Injection mold with uniform and quick cooling capability

An injection mold and fast technology, applied in the field of injection molds, can solve the problems of uniform cooling rate influence, influence on waiting time, influence on production efficiency, etc., and achieve the effect of shortening production time, light weight and good environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to better understand the present invention, the present invention is further described below in conjunction with specific embodiment and accompanying drawing.

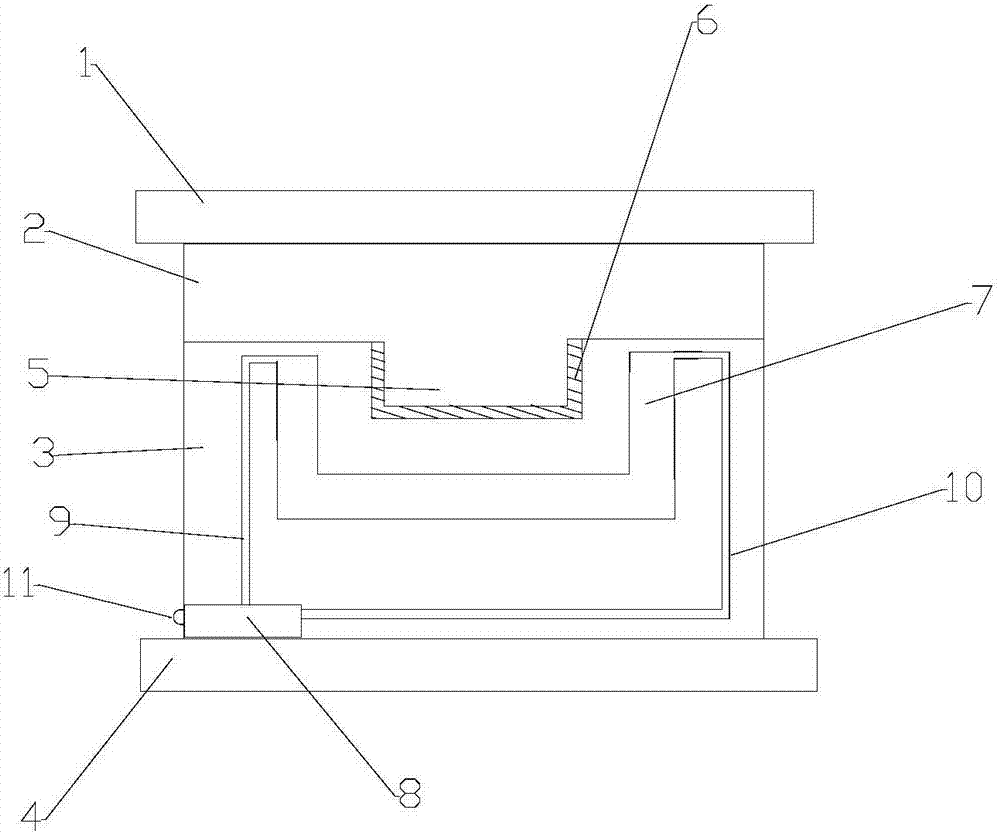

[0012] As shown in the figure, the present invention provides a uniform and rapid cooling injection mold, including: a movable mold fixed plate 1, a movable mold 2, a fixed mold 3, and a fixed mold fixed plate 4, and the movable mold 2 is arranged on the movable mold fixed plate 1, the fixed mold 3 is set on the upper end of the fixed mold fixed plate 4, the lower end of the movable mold 2 is provided with a mold core 5, and the upper end of the fixed mold 3 is provided with a mold groove, and the mold core 5 and the mold groove cooperate to form Cavity 6, a cooling cavity 7 in the shape of a "concave" rotating body is provided around the cavity in the fixed mold 3, so that the cooling cavity 7 surrounds the bottom and surroundings of the cavity. The material between the die groove and the cooling cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com