Three-cavity linkage type laminator special for double glass assemblies

A linkage type and lamination machine technology, applied in lamination, lamination device, control lamination, etc., can solve the problems that cannot meet the requirements of large-scale production, and achieve the effect of improving labor productivity, simplifying work procedures, and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

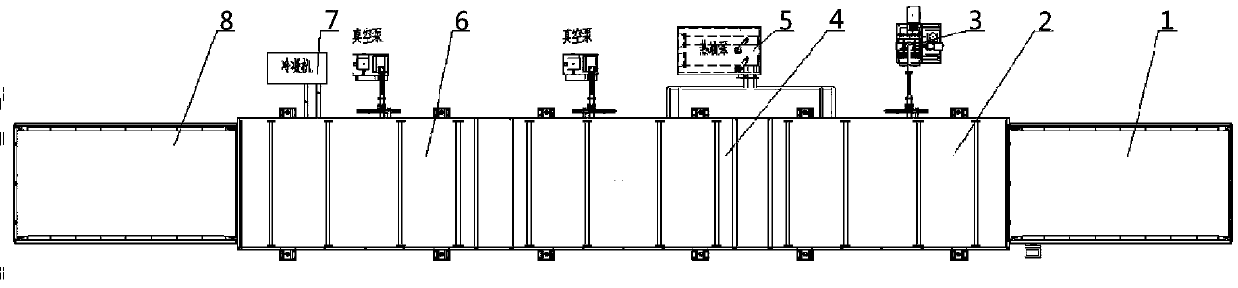

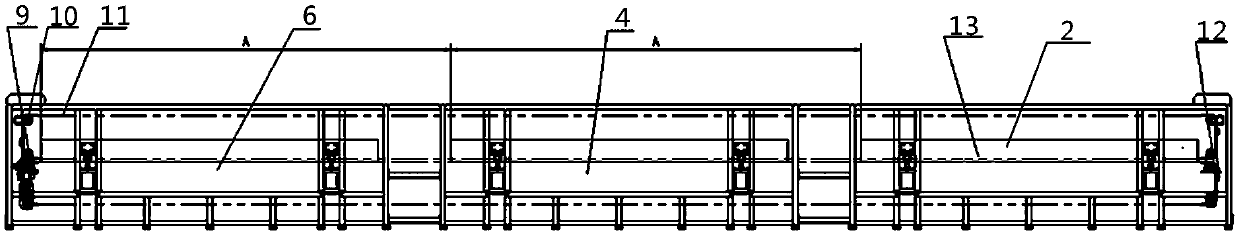

[0011] See Figure 1 to Figure 2 A three-chamber linkage laminator shown includes a lamination stage 2, a solidification stage 4, and a cooling stage 6 that are sequentially connected into one body, and the two ends of the lamination stage 2 and the cooling stage 6 are connected with a feeding stage 1 and discharge level 8. A Roots vacuum pump group 3, a heating system 5, a cooling stage 6 and a condenser 7 are respectively installed on the lamination stage 2, the solidification stage 4 and the cooling stage 6. The same transmission system is installed in the three-stage lamination cavity of the lamination level 2, the solidification level 4 and the cooling level 6. The same transmission system described in this embodiment includes two ends of the cooling level 6 and the lamination level 2. There are two sets of meshing gears 10 and 12 arranged up and down, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com