Spraying and quenching device for steel pipe, petroleum well pipe and drill pipe medium frequency heat treatment system

A heat treatment system and oil well pipe technology, applied in the field of heat treatment, can solve the problems of large bending deformation, inability to quickly, uniformly and completely harden oil oil well pipes and drill pipes, and achieve the effect of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

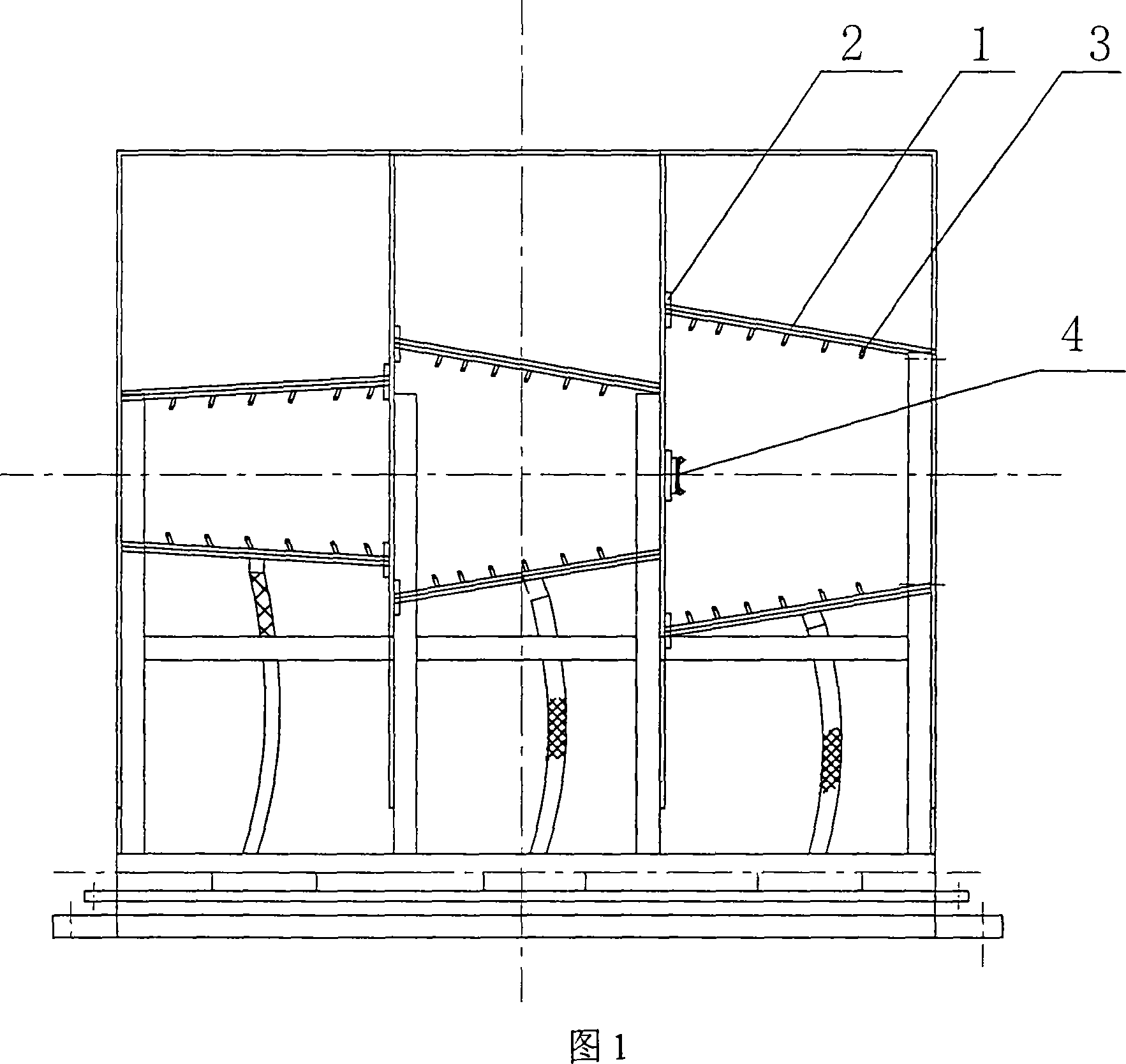

[0008] Referring to the accompanying drawings, its structure includes a sprinkler 1, a water pump 2, and a spray quenching angle adjustment device 3, wherein the sprinkler 1 is distributed in a ring shape; the water inlet pipe of the sprinkler 1 is connected to the water pump 2, and the spray quenching angle is adjusted Device 3 is installed on the shower 1, and several nozzles 4 are housed on the shower 1, and the diameter of this nozzle 4 is 1.2-4mm, and the injection shape of nozzle 4 is cone shape or fan shape, and several nozzles 4 is arranged symmetrically; the center line of the spray quenching device is coaxial with the center line of the workpiece steel pipe or oil well pipe or drill pipe.

[0009] The pressure of water pump 2 is set at 5-15Kg / cm 2 , Nozzle 4 is detachable. An electromagnetic flowmeter, a pressure gauge and a temperature sensor are installed on the water inlet pipe of the sprinkler 1 .

[0010] The spray quenching angle adjusting device 3 can adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com