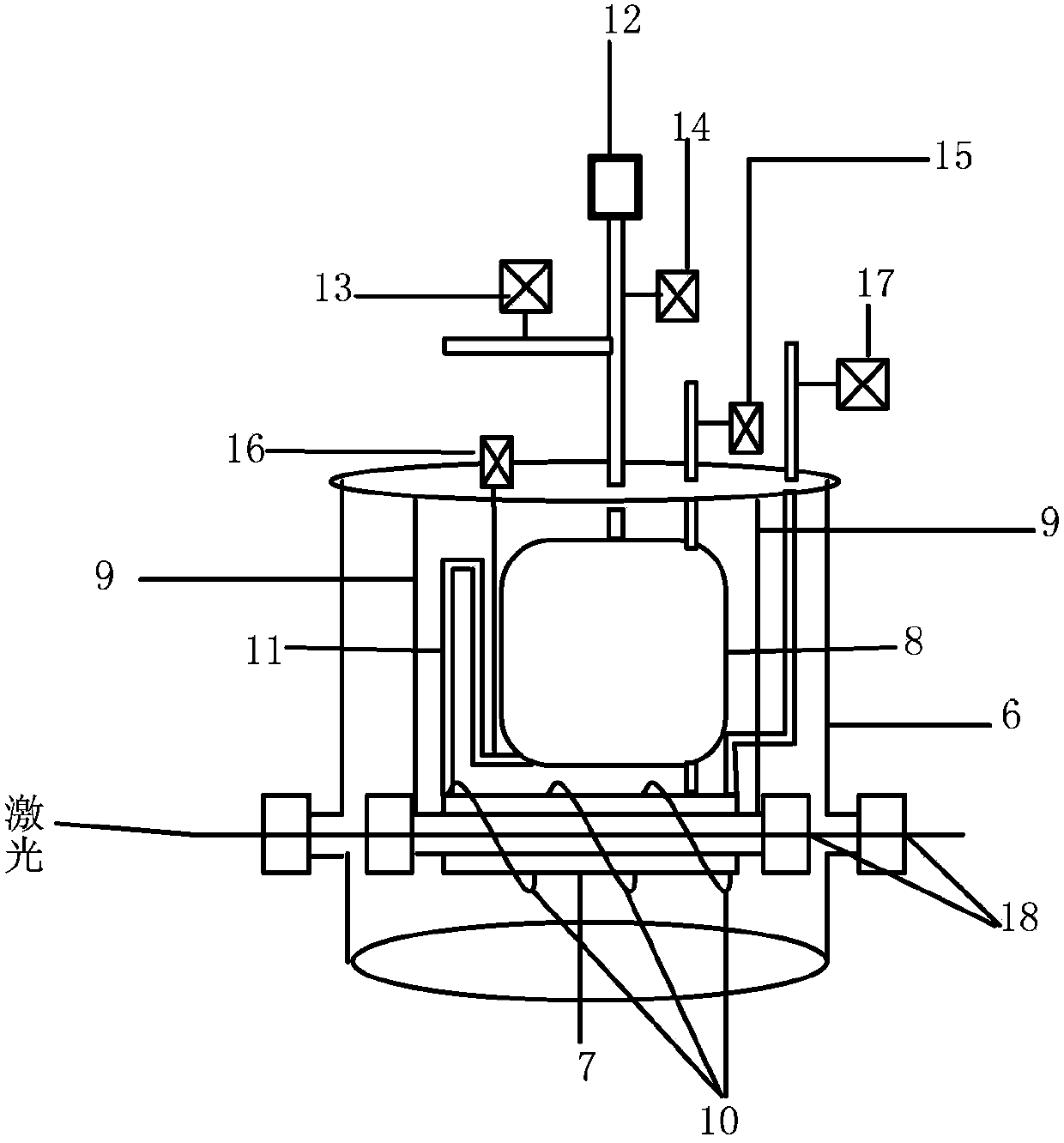

Multi-parameter temperature-controlled absorption cell device capable of simulating vertical atmospheric environment

ActiveCN103424358AReduce temperature stability effectsRapid and uniform coolingMaterial analysis by optical meansAtmospheric layerAtmospheric air

The invention discloses a multi-parameter temperature-controlled absorption cell device capable of simulating the vertical atmospheric environment. The absorption cell device is characterized by comprising a parameter-controllable, single-optical path, single-pass and low-temperature absorption cell, a parameter-controllable, single-optical path, single-pass and moderate-temperature absorption cell and a parameter-controllable, single-optical path, single-pass and ordinary-temperature absorption cell which are connected in series, wherein the low-temperature and the moderate-temperature absorption cell are connected with each other through a first optical path means; the moderate-temperature and the ordinary temperature absorption cell are connected with each other through a second optical path means; through adjusting the temperature of the single absorption cell and the gas volume mixing ratio thereof, the parameters, such as temperature gradient and pressure gradient, of the vertical atmospheric layer can be simulated in a laboratory. The absorption cell device can be used for measuring and analyzing parameters of atmosphere molecule absorption spectrum in direct combination with an absorption spectrum technology, based on which the vertical atmosphere transmittivity can be obtained, and discipline of atmosphere molecule absorption spectrum can be generalized; as the indoor environment is more stable, the device has the advantages of high precision, good stability and the like, and has important meaning for research of atmospheric optics.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

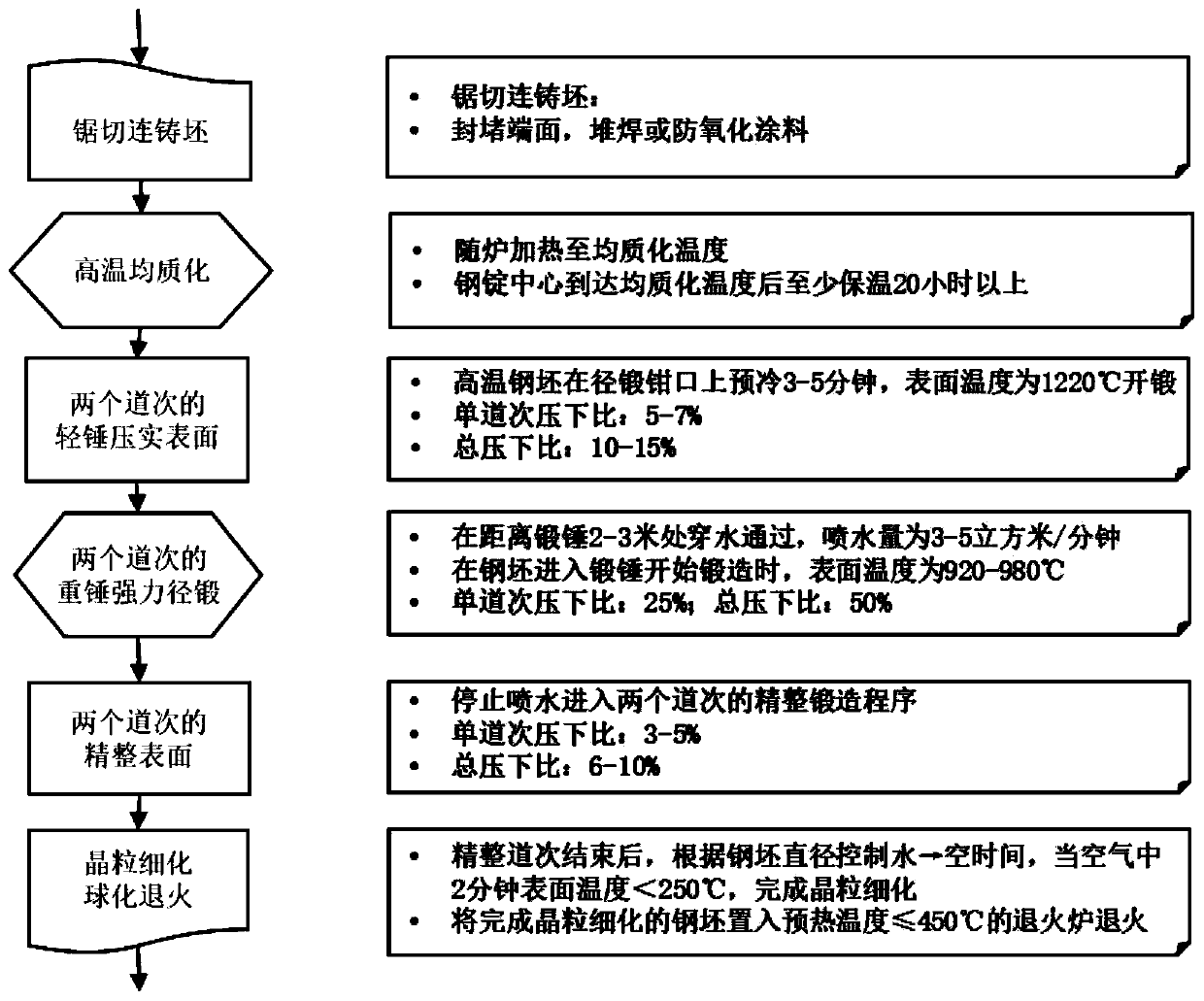

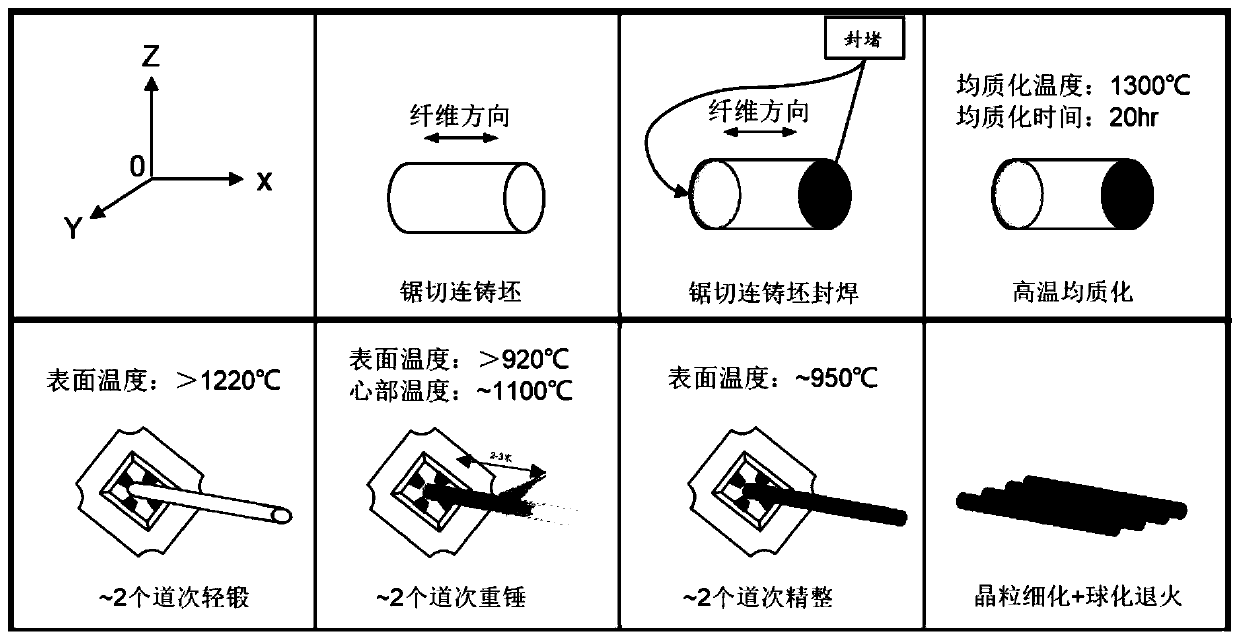

Process method for directly forging continuous casting billet to produce die steel

ActiveCN110512061AImprove toughnessImprove isotropyMetal-working apparatusFurnace typesCarbideLiquation

The invention provides a process method for directly forging a continuous casting billet to produce die steel. The process method specifically includes the steps that the continuous casting billet ispretreated and homogenized at the temperature of 1,280 DEG C-1,320 DEG C for 20 h or longer; the homogenized continuous casting billet deforms at a small pressing ratio (10%-15%); and then the surfaceof a forging blank is cooled in a water spraying mode from one end of the forging blank at a normal radial forging rotary feeding speed, a hard shell is formed, and when the steel surface temperatureis 920 DEG C-980 DEG C, two-pass large pressing (the total pressing ratio is 45%-50%) heavy punch radial forging is carried out. Then a finishing pass with the small pressing amount of 4%-5% is set.The final forging temperature is 850 DEG C-900 DEG C. The product is obtained after grain refinement and annealing are completed. The continuous casting billet is specially treated, two times of hardshell radial forging are carried out, dynamic conditions beneficial for kneading of the center defect of the continuous casting billet are created, and continuous loose air holes and other defects inthe center of the continuous casting billet, decomposed liquation carbide and banded structures generated due to dendritic segregation are completely eliminated.

Owner:江阴华润制钢有限公司

Novel casting die cooling device

The invention discloses a novel casting die cooling device. The novel casting die cooling device comprises an upper die body and a lower die body, wherein an upper die cavity and a lower die cavity are respectively formed in the bottom end of the upper die body and the top of the lower die body, an upper cooling tank is embedded in the upper part of the upper die cavity, the left end of the upper die cavity is communicated with an upper water inlet, an upper spiral water path is further arranged in the upper die body, the bottom end of the upper die body extends to form an upper water outlet, a lower cooling tank is embedded at the lower part of the lower die cavity, the left end of the lower die cavity is communicated with a lower water inlet, a lower spiral water path is further arranged in the lower die cavity, the top of the lower cavity extends to form a water outlet, the device further comprises a water storage tank, a water tank water outlet and water tank return water opening are respectively formed in the water storage tank, a water outlet pipeline is connected to the water tank water outlet, the upper water inlet and the lower water inlet are both connected with the water outlet pipeline, both the upper water outlet and the lower water outlet are connected with the water tank return water opening, and a water pump is further connected onto the water outlet pipeline. Due to the adoption of the structure, the novel casting die cooling device provided by the invention can carry out cooling sufficiently, quickly and evenly, therefore, the product quality and the die usability are improved greatly.

Owner:CHENGDU JIAMEIJIA SCI & TECH

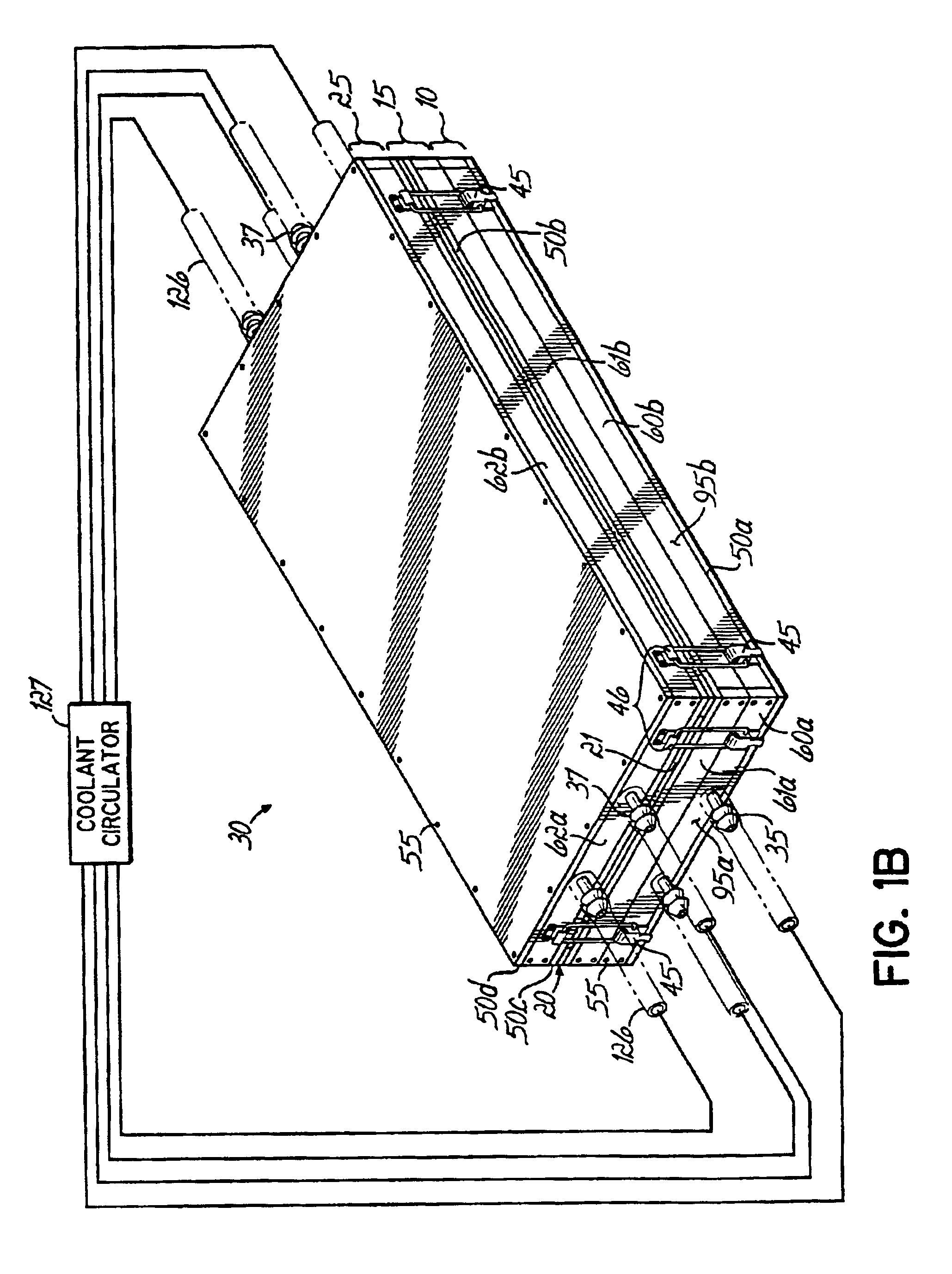

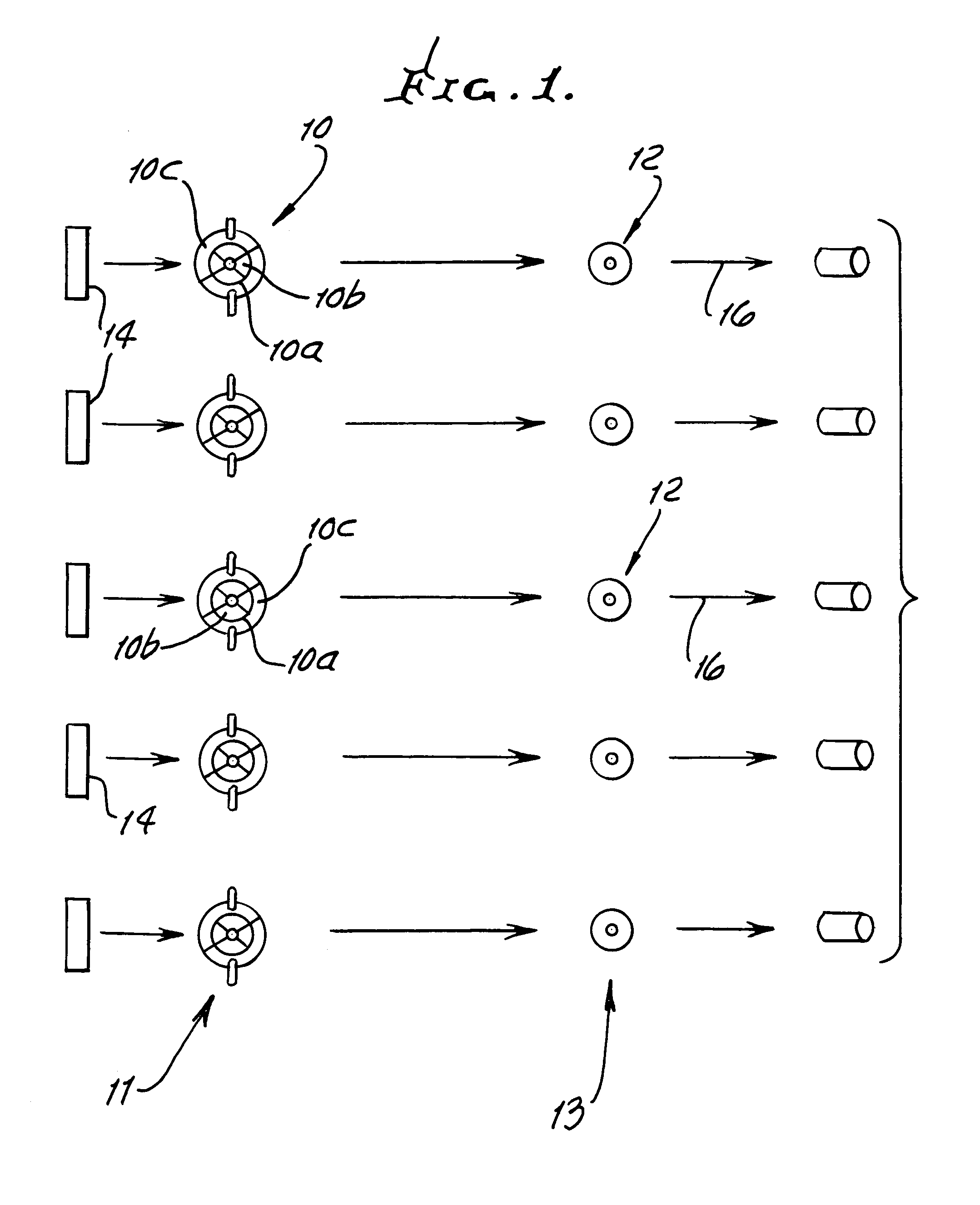

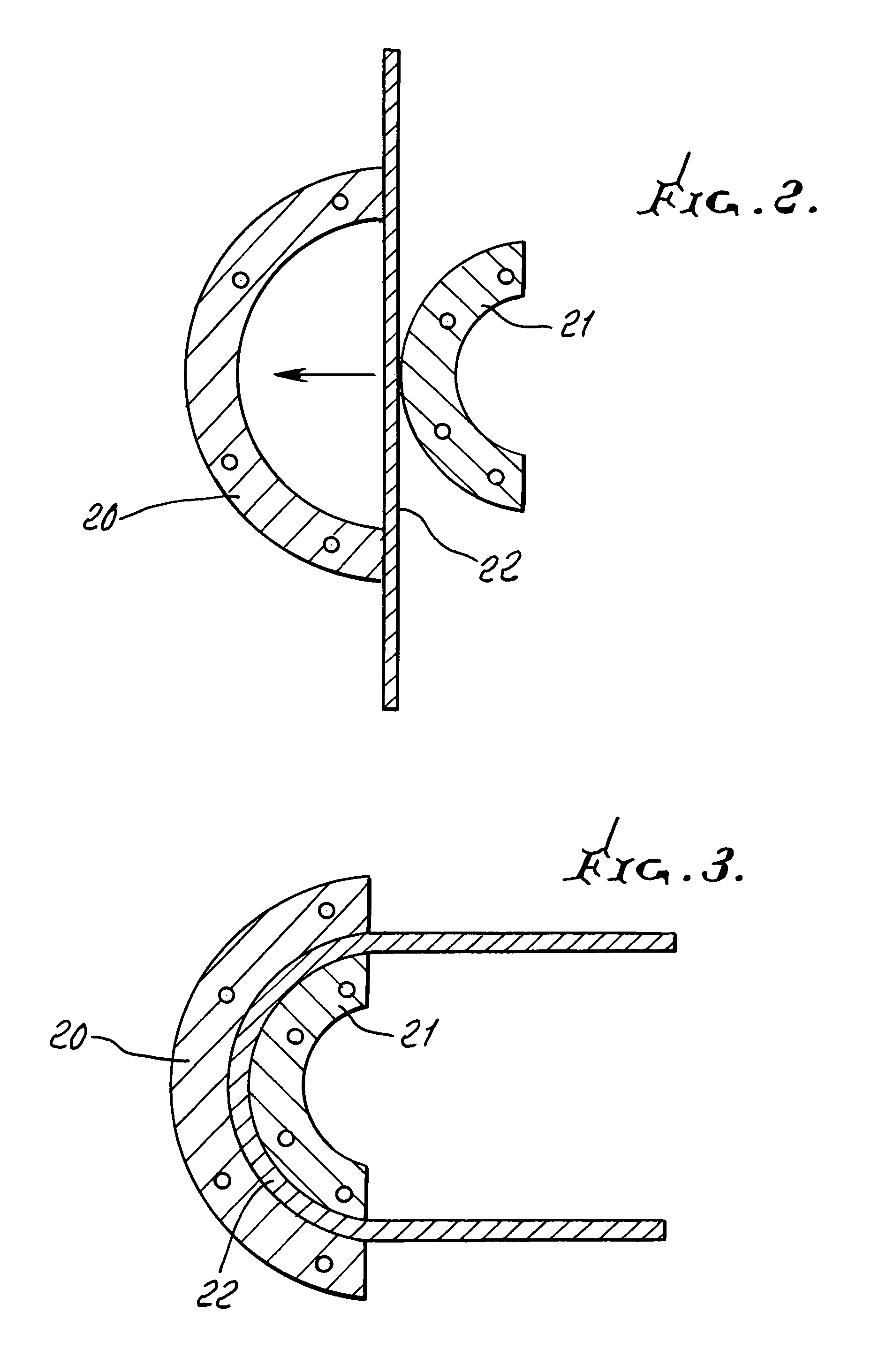

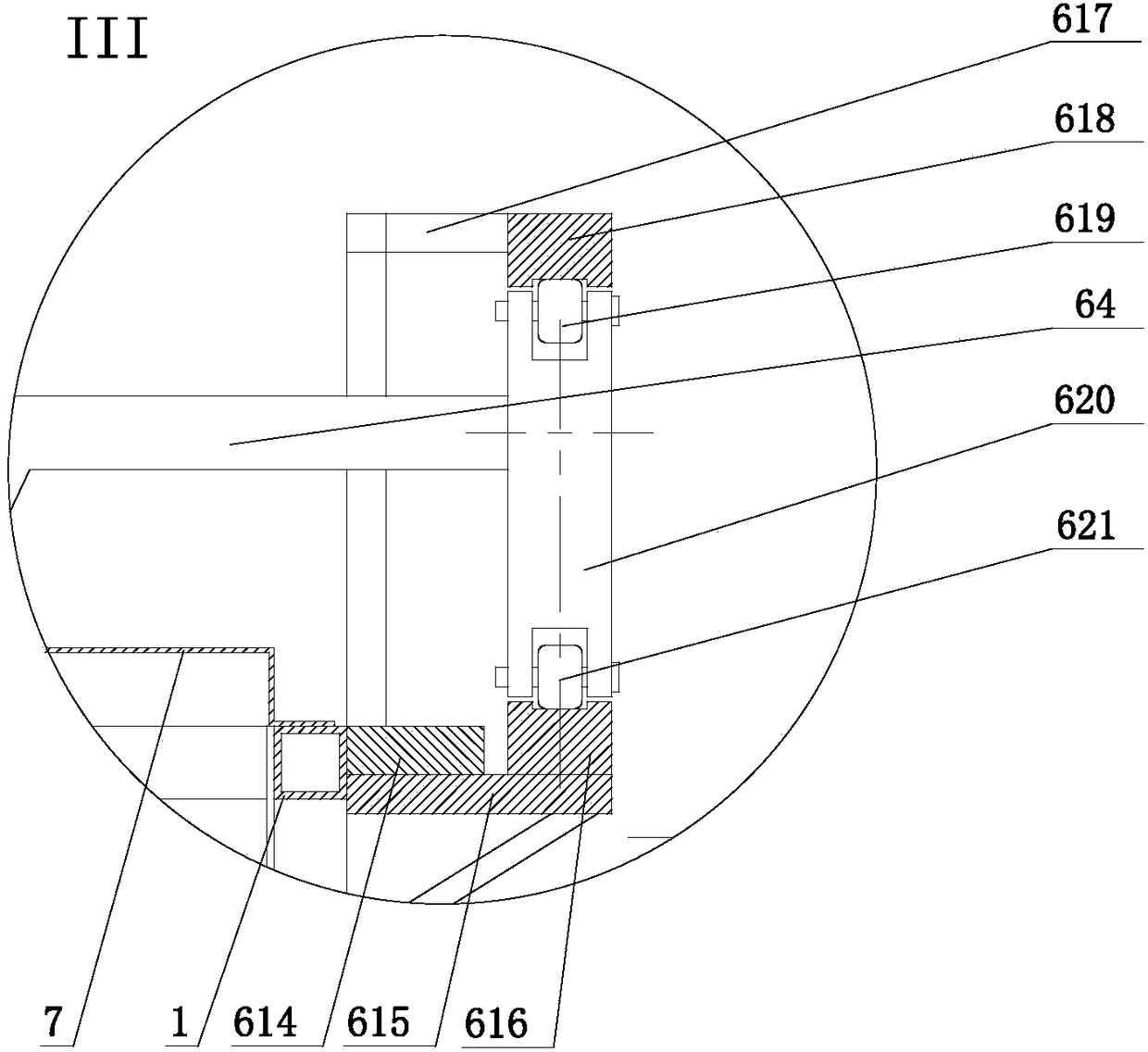

Drum shell formation

ActiveUS7942176B1Improve consistencyHigh speedWood veneer joiningWood stock bendingHigh pressureMechanical engineering

In the method of forming a drum shell that consists of plywood, the steps that includes forming the shell under pressure and heat into cylindrical configuration, providing inner and outer cooling platens adapted to respectively engage the interior and exterior surfaces of the heated shell, trapping the heated shell between the platens, at elevated pressure, allowing the shell to cool by heat transfer from shell side wall or walls into pressure exerting side walls, and while trapped between such platens, at elevated pressure, and removing the cooled shell from between the cooling platens.

Owner:DRUM WORKSHOP

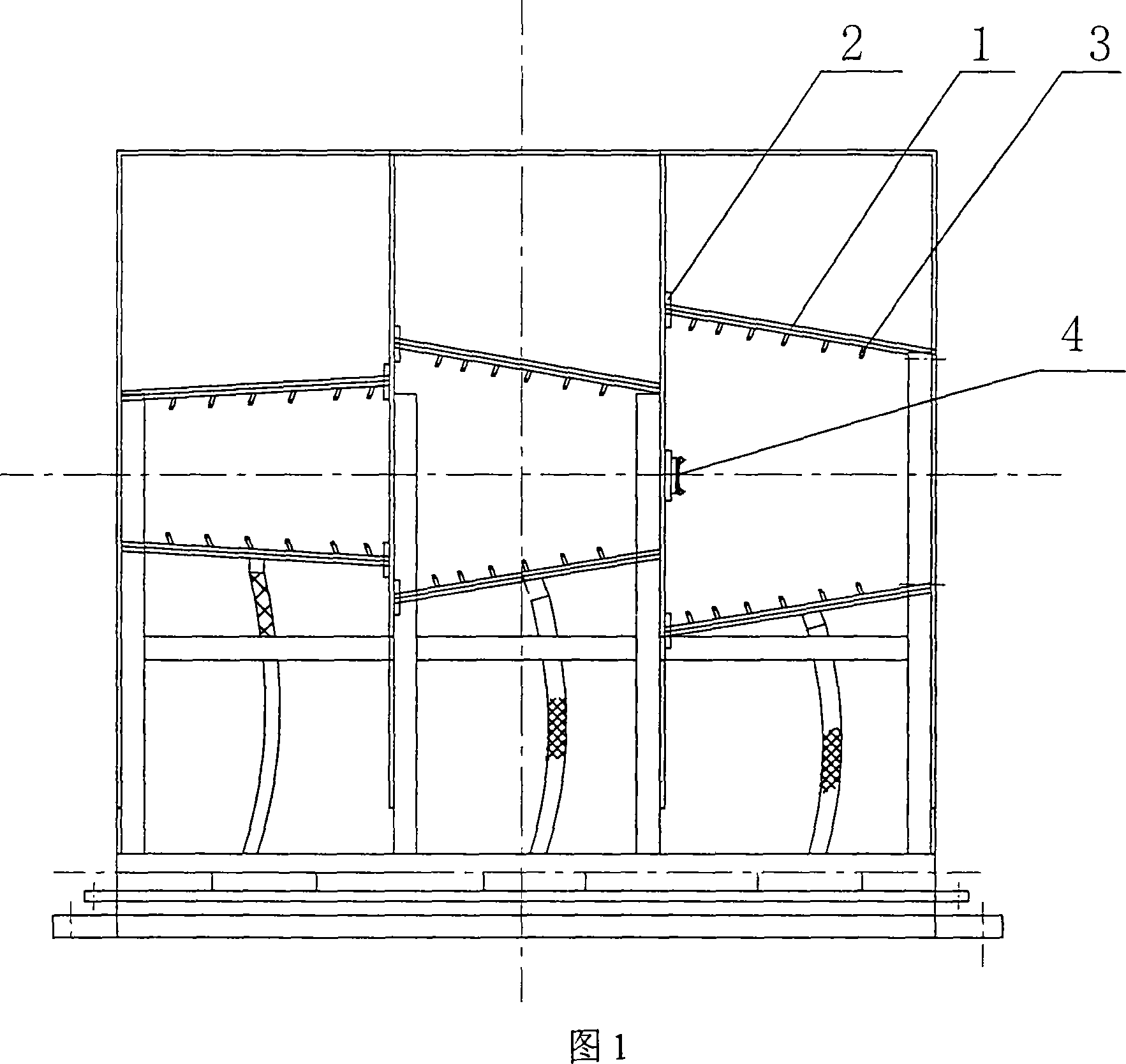

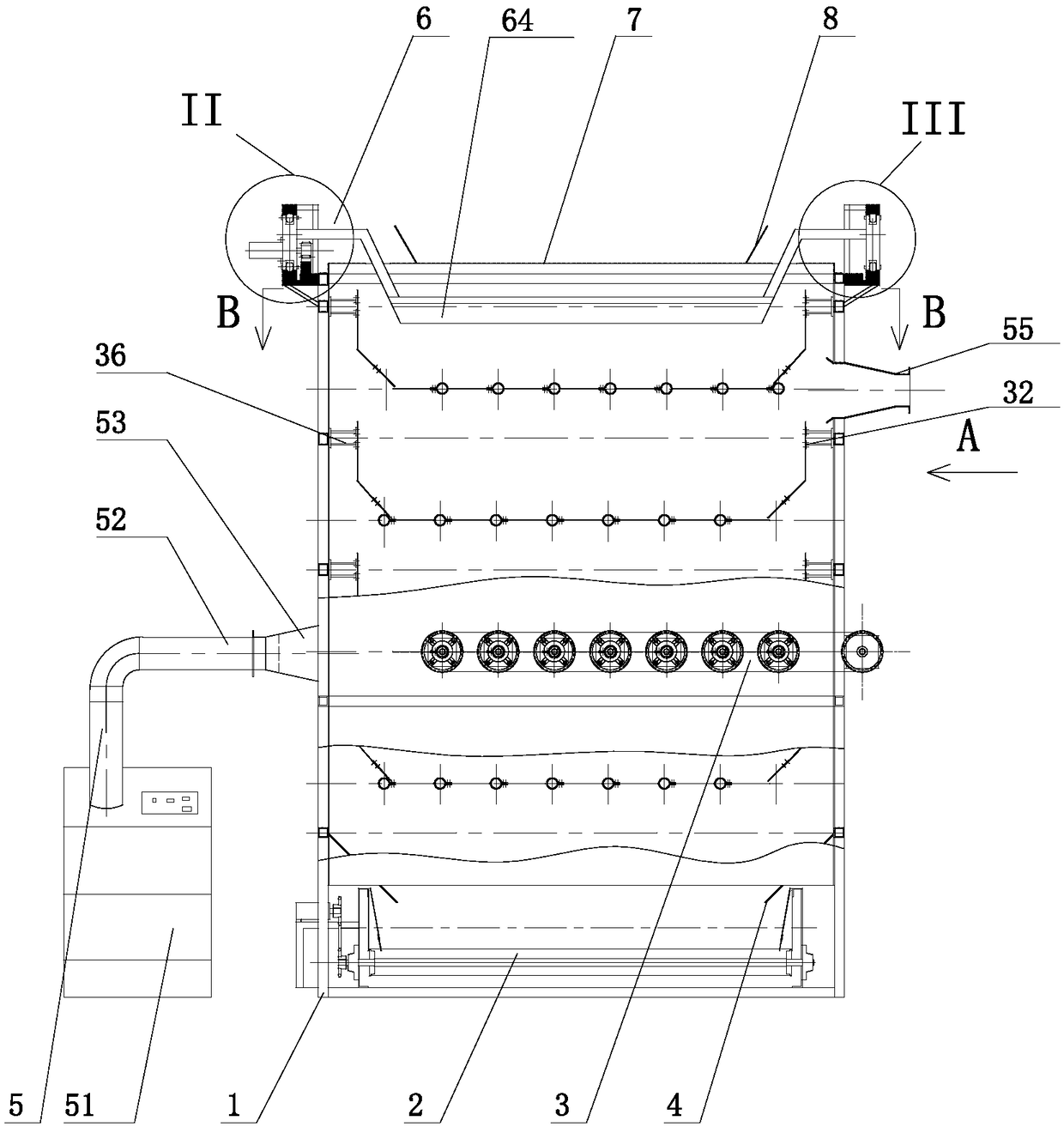

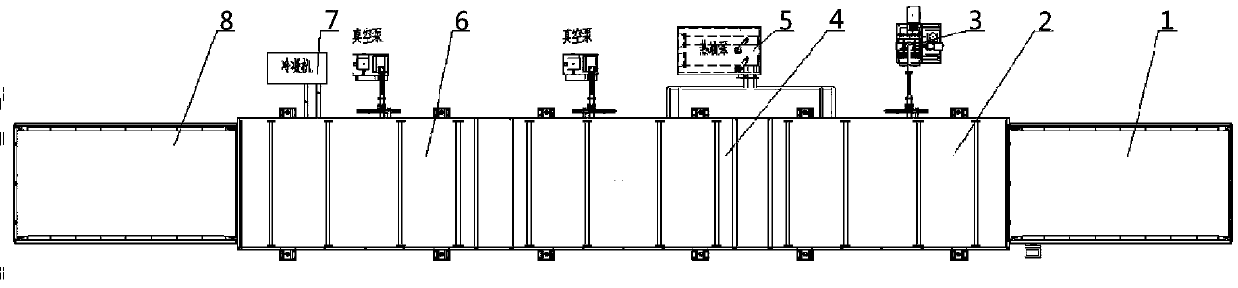

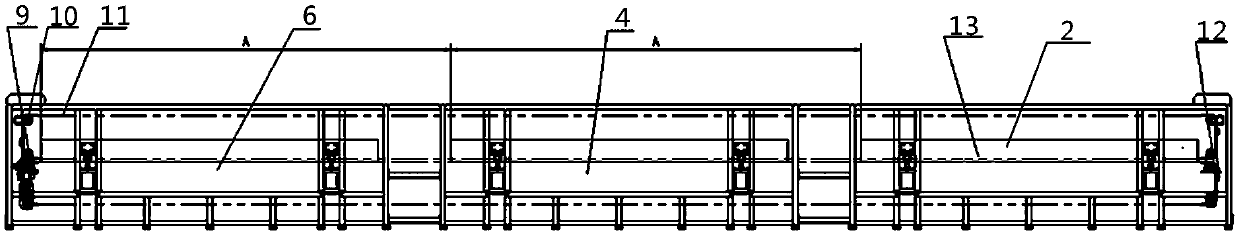

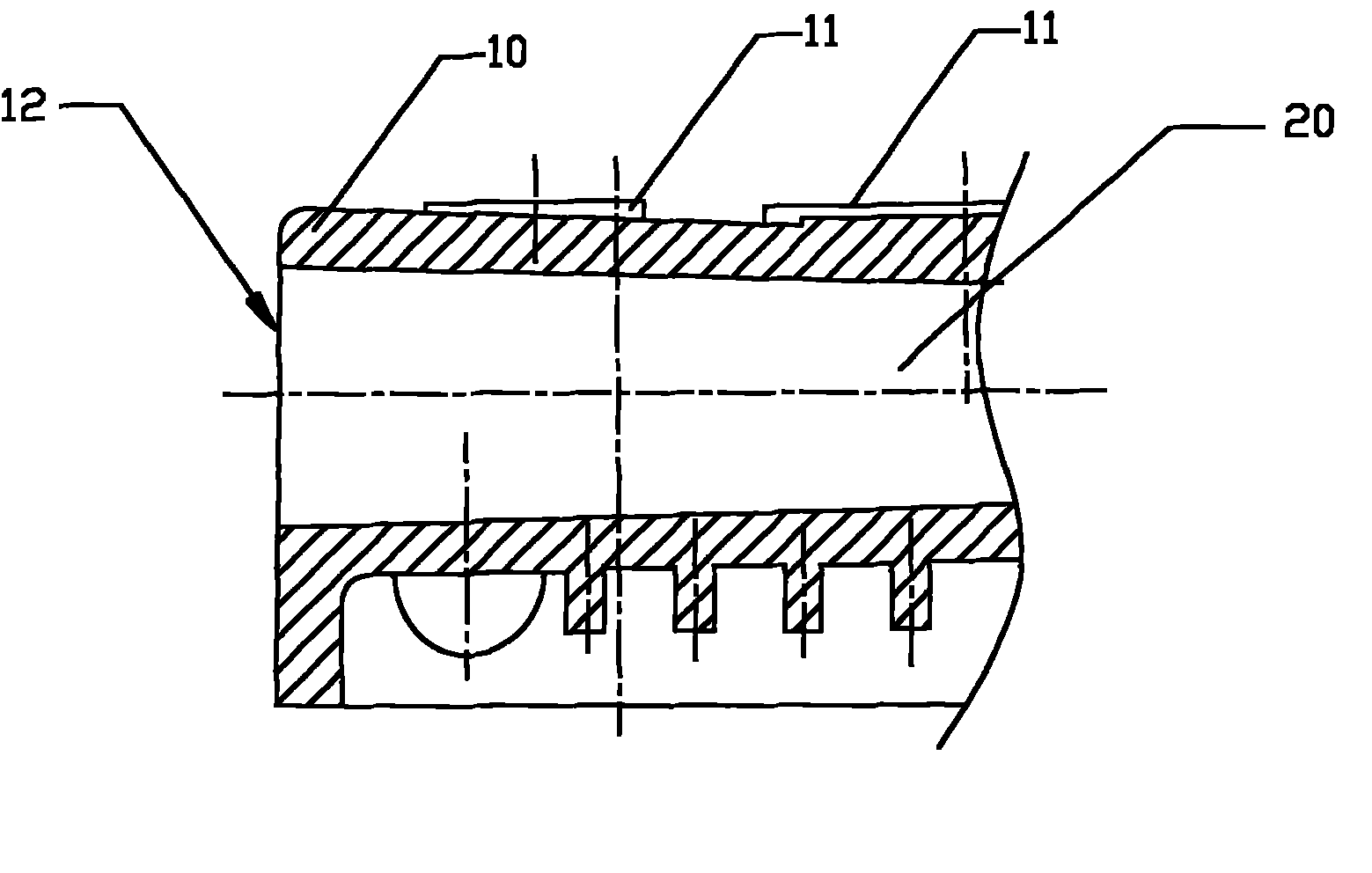

Continuous cooling dampening machine capable of performing cooling and moisturizing on scented tea

ActiveCN108294123AUniform and rapid coolingMoisturize evenlyPre-extraction tea treatmentContinuous operationTea leaf

The invention discloses a continuous cooling dampening machine capable of performing cooling and moisturizing on scented tea. The continuous cooling dampening machine comprises a machine frame, a flattransmission machine, a feeding hopper, a discharging hopper, a cooling and moisturizing device, a tea leaf leveling device and a tea leaf spreading and falling device, wherein a closed machine bodyis arranged on the machine frame; the executing tail end of the tea leaf leveling device and the tea leaf spreading and falling device are located in the closed machine body; and the input end and theoutput end of the cooling and moisturizing device are respectively connected with the closed machine body. According to the continuous cooling dampening machine disclosed by the invention, the temperature in the machine body can be controlled, so that after fixation, the continuous, uniform and quick cooling of tea leaves can be realized, and the characteristic of being ''green in color'' of thetea leaves is maintained; the humidity of the inner environment of the machine body can be controlled, and the closed space is combined, so that moisture in the tea leaves cannot be liable to dissipate in a humid environment of which the moisture content is close to saturation, and the dampening effect is easy to achieve; the dampening is uniform and short in time, so that the dampening quality ofthe tea leaves and the quality of finished product tea are improved, and the production efficiency is also greatly improved; and the continuous cooling dampening machine is compact in structure, canperform continuous operation, and is suitable for continuous automatic production lines to use.

Owner:HANGZHOU TEA RES INST CHINA COOP

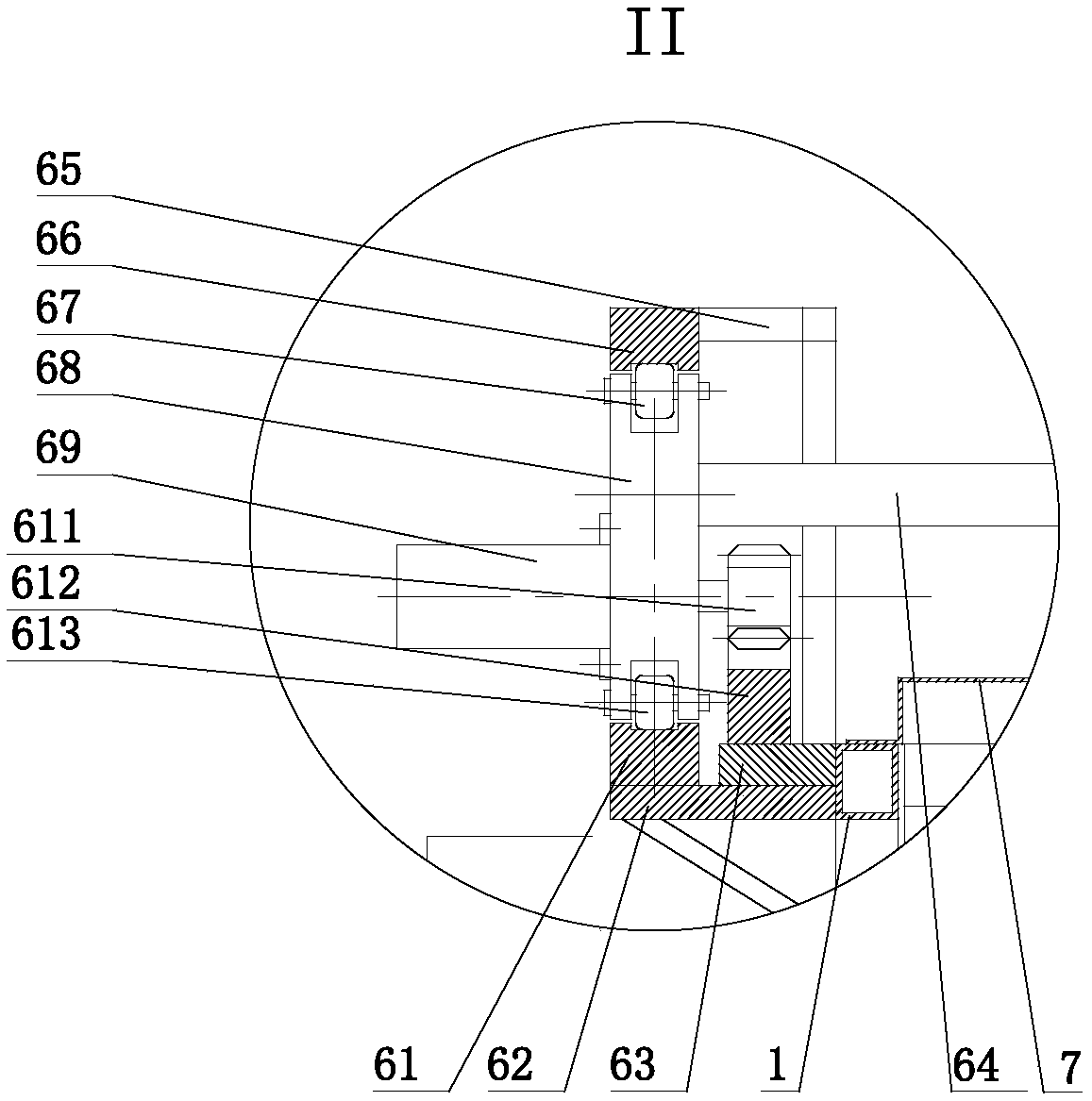

Mold with shape follow-up temperature control pipeline and manufacturing method thereof

ActiveCN105798561ARapid and uniform coolingCutting costsTemperature controlComputer-aided engineering

The invention provides a mold with a shape follow-up temperature control pipeline and a manufacturing method thereof. The manufacturing method comprises the steps that 1, the temperature distribution and change of the mold during cooling are simulated through computer-aided engineering; 2, a mold bottleneck position which is slowest in heat dissipation is calculated; and 3, according to the size dimension, the geometrical shape and the precise requirement condition of the position, the shape follow-up temperature control pipeline is manufactured in the mold by using the processing technology, and the shape of the shape follow-up temperature control pipeline is attached to the profile of the surface of the mold. According to the mold with the shape follow-up temperature control pipeline, a molded product can be quickly and uniformly cooled.

Owner:HONG KONG PRODUCTIVITY COUNCIL

Three-cavity linkage type laminator special for double glass assemblies

InactiveCN105500887AImprove surface qualityIncrease productivityLamination ancillary operationsControlling laminationThree stageEngineering

The invention discloses a three-cavity linkage type laminator special for double glass assemblies. The three-cavity linkage type laminator comprises a laminating stage, a curing stage and a cooling / heating stage which are sequentially connected into a whole. A feeding stage and a discharging stage are connected to the two ends of the laminating stage and the two ends of the cooling / heating stage. The same conveying system is installed in three stages of laminating cavities of the laminating stage, the curing stage and the cooling / heating stage. Corresponding upper box, vacuum and lifting structures are independently arranged in the three stages of laminating cavities of the laminating stage, the curing stage and the cooling / heating stage respectively. Thus, the three-cavity linkage type laminator is provided with five working units. Under the high-vacuum laminating environment of the first stage of working unit, the last stage of the laminating working stage has the function of carrying out rapid circuiting water cooling or heating on the assemblies in a vacuum state, it is guaranteed that the relative positions of the assemblies are unchanged in the three-stage laminating process, and the product quality of the assemblies is guaranteed. In addition, the three-furnace assemblies can be laminated in the same time period through three-stage linkage, and the aim of fully utilizing time is achieved.

Owner:HEBEI YIHENG SCI & TECH CO LTD

Automobile cylinder cover

InactiveCN101988441AImprove cooling effectProtection from damageCylinder headsCylindersEngineeringCooling fluid

The invention provides an automobile cylinder cover. The outer part of the automobile cylinder cover comprises a body, a plurality of cooling liquid inlets and a cooling liquid outlet, wherein the cooling liquid inlets and the cooling liquid outlet are connected through a water cavity which is formed in the body; the cooling liquid inlets are formed in a heat concentration region; the cooling liquid outlet is formed at the rear end of the cylinder cover; an anti-freezing plug is also arranged in the water cavity and consists of a hollow plug body and a plug head of which one end is connected with the plug body; the other end of the plug head is connected with a water cavity hole of the water cavity; and the plug head is provided with a through hole which is communicated with the cavity of the plug body. Through the technical scheme provided by the invention, temperature in the cylinder cover can be rapidly and uniformly reduced, the cooling effect can be improved, and expansion pressure caused by freezing the cooling liquid can be released to protect the cylinder cover from damage.

Owner:WUHU YONGYU AUTOCAR INDAL

Apparatus for preparing a biocompatible matrix

InactiveUS20050221484A1Facilitates rapid transfer of heatImproved device for ingrafting or implanting in a patientSkin implantsTissue cultureReticular formationConductive materials

An apparatus and method of using the apparatus to prepare a biocompatible biodegradable matrix capable of supporting cells to form an implantable or engraftable surgical device. A matrix-forming fluid is contained within a chamber defined by top and bottom surfaces of a thermally conductive material and spacers defining the thickness of the matrix. The chamber is then cooled to freeze the solution at a controlled rate, resulting in a matrix with a desired and uniform thickness having symmetric and uniform reticulations. The apparatus and method reproducibly forms such a matrix, which may be populated with cells for transplantation and engraftment into a wound.

Owner:UNIVERSITY OF CINCINNATI +1

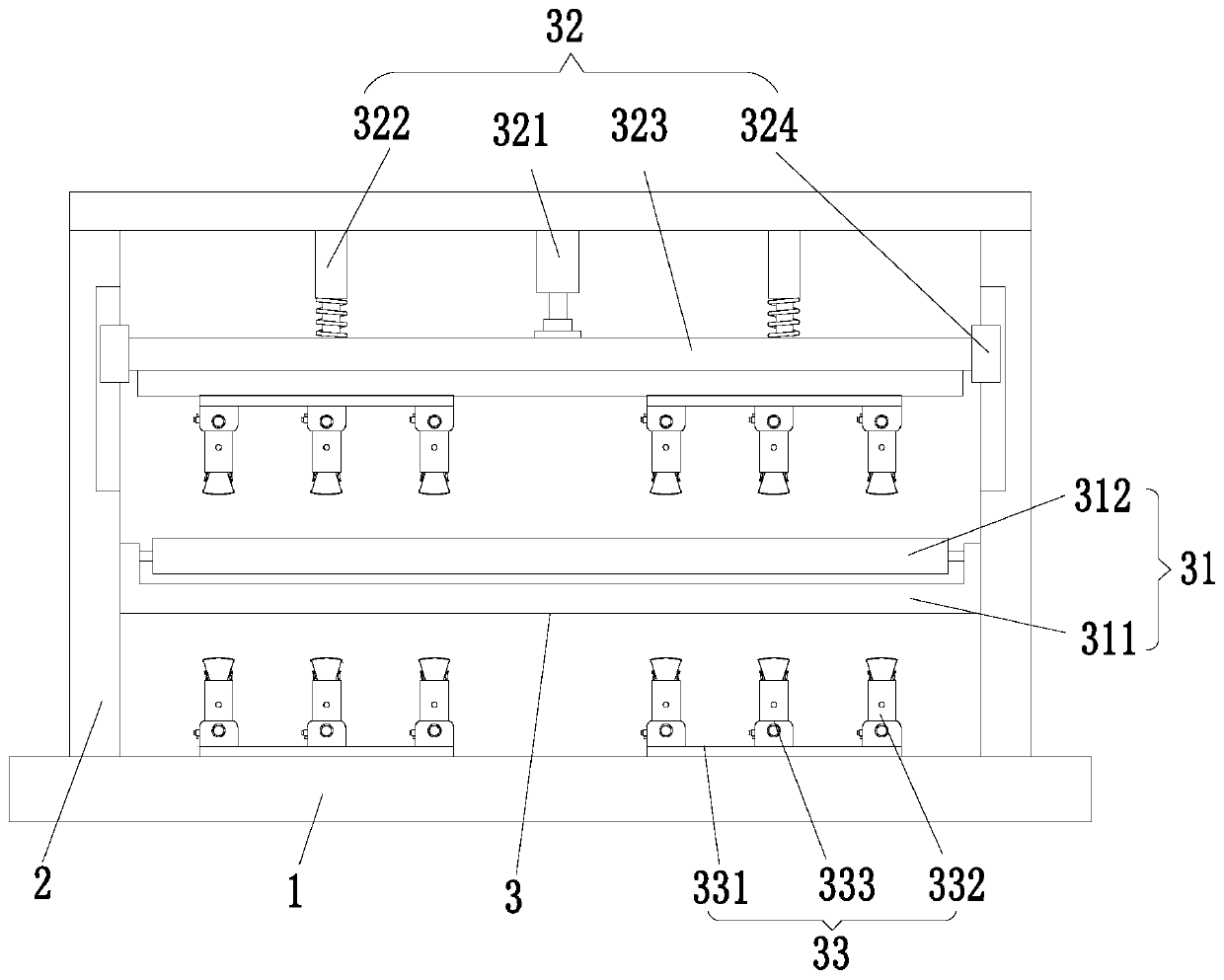

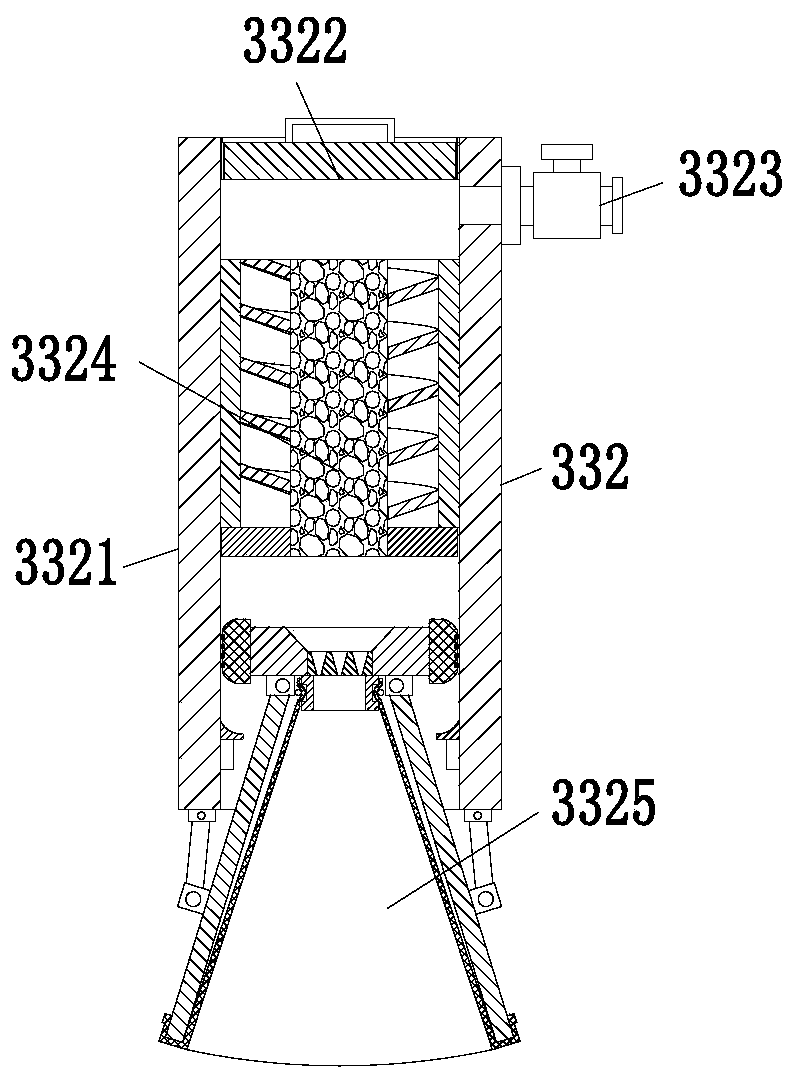

Tempered glass thermal tempering treatment method

ActiveCN110372192ASolve the flatnessSolve the phenomenon such as bulgeGlass tempering apparatusCold airHigh pressure

The invention relates to a tempered glass thermal tempering treatment method. The tempered glass thermal tempering treatment method comprises a bottom plate, a condensation frame and a tempering treatment device, the condensation frame is installed at the upper end of the bottom plate, the condensation frame is of a U-shaped structure, the tempering treatment device is installed in the condensation frame, and the lower end of the tempering treatment device is located on the bottom plate. The tempered glass thermal tempering treatment method can solve the problems that the surface of the tempered glass plate is not flat, and phenomena such as concave marks and protrusions are prone to appearing due to the fact that when existing tempered glass is performed thermal tempering treatment, usually high-pressure cold air is blown to two sides of a glass plate by adopting a high-pressure spraying nozzle, and then the high-pressure spraying nozzle cannot filter and eliminate impurities such asdust and particles in the air; and meanwhile, an existing high-pressure spraying nozzle has a poor air spraying effect, a spraying range is fixed usually, the spraying area cannot be adjusted rapidly,and using is not facilitated.

Owner:南京耀祥钢化玻璃有限公司

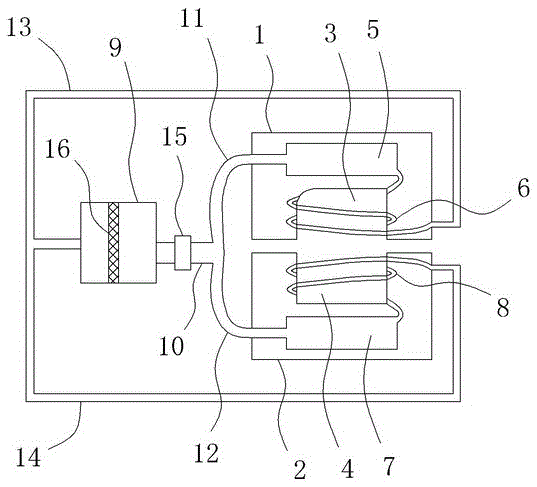

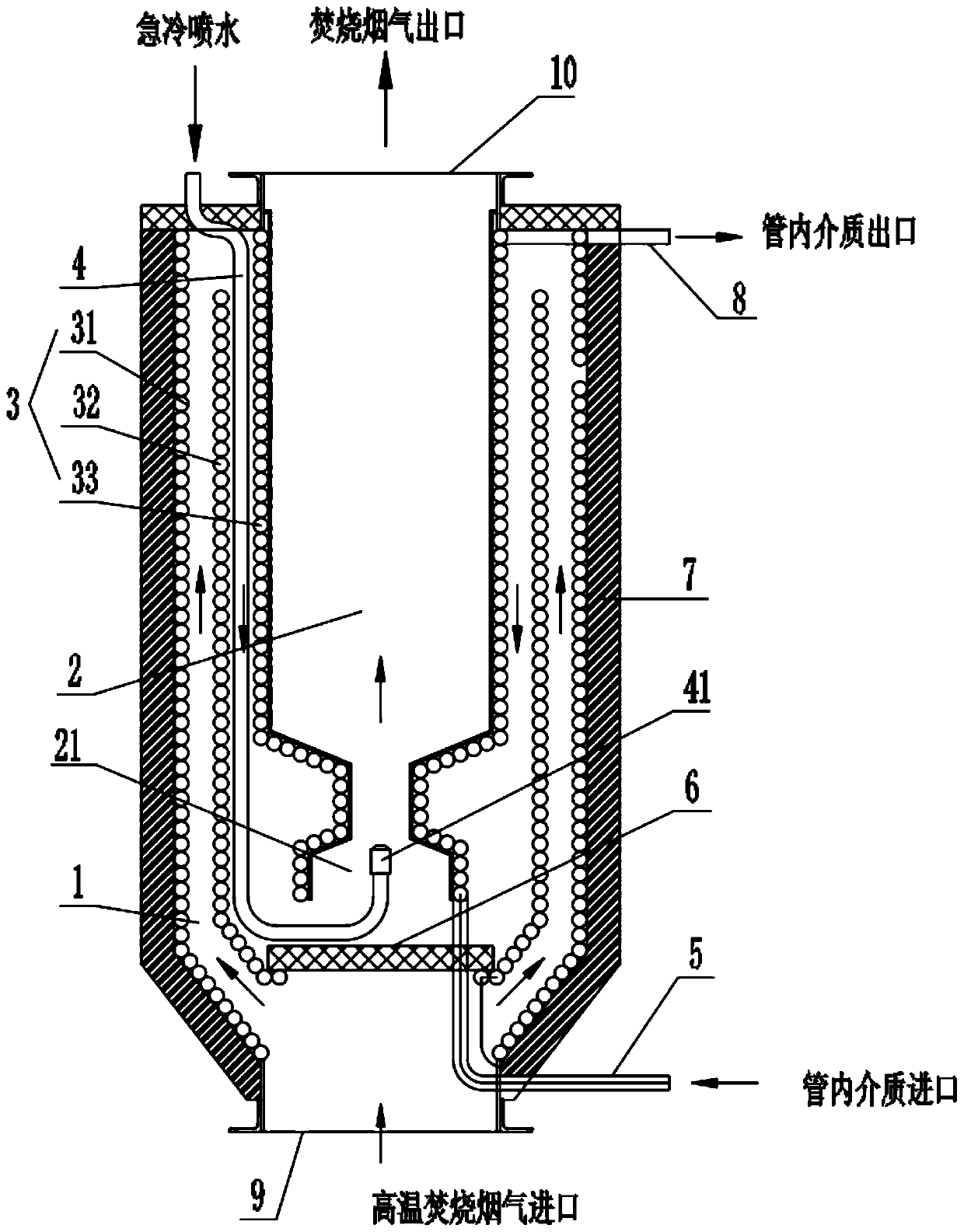

Waste incineration flue gas cooling and quenching integrated device

PendingCN111351374AImprove heat transfer effectReduce fire and high temperature requirementsCombustion technology mitigationTrickle coolersThermodynamicsFlue gas

The invention relates to a waste incineration flue gas cooling and quenching integrated device. The waste incineration flue gas cooling and quenching integrated device comprises a first furnace body and densely-distributed coiled pipes, wherein a reduced-diameter second furnace body which communicates with the first furnace body is arranged in the first furnace body; the bottom of the second furnace body is provided with a furnace body inlet; a guide baffle is arranged in the first furnace body below the furnace body inlet; the densely-distributed coiled pipes include first coiled pipes whichare attached to an inner wall of the first furnace body and are closely arranged along a circumferential direction in a way of spirally extending in an axial direction; second coiled pipes and third coiled pipes which communicate with the first coiled pipes and are distributed in the same way are arranged on inner rings of the first coiled pipes in sequence; flue gas flow channels are formed between the first coiled pipes and the second coiled pipes, as well as between the second coiled pipes and the third coiled pipes; the third coiled pipes are closely arranged in a way of being attached toan outer wall of the second furnace body; a quenching water spray pipe is arranged between one of the second coiled pipes and one of the third coiled pipes; and two sides of a pipe wall of the quenching water spray pipe are close to pipe walls of the second coiled pipes and the third coiled pipes respectively. Through the adoption of the waste incineration flue gas cooling and quenching integrateddevice, the heat exchanging effect of a heat exchanging segment is improved; the requirements of fire resistance and high temperature resistance on materials of the heat exchanging segment and a quenching segment are lowered; and the running reliability is improved.

Owner:上海工业锅炉(无锡)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com