Process method for directly forging continuous casting billet to produce die steel

A process method and continuous casting slab technology, which is applied in the field of continuous casting slab direct forging to produce high-quality die steel, can solve problems such as low die life and die cracking, achieve low production cost, fast crystallization speed, and eliminate structure segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

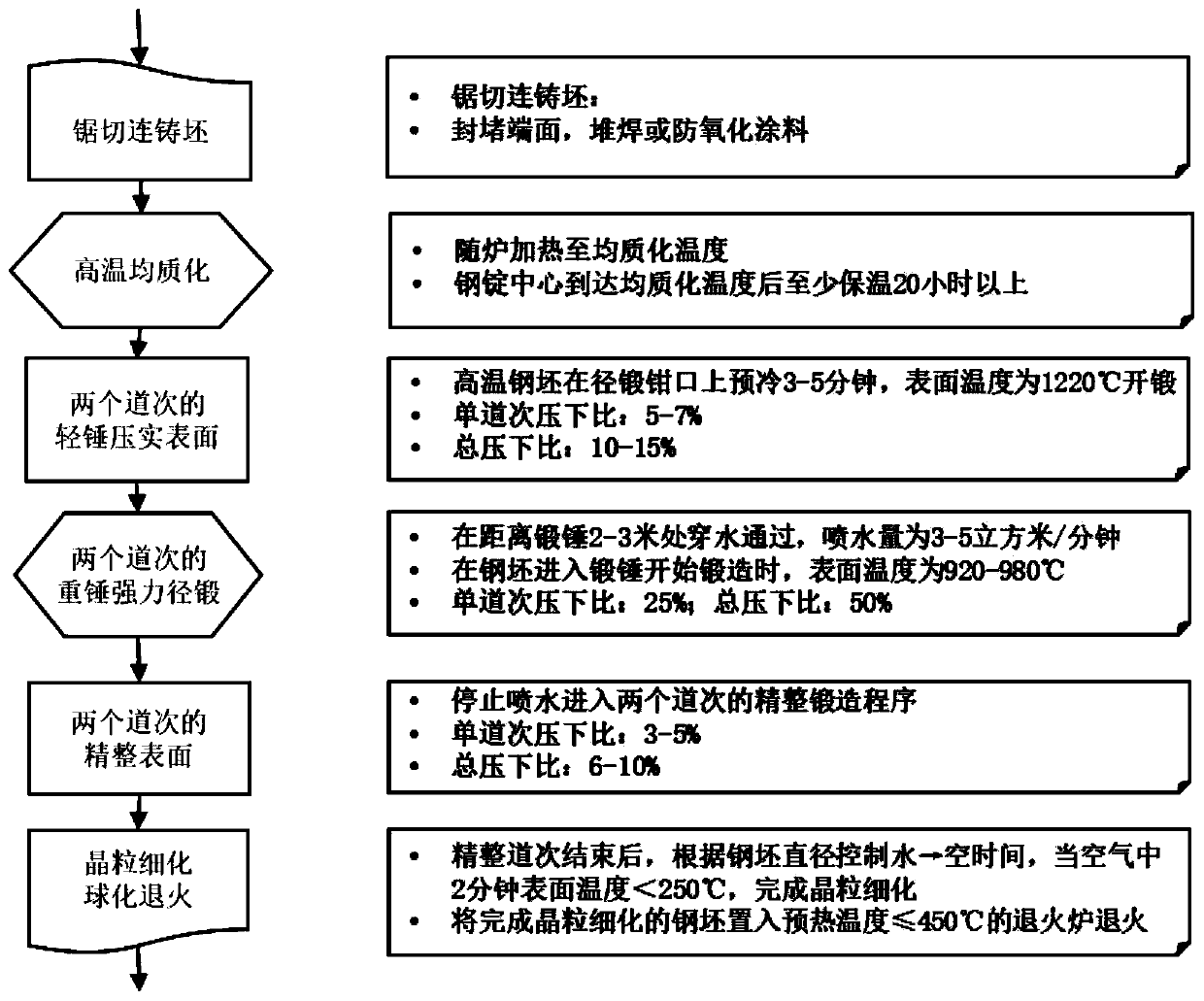

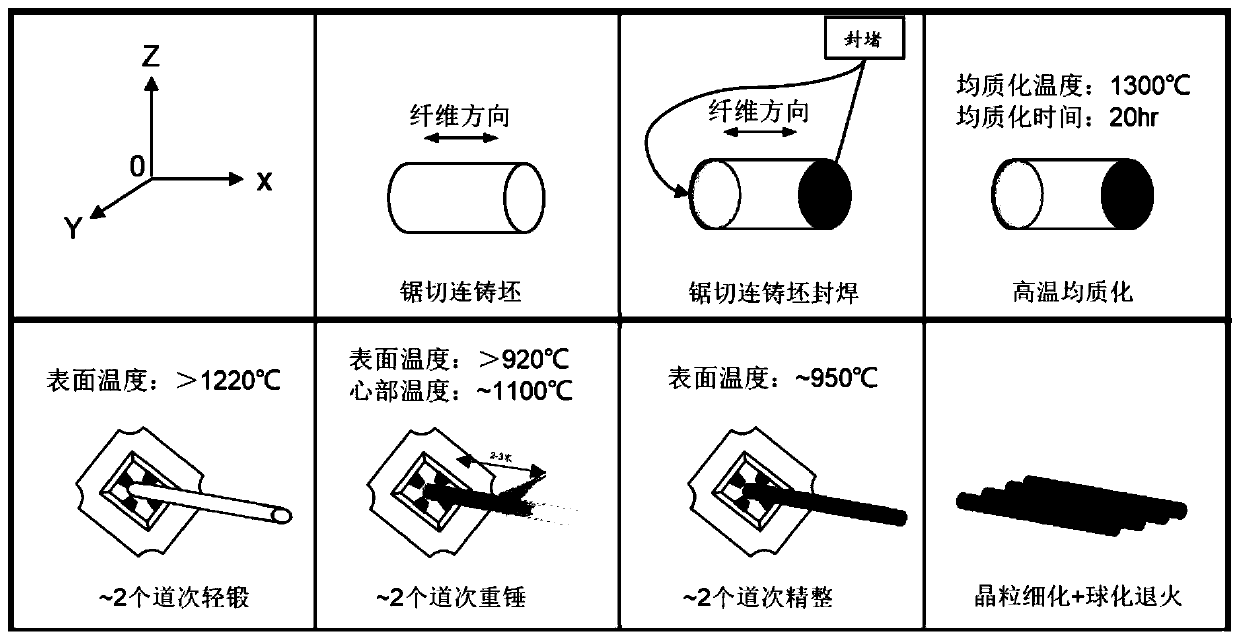

[0043] A process for producing high-quality mold round steel by continuous casting slab hard shell strong radial forging:

[0044] The first step: the annealed continuous casting billet φ500mm (steel type and model is H13 (4Cr5MoSiV1)), sawing and cutting length is 1500mm.

[0045] Step 2: The two sawn end faces of the continuous casting slab are blocked with high-temperature anti-oxidation paint, and the paint plugging covers at least 2 / 3 of the central surface of the ends.

[0046] The third step: the plugged continuous casting slab is placed in a heating furnace and heated to 1300 ° C, and the center reaches the set temperature and then is kept for 20 hours for homogenization treatment.

[0047] Step 4: The homogenized continuous casting billet is transferred to the operating tongs of the radial forging machine, and pre-cooled in the air for 2 to 5 minutes. When the surface temperature of the billet is 1200-1240, two passes of light hammer are carried out. For radial forgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com