Mold with shape follow-up temperature control pipeline and manufacturing method thereof

A production method and pipeline technology, which is applied to molds with built-in complex conformal temperature control pipelines, copper welding and thermal spraying processes for its production, wide-spread welding, direct metal laser sintering, can solve the problem of inability to manufacture temperature control pipelines, Problems such as internal stress warping of finished products and unusable molds are formed to achieve the effect of shortening the product molding cycle time, reducing the cost of multiple molds and production workshops, and improving the overall production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to facilitate a further understanding of the structure and method of the present invention and the effects achieved, the detailed description of the preferred embodiments is as follows.

[0040] The present invention first simulates the temperature distribution and change of the mold during cooling through computer-aided engineering, so as to find out the bottleneck position of the slowest heat dissipation. Depending on the size, geometric shape, and precision requirements of the position, the following methods are used to realize the mold The complex conformal temperature control pipeline inside.

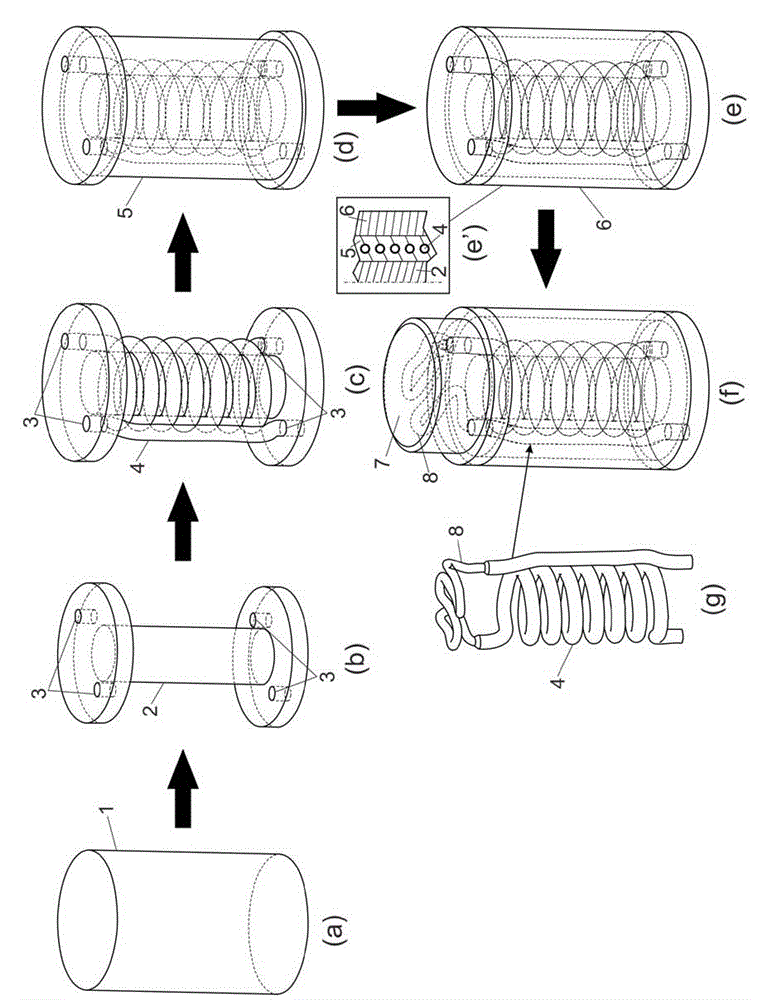

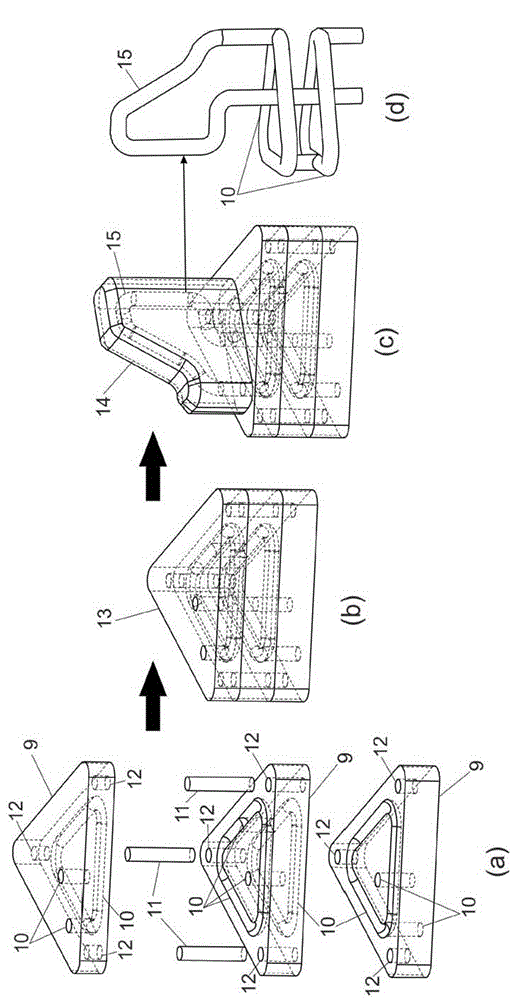

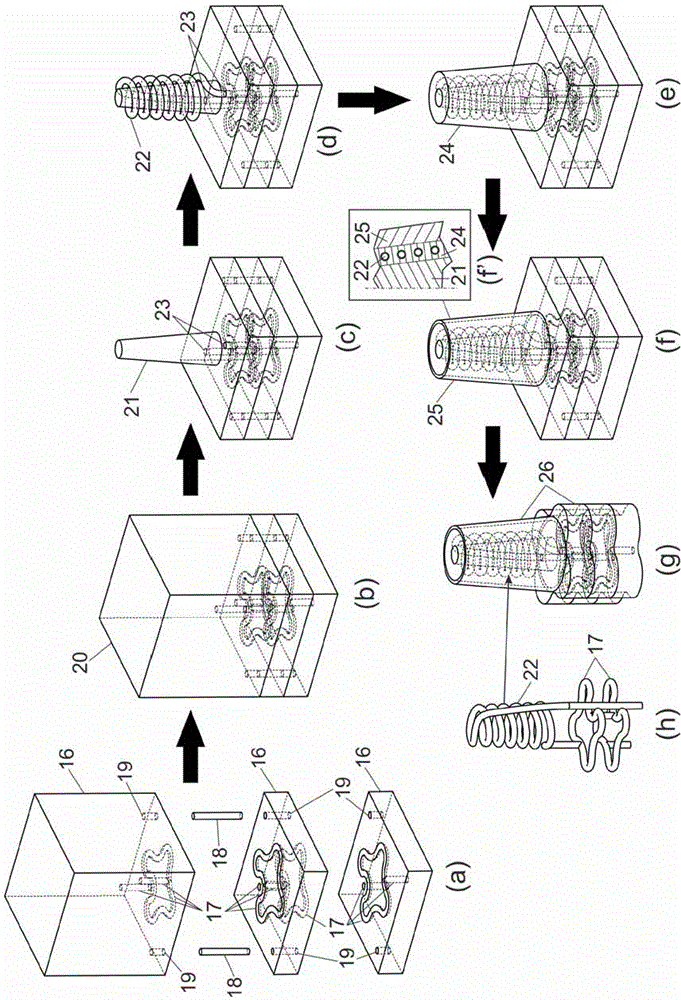

[0041] figure 1 It shows the method steps of realizing complex conformal temperature control pipeline by comprehensively utilizing copper welding, thermal spraying and direct metal laser sintering technology in the present invention. First make the appearance of the mold 1 (such as figure 1 shown in (a)), and hollow out the part that needs to be equipped with conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com