Method for treating low-concentration ammonia-containing tail gas

A low-concentration, tail gas technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as rising and decreasing ammonia solubility, and achieve the goals of reducing pollution, increasing absorption, and reducing water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

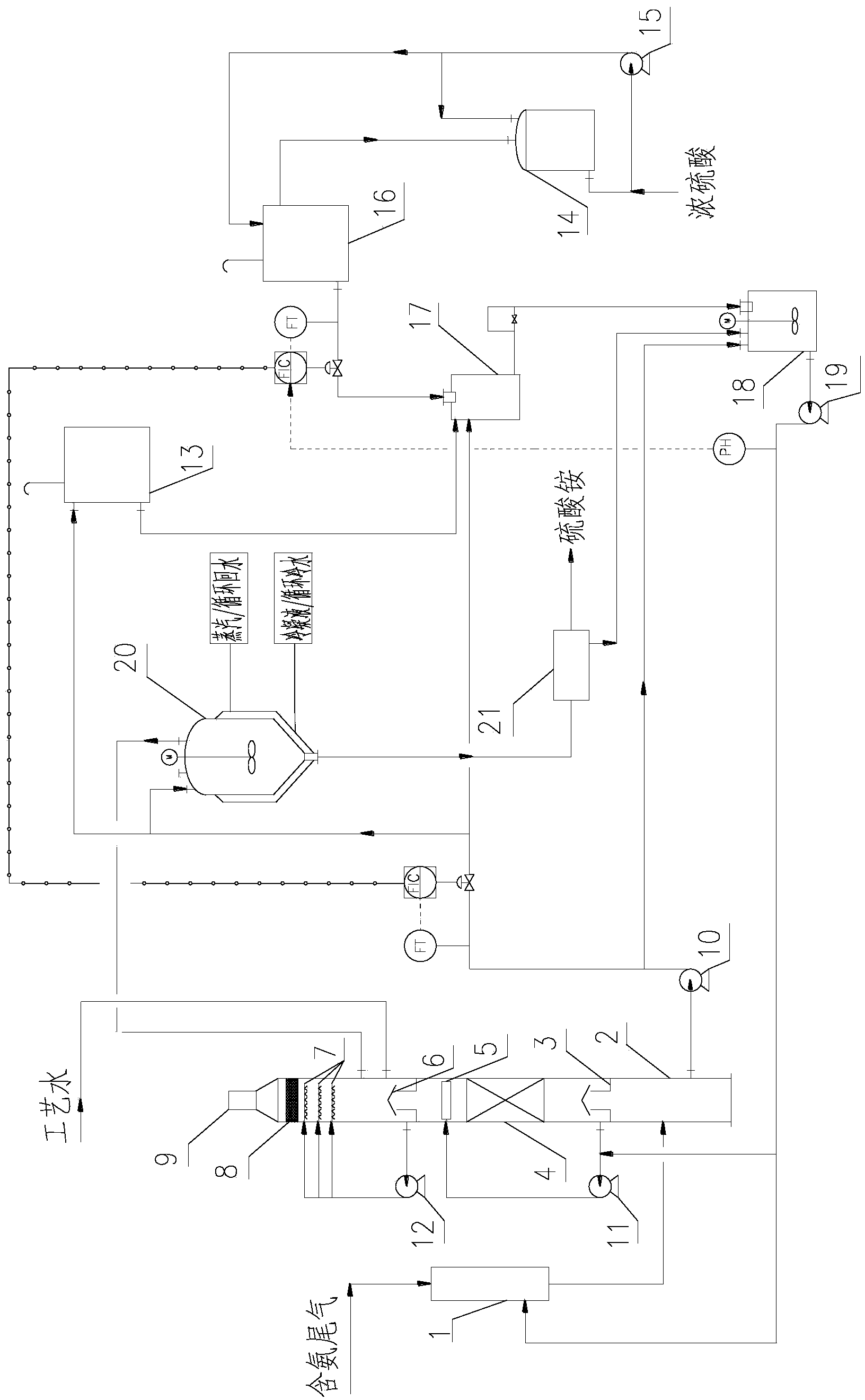

Method used

Image

Examples

Embodiment 1

[0054] (1), the concentration of ammonia from the upstream device is 259mg / m 3 Low-concentration ammonia-containing tail gas 46000m 3 / h enters from the top of the high-efficiency absorber 1, and the lower part of the high-efficiency absorber 1 sprays acidic ammonium sulfate mother liquor with a pH of 3 to 3.5 and an ammonium sulfate mass concentration of 20% to 25%, so that the acidic ammonium sulfate mother liquor and low-concentration ammonia-containing tail gas countercurrent fully Contact, countercurrent absorption, and primary absorption of ammonia;

[0055] (2), the ammonia-containing tail gas absorbed by the first stage enters the lower part of the absorption tower 2 together with the ammonium sulfate mother liquor. After the gas-liquid separation, the ammonium sulfate mother liquor stays at the bottom of the absorption tower 2 for buffering, and the tail gas passes through the first gas from the absorption tower lower part 2 The distributor 3 enters the packing layer ...

Embodiment 2

[0058] (1), the concentration of ammonia from the upstream device is 1000mg / m 3 Low-concentration ammonia-containing tail gas 23000m 3 / h enters from the top of the high-efficiency absorber 1, and the lower part of the high-efficiency absorber 1 sprays acidic ammonium sulfate mother liquor with pH=2.8-3.2 and ammonium sulfate mass concentration of 25%-30%, so that the acidic ammonium sulfate mother liquor and low-concentration ammonia-containing tail gas countercurrent fully Contact, countercurrent absorption, and primary absorption of ammonia;

[0059] (2), the ammonia-containing tail gas and the ammonium sulfate mother liquor absorbed by the first stage enter the lower part of the absorption tower 2 together. After the gas-liquid separation, the ammonium sulfate mother liquor stays at the bottom of the absorption tower 2 for buffering, and the tail gas passes through the first gas from the lower part of the absorption tower 2. The distributor 3 enters the packing layer 4 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com