Integrated radiation vacuum freeze-dry device and method

A vacuum freeze-drying, integrated technology, used in lighting and heating equipment, drying, drying solid materials, etc., can solve the problems of inability to guarantee freeze-drying quality, shrinkage and deformation of materials, limited cooling effect, etc., to reduce equipment investment. and processing costs, sufficient moisture vaporization, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

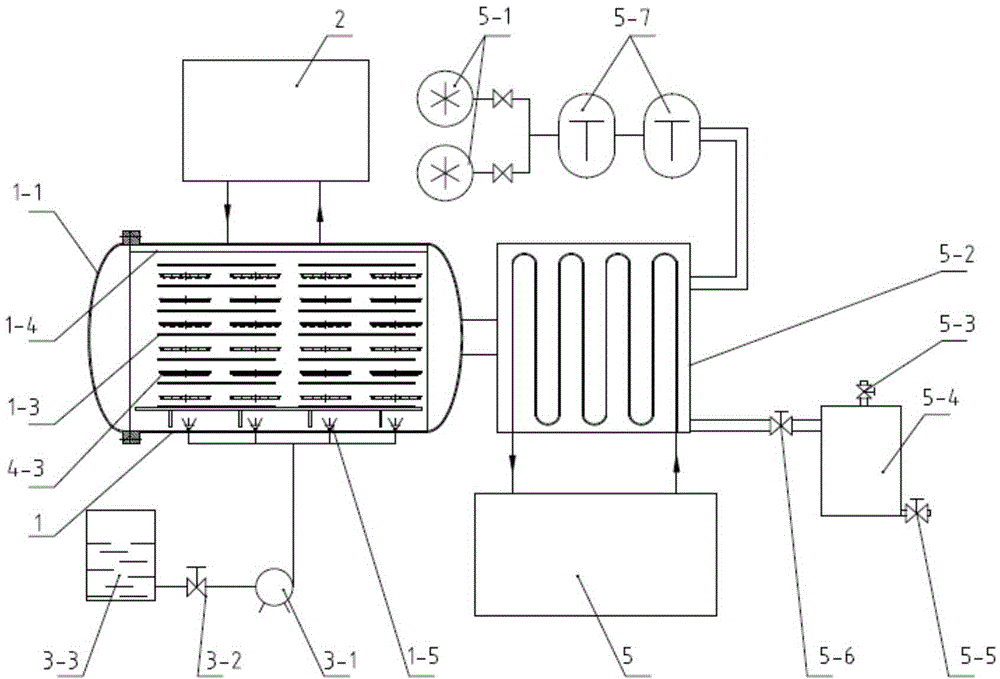

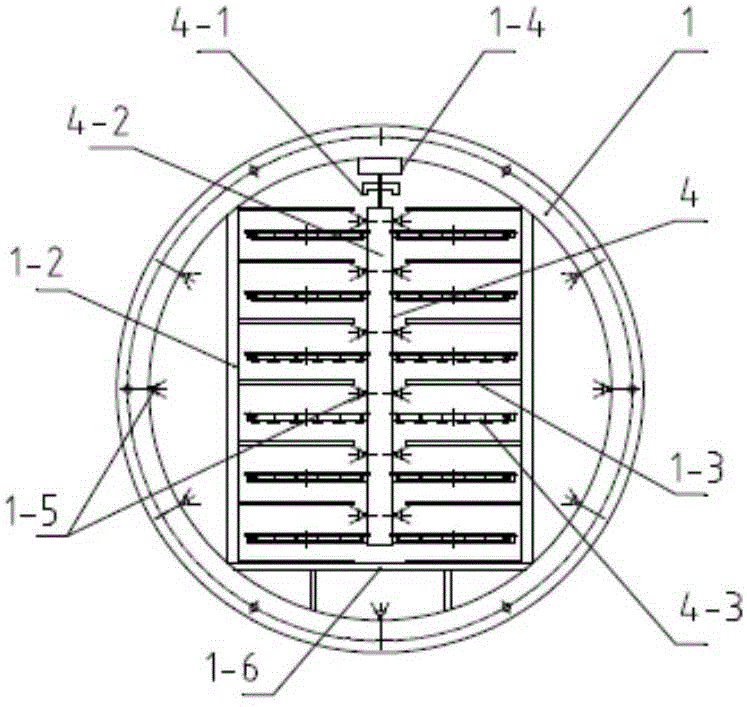

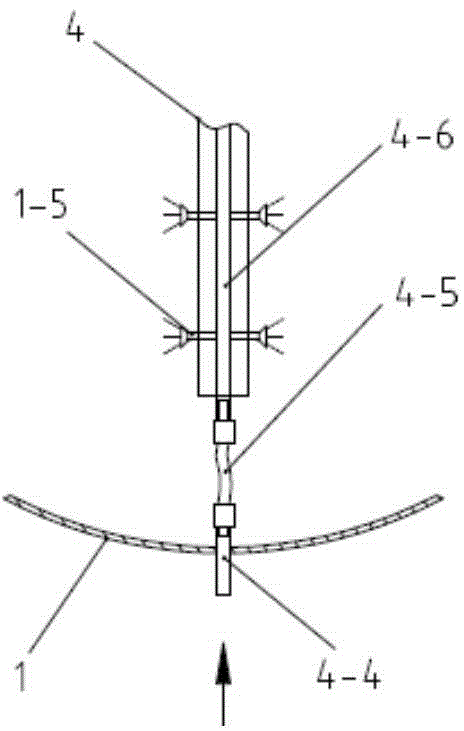

[0027] The integrated radiation vacuum freeze-drying complete set of equipment of this embodiment is as follows: figure 1 , figure 2 As shown, it includes a cylindrical vacuum chamber body 1 extending in the horizontal direction and communicating with the refrigeration unit 5 and the vacuum unit. One end of the vacuum chamber body 1 has an openable chamber door 1-1, and both sides of the inner width direction are fixed to the bottom bracket. 1-6 are fixed vertical side supports 1-2, and the side supports 1-2 on both sides relatively extend out of horizontal hollow heating shelves 1-3 spaced up and down. Its specific structure is as Figure 4 with Figure 5 As shown, the heating shelves 1-3 are made of aluminum profiles coated with manganese oxide (or copper oxide, iron oxide) as a transition metal oxide infrared radiation coating on the surface, and there are evenly distributed circuitous flow channels for heat exchange medium circulation inside. , the inlet IN and outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com