Patents

Literature

145results about How to "Improve atomization quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

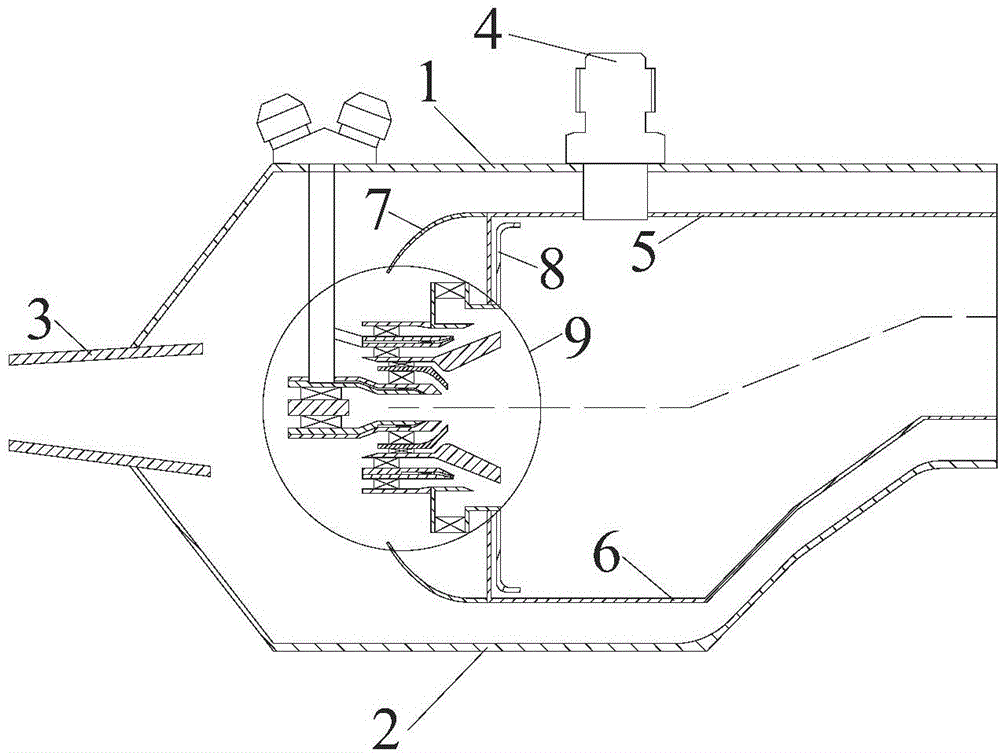

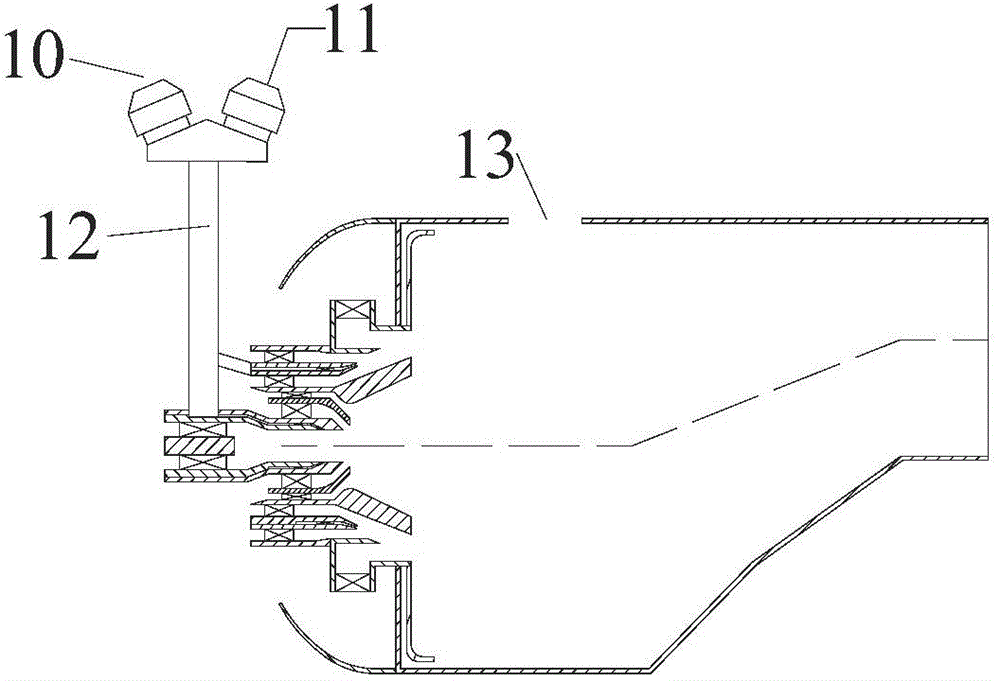

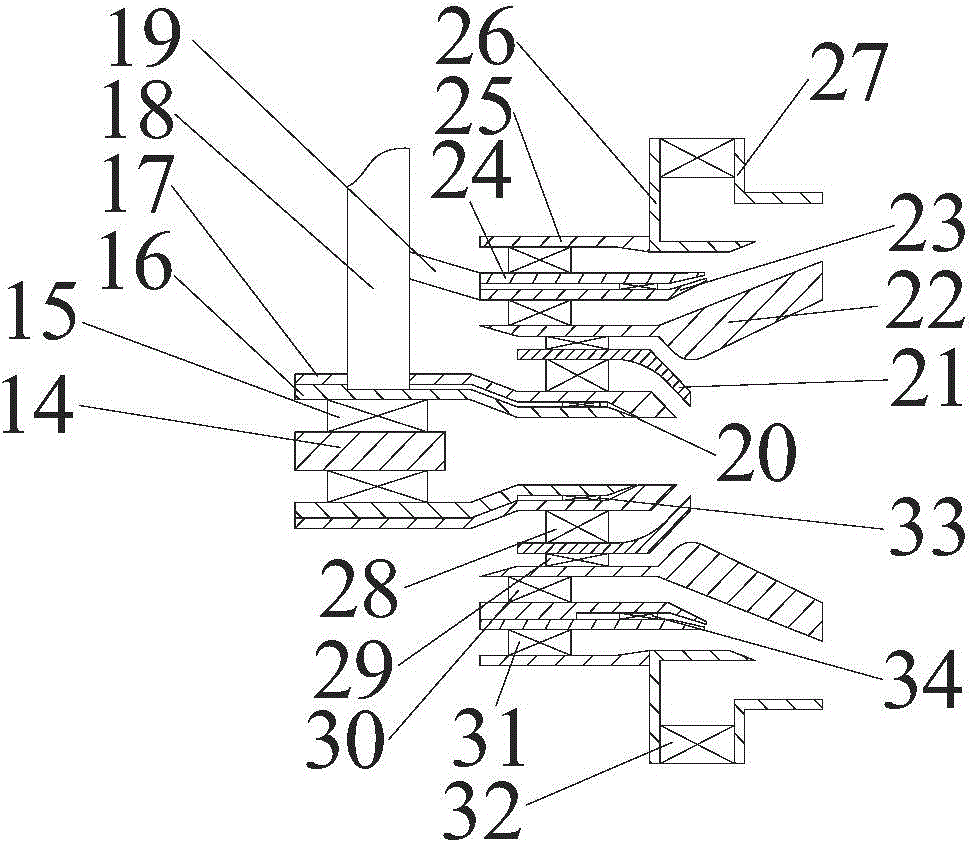

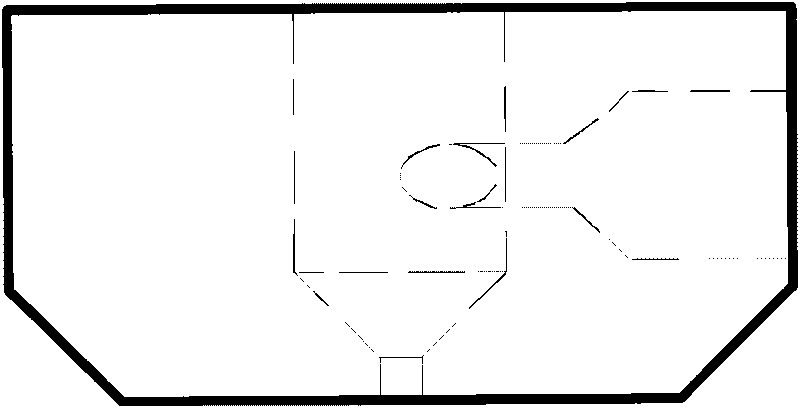

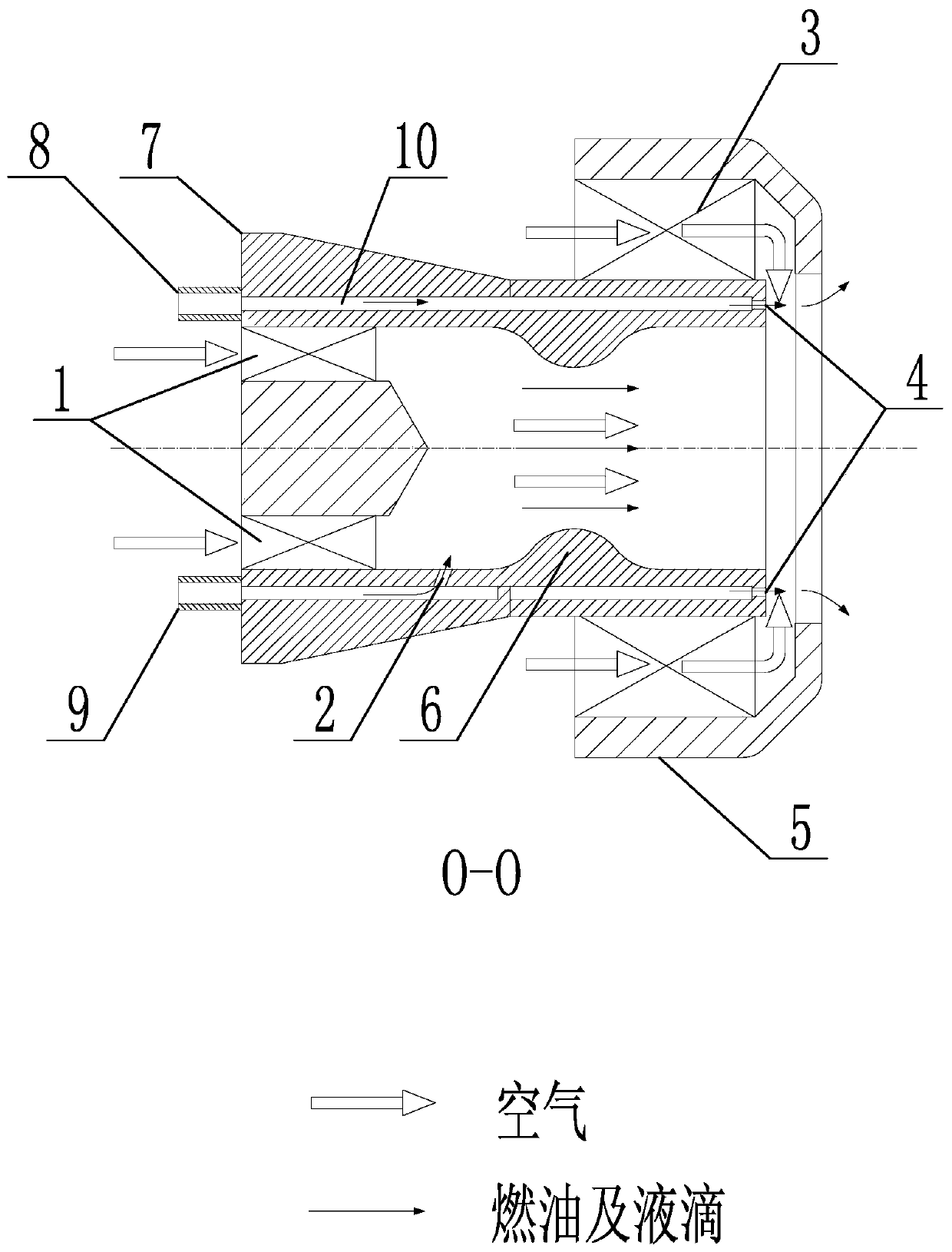

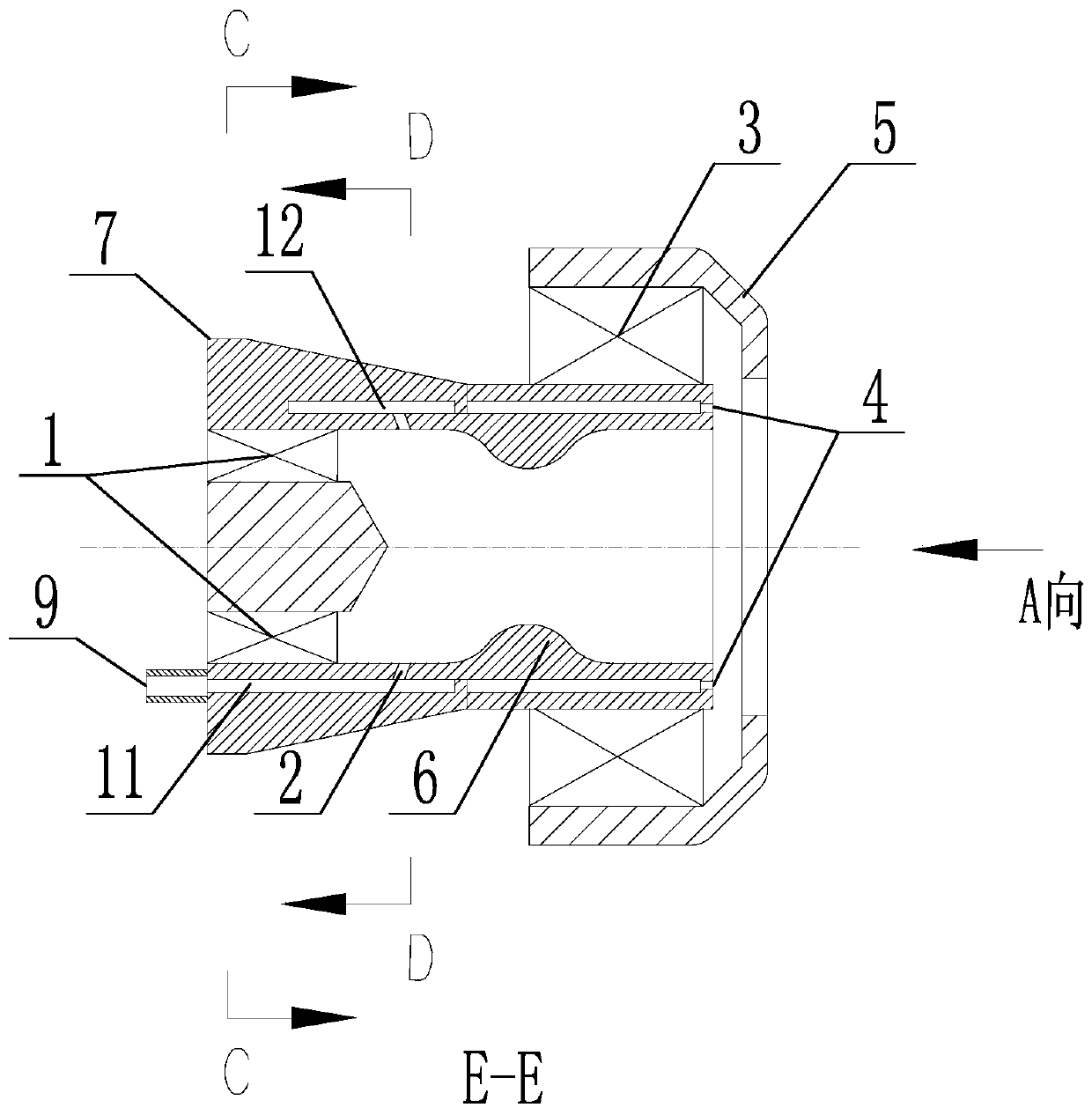

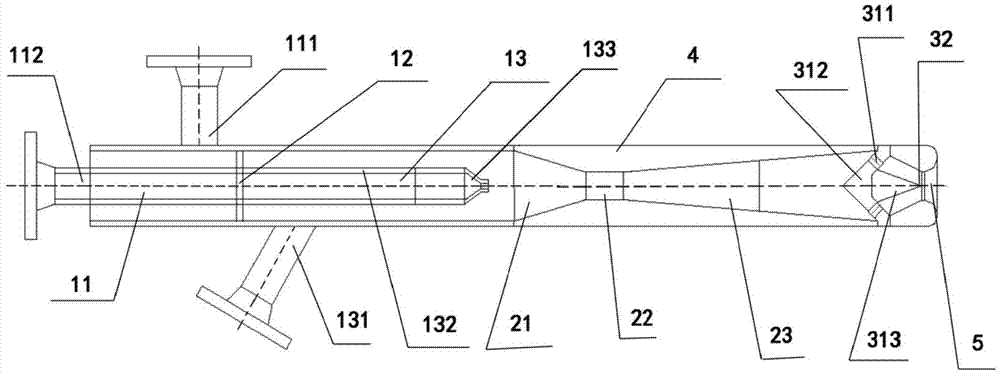

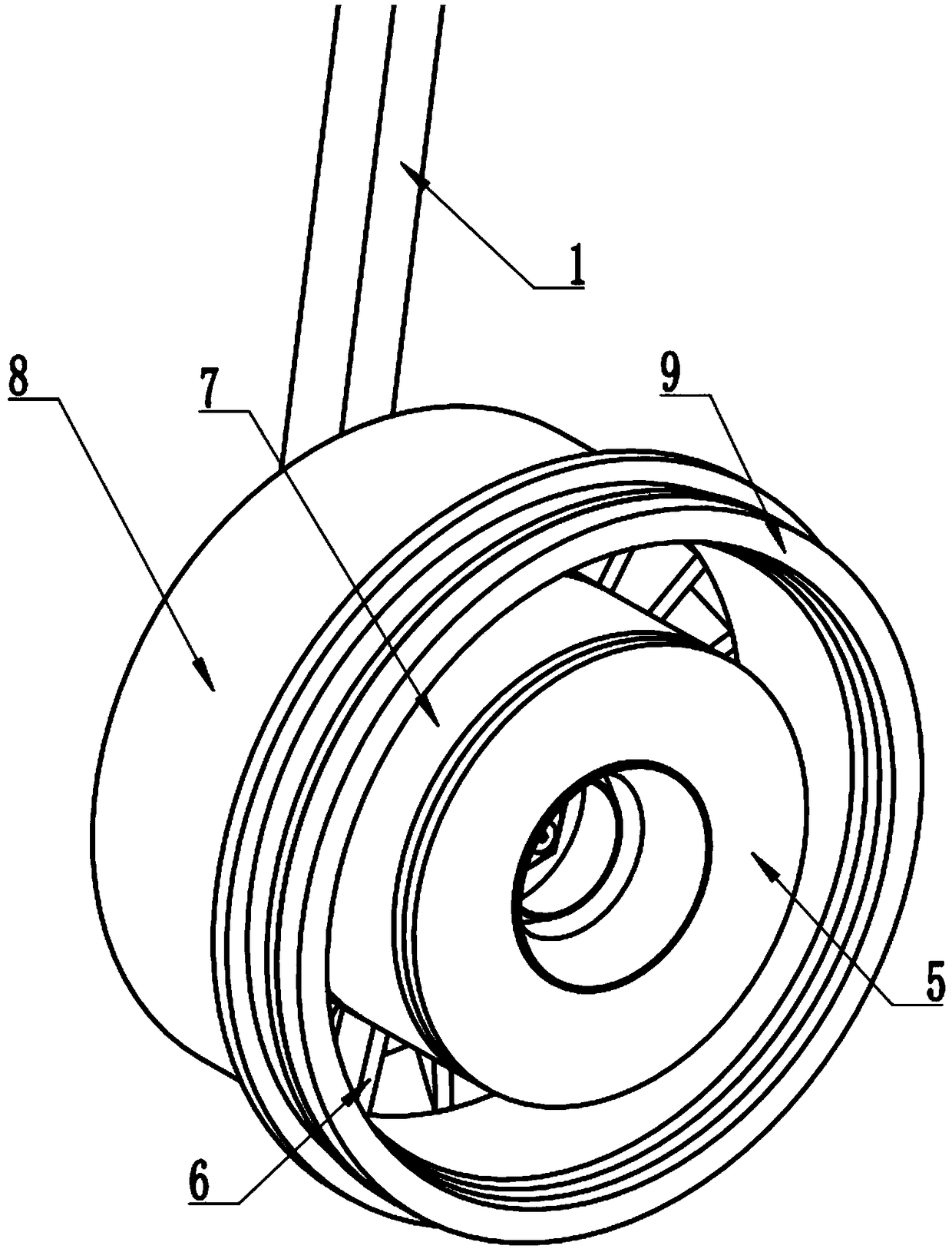

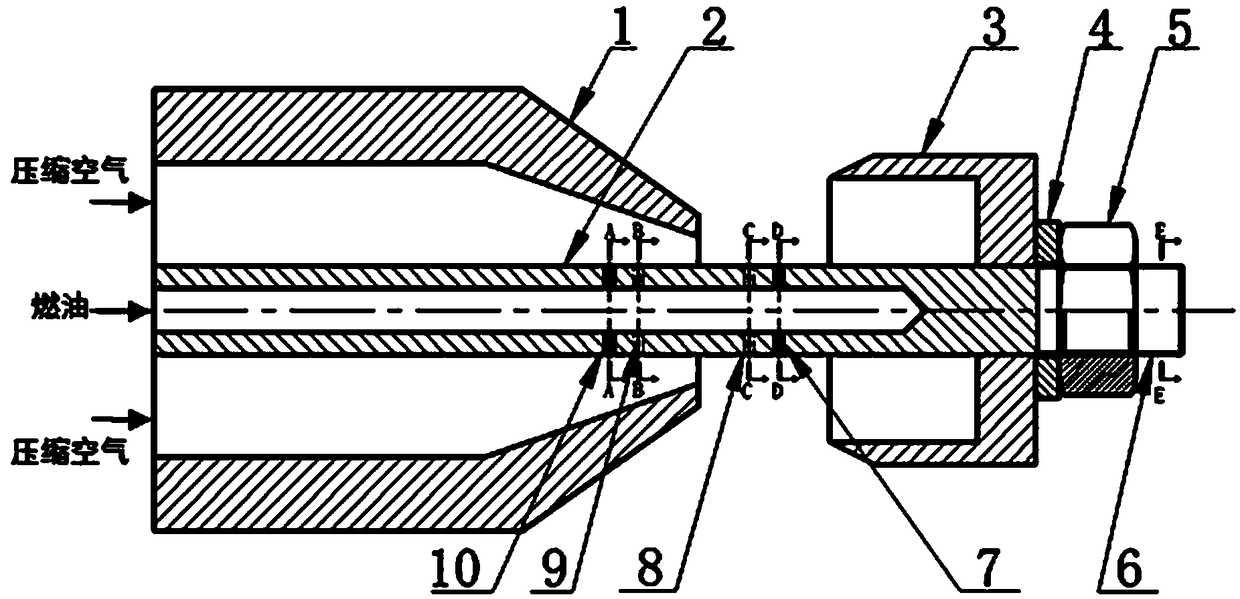

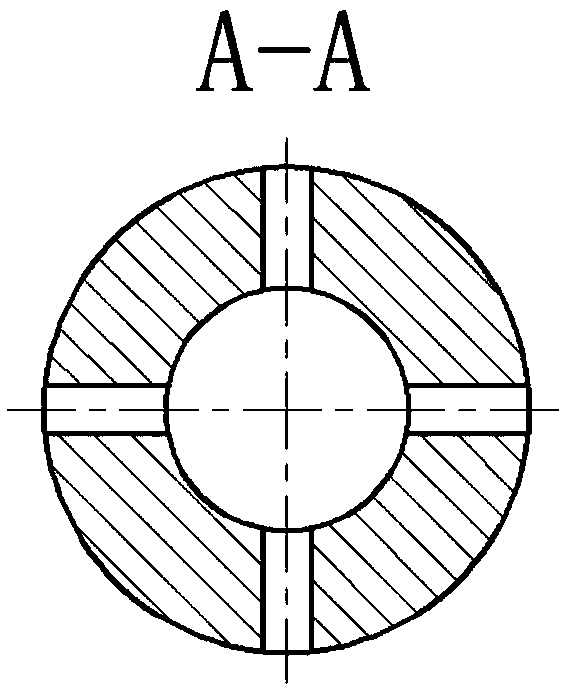

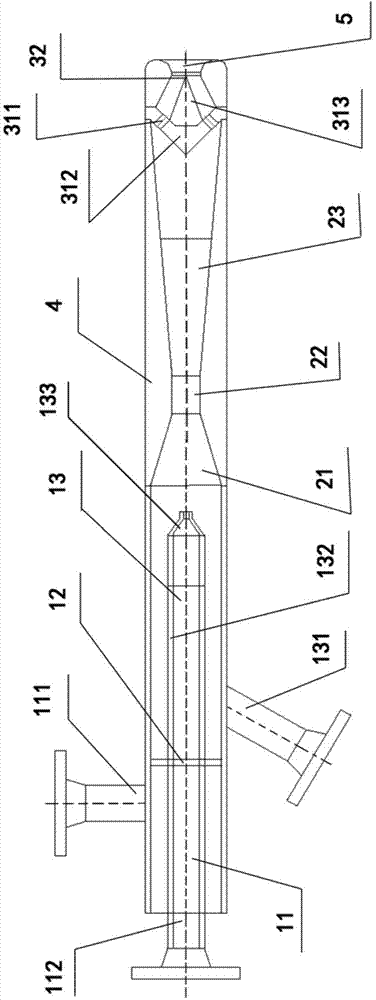

Two-stage prefilming delamination part premixing high-temperature-rise combustion chamber structure

ActiveCN104406196AExpand the scope of workImprove the quality of temperature distributionContinuous combustion chamberCombustion chamberEngineering

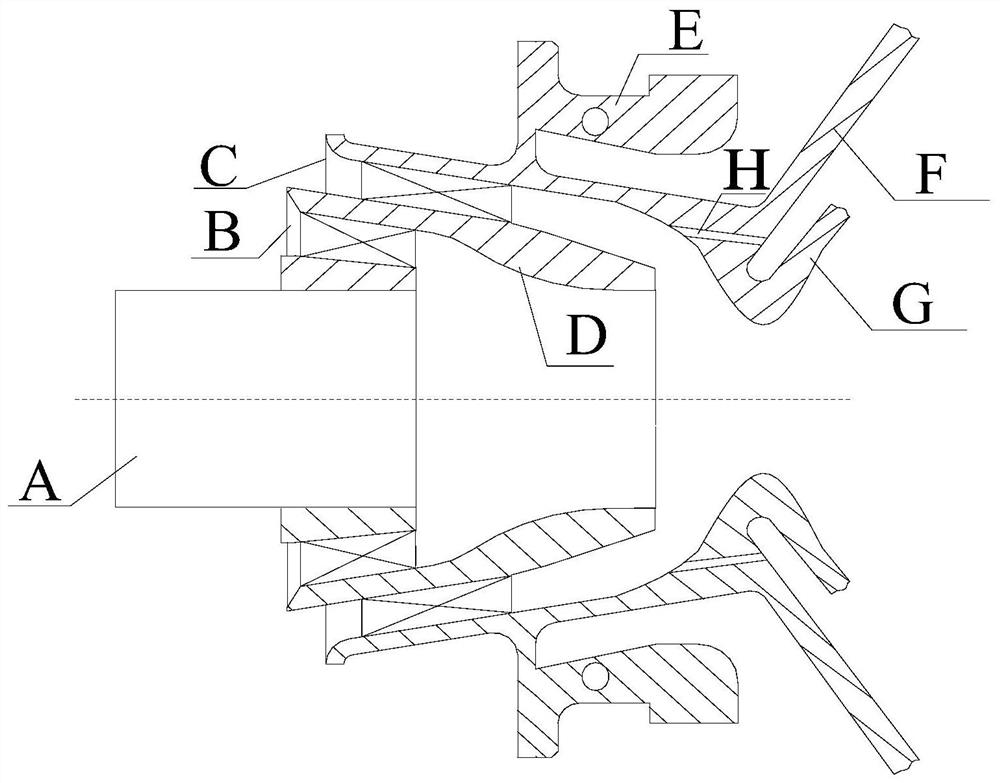

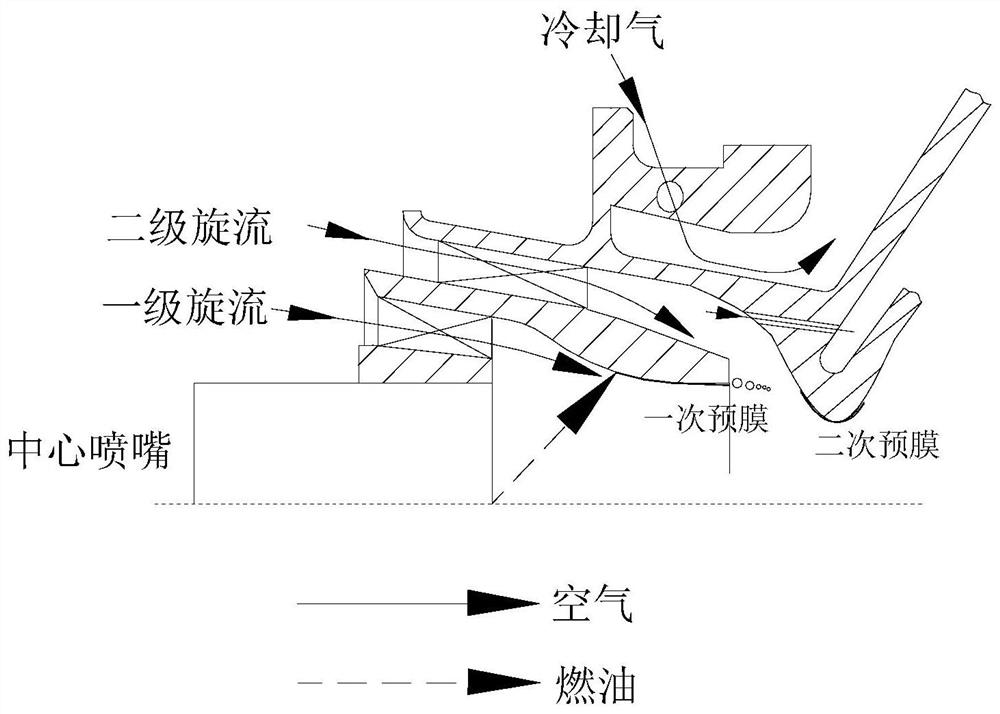

The invention discloses a two-stage prefilming delamination part premixing high-temperature-rise combustion chamber structure. The flame of a main combustion region in a combustion chamber is divided into a precombustion stage and a main combustion stage which respectively adopt diffusion combustion and fuel oil direct spray combustion, and the diffusion combustion and the fuel oil direct spray combustion are coupled for realizing the delamination part premixing combustion. Both main combustion stage fuel oil and precombustion stage fuel oil adopts an in-passage prefilming air atomization technology, the precombustion stage utilizes a rotational flow and flange stabilizing device for enlarging the stable work range of an engine in the small-thrust state and providing a stable ignition source for the two-stage prefilming delamination part premixing high-temperature-rise combustion chamber under the great-thrust state of the engine, and the main combustion flame utilizes rotational flow and precombustion stage flame for providing high-temperature fuel gas stable flame. A precombustion stage spray nozzle improves the atomization quality through two-stage rotational flow prefilming air atomization, and a main combustion stage spray nozzle realizes fast uniform blending mixing of oil and gas in a way of separating the fuel oil atomization process from the blending and mixing process.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

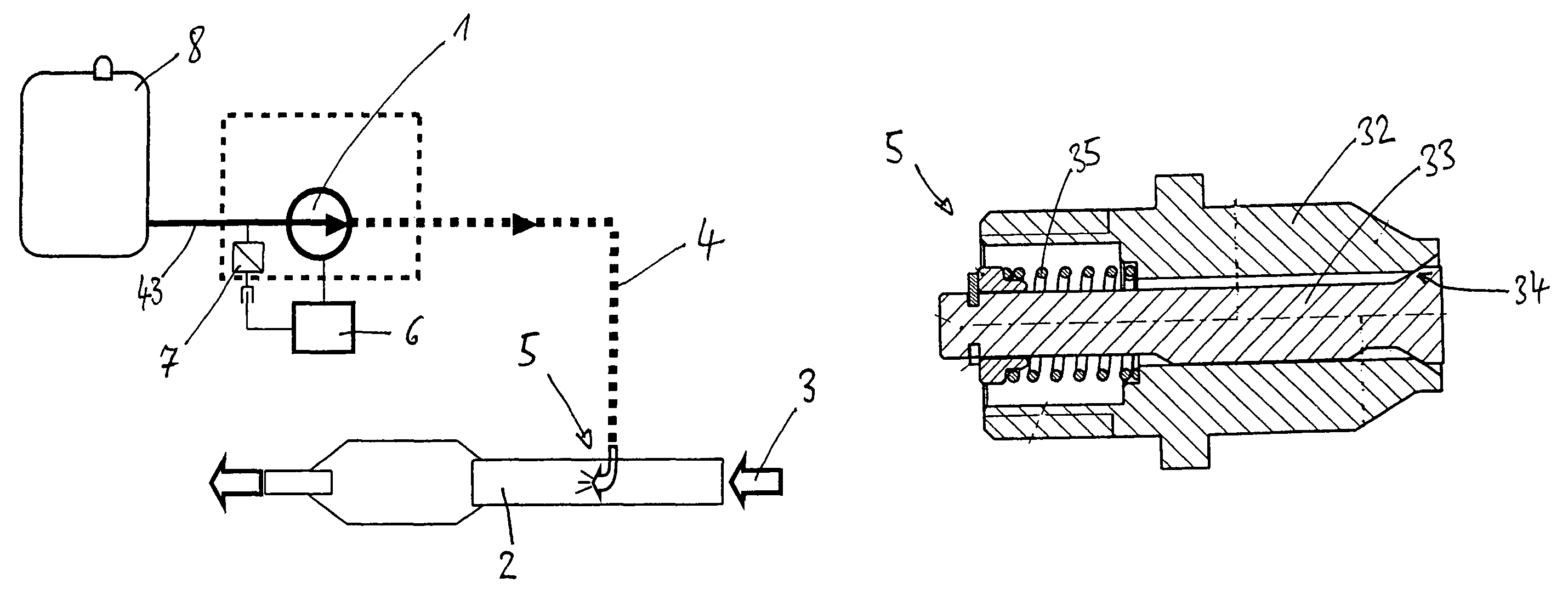

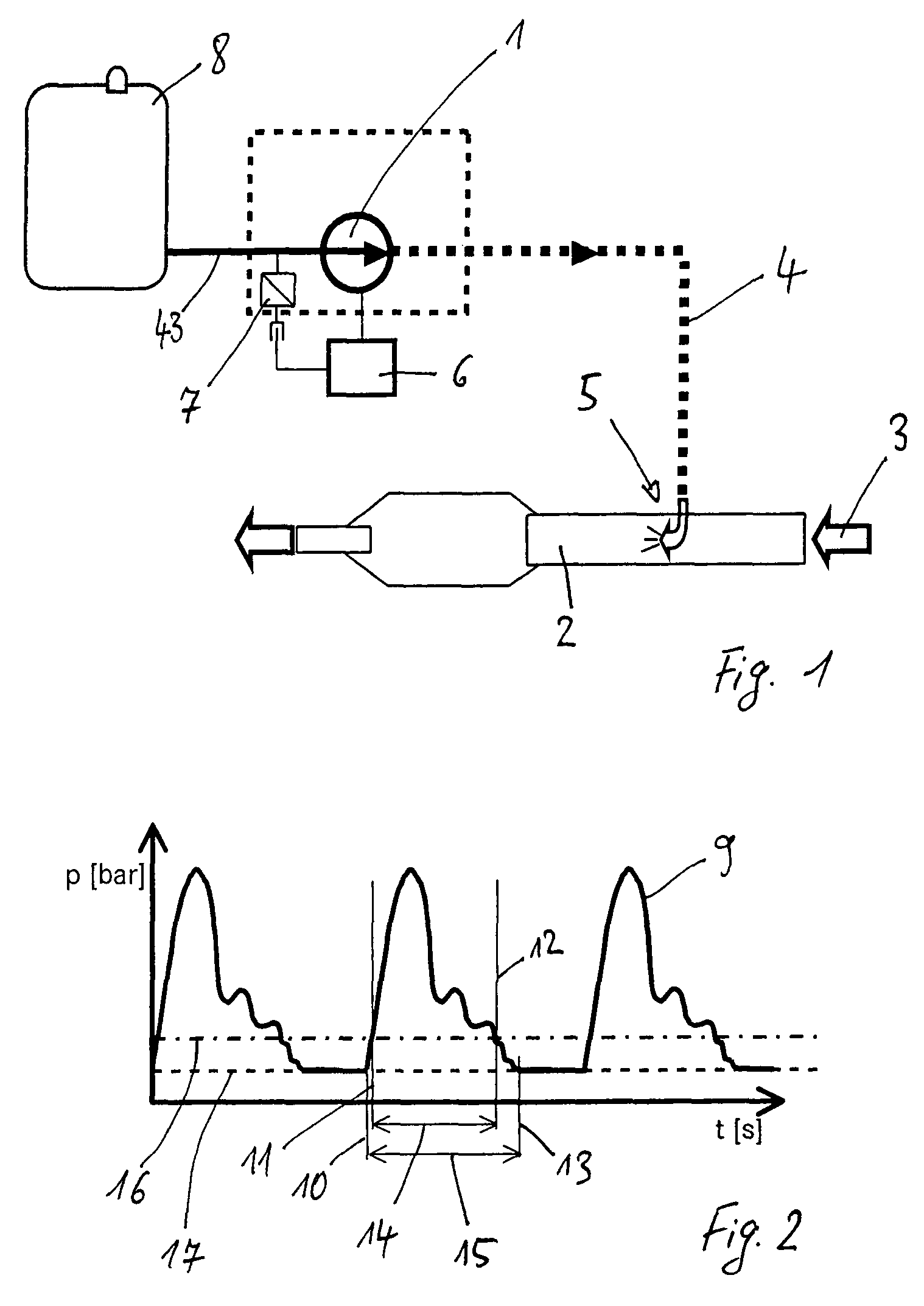

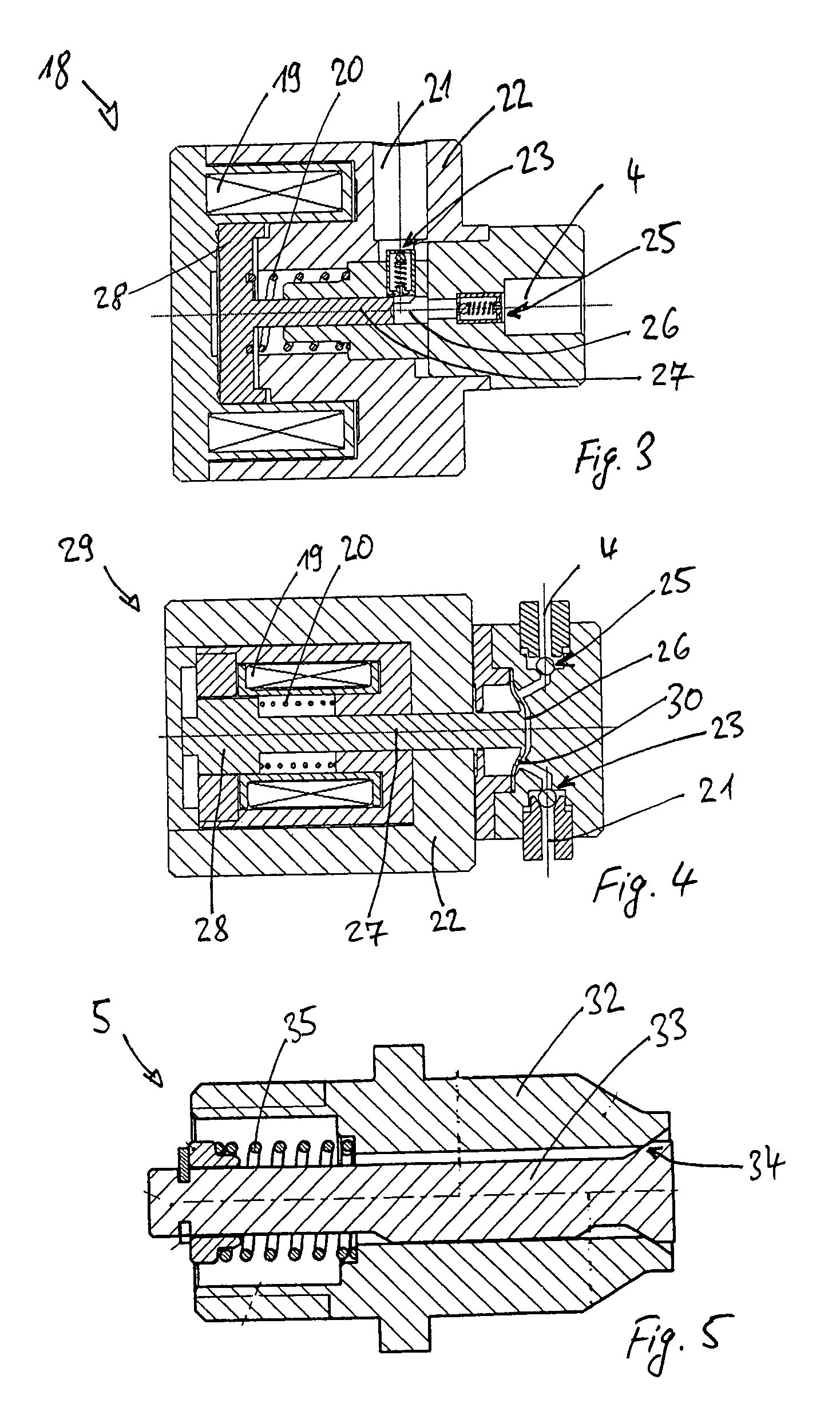

Arrangement for the dosed injection of a reducing medium into the exhaust tract of an internal combustion engine

InactiveUS7866144B2Simple and inexpensivePromote atomizationInternal combustion piston enginesExhaust apparatusExternal combustion engineEngineering

In an arrangement for the dosed injection of a reducing agent into the exhaust tract of an internal combustion engine, comprising a pump for the pulsed pumping of the reducing agent and an atomizing injection nozzle disposed in the exhaust tract of the internal combustion engine, the injection nozzle includes a valve element which opens and closes the injection nozzle depending on the pressure generated by the pump and permits the injection of the reducing agent into the exhaust tract only when the pressure of the reducing agent is in excess of a certain value in order to ensure proper atomization of any reducing agent injected into the exhaust tract.

Owner:L'ORANGE GMBH

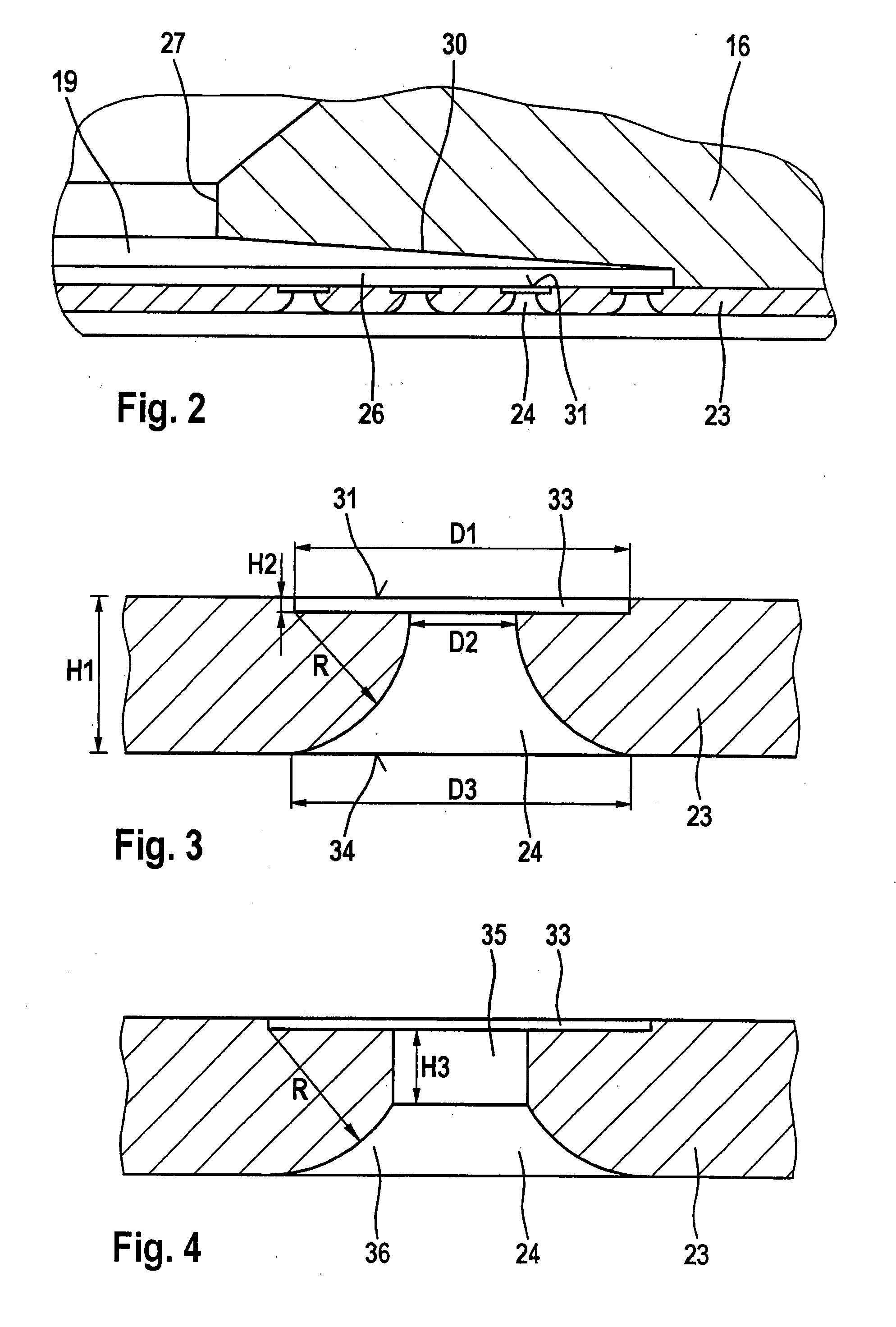

Fuel injection valve

InactiveUS20070012805A1Reduced service lifeAvoid scorchingSpray nozzlesFire rescueCombustion chamberInternal combustion engine

A fuel injector for the direct injection of fuel into a combustion chamber of an internal combustion engine includes an energizable actuator, a valve needle, which is in operative connection with the actuator and acted upon by a restoring spring in a closing direction to actuate a valve-closure member, which forms a sealing seat together with a valve-seat surface formed at a valve-seat body. The valve-seat body includes at least two spray-discharge orifices. The pressure of the fuel flowing through the fuel injector is greater than 10 bar.

Owner:ROBERT BOSCH GMBH

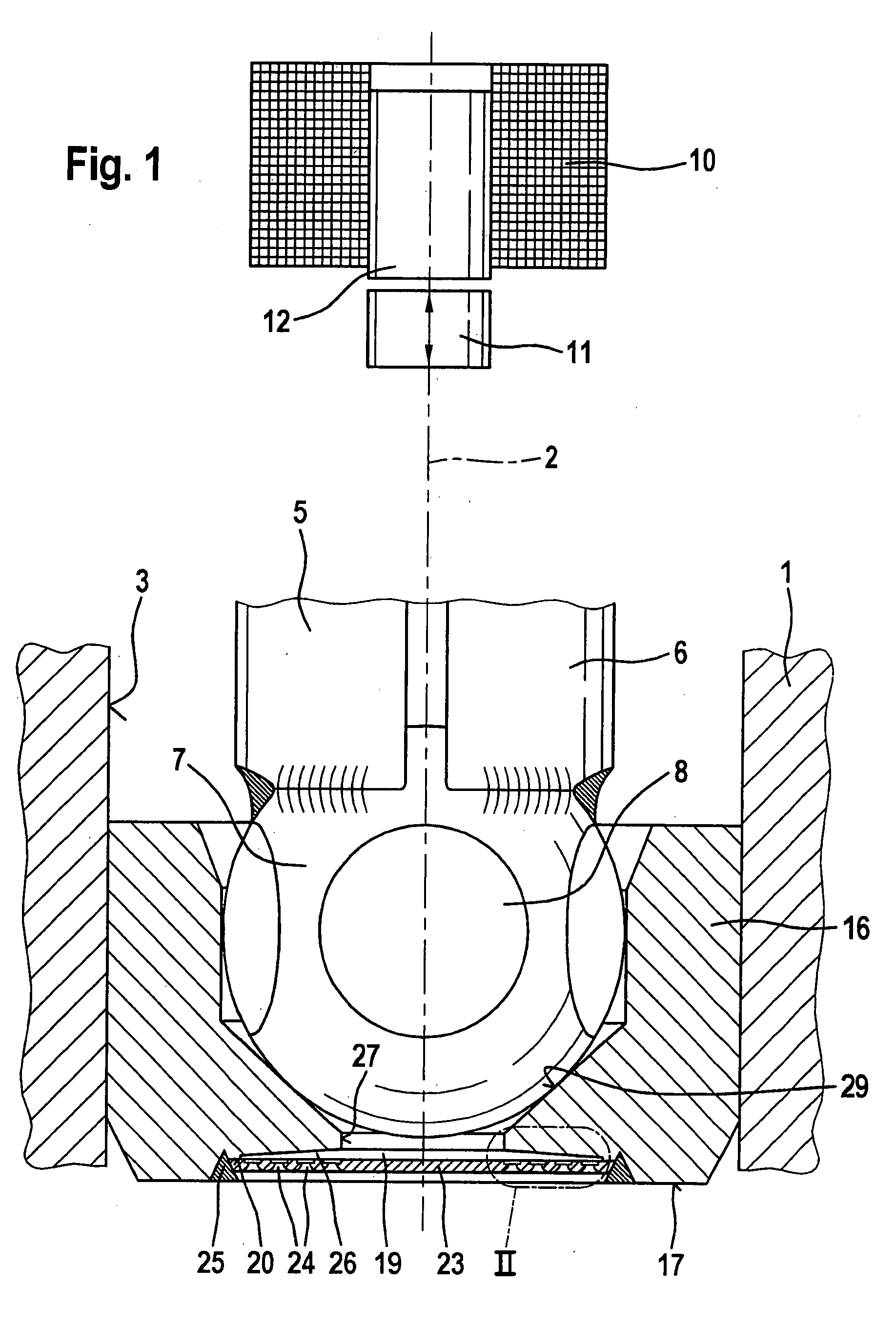

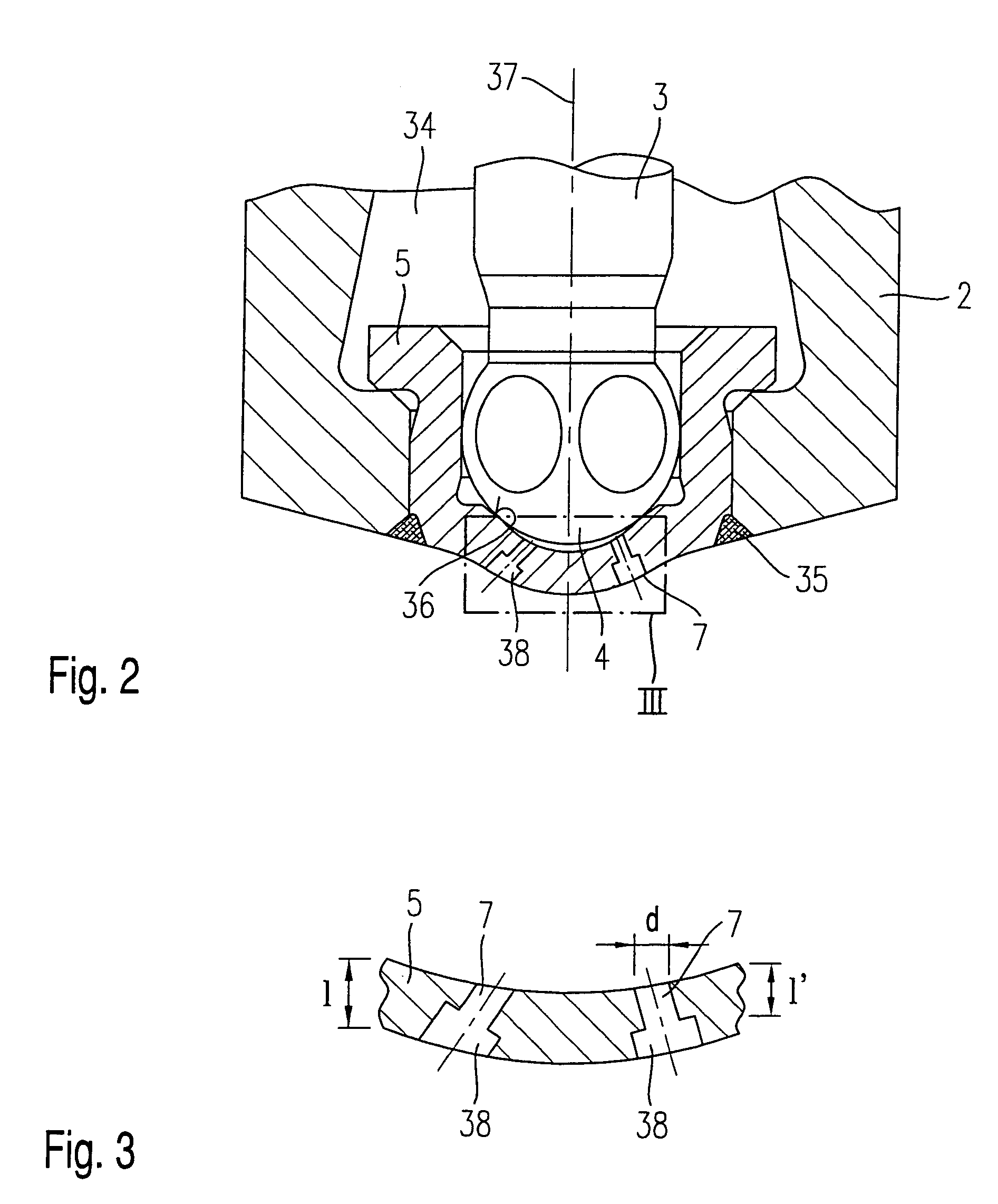

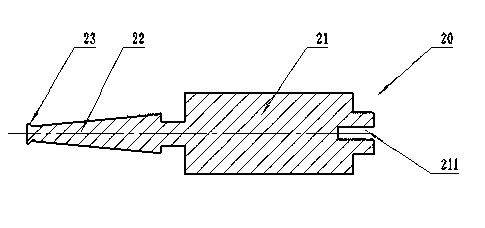

Fuel injector

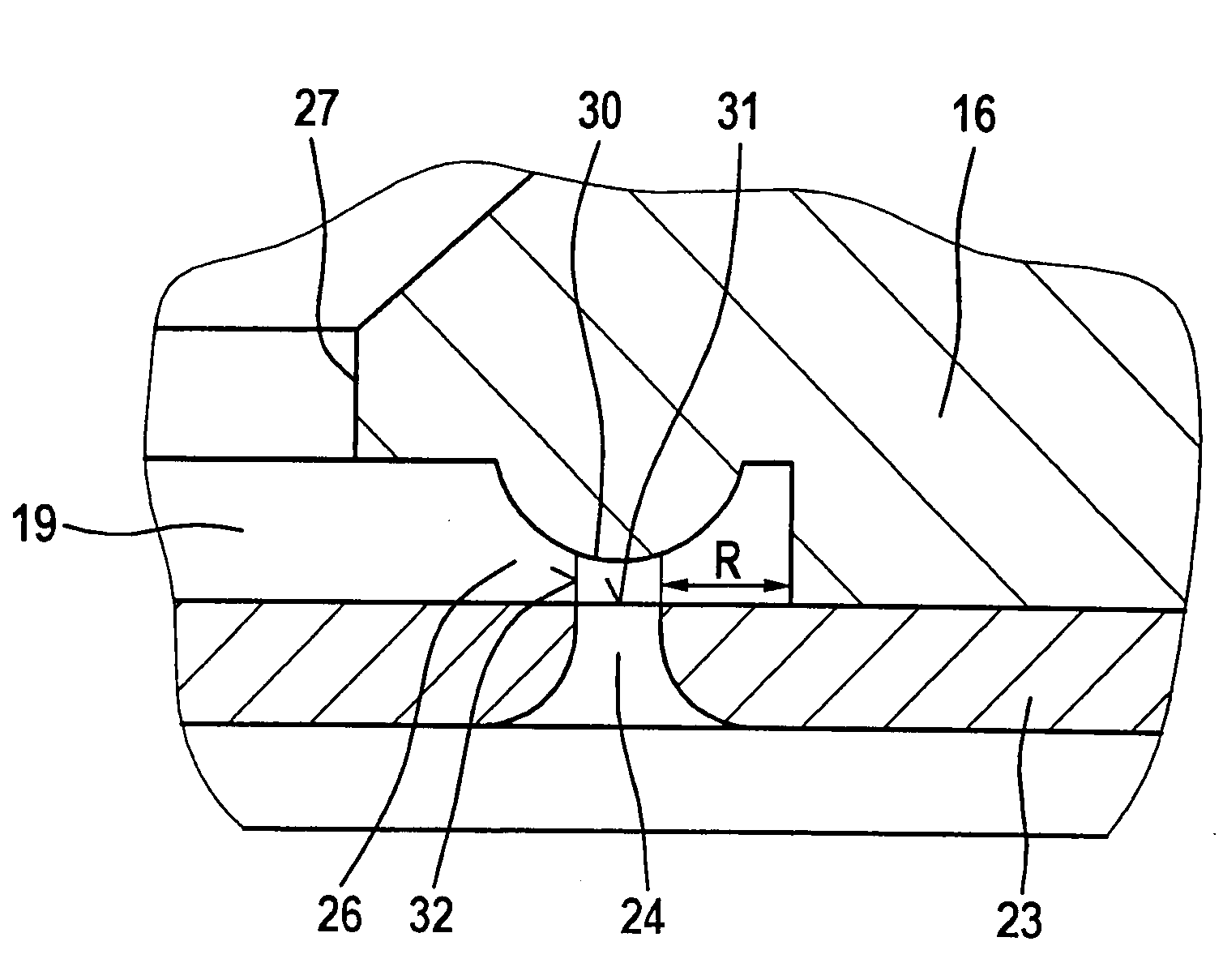

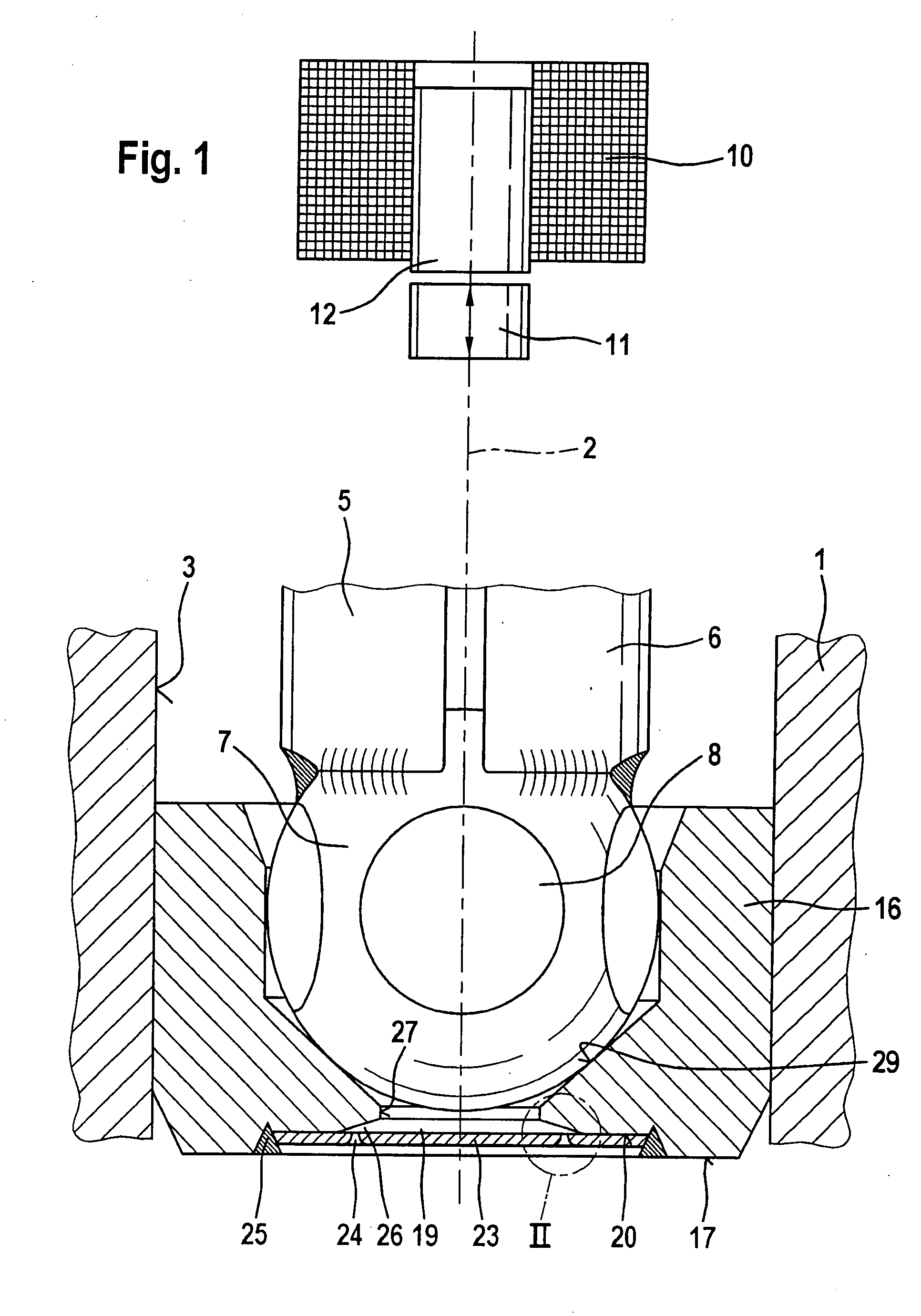

InactiveUS20090200402A1Uniform and very fine atomization of fuelSimple wayMachines/enginesFuel injecting pumpsVena contracta diameterSharp angle

The fuel injector including an orifice plate which is provided with a multitude of outlet openings and situated downstream from a valve-seat body having a fixed valve seat. Directly upstream from the outlet openings is an inflow opening having an annular inflow cavity. The valve-seat body covers the inflow cavity in such a way that the downstream outlet openings of the orifice plate are covered. The outlet openings each have an inflow region whose diameter D1 is considerably larger than the diameter D2 of a region that abuts at a sharp angle directly downstream therefrom, which forms the narrowest cross section of the outlet opening and from where the outlet opening widens in the flow direction to a diameter D3 in a trumpet-shaped manner. The fuel injector may be particularly suitable for use in fuel injection systems of mixture-compressing ignition engines having externally supplied ignition.

Owner:ROBERT BOSCH GMBH

Nozzle for direct-injection engine

InactiveCN101737218AReduces tendency to fluctuate randomlyAvoid tip jettingFuel injection apparatusMachines/enginesInjection pressureSpray cone

The invention relates to a nozzle for a direct-injection engine in the technical field of automobile engines, which comprises a shell, a valve rod, an oil-injection hole, an oil supply hole and oil ways, wherein the oil-injection hole and the oil supply hole are arranged at both ends of the shell respectively; the oil way is positioned in the shell, and both ends of the oil ways are connected with the oil supply hole and the oil-injection hole respectively; one end of the valve rod is arranged inside one side of the shell close to the oil supply hole and is positioned at the center of a plurality of oil ways. The nozzle enables fuel to generate swirl, can ensure the large spray cone angle (namely dispersibility) under the low injection pressure and high backpressure, and simultaneously, avoid undesirable tip injection of atomization, so that the atomization performance of the nozzle is improved.

Owner:SHANGHAI JIAO TONG UNIV

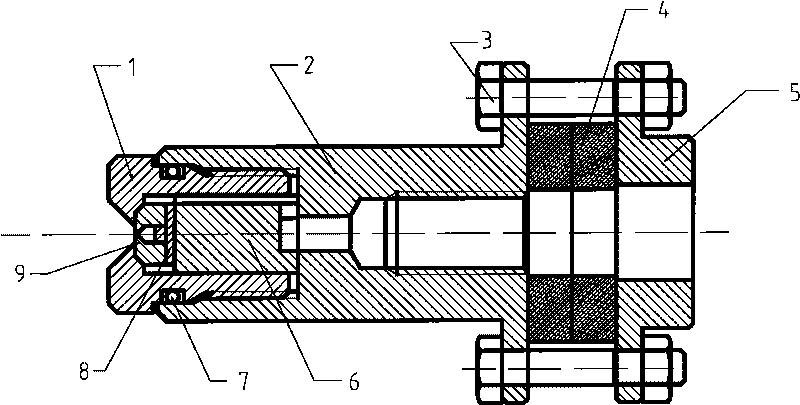

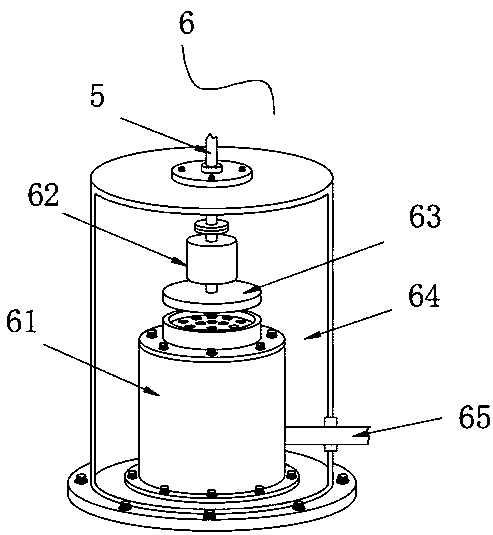

Ultrasonic wave and pressure rotary atomizer

InactiveCN101703980AOvercoming pressure bottlenecksStrong disturbanceLiquid spraying apparatusUltrasonic sensorEngineering

The invention provides an ultrasonic wave and pressure rotary atomizer, comprising an ultrasonic wave energy converter and a pressure rotating liquid nozzle, wherein the ultrasonic wave energy converter comprises an energy converter back cover plate, a pretightening bolt and a pretightening nut, piezoelectric crystal and a nozzle front cover; the pressure rotating liquid nozzle comprises a drainage member, a gasket, a swirl member and a nozzle head; the piezoelectric crystal is clamped between the nozzle front cover and the energy converter back cover plate by the pretightening bolt and the pretightening nut; the nozzle head is installed on the drainage member and arranged at the front end of the nozzle front cover; the drainage member and the swirl member are arranged in the nozzle head; the gasket is clamped between the drainage member and the swirl member; an O-shaped seal ring is arranged between the nozzle head and the nozzle front head; and a swirl chamber is arranged in the middle of the swirl member. The atomizer can further generate liquid drops the Sauter diameters of which are several microns to one micron on the basis of the pressure rotating nozzle, thereby overcoming the pressure bottleneck of the pressure rotating nozzle after the size of the liquid drop is decreased to a certain degree.

Owner:HARBIN ENG UNIV

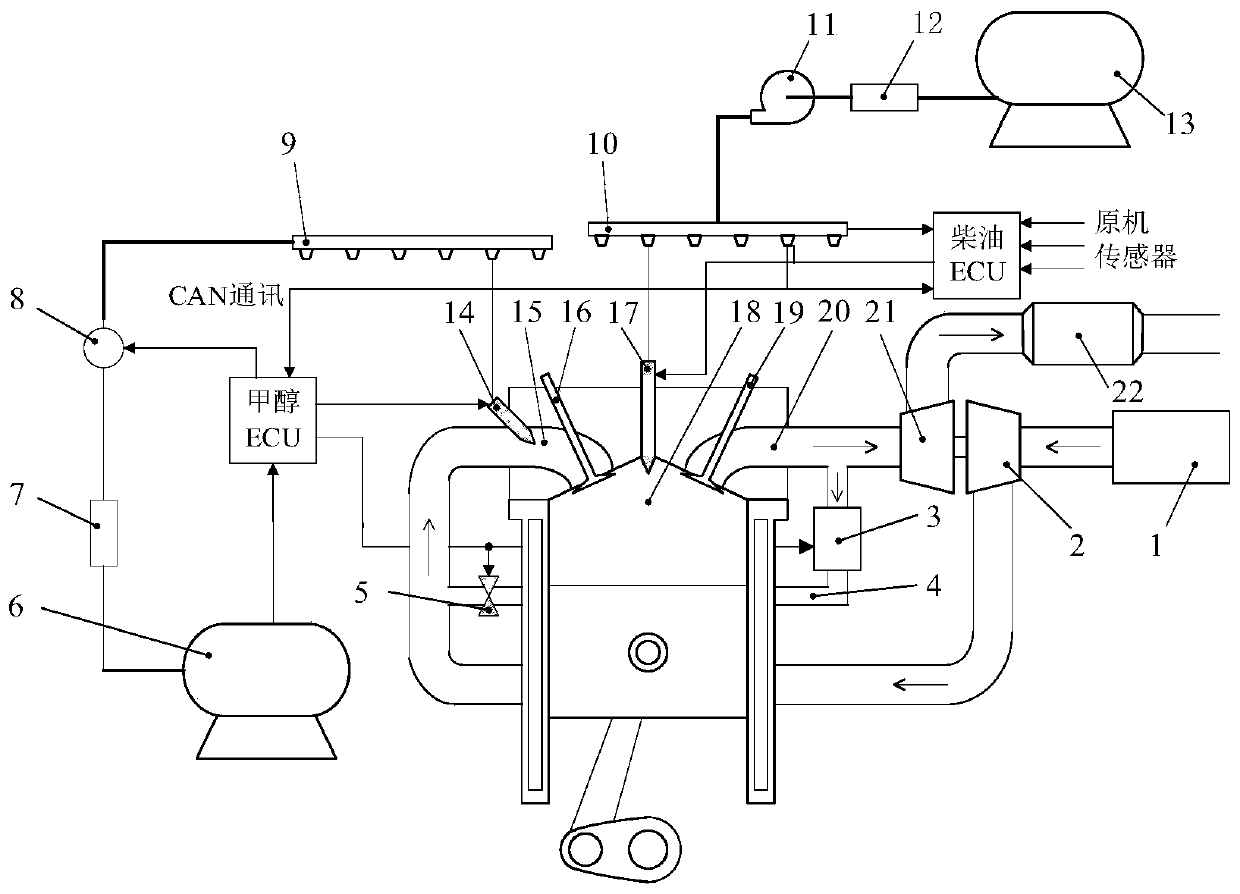

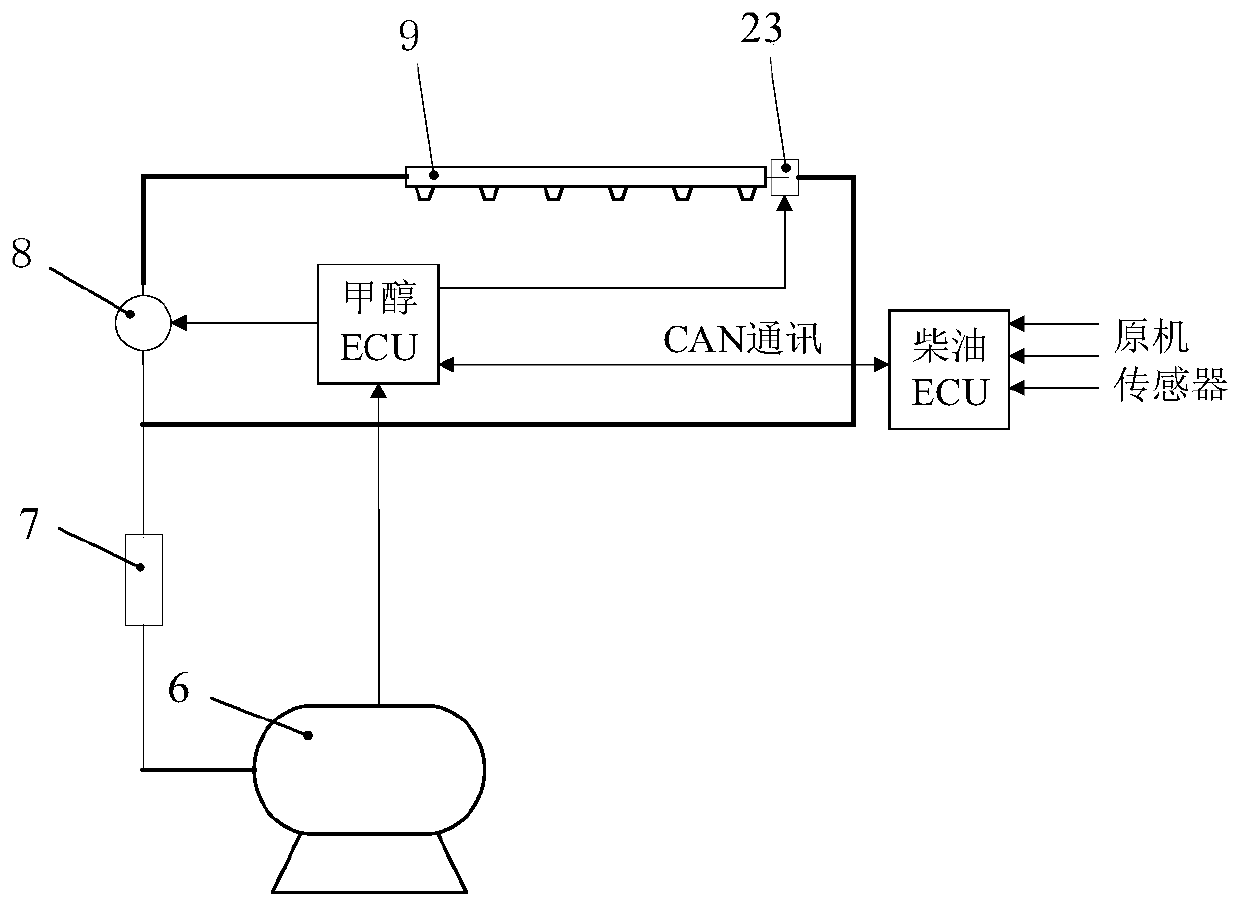

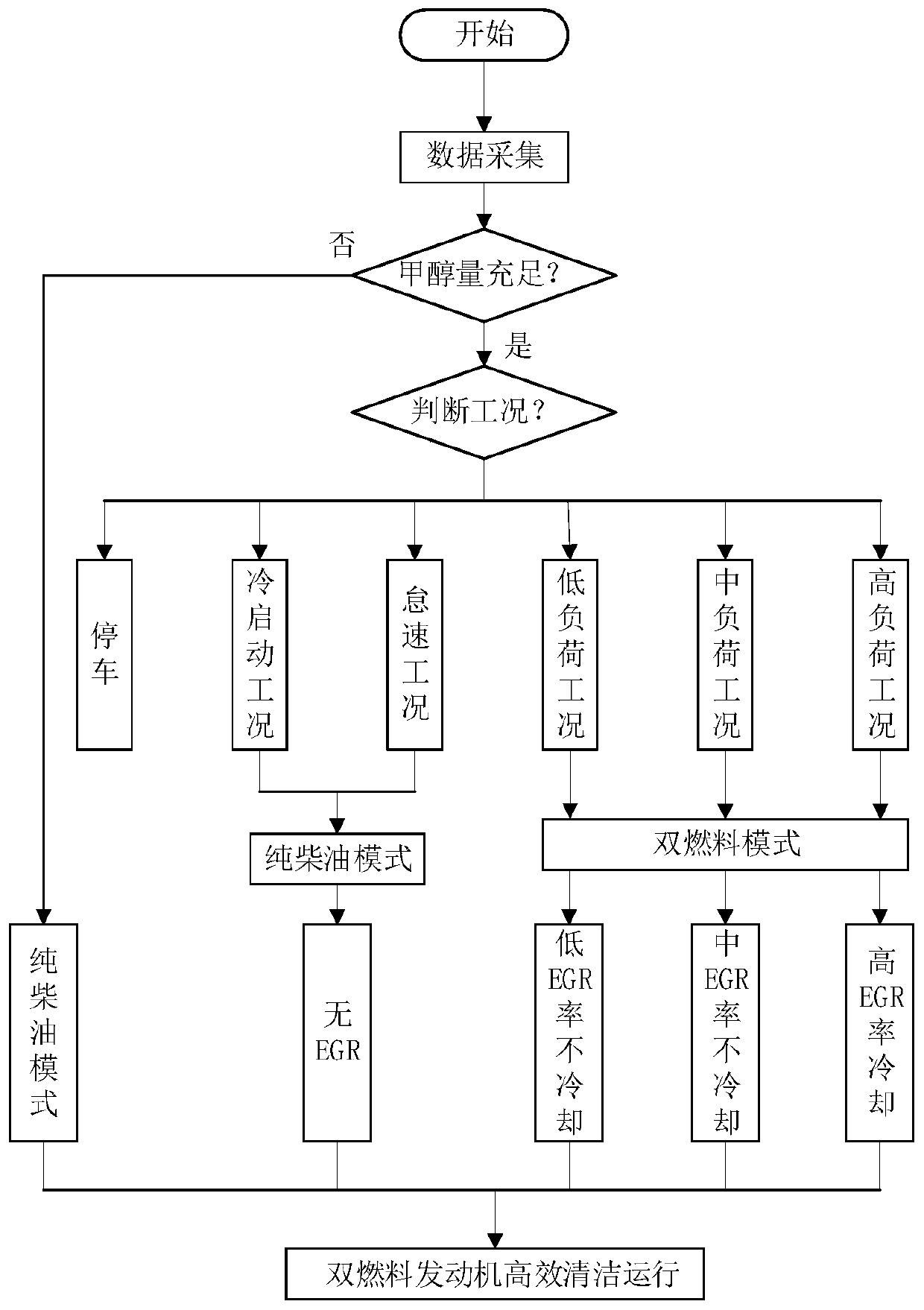

Electronic control diesel-methanol dual-fuel engine control system and method based on EGR technology

PendingCN111206999AAvoid knockingReduce power fluctuationsElectrical controlMachines/enginesEngine knockingFresh air

The invention discloses an electronic control diesel-methanol dual-fuel engine control system and method based on the EGR technology and relates to the field of internal combustion engines. The electronic control diesel-methanol dual-fuel engine control system comprises an air inlet system, an air discharging system, an EGR system, a diesel supplying system and a methanol supplying system. The airinlet system is used for providing fresh air for an engine. The EGR system is used for leading waste gas obtained after combustion into an air inlet manifold. The diesel supplying system is used forproviding the fuel diesel. The methanol supplying system is used for providing the fuel methanol, and the methanol is sprayed into the air inlet manifold. The control system comprises a diesel ECU, amethanol ECU, a sensor and CAN communication, the two ECUs share signals in real time through the CAN communication, the methanol supplying amount and the diesel supplying amount are adjusted in a linked manner, and therefore mode and work condition stable transition can be achieved. By means of the electronic control diesel-methanol dual-fuel engine control system and method based on the EGR technology, high-temperature waste gas is used for accelerating vaporization of the methanol, the quality of the methanol mixed gas is improved, the temperature and the pressure rise rate in a cylinder are controlled, NOx discharging and detonating are inhibited, and finally clean and efficient combustion of the double-fuel engine is achieved.

Owner:JIANGSU UNIV

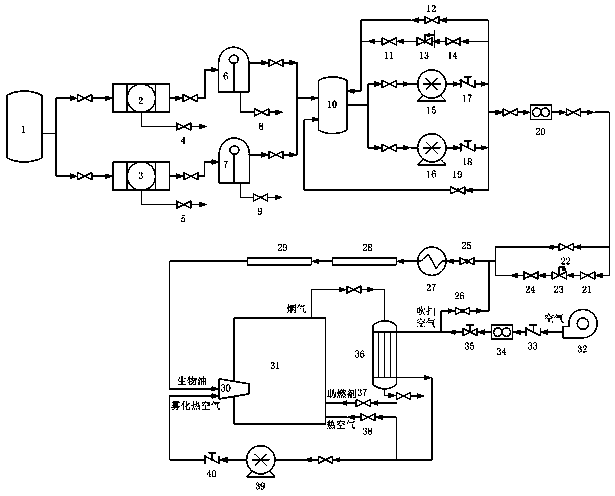

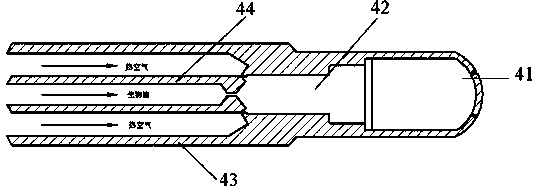

Industrial furnace high-pressure inner-mixed type system for atomizing vegetable fat or bio-oil to be burned and method thereof

ActiveCN103672952AIncrease the heat carriedEasy to igniteLiquid fuel feeder/distributionIndirect carbon-dioxide mitigationOil and greaseCombustion system

The invention provides an industrial furnace high-pressure inner-mixed type system for atomizing vegetable fat or bio-oil to be burned and a method thereof, and belongs to the technical field of energy sources and environments. The vegetable fat or the bio-oil which is filtered and dehydrated serves as an incendiary agent, the high-temperature air serves as an atomizing medium, the oil gas is conveyed into a high-pressure oil and gas mixing chamber of a burner through an automatic adjusting valve control device, a high-pressure blowing nozzle is inserted into a furnace combustion chamber from the periphery of an industrial furnace, the nozzle atomizes the oil gas into the combustion chamber of the industrial furnace to be burned in a corner tangential mode, hot air fed from other inlets supply sufficient oxygen, the problems that the vegetable fat and the bio-oil atomizing particles are large, incomplete in combustion, low in combustion efficiency and the like are solved, and the system has the advantages that the vegetable fat and the bio-oil atomizing particles are small, the atomizing quality is good, combustion is sufficient, the combustion efficiency is high, oil is saved, and low emission is achieved.

Owner:KUNMING UNIV OF SCI & TECH

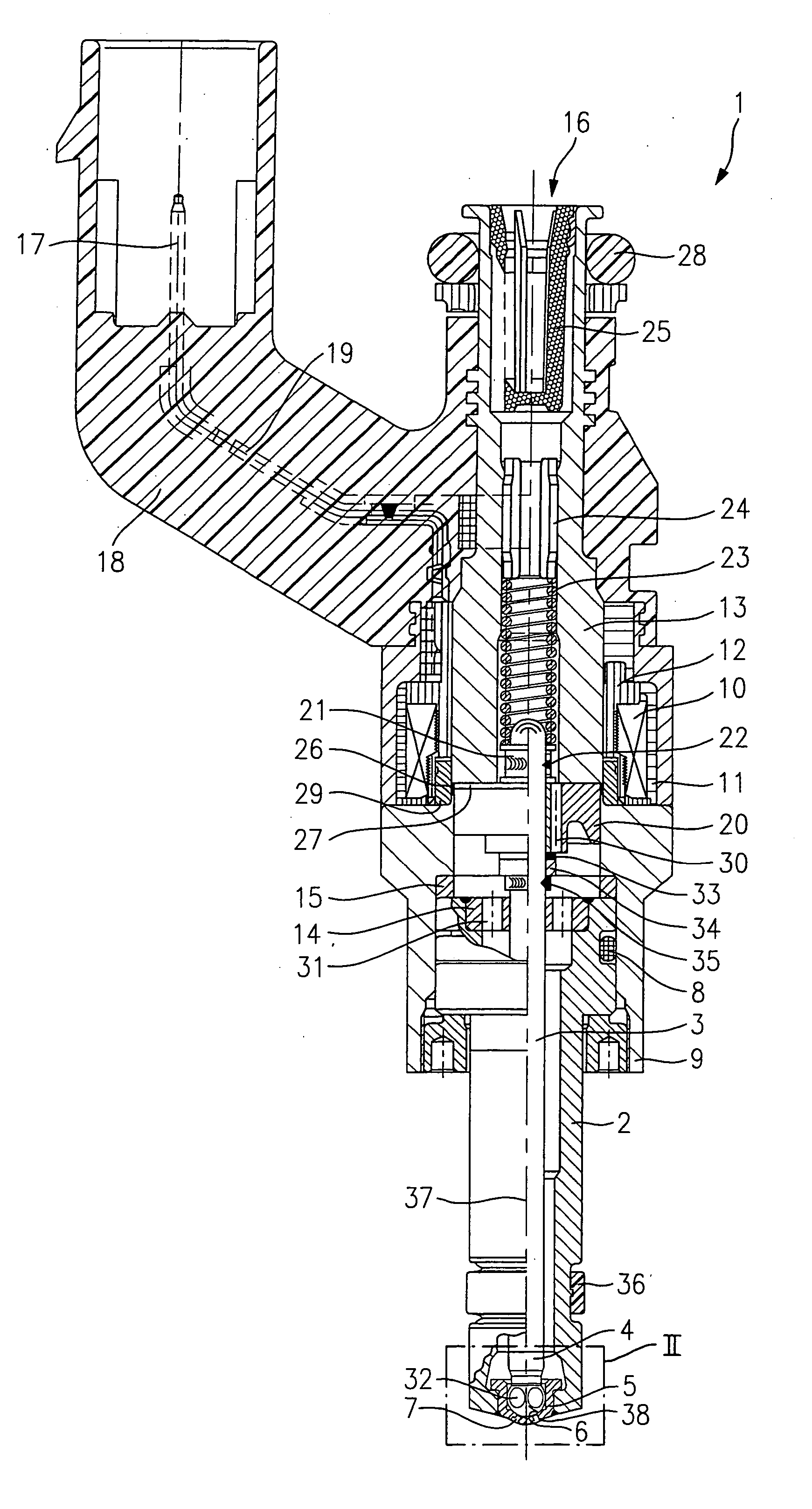

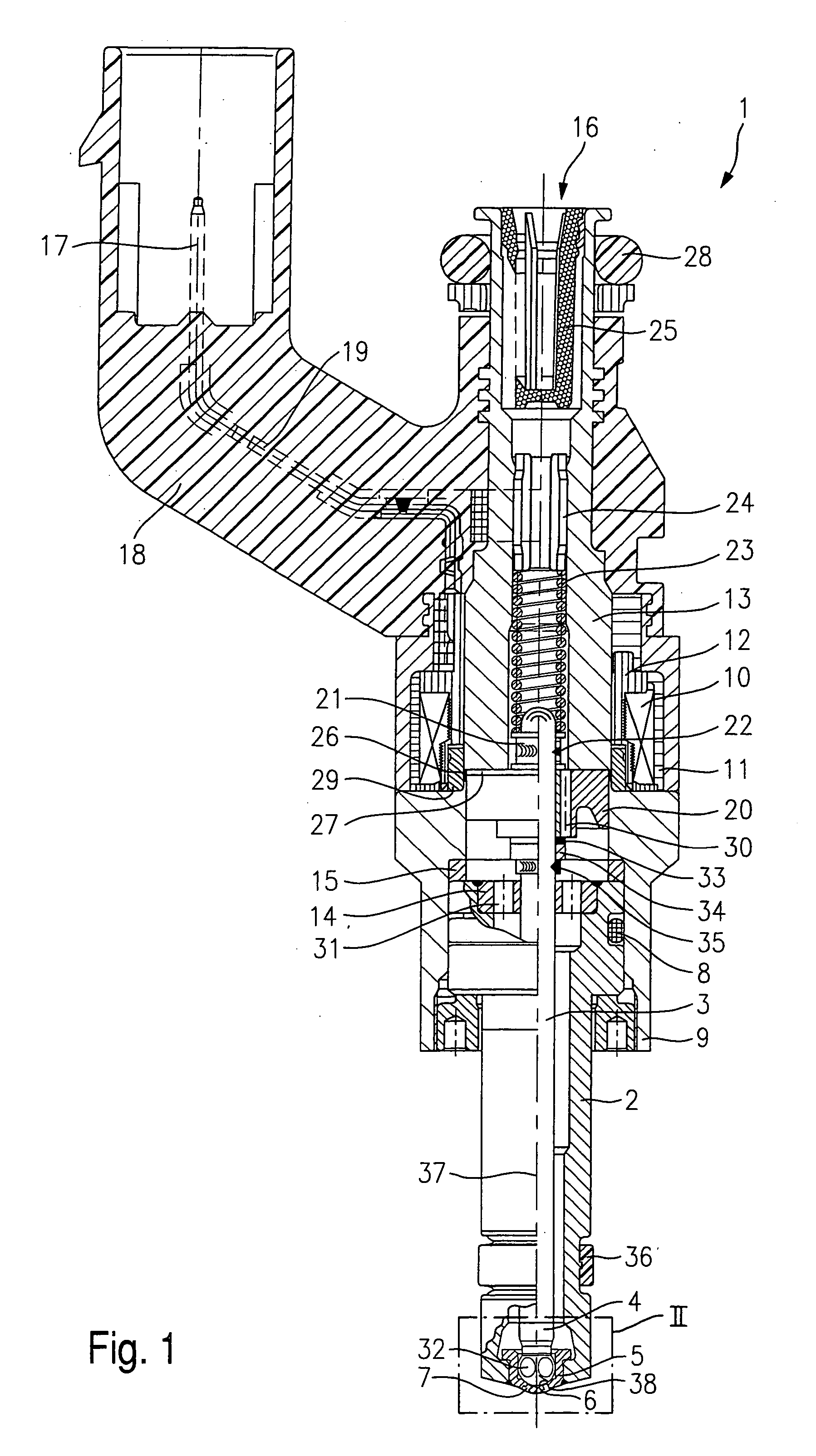

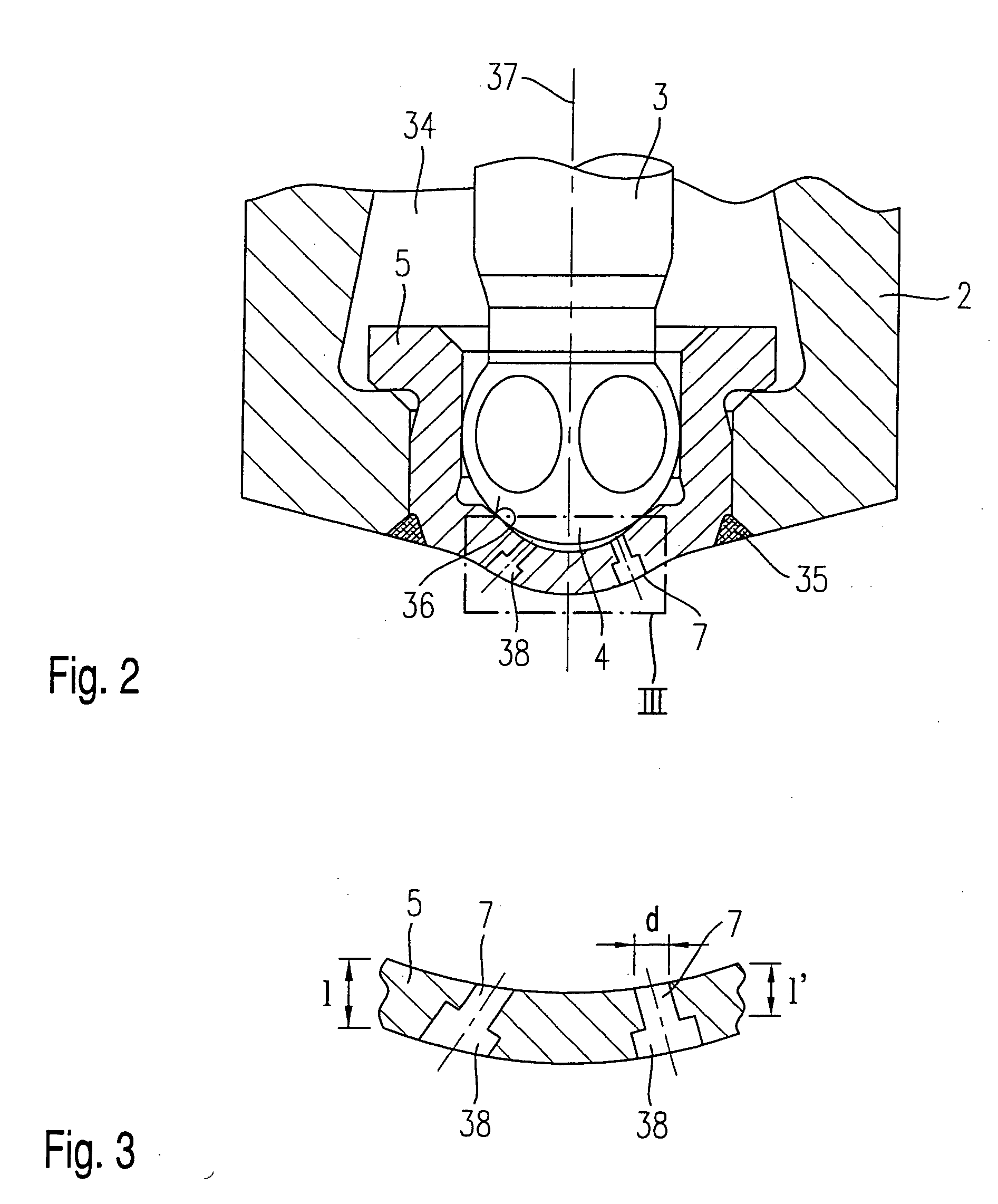

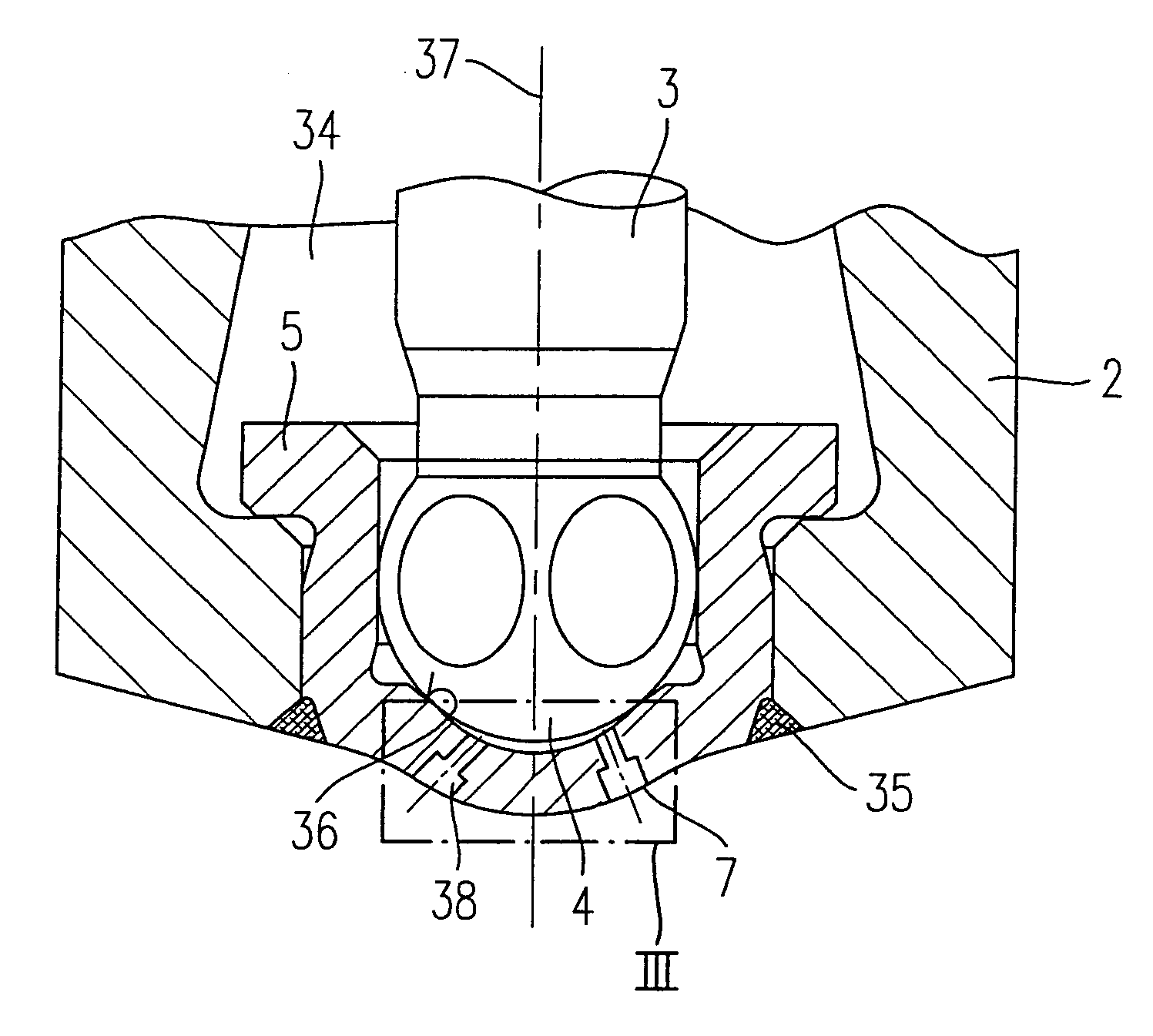

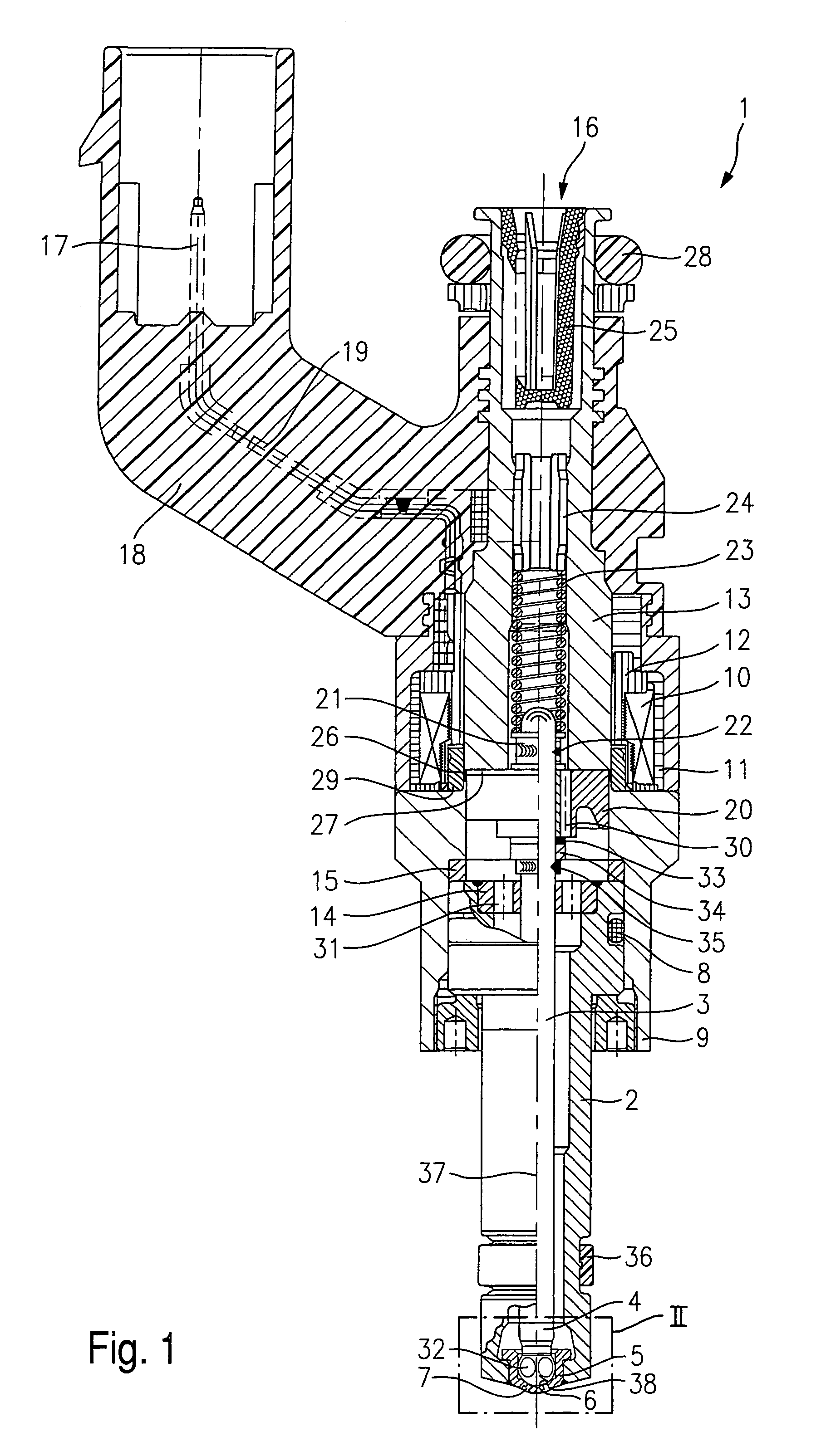

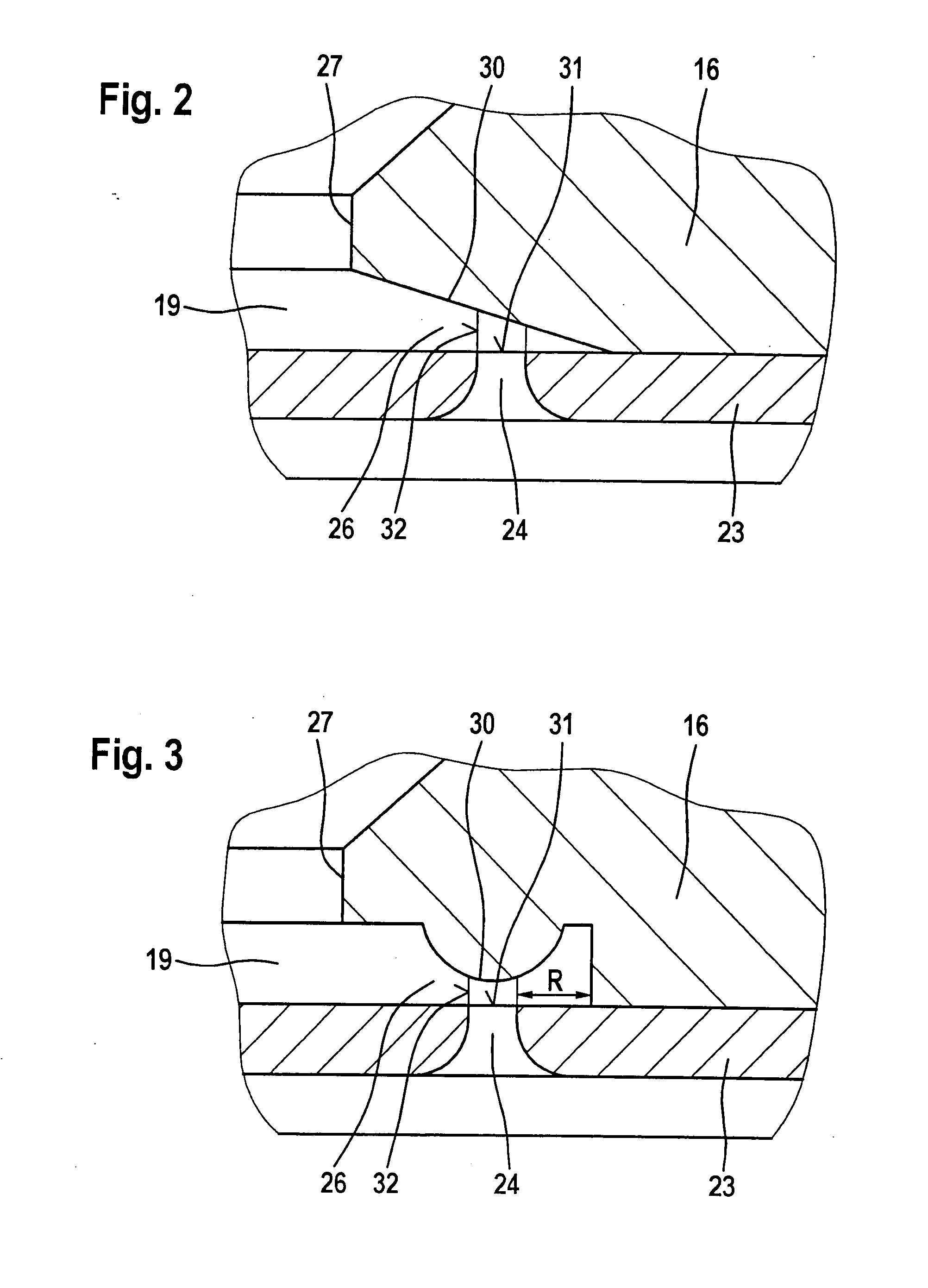

Fuel injection valve

InactiveUS7677478B2Improve atomization qualityIncrease fuel consumptionSpray nozzlesFire rescueCombustion chamberInternal combustion engine

A fuel injector for the direct injection of fuel into a combustion chamber of an internal combustion engine includes an energizable actuator, a valve needle, which is in operative connection with the actuator and acted upon by a restoring spring in a closing direction to actuate a valve-closure member, which forms a sealing seat together with a valve-seat surface formed at a valve-seat body. The valve-seat body includes at least two spray-discharge orifices. The pressure of the fuel flowing through the fuel injector is greater than 10 bar.

Owner:ROBERT BOSCH GMBH

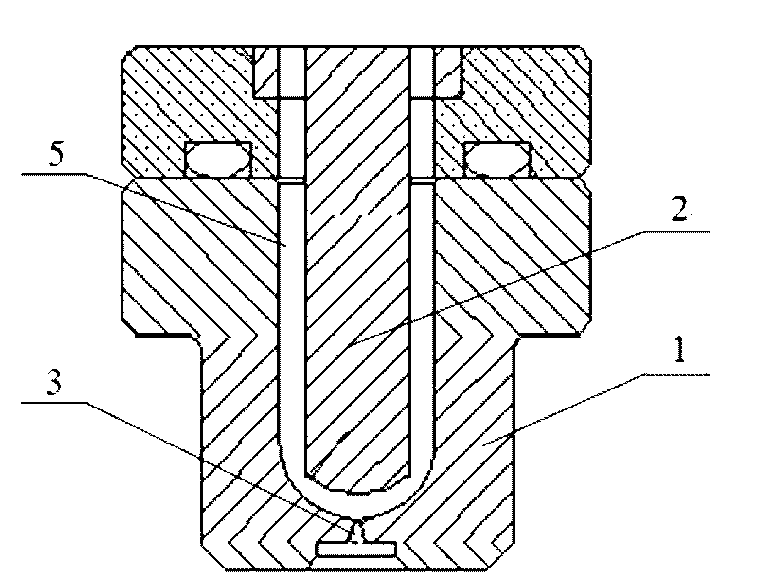

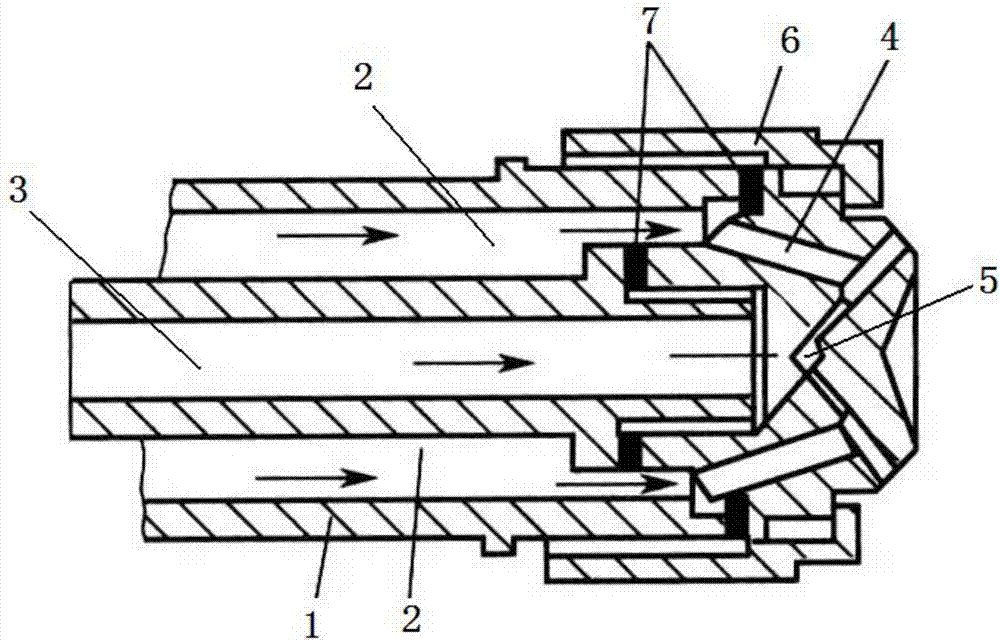

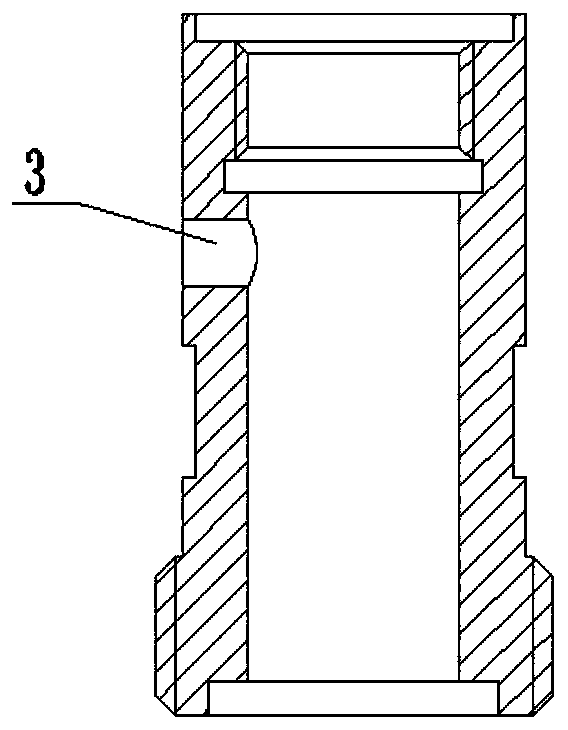

Internal mixing type steam atomization nozzle

InactiveCN106861960ASafe to useGood atomization qualityLiquid spraying apparatusFuel oilMixing chamber

The invention discloses an internal mixing steam atomizing nozzle, which includes a nozzle body, and is characterized in that it also includes an oil inlet passage, a steam inlet passage, an oil nozzle and a mixing chamber, and a ring of oil inlet passages is arranged in the nozzle body. There is a circle of steam inlet passage in the oil inlet passage, and an oil nozzle is arranged at the end of the oil inlet passage. The oil inlet passage sends fuel into the mixing chamber through the oil nozzle for mixing, and the steam is sent into the mixing chamber through the steam inlet passage for mixing. , the diameter of the steam inlet passage is greater than the diameter of the oil inlet passage. The invention provides an internal mixing steam atomizing nozzle with simple structure, convenient use, good atomizing effect and fast spraying speed.

Owner:包光华

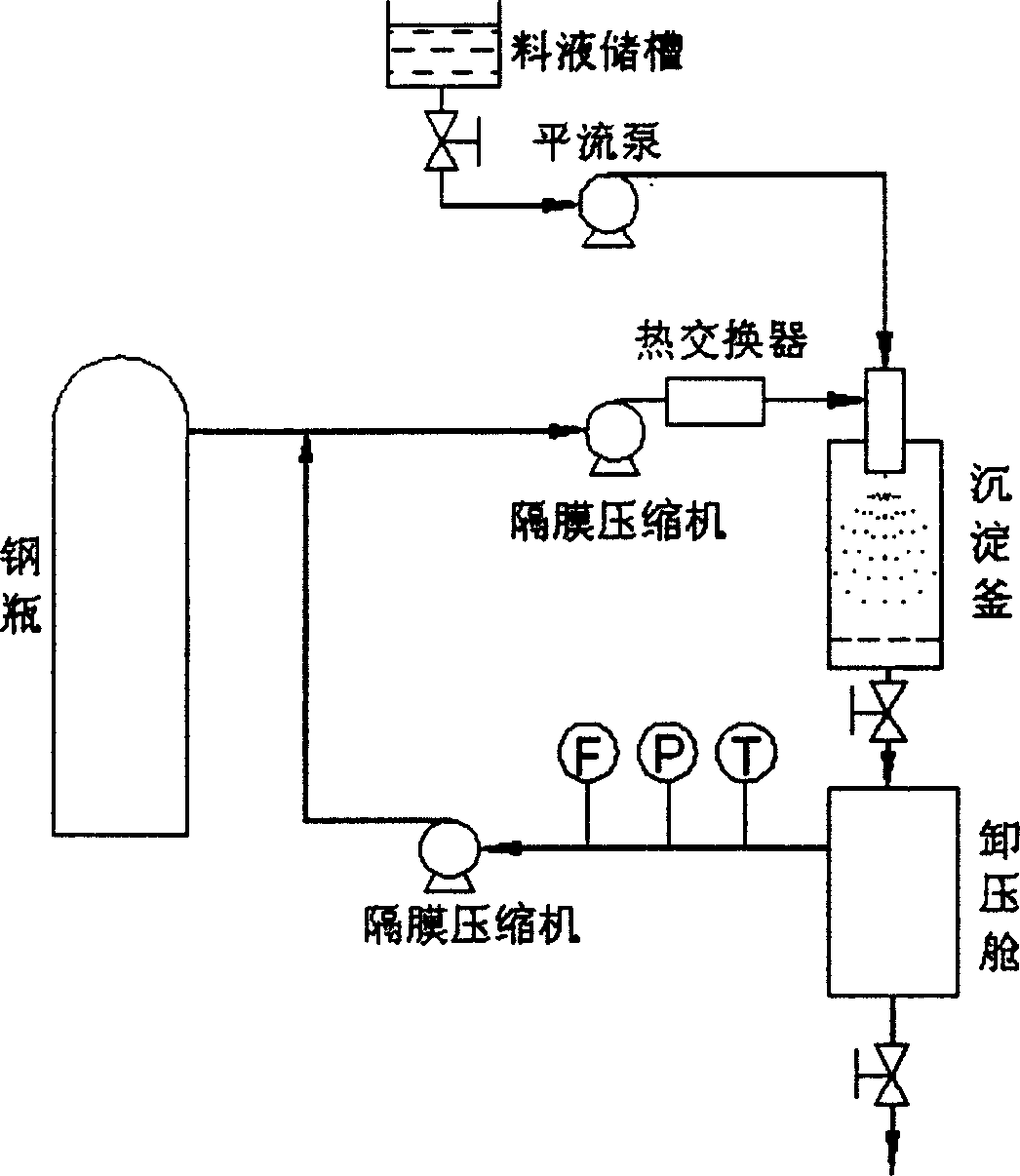

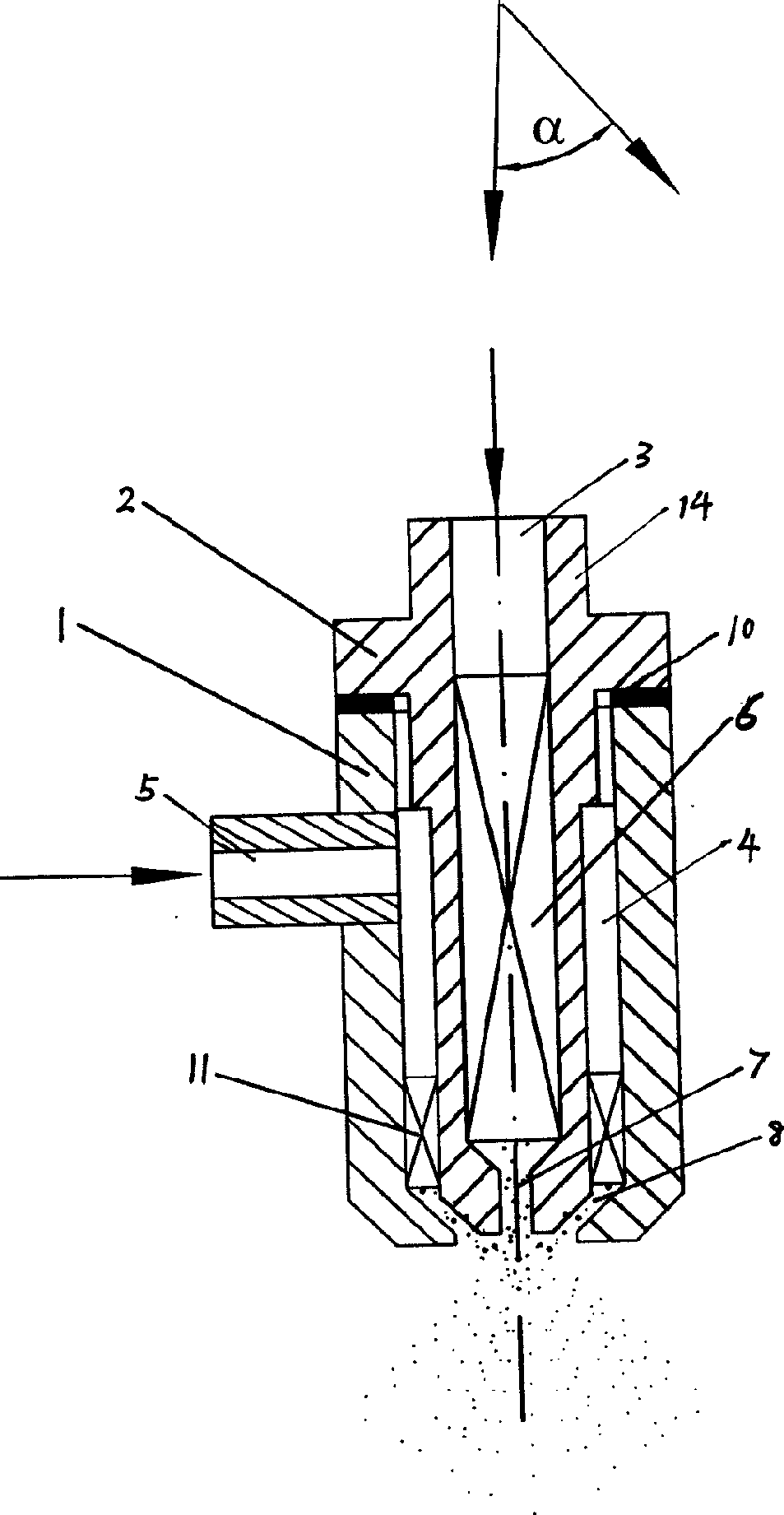

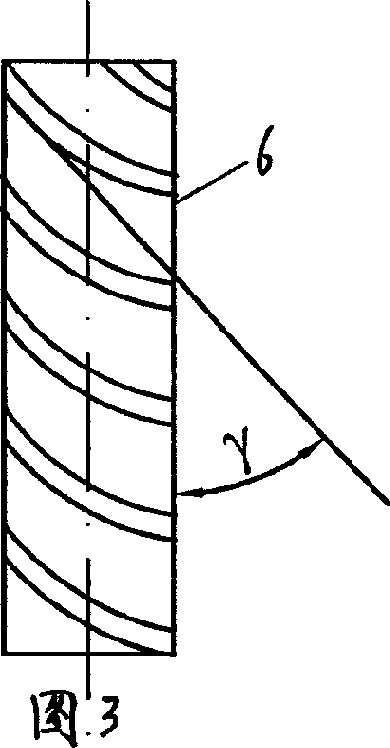

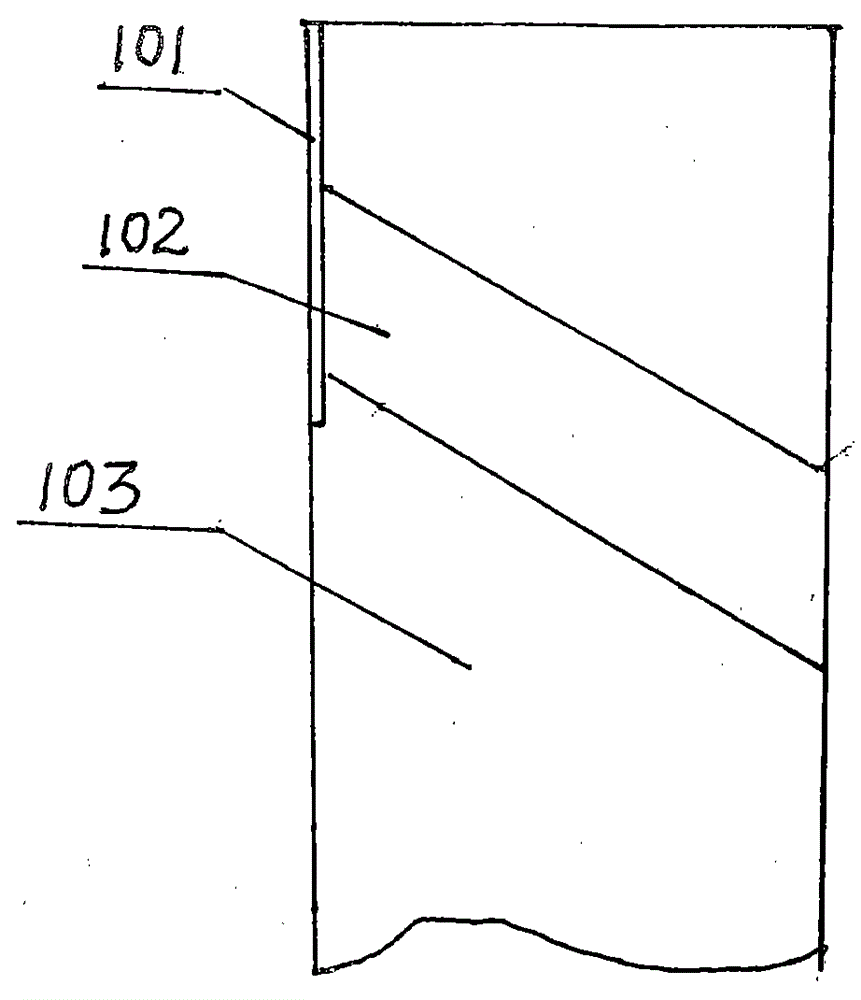

Film pre-forming two flowing type nozzle, stillpot with the nozzle and technique for producing ultra-fine dust utilizing the stillpot

InactiveCN1689682AIncrease mass transfer rateReduce the flow cross-sectional areaSolution crystallizationChemical/physical/physico-chemical nozzle-type rreactorsUltra fineSupercritical fluid

The present invention discloses one kind of pre-filming flow nozzle, stillpot with the nozzle and the production process of superfine particle in the stillpot with the nozzle. The nozzle includes casing, pre-filming unit, flow channel, ring gap flow channel, etc. and has the structure with greatly lowered flow resistance on solution and less jamming caused by the solute particle. The stillpot has simple structure, convenient operation, light labor strength and excellent sealing effect owing to the C-shaped metal sealing part with upper and lower sealing planes in linear contact state. By means of the supercritical fluid forced dispersing solution process in the stillpot with the nozzle, superfine solute particle may be prepared.

Owner:贺文智 +2

Magnetic force swinging type soybean oil atomizing and spraying device of ornamental type fish color increasing feed

ActiveCN107997220ARealize reciprocating movementWell mixedFeeding-stuffMagnetic tension forceMagnetic poles

The invention discloses a magnetic force swinging type soybean oil atomizing and spraying device of an ornamental type fish color increasing feed. Through the magnetic suction effect of each iron block and a corresponding third magnet, each moving column in a corresponding elastic telescopic device extends outwards to drive a corresponding material pushing plate to move, so that the purpose of moving the material pushing plates in a reciprocating manner is realized, the mixing effect of soybean oil is obvious, and the atomizing quality is improved; the directions of the south magnetic pole andthe north magnetic pole of two first magnets are opposite, and the directions of the south magnetic pole and the north magnetic pole of two second magnets are the same, so that the first magnets andthe second magnets arranged in corresponding positions are alternatively attracted and repelled, and a material guiding platform is in reciprocating swinging; raw materials in a housing are transported to the material guiding platform through a material cycling device, so that the raw materials on the material guiding platform are continuously rolled, the adsorbing effect of vaporific soybean oilby the raw materials is improved, and the quality of products is improved; and first spiral springs are used for enabling the material guiding platform to have certain buffering in the swinging process, so that the rolling speed of the raw materials is uniform.

Owner:安徽东升农牧科技有限公司

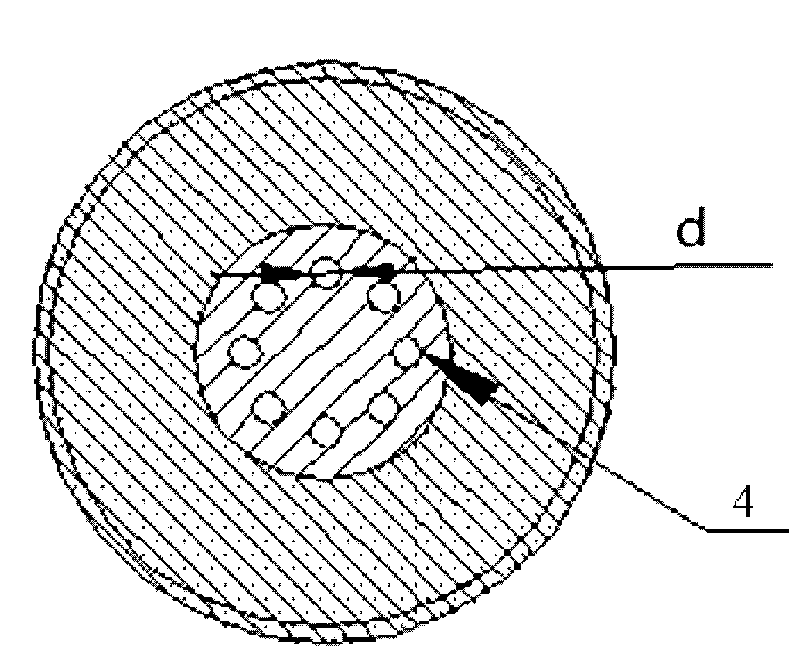

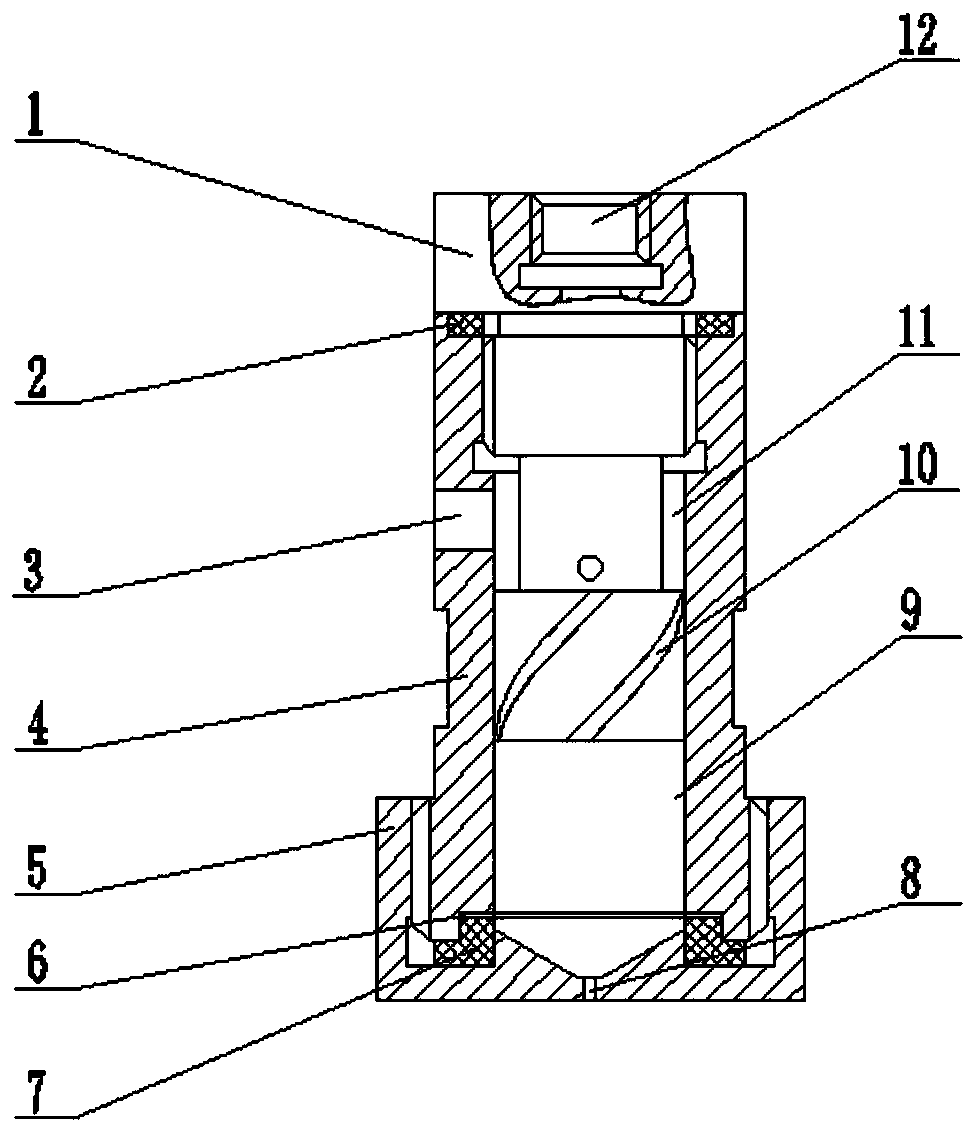

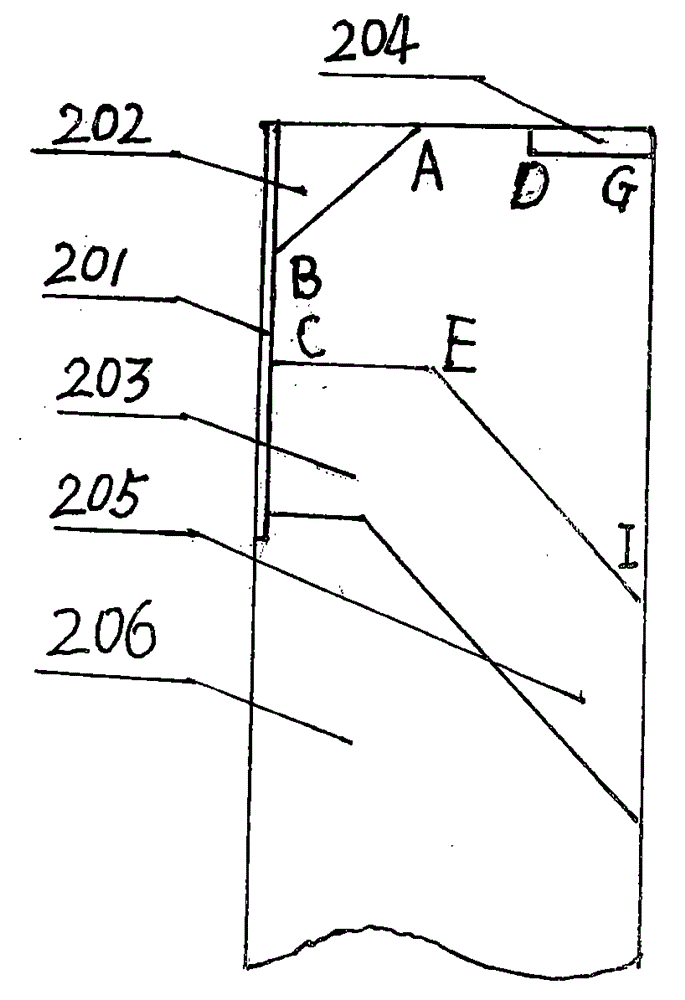

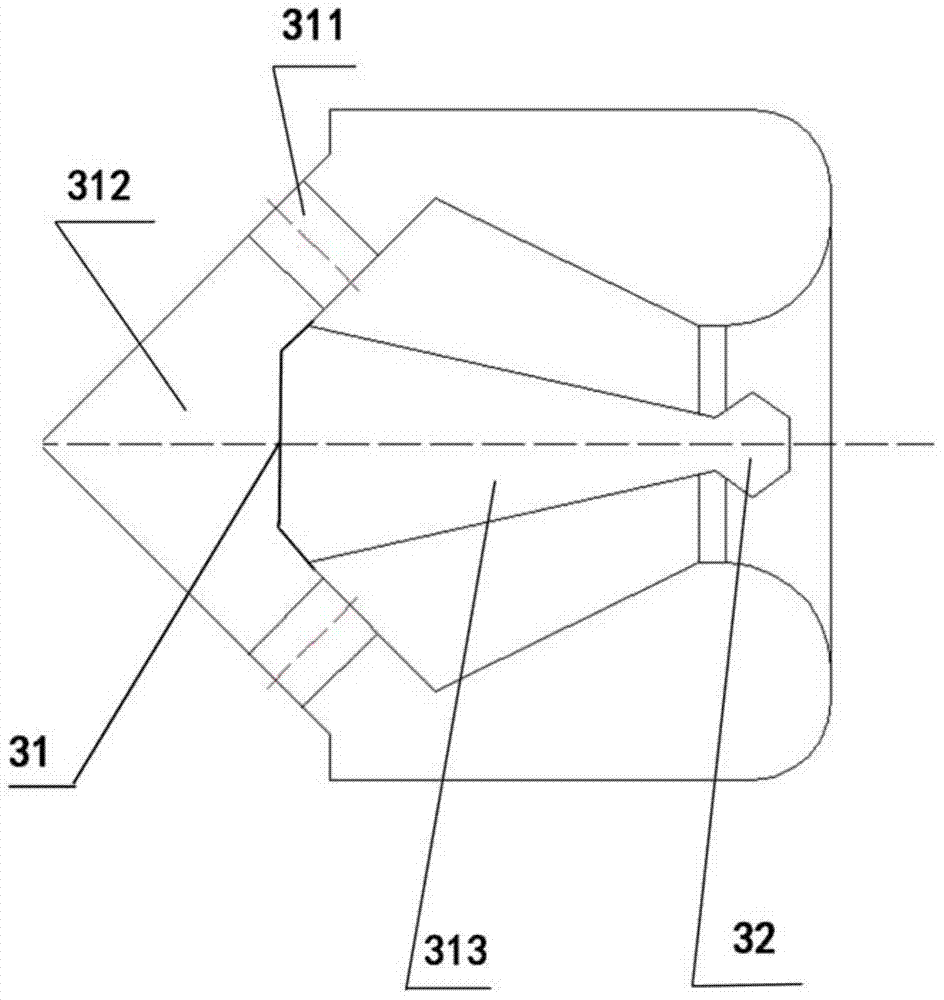

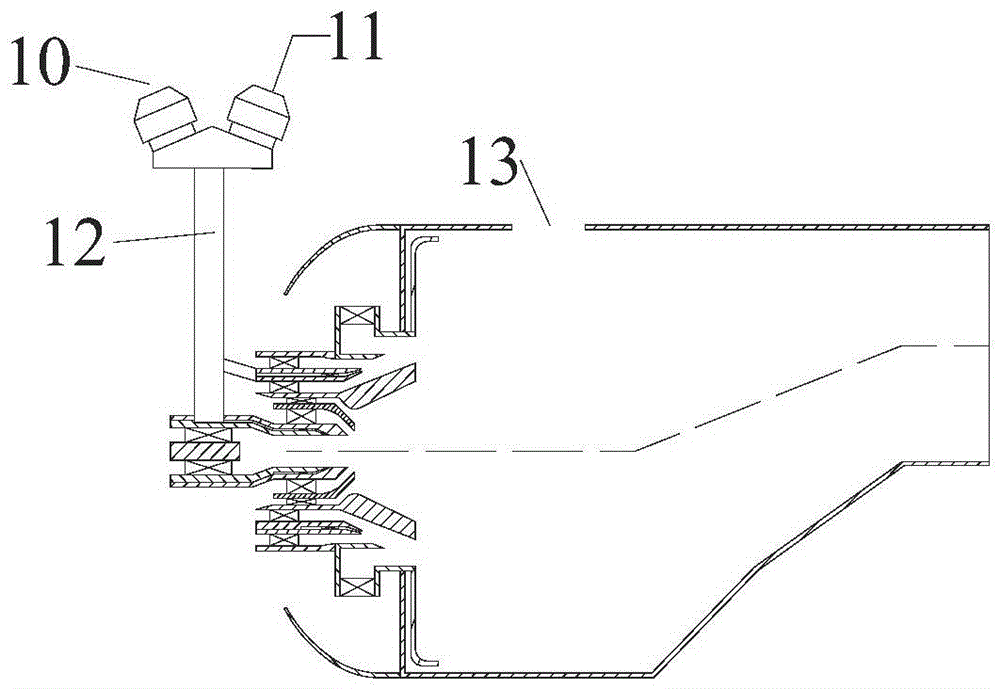

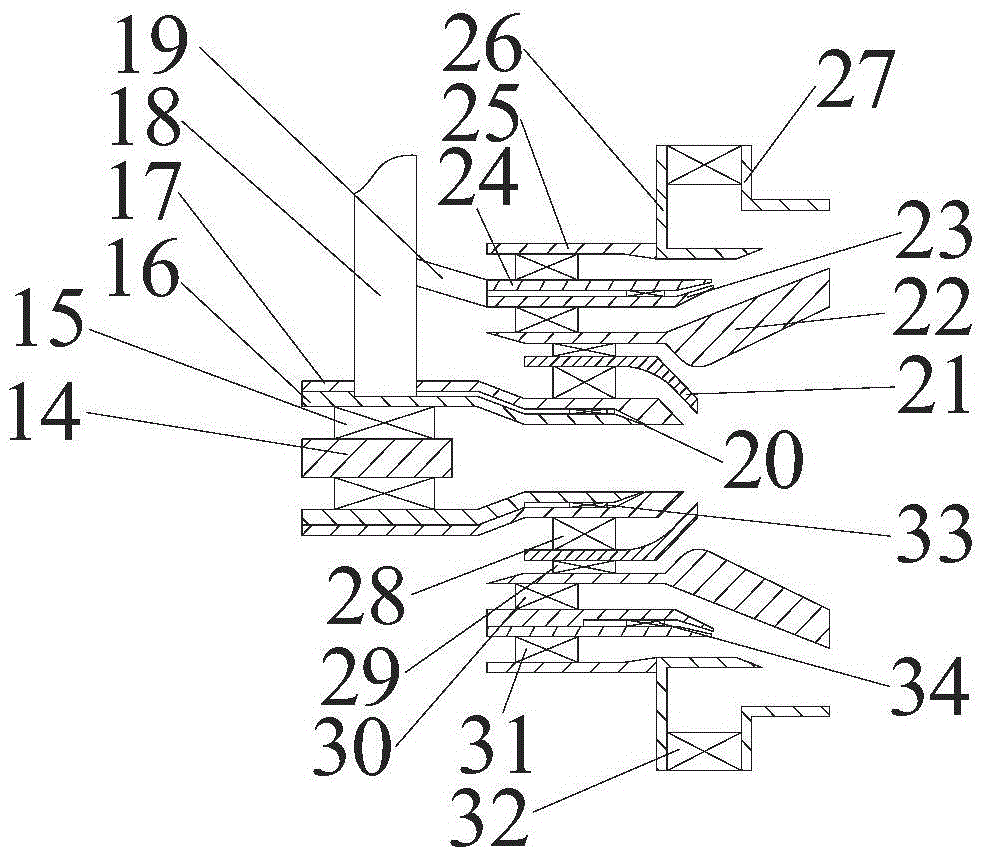

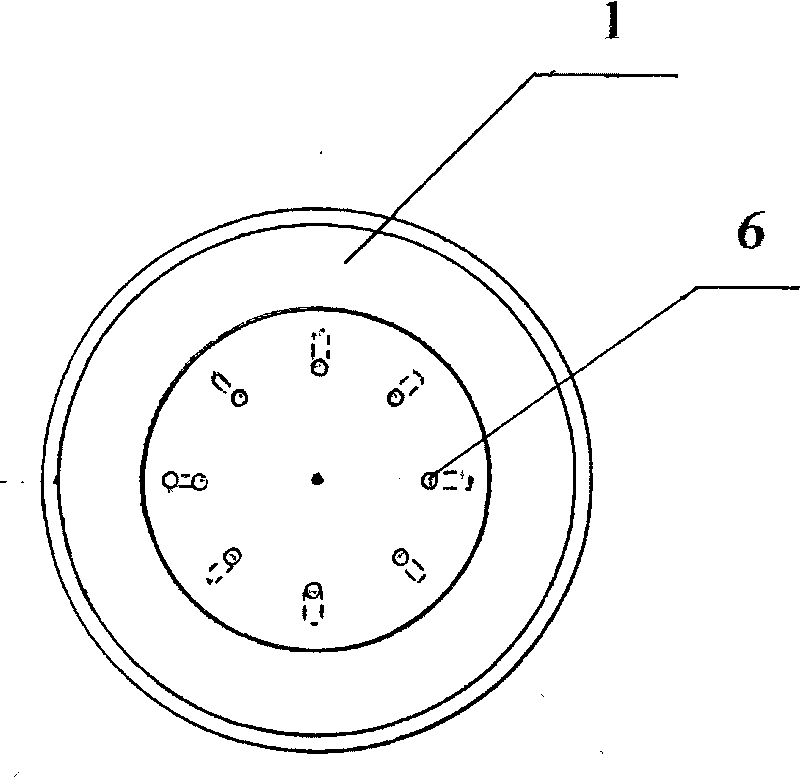

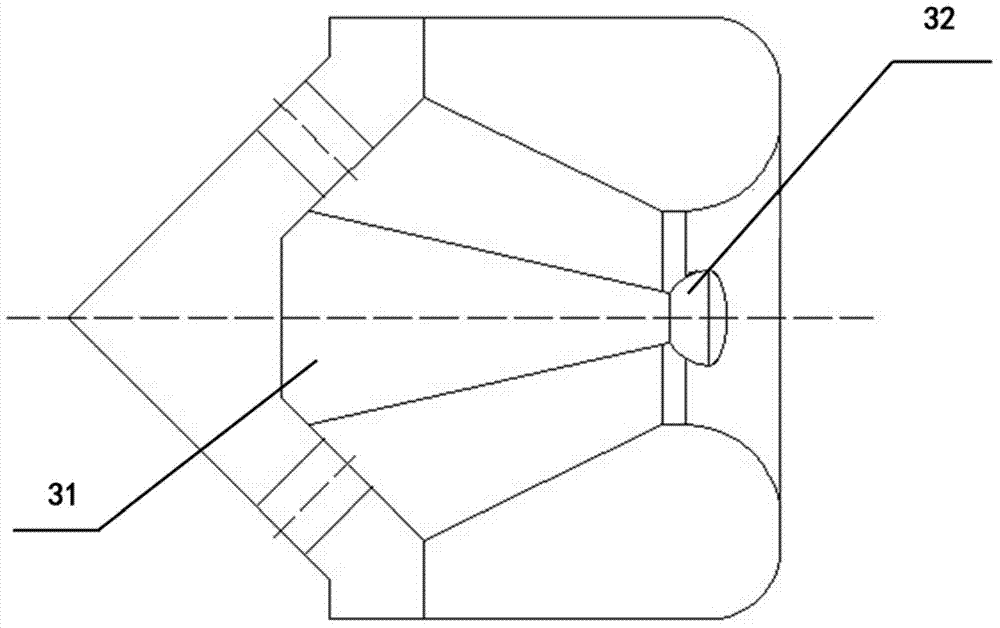

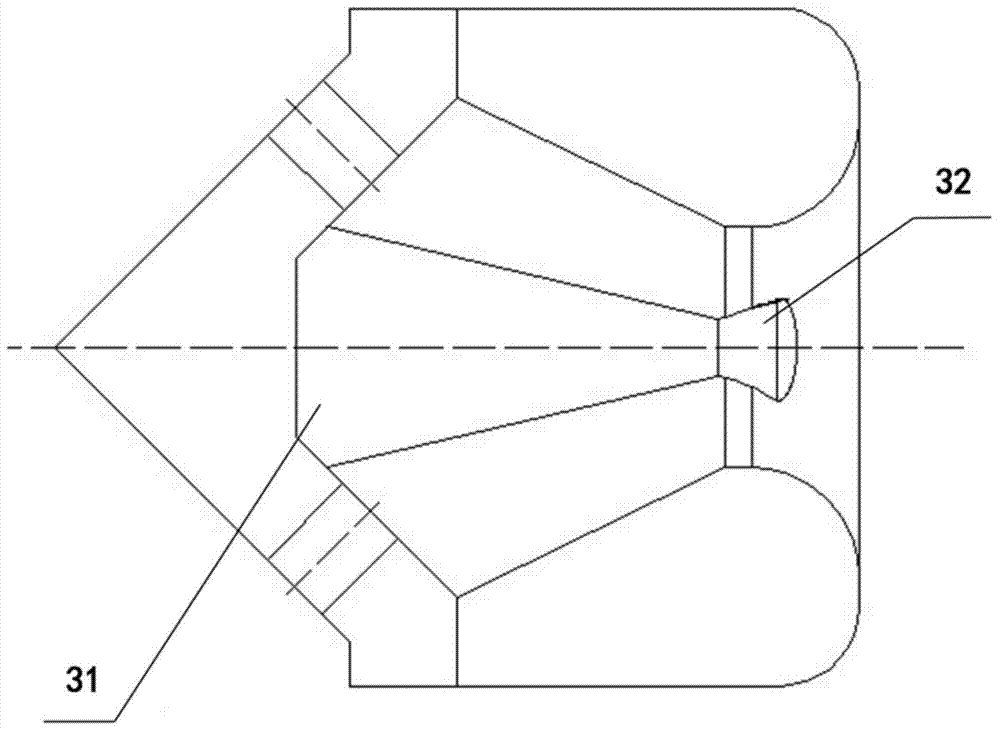

Air atomization nozzle of double-oil-path and double-rotational-flow structure

PendingCN109827192AIncrease oil supply pressureIncrease fuel speedContinuous combustion chamberCombustion chamberPower engineering

The invention discloses an air atomization nozzle of a double-oil-path and double-rotational-flow structure, and relates to the field of heat energy and power engineering equipment. An existing nozzleis a single-oil-path nozzle, and under the situation that the fuel flow is low, the fuel pressure difference is low, and the combustion chamber efficiency is low. The air atomization nozzle comprisesa first-level whirlcone, a second-level whirlcone and a nozzle body, wherein the first-level whirlcone is arranged in the nozzle body, the second-level whirlcone sleeves the spraying port end of thenozzle body, air sprayed out of the second-level whirlcone is subjected to flow guiding through a flow guiding sleeve, and the nozzle body is provided with a main oil path oil inlet pipe and an auxiliary oil path oil inlet pipe. A main oil path oil inlet hole, an annular main oil path oil inlet hole, an auxiliary oil path oil inlet hole, an arc auxiliary oil path oil inlet hole, a main oil path oil spraying hole and an auxiliary oil path oil spraying hole are formed in the nozzle body, the main oil path oil inlet pipe, the main oil path oil inlet hole, the annular main oil path oil inlet holeand the main oil path oil spraying hole are connected and are in communication, and the auxiliary oil path oil inlet pipe, the auxiliary oil path oil inlet hole, the arc auxiliary oil path oil inlet hole and the auxiliary oil path oil spraying hole are connected and are in communication. The air atomization nozzle is used for gas turbine liquid fuel atomization.

Owner:中国船舶重工集团公司第七0三研究所

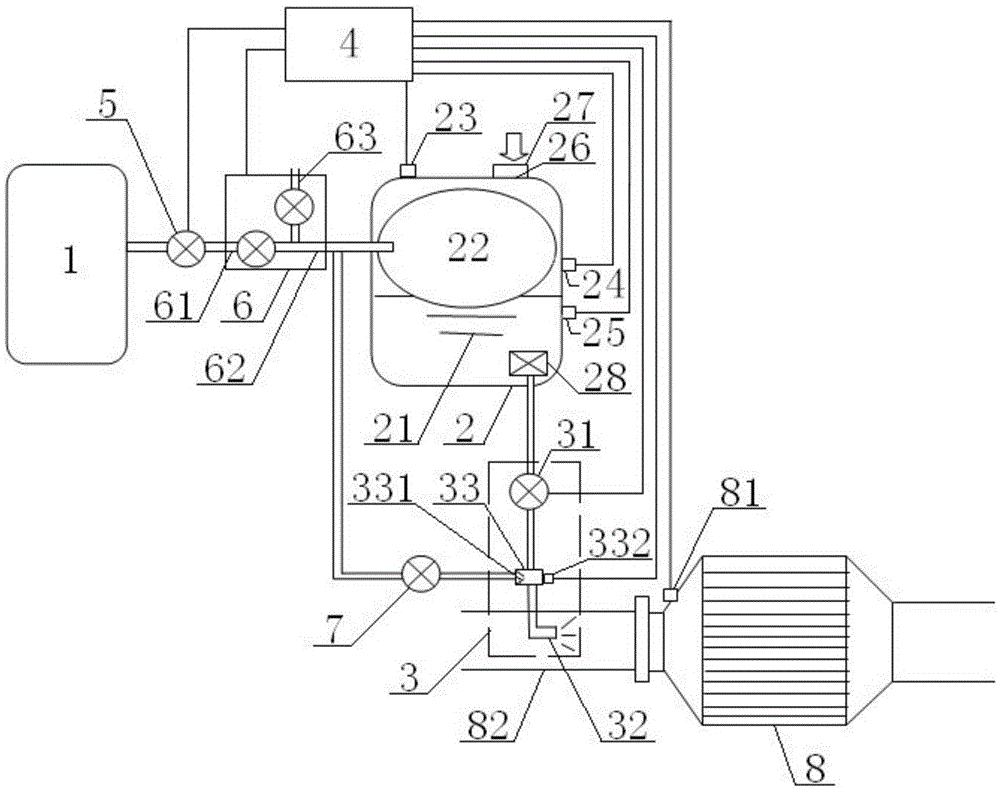

Air-assisting atomized urea spraying system and control method thereof

ActiveCN105545422AReduce use costReduce maintenance costsInternal combustion piston enginesExhaust apparatusAtmospheric airEngineering

An air-assisting atomized urea spraying system comprises an air source, an air bag pressure tank with a urea solution area and an air bag inside, and a spraying pipeline system. The air bag is connected with an air source air way after passing through a two-position three-way valve and a pressure-stabilizing valve in sequence and is communicated with the atmosphere after passing through the two-position three-way valve. The spraying pipeline system comprises a metering valve, a spraying nozzle and a mixing cavity. The spraying nozzle is connected with a urea solution area liquid way after passing through the mixing cavity and the metering valve in sequence. The mixing cavity is connected with the air source air way after passing through a pneumatic switch valve, the two-position three-way valve and the pressure-stabilizing valve in sequence. The two-position three-way valve and the metering valve are both connected with a control unit through signals. In the control process, the air source inflates and pressurizes the air bag, and therefore urea and air in the mixing cavity are mixed and then sprayed; when urea stops being sprayed, air in the air bag enters the mixing cavity and the spraying nozzle after passing through the pneumatic switch valve to purge the spraying pipeline system, air in the air bag is led to the atmosphere after passing through the two-position three-way valve so that the air bag can be deflated and depressurized. The air-assisting atomized urea spraying system is low in cost and high in reliability.

Owner:DONGFENG COMML VEHICLE CO LTD

Platinum channel and manufacturing method and coating zirconium oxide dry powder mixture thereof

ActiveCN107739141ASpeed up meltingImprove melting effectLiquid surface applicatorsGlass furnace apparatusThermal insulationPt element

The invention discloses a platinum channel and a manufacturing method and a coating zirconium oxide dry powder mixture thereof. After the zirconium oxide dry powder mixture is sprayed on the surface of a platinum channel body, oxidization and volatilization of platinum in the platinum channel in a sintering process under high temperature can be effectively prevented. The zirconium oxide dry powdermixture is prepared from the following ingredients of 9.3% to 16% of SiO2, 2.7% to 4.3% of Al2O3, 80% to 87% of ZrO2 and 0.01% to 0.03% of Na2O. According to the platinum channel, the outer surface of the platinum channel is coated by a coating layer of the zirconium oxide dry powder mixture; a zirconium oxide dry powder filling material, a zirconium oxide groove profile brick and a zirconium oxide thermal insulation brick which are in tight contact are sequentially arranged outside the coating layer from inside to outside; the thickness of the coating layer is 0.8 to 1mm.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

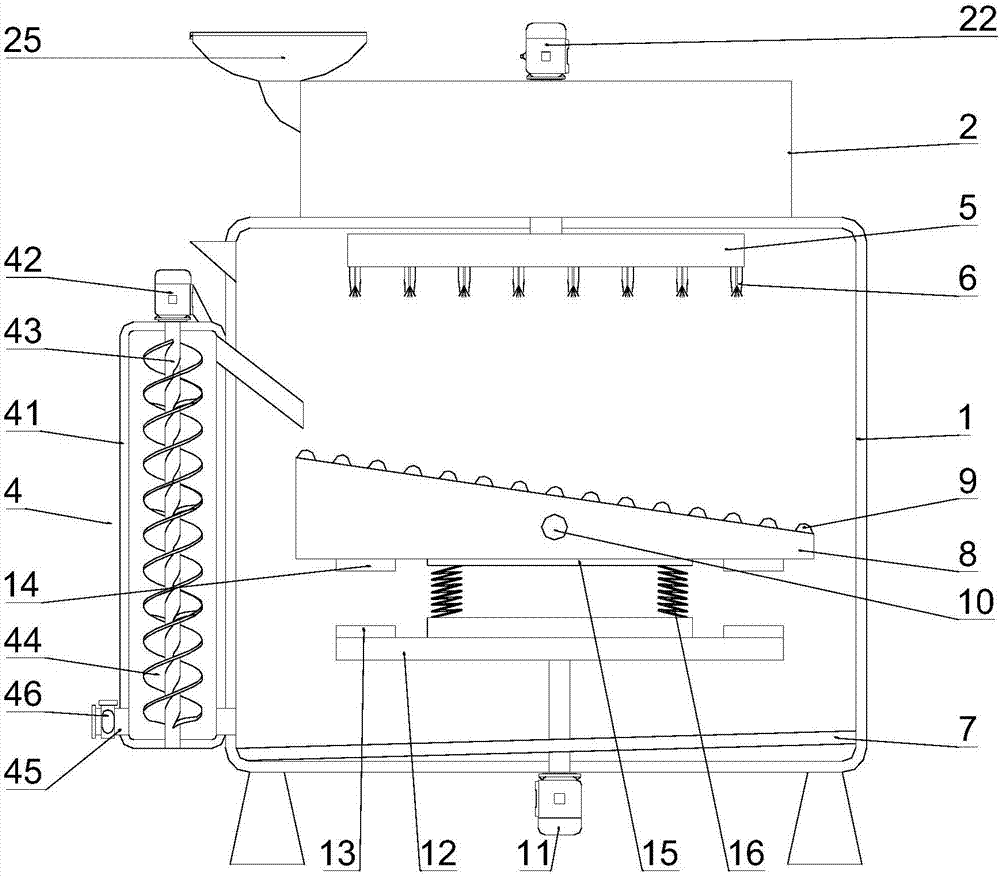

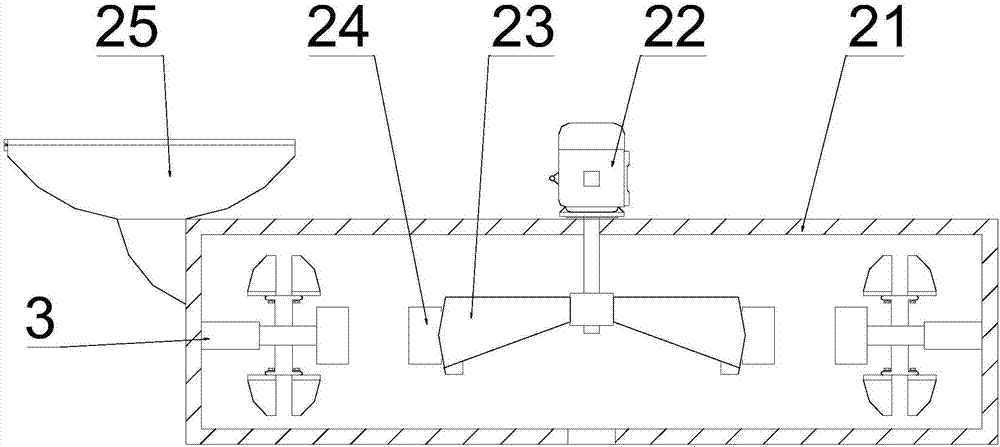

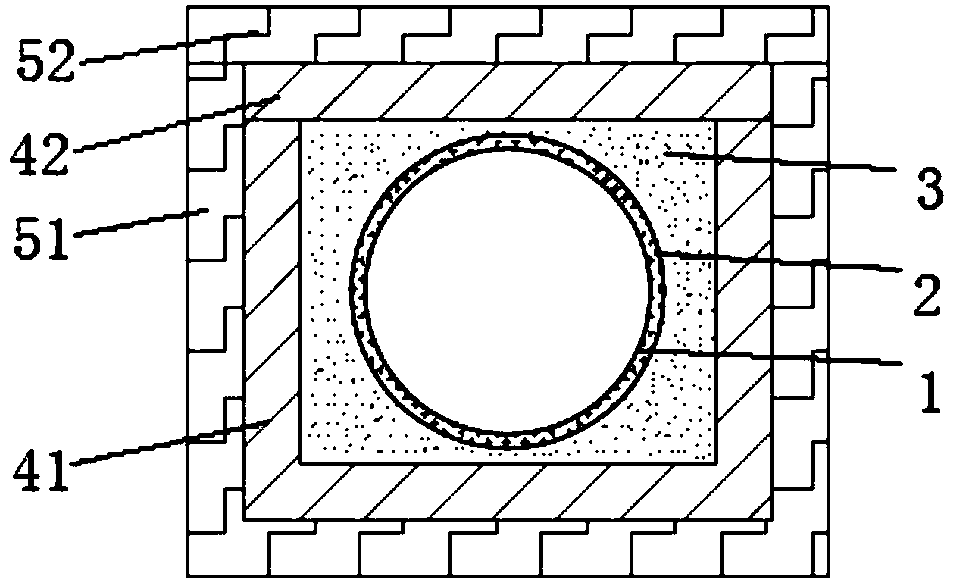

Fumigation solution atomization device based on fumigation food processing and atomizing method

ActiveCN109699729ASmall particlesImprove atomization qualityMeat/fish preservationFood processingEngineeringFood processing

The invention discloses a fumigation solution atomization device based on fumigation food processing and an atomizing method, and relates to the technical field of fumigation food processing. The fumigation solution atomization device comprises a car carrier, wherein an atomizing unit is fixedly mounted on one side close to an exhaust fan, on the upper surface of the car carrier; an outlet of a transfer pump is fixedly connected with an inlet of the atomizing unit through a conveying pipe I; and a driving motor is fixedly mounted on one side close to the atomizing unit, on the upper surface ofthe car carrier. The invention further discloses an atomizing method of the fumigation solution atomization device based on fumigation food processing. The atomizing method comprises the steps of adding a fumigation solution, starting conveying, breaking up atomizing, and performing attraction conveying. According to the fumigation solution atomization device, a heating atomizing manner for conventional fumigation materials is rejected, and a centrifugal atomization manner is used for atomizing treatment on the fumigation solution. The centrifugal atomization can complete atomizing only needing to provide impact centrifugal environment. Compared with the heating atomizing manner, the centrifugal atomization is more energy-saving and environment-friendly, and formed atomized liquid is small in granules and high in atomizing quality.

Owner:烟台爵巧食品有限公司

Saver and cleanser for gasoline

InactiveCN1445341AImprove atomization qualityLower activation energyLiquid carbonaceous fuelsAlcoholCombustion

An oil-saving cleaner of gasoline for car contains cleaning disperser (the mixture of dichloroethane and N-methyl-2-pyrrolidone), combustion promoter (alcohol-in-benzene), anti-explosion agent (the mixture of ferrocene and isopropanol), polar solvent (methanol or ethanol) and non-polar solvent (benzene, toluene, xylene, or their mixture). It can improve performance of gasoline, clean gasoline, making gasoline fully burn, and decrease pollution of tail gas.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

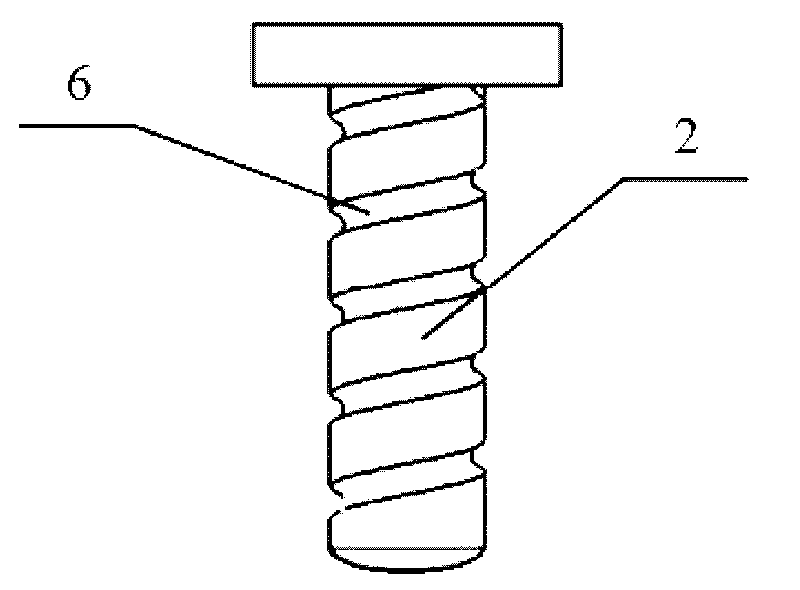

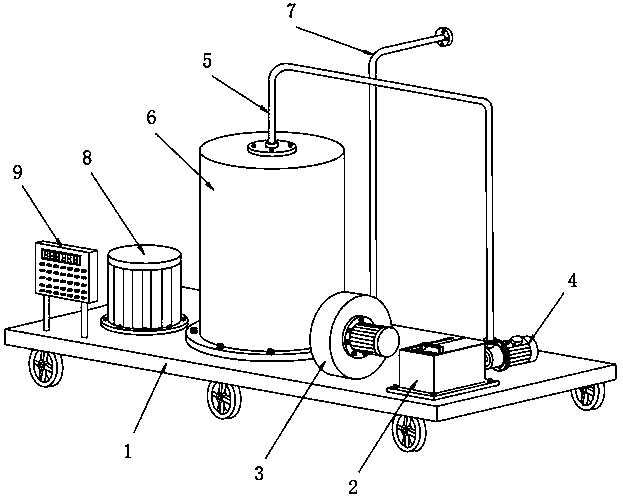

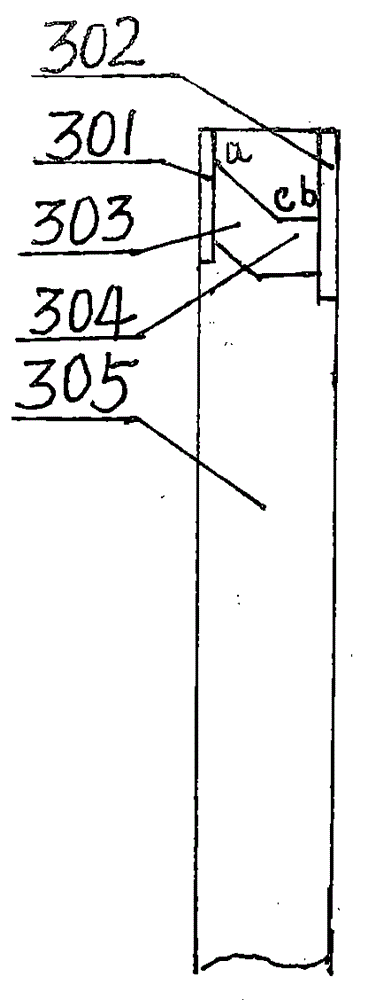

Novel atomizing nozzle based on bubble cutting

PendingCN110449283ASmall diameterImprove atomization qualityLiquid spraying apparatusEngineeringMixing chamber

The invention provides a novel atomizing nozzle based on bubble cutting. The novel atomizing nozzle comprises an internal assembly and an external assembly, wherein closed space formed by the internalassembly and the external assembly constitutes a mixing chamber of the nozzle, the internal assembly comprises an inner core and a bubble divider, the external assembly comprises a casing and a sprayhead, a first air inlet hole is formed in the top of the inner core, an external thread is formed at the upper part of the inner core below the first air inlet hole, multiple second air inlet holes are formed in the inner core below the external thread, and swirling grooves are formed in the inner core located below the second air inlet holes; the casing is a hollow opening round tube, an internal thread at the upper part of the casing is tightly connected with the external thread on the inner core through a sealing structure, a liquid inlet hole is formed in the side surface of the casing, and an external thread is formed at the lower part of the casing; an internal thread is formed at the upper part of the spray head, a spray hole is formed in the central position of the closed end of the spray head, the bubble divider is mounted in a hollow cavity in the lower part of the casing, and the casing and the bubble divider are tightly connected with the spray head through a sealing structure. The novel atomizing nozzle has higher atomizing quality, and the average diameter of particles is smaller and more uniform.

Owner:HEBEI UNIV OF TECH

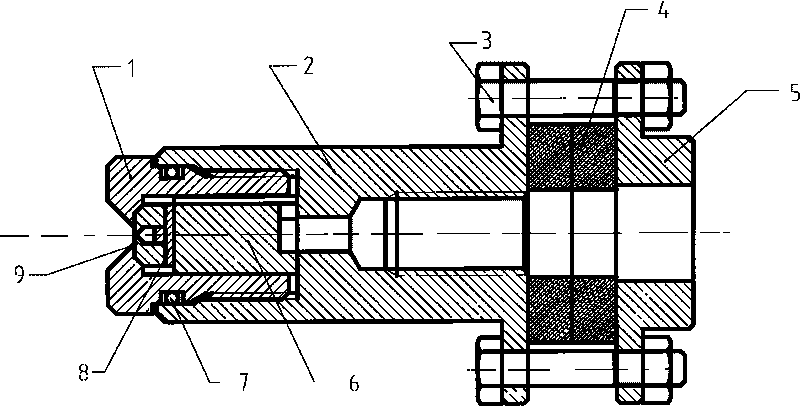

In-line type fuel pump with variable pre-travel as well as accurately-controlled SCR (selective catalyst reduction) system of in-line type fuel pump

ActiveCN104948365AReduce start-up smokeReduce the content of particulate matterInternal combustion piston enginesExhaust apparatusShape changeChemical reaction

The invention relates to an in-line type fuel pump with a variable pre-travel as well as an accurately-controlled SCR (selective catalyst reduction) system of the in-line type fuel pump. The fuel pump comprises a fuel pump assembly and the SCR system, wherein a fuel pump body is connected with a pump body of a urea pump; a fuel pump cam shaft is connected with a urea pump cam shaft; a fuel pump pull rod is connected with a urea pump pull rod; the fuel pump is connected with the SCR system through the urea pump; a speed regulator of the fuel pump synchronously and accurately controls the fuel injection quantity of the fuel pump and the liquid spraying quantity of the urea pump according to the work condition of a diesel engine. The pump end pressure is increased by reducing the diameter of a plunger of the fuel pump; the content of CO (carbon monoxide), HC (hydrocarbon compounds) and especially NOx in tail gas of the diesel engine of the fuel pump with the variable pre-travel can be effectively reduced due to shape change of a work surface of the plunger; the urea pump synchronously and accurately controlled by the speed regulator can spray a urea solution matched with the content of NOx in the tail gas of the diesel engine at any time, and the urea solution can have a chemical reaction after entering an SCR box to further eliminate remaining NOx; the fuel consumption, the urea consumption and the fault rate of the diesel engine can be effectively reduced on the premise that exhaust emission meets a standard.

Owner:ANHUI HONGFU NEW AUTOMOBILE SCI & TECH

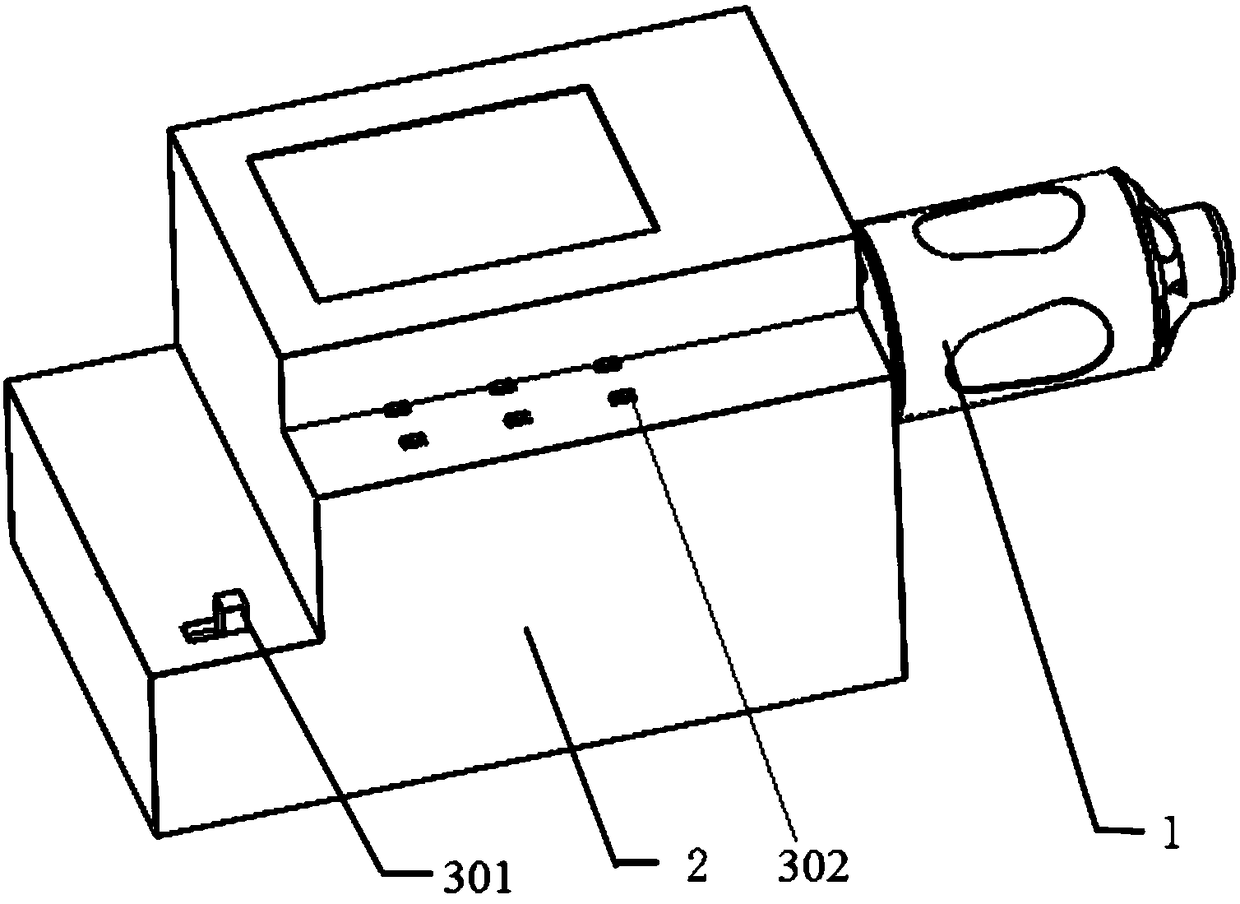

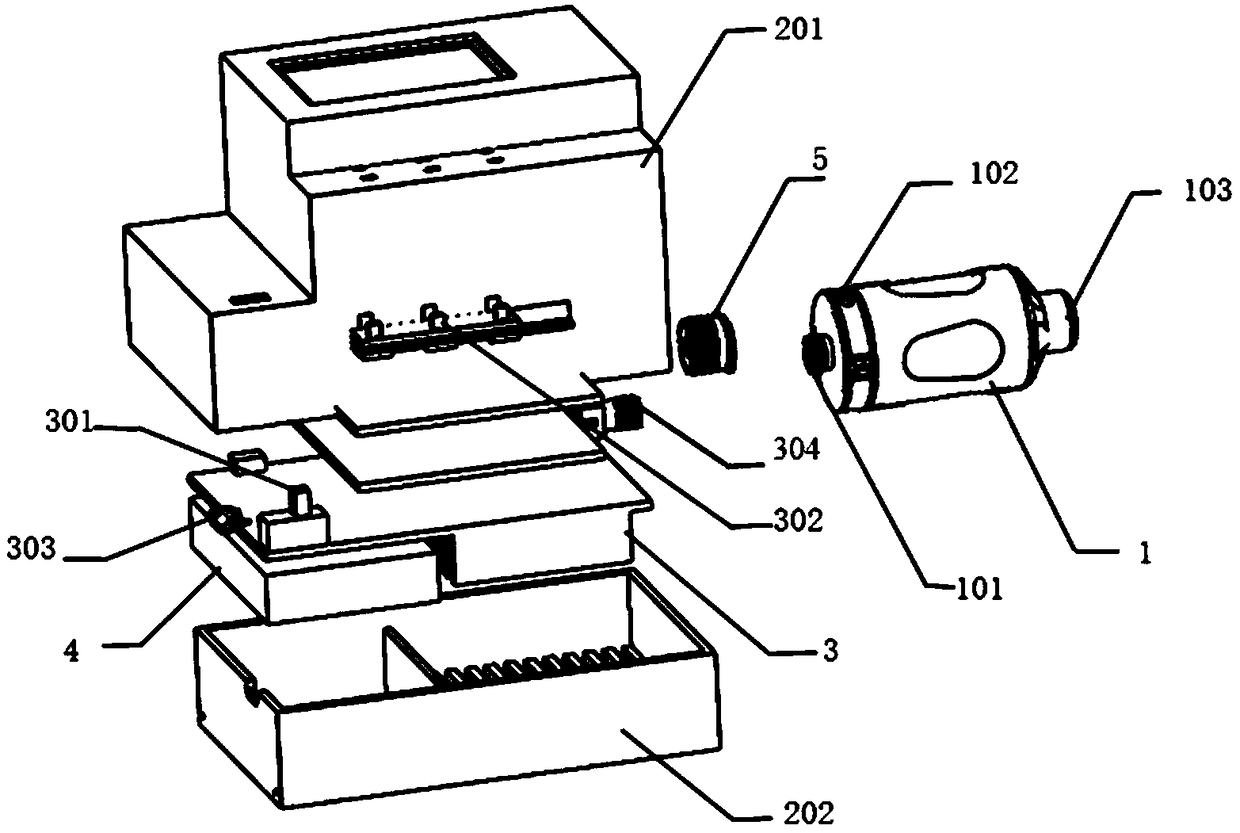

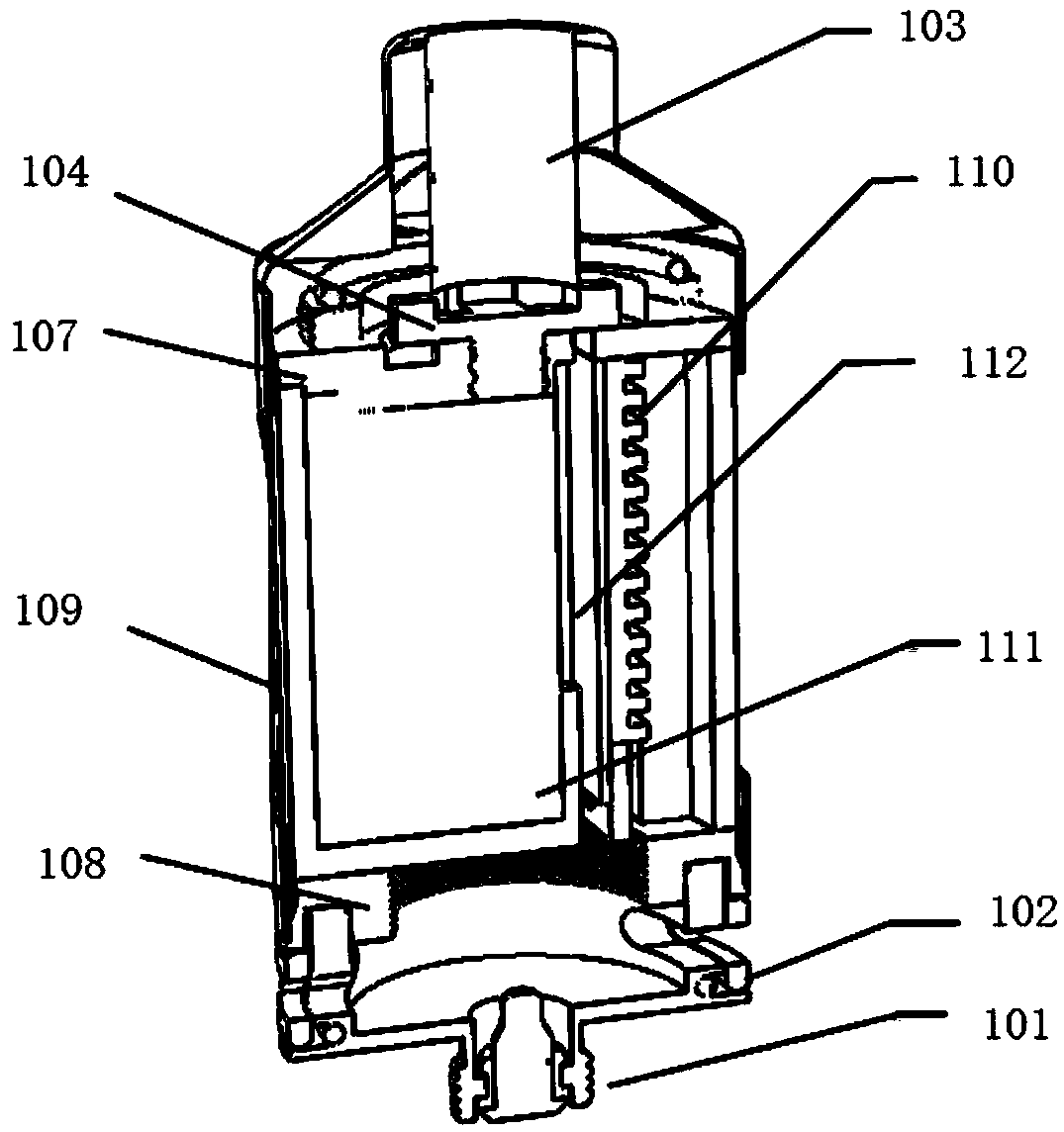

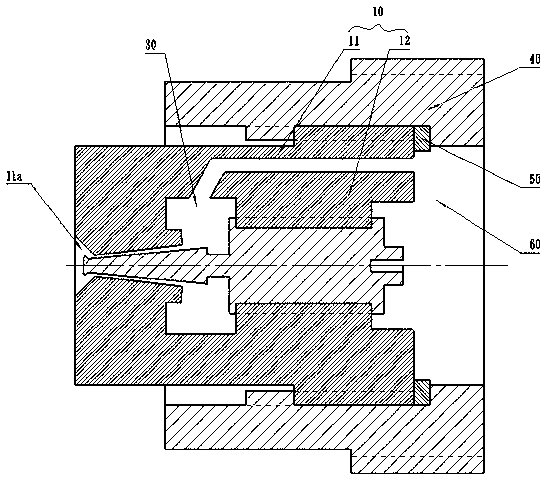

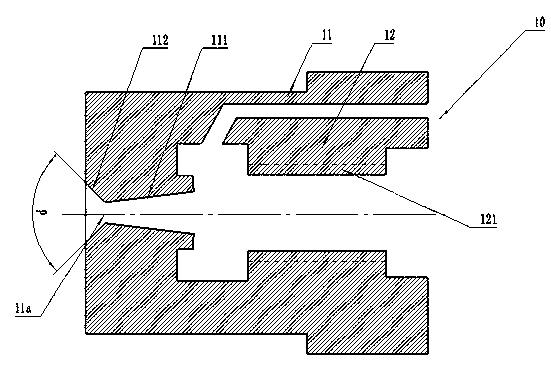

Electronic smoking set capable of outputting smoke with different particle sizes and method for applying electronic smoking set

PendingCN109480335AUniform atomizationImprove atomization qualityTobacco devicesNebulizerEngineering

The invention discloses an electronic smoking set which comprises an atomizer (1), a shell (2), a radiofrequency signal source (3) and a threaded shaft sleeve (5). The radiofrequency signal source (3)is positioned in the shell (2); an atomization chip (110) and oil guide cotton (112) are arranged in the atomizer (11), the oil guide cotton (112) clings onto the atomization chip (110), and a plurality of interdigital transducers (1102) with different wavelengths are arranged on the atomization chip (110) and can be driven by radiofrequency signals to generate traveling waves and acoustic surface waves, so that cigarette liquid on the oil guide cotton (112) can be atomized; the atomizer (1) and the radiofrequency signal source (3) are connected with each other by the threaded shaft sleeve (5). The invention further discloses a method for applying the electronic smoking set.

Owner:CHINA TOBACCO YUNNAN IND

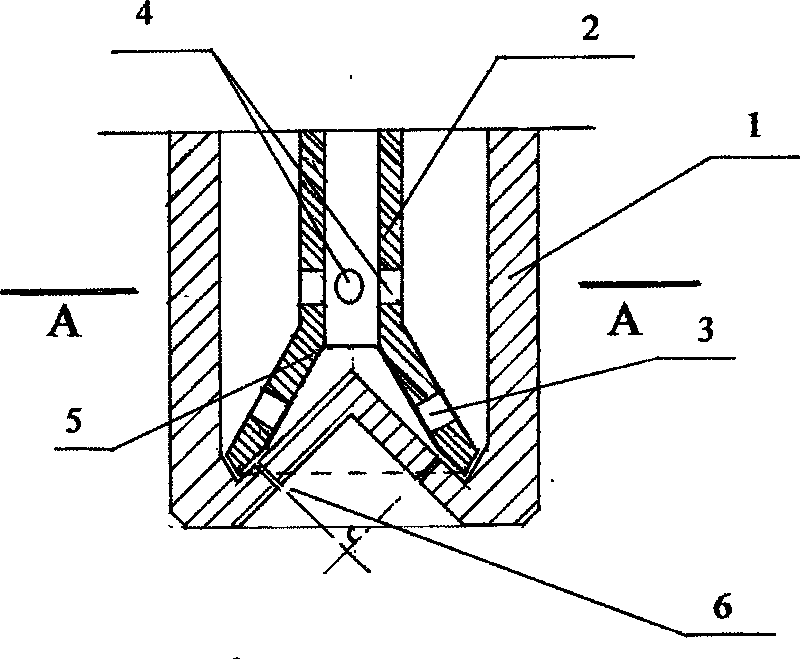

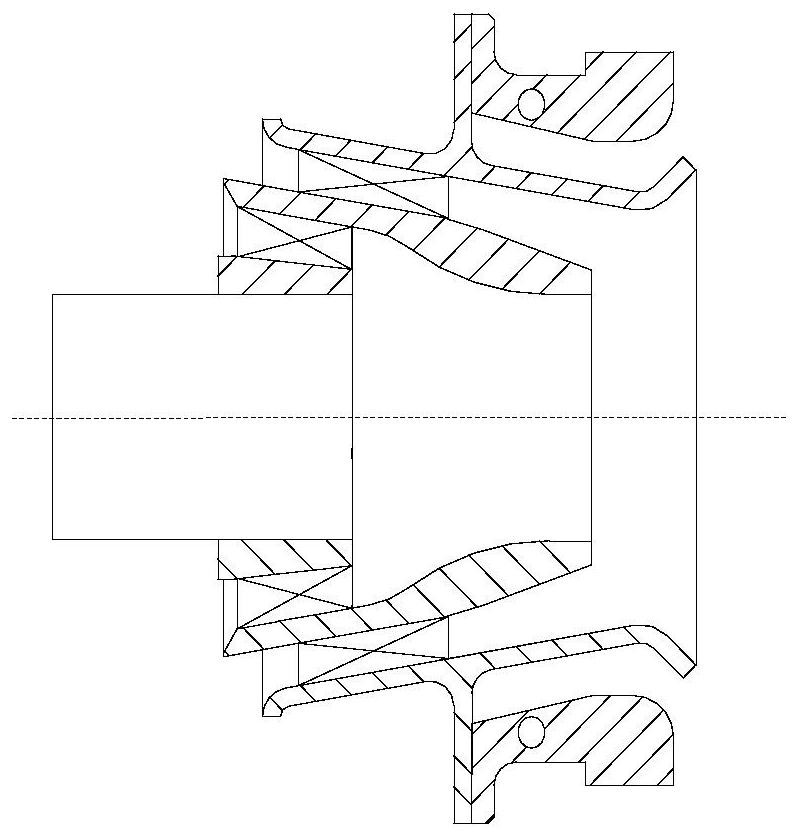

Heavy oil catalysis atomizing nozzle

InactiveCN104293373AImprove atomization qualitySimple structureCatalytic crackingLiquid spraying apparatusFuel oilMixing chamber

The invention relates to a heavy oil catalysis atomizing nozzle, which comprises a first mixing chamber, a second mixing chamber, a nozzle chamber and a nozzle, the first mixing chamber and the second mixing chamber are fixed in the nozzle chamber, the first mixing chamber is arranged at an inlet end of the nozzle chamber, and the nozzle is arranged at an outlet end of the nozzle chamber; the heavy oil catalysis atomizing nozzle also comprises an atomization structure which is fixedly arranged in the nozzle chamber; the atomization structure comprises a support member and an atomization body, and the support member and the atomization body are fixed together. According to the invention, oil and gas are fully mixed, by means of the atomization body, oil and gas can be fully atomized to form a taper-shaped controllable solid mist field, and the heavy oil catalysis atomizing nozzle has the advantages of simple structure, convenient usage, good operation elasticity and high reliability.

Owner:洛阳帝博石化装备有限公司

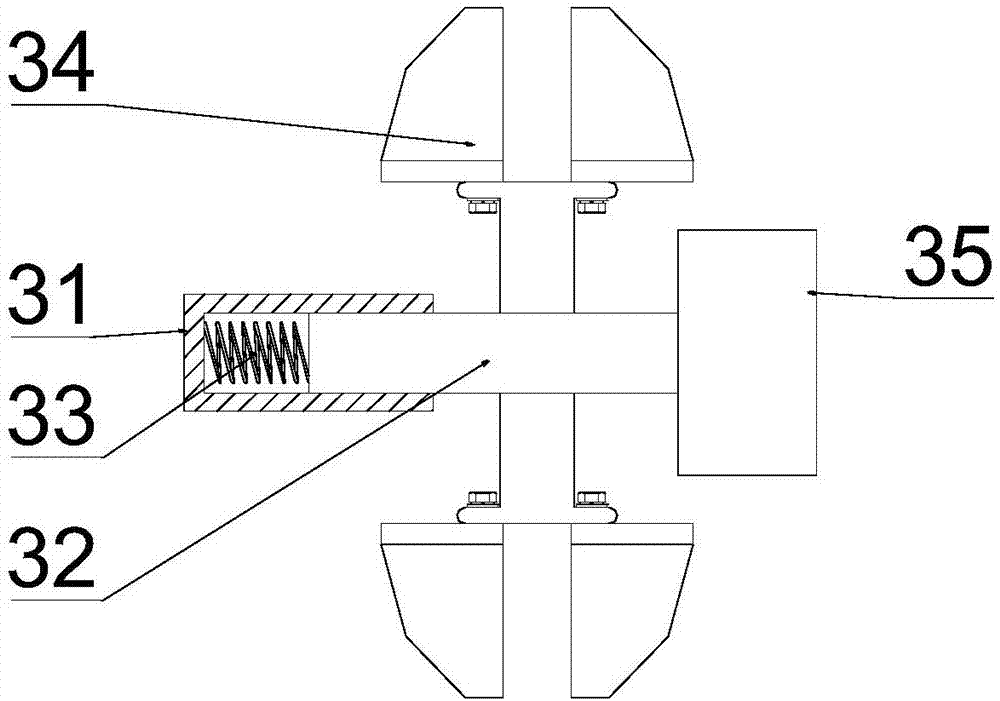

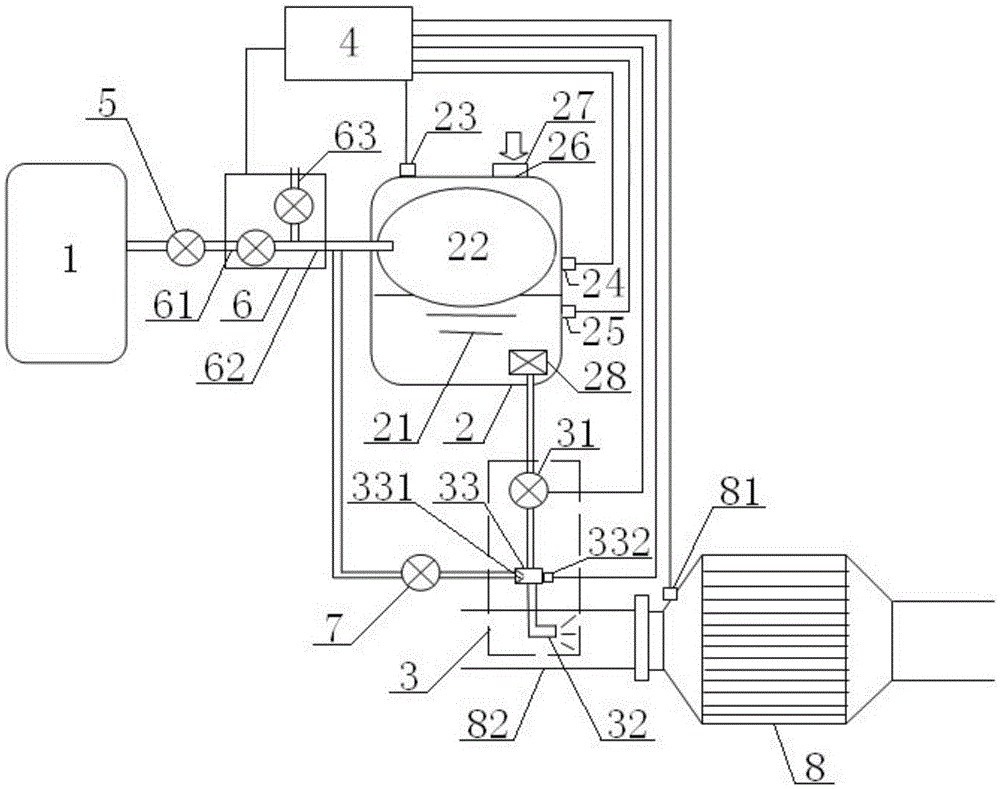

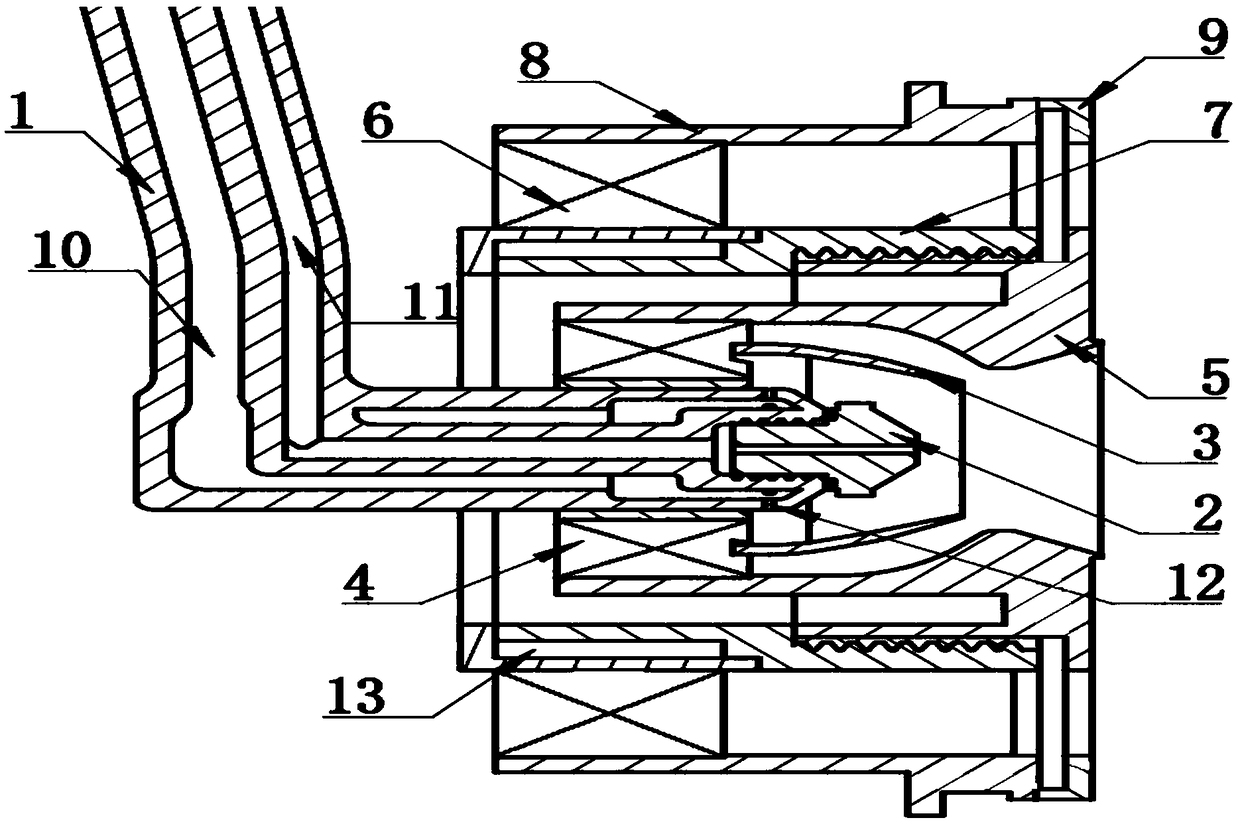

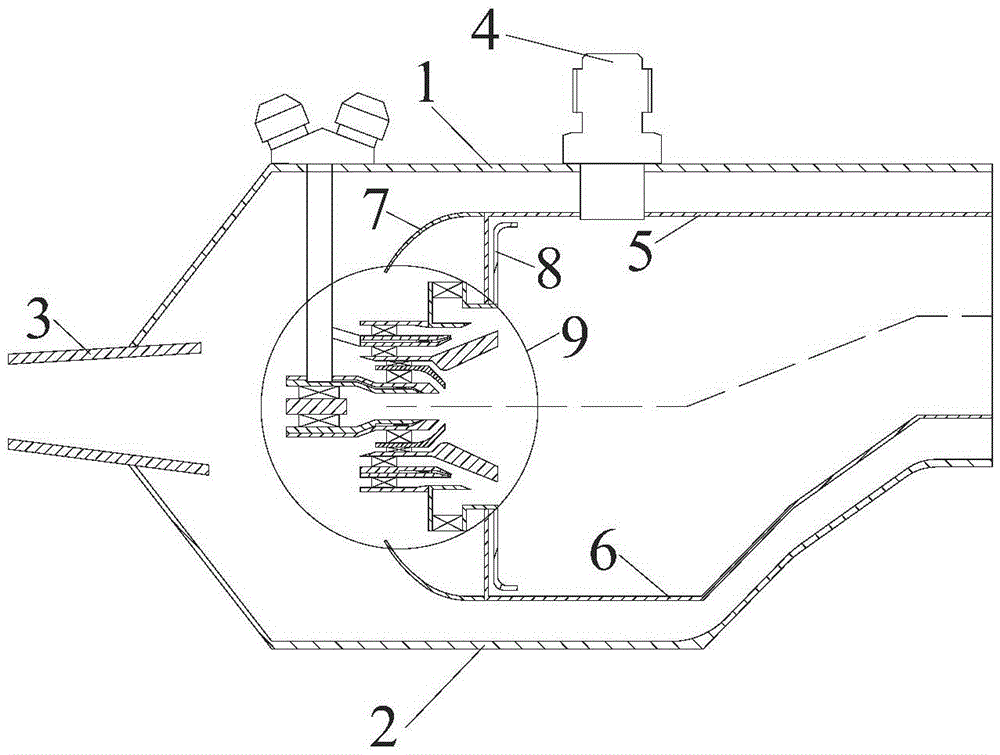

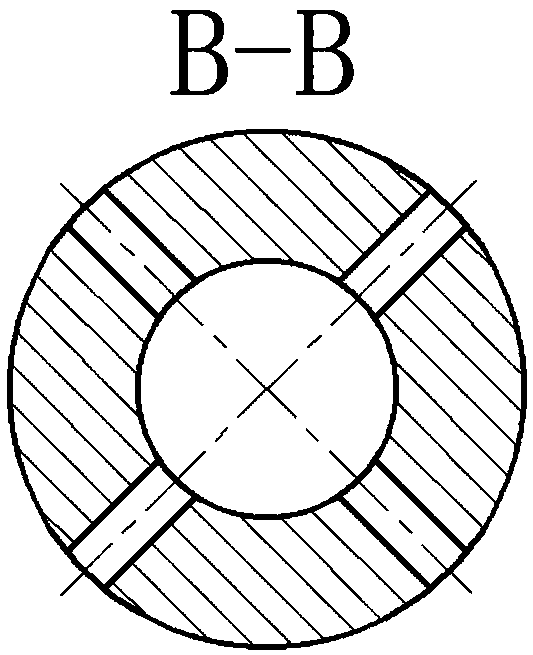

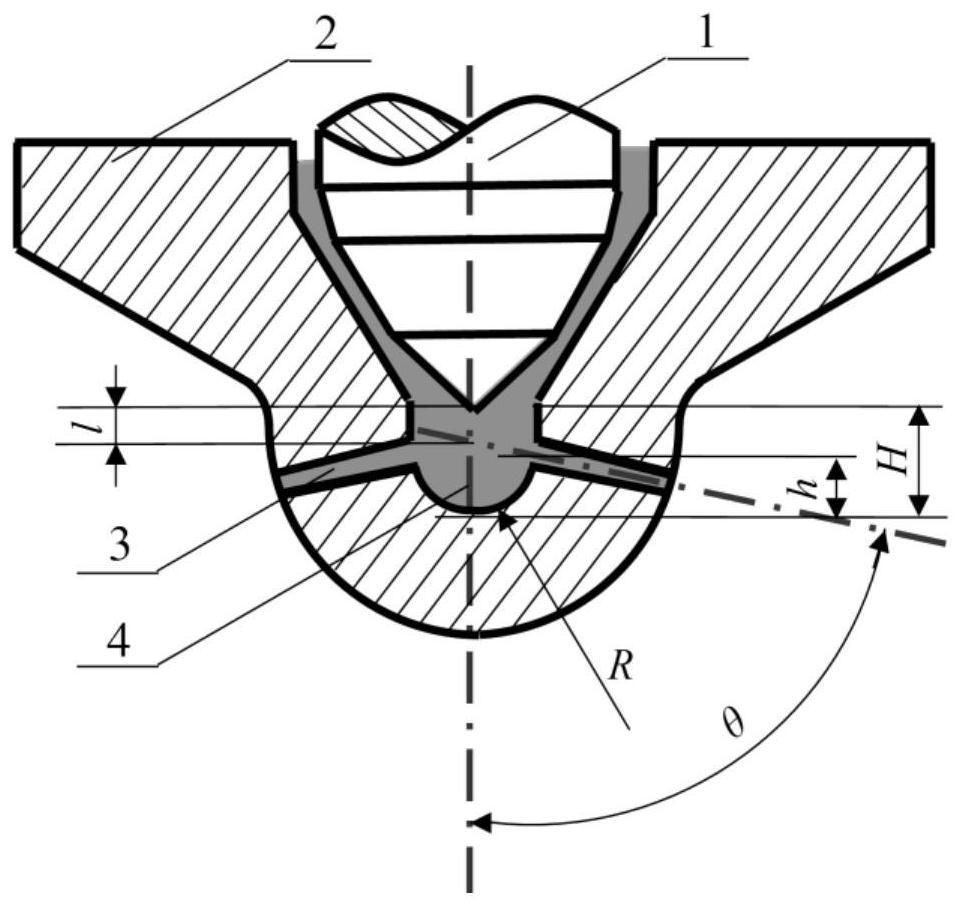

Center split-stage low-emission combustor head having precombustion stage with pre-film plate structure

ActiveCN108916911AImprove atomization qualityImprove atomization effectContinuous combustion chamberCycloneCombustion chamber

The invention discloses a center split-stage low-emission combustor head having a precombustion stage with pre-film plate structure. The center split-stage low-emission combustor head has split-stagecenter and dual-oil-circuit precombustion stage design. Dual oil circuits of the precombustion stage include a main oil circuit and an auxiliary oil circuit. In case of low fuel flow, only the auxiliary oil circuit of the precombustion stage provides fuel so that a nozzle gains high atomizing quality under small conditions. In case of high fuel flow, the main oil circuit and auxiliary oil circuitof the precombustion stage provide fuel at the same time. The fuel supplied by the main oil circuit of the precombustion stage is sprayed to the inner surface of a pre-film plate through spray holes of the main oil circuit of the precombustion stage, and an oil film is formed. The oil film breaks under the action of internal and external air cyclones, and good atomizing effect can be ensured. Theprecombustion stage dual-oil-circuit design can ensure high atomizing quality for the nozzle within a wide working pressure range, sufficient combustion of the fuel in a combustor is benefited, and pollutant generation is reduced.

Owner:BEIHANG UNIV

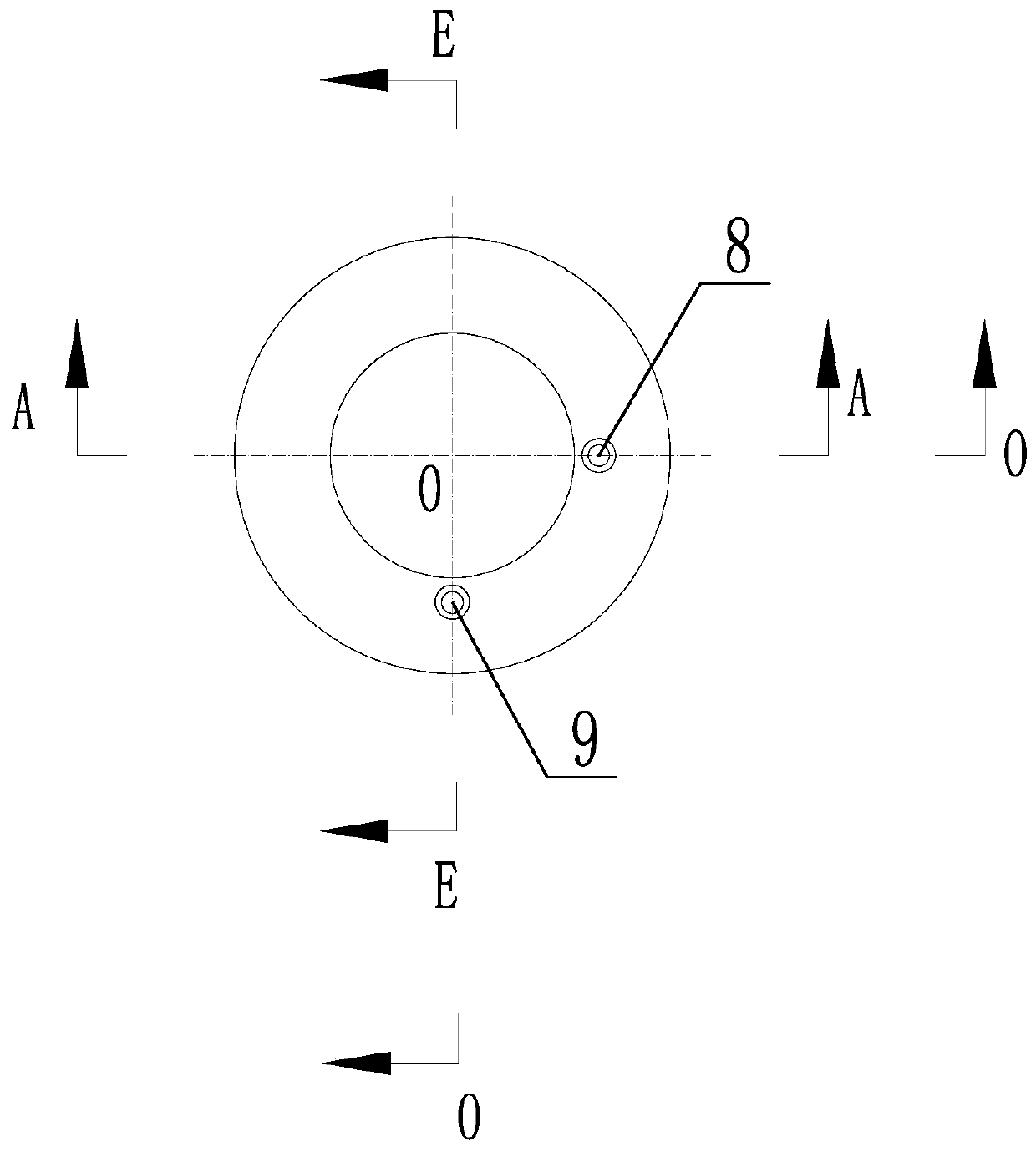

A two-stage pre-film layered partly premixed high-temperature rise combustor structure

ActiveCN104406196BMore air intakeWiden the stable working range of combustionContinuous combustion chamberDual stageCombustion chamber

The invention discloses a two-stage prefilming delamination part premixing high-temperature-rise combustion chamber structure. The flame of a main combustion region in a combustion chamber is divided into a precombustion stage and a main combustion stage which respectively adopt diffusion combustion and fuel oil direct spray combustion, and the diffusion combustion and the fuel oil direct spray combustion are coupled for realizing the delamination part premixing combustion. Both main combustion stage fuel oil and precombustion stage fuel oil adopts an in-passage prefilming air atomization technology, the precombustion stage utilizes a rotational flow and flange stabilizing device for enlarging the stable work range of an engine in the small-thrust state and providing a stable ignition source for the two-stage prefilming delamination part premixing high-temperature-rise combustion chamber under the great-thrust state of the engine, and the main combustion flame utilizes rotational flow and precombustion stage flame for providing high-temperature fuel gas stable flame. A precombustion stage spray nozzle improves the atomization quality through two-stage rotational flow prefilming air atomization, and a main combustion stage spray nozzle realizes fast uniform blending mixing of oil and gas in a way of separating the fuel oil atomization process from the blending and mixing process.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

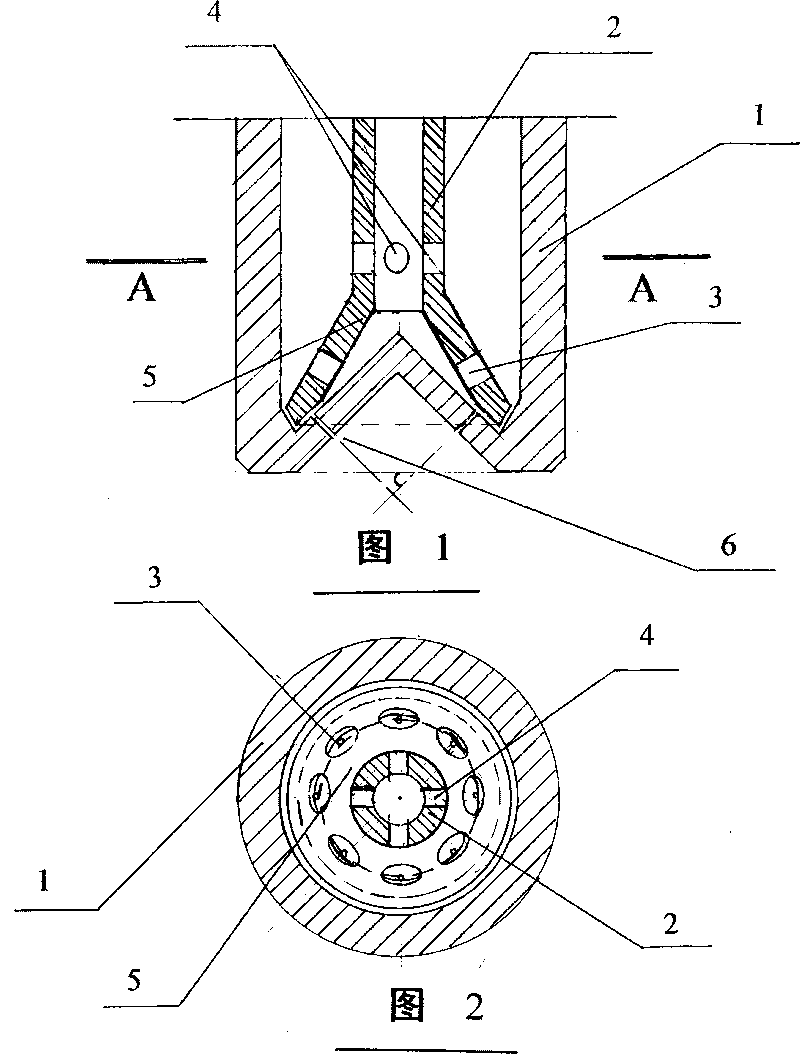

Fuel injection nozzle of opposite-spraying atomizing internal combustion engine

InactiveCN101749160AEasy to replaceImprovement of energy saving and emission indicatorsFuel injection apparatusMachines/enginesInjection pressureJet engine

The invention provides a fuel injection nozzle of an opposite-spraying atomizing internal combustion engine. On the basis of a traditional fuel injection nozzle, the original needle valve is changed to a cup-shaped tubular valve which is sleeved on a conical valve seat to control a plurality of oil injection holes on the valve seat. The bottom of the fuel injection nozzle and the valve seat are correspondingly provided with conical pits, the oil injection holes correspondingly arranged on the valve seat inject oil beams with the same horizontal included angle, a plurality of oil beams are oppositely impacted at the same potion, thus, the primarily atomized fuel particles are secondarily atomized. By using the fuel injection nozzle of the invention, the construction is simple, the manufacture is easy, and more excellent atomization effect can be obtained under the same oil injection pressure. The fuel injection nozzle is capable of replacing the traditional fuel injection nozzles and widely applied to the prior engines. The fuel injection nozzle can be made into the fuel injection nozzle of diesels or the fuel injection nozzle of gasoline engines and can be applied to the fuel injection nozzle of jet engines and mechanical equipment needing to atomize fuel.

Owner:么烈

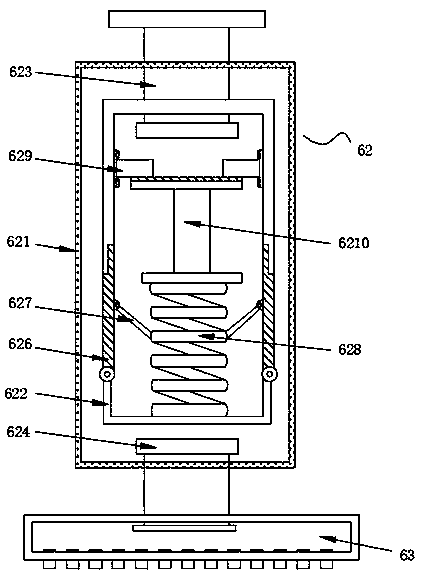

Double-pre-film type ultrasonic spray nozzle

PendingCN108644810AImprove atomization qualityIncrease contact areaContinuous combustion chamberResonant cavityCombustor

The invention discloses a double-pre-film type ultrasonic spray nozzle, specially an ultrasonic atomizing spray nozzle suitable for a combustor, which belongs to the field of industrial combustion. The double-pre-film type ultrasonic spray nozzle comprises a spray tube, a central rod, a resonant cavity, a flat gasket and a hexagonal nut, wherein the outlet section of the spray tube is equipped with a convergent spray tube; the inner part at the left end of the central rod is hollow; the right end of the central rod is equipped with a solid rod; the outer surface of the solid rod is tapped withthreads; and the resonant cavity, the flat gasket and the hexagonal nut are connected by the central rod. Double-pre-film type oil spray and convergent spray tube type design are adopted, so that thespray nozzle can realize secondary atomizing; fuel oil flow and air flow can be met according to the dimension of a to-be-regulated structure; and meanwhile, a distance from the resonant cavity to anoutlet of the spray tube can be regulated to obtain different spray angles. The double-pre-film type ultrasonic spray nozzle is simple in structure, is small in gas-liquid ratio, is good in atomizingeffect, is great in atomizing angle variable range, sufficiently utilizes structure characteristics, flow field characteristics and sound pressure characteristics of an ultrasonic generator, greatlyimproves atomizing quality of fuel oil from structure and principle, and improves combustion efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

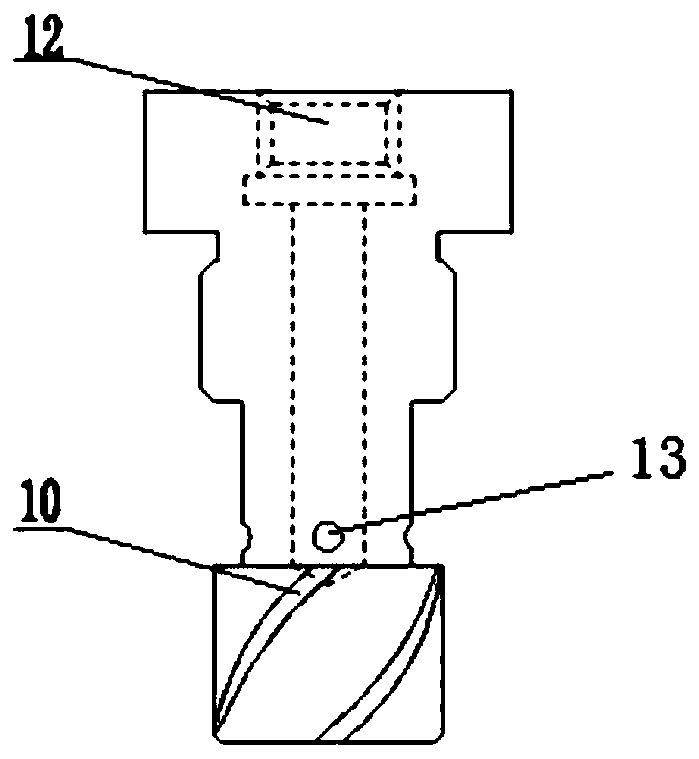

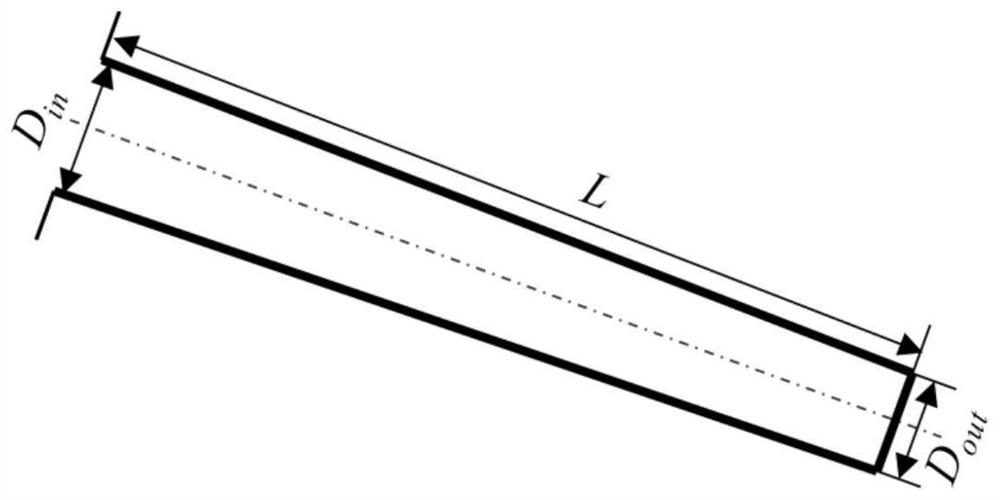

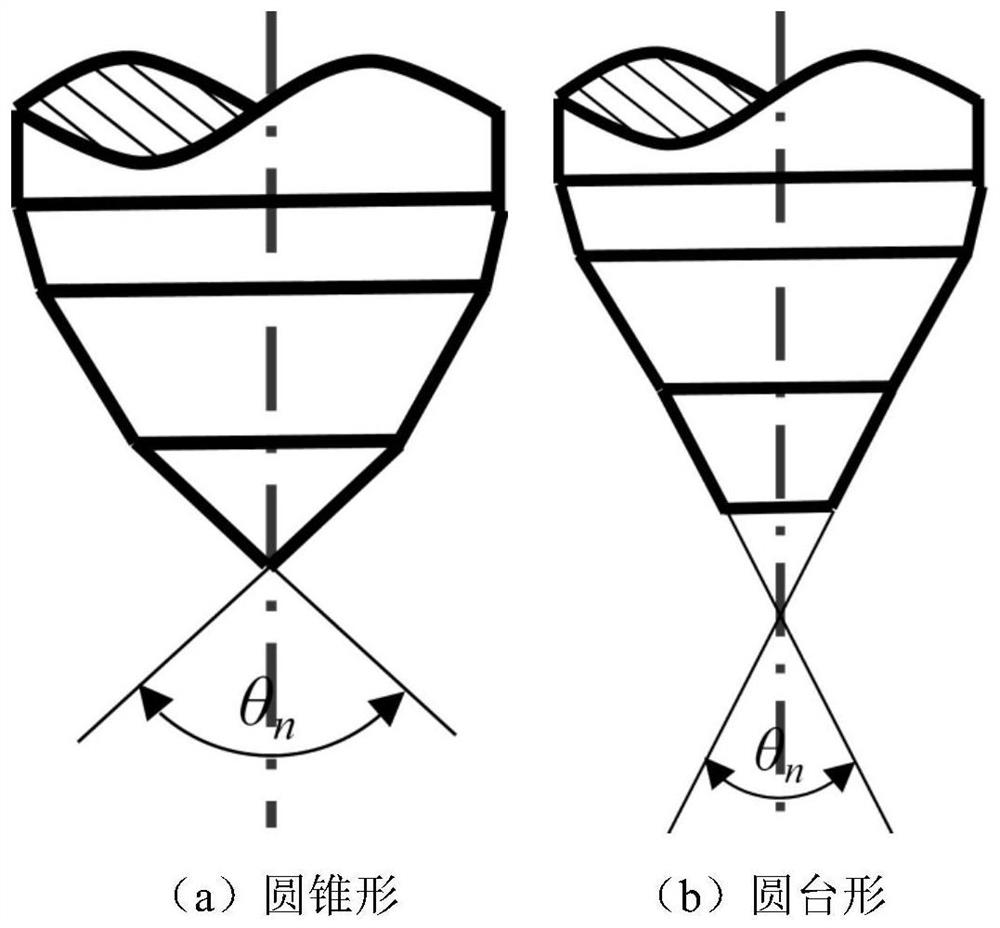

Diesel injector based on nozzle inner vortex cavitation induced hollow spraying structure

ActiveCN112228262AEnhancing and stabilizing the cavitation phenomenon of inner vortex linesEnhance and stabilize cavitationInternal combustion piston enginesFuel injection apparatusDiesel injectorDieseling

The invention discloses a diesel injector based on a nozzle inner vortex cavitation induced hollow spraying structure. The diesel injector comprises a needle valve, a needle valve body, spraying holesand a pressure chamber; the axis of the needle valve of the injector coincides with the axis of the needle valve body; the multiple identical reduced conical spraying holes are evenly distributed inthe head of the needle valve body; and the outlet ends of all the spraying holes communicate with the pressure chamber. The pressure chamber of the injector is composed of the hemisphere and the cylinder which are equal in diameter, the geometrical structure of the injector is optimized, the vortex cavitation phenomenon in the diesel injector under different loads is strengthened, and the fuel atomization quality of the injector is effectively improved.

Owner:JIANGSU UNIV

Heavy oil catalysis atomizing nozzle

ActiveCN104293372AImprove atomization qualitySimple structureCatalytic crackingSpray nozzlesFuel oilMixing chamber

The invention relates to a heavy oil catalysis atomizing nozzle, which comprises a first mixing chamber, a second mixing chamber, a nozzle chamber and a nozzle, the first mixing chamber and the second mixing chamber are fixed in the nozzle chamber, the first mixing chamber is arranged at an inlet end of the nozzle chamber, and the nozzle is arranged at an outlet end of the nozzle chamber; the heavy oil catalysis atomizing nozzle also comprises an atomization structure which is fixedly arranged in the nozzle chamber; the atomization structure comprises a support member and an atomization body, and the support member and the atomization body are fixed together; and the shape of the atomization body can be spherical shape, semispherical shape, progressively arc, elliptical shape or paraboloid. According to the invention, oil and gas are fully mixed, by means of the atomization body, oil and gas can be fully atomized, the taper-shaped controllable solid mist field can be formed, and the heavy oil catalysis atomizing nozzle has the advantages of simple structure, convenient usage, good operation elasticity and high reliability.

Owner:洛阳帝博石化装备有限公司

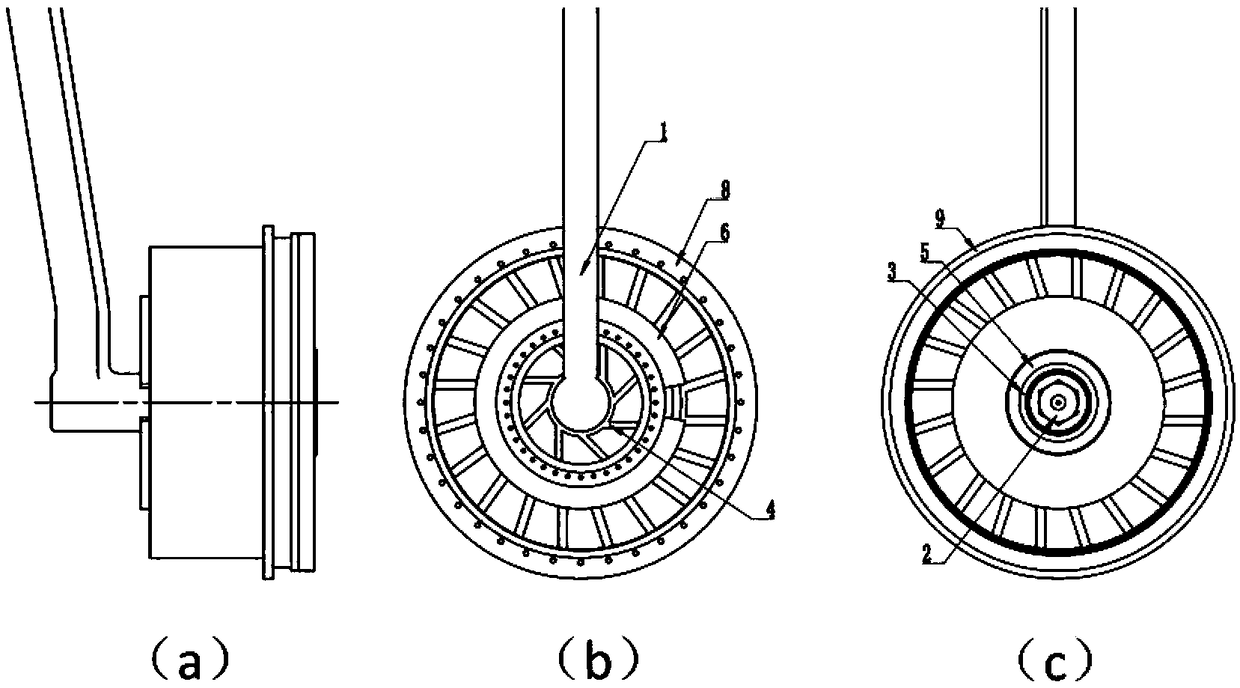

Machining ring type pre-film cyclone

InactiveCN113864822AImprove atomization qualityImprove qualityContinuous combustion chamberCombustion instabilityCombustion chamber

The invention provides a machining ring type pre-film cyclone. An outlet section of a sleeve of a conventional cyclone is designed into a machining ring structure, fuel oil sprayed out of a center nozzle impacts on a venturi tube to form an oil film, primary pre-film atomization is formed under the shearing action of primary cyclone gas and secondary cyclone gas, then oil mist passes through the arc surface of the machining ring structure to be subjected to secondary pre-film atomization, the fuel oil atomization quality can be effectively improved, the mixing and distribution of the fuel oil at an outlet of the cyclone are enhanced, the ignition performance of a combustion chamber is improved, and the temperature distribution of the outlet is improved. In addition, due to the introduction of a machining ring, the secondary cyclone gas flow enters the ring and can play a cooling role, meanwhile, due to the existence of a slope limiting area, the angle vortex of the combustion chamber can be weakened or eliminated, then the combustion instability is inhibited, and the ablation risk of a flame tube is reduced. The machining ring type pre-film cyclone can be used in the fields of gas turbine engines and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

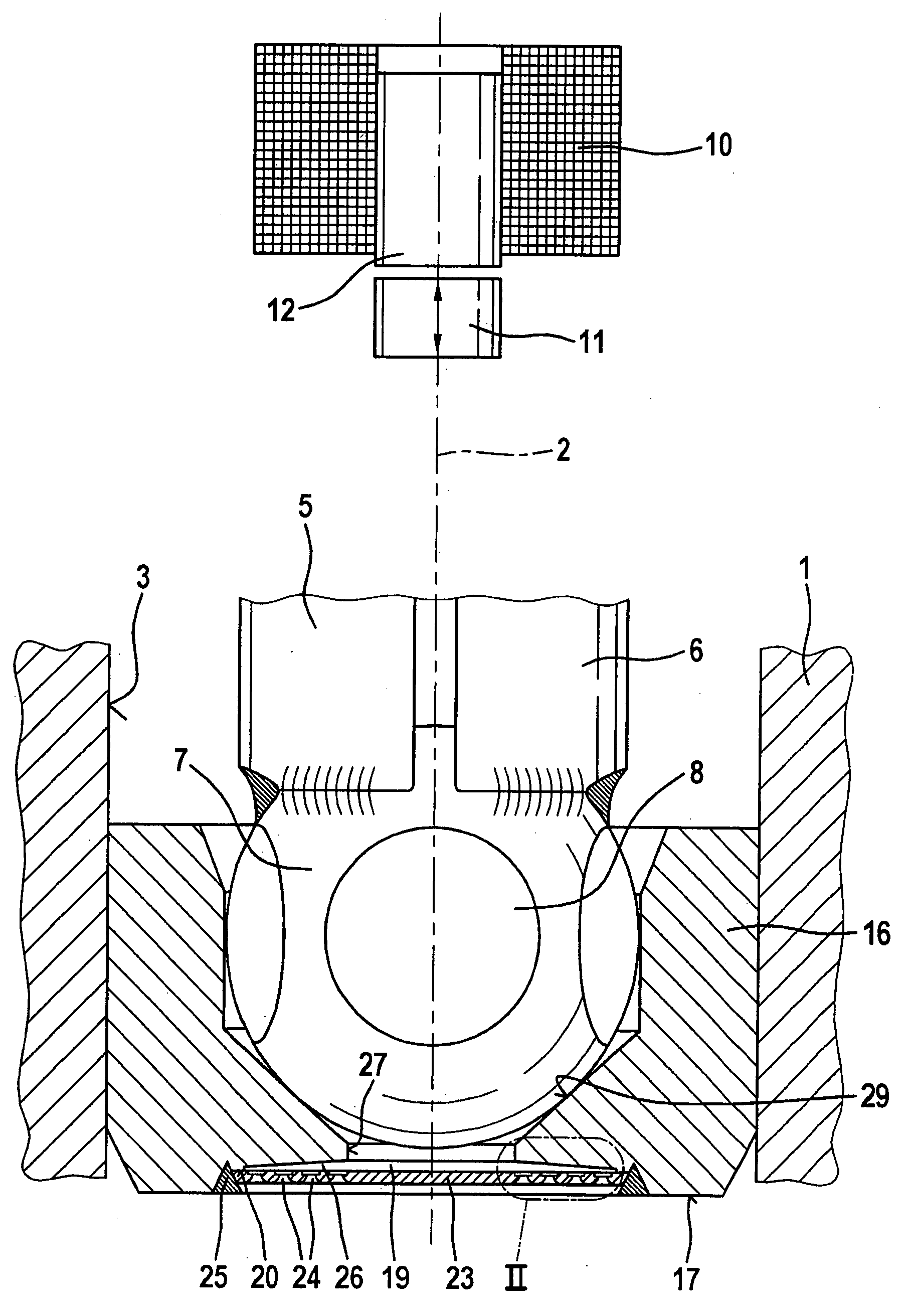

Fuel injector

InactiveUS20090057444A1Uniform and very fine atomization of fuelHigh conditioningSpray nozzlesFuel injection apparatusVena contracta diameterCombustion

The fuel injector configured according to the invention is characterized by an orifice plate being situated downstream from a valve-seat body having a fixed valve seat, the orifice plate having at least one outlet opening. Directly upstream from the outlet openings is an inflow opening having an annular inflow cavity. The valve-seat body covers the inflow cavity in such a way that the downstream outlet openings of the orifice plate are covered. The flow-exposed flow-through area above each outlet opening, which is calculated as the product of the circumference of the outlet opening in the region of its entry plane and the free height in the inflow cavity, is smaller than the area of the inflow plane of the outlet opening. The fuel injector is particularly suitable for use in fuel injection systems of the mixture-compressing internal combustion engines having externally supplied ignition.

Owner:ROBERT BOSCH GMBH

Hot-blowing adjustable nozzle

InactiveCN102937529AImprove atomization qualitySimple structureMachine part testingBurnersFuel supplyEngineering

The invention provides a hot-blowing adjustable nozzle which comprises a nozzle body and a nozzle core movably arranged in the nozzle body. The nozzle body comprises a nozzle casing and an installation portion which is used for installing the nozzle core and arranged in the nozzle casing; the inner wall surface of the nozzle casing and the outer wall surface of the installation portion form a fuel passage; and a nozzle opening communicated with the fuel passage is arranged in the nozzle casing. According to the hot-blowing adjustable nozzle, the nozzle core is movably arranged in the nozzle body, and a taper angle of a taper body is slightly smaller than a taper angle of an inner taper cavity, so that the hot-blowing adjustable nozzle can meet environment requirements of different fuel supplies and pressure, and fuel sprays sprayed out can be guaranteed to be uniform; an inverted taper body enable the fuel to be further impacted into particles to form fuel sprays, and the atomization quality is improved; and an adjustable opening is convenient for pushing the nozzle core to move axially, and various fuel supply environment requirements are met.

Owner:浙江奥凯嘉汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com