In-line type fuel pump with variable pre-travel as well as accurately-controlled SCR (selective catalyst reduction) system of in-line type fuel pump

A technology of SCR system and fuel pump, applied in charging system, fuel injection pump, combustion engine, etc., can solve problems such as less than ideal starting and climbing performance, inconvenient maintenance service, high-clean fuel dependence, etc., to eliminate harmful The effect of material and various huge expenses, improving idle speed stability, reducing production cost and failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

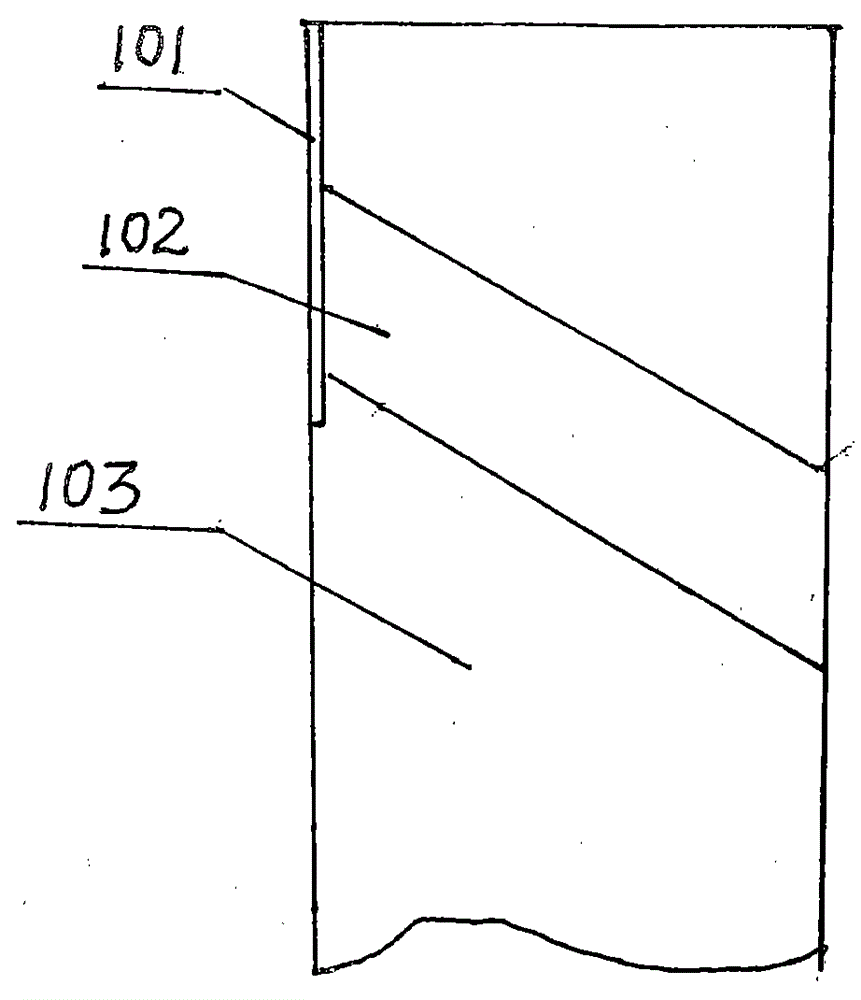

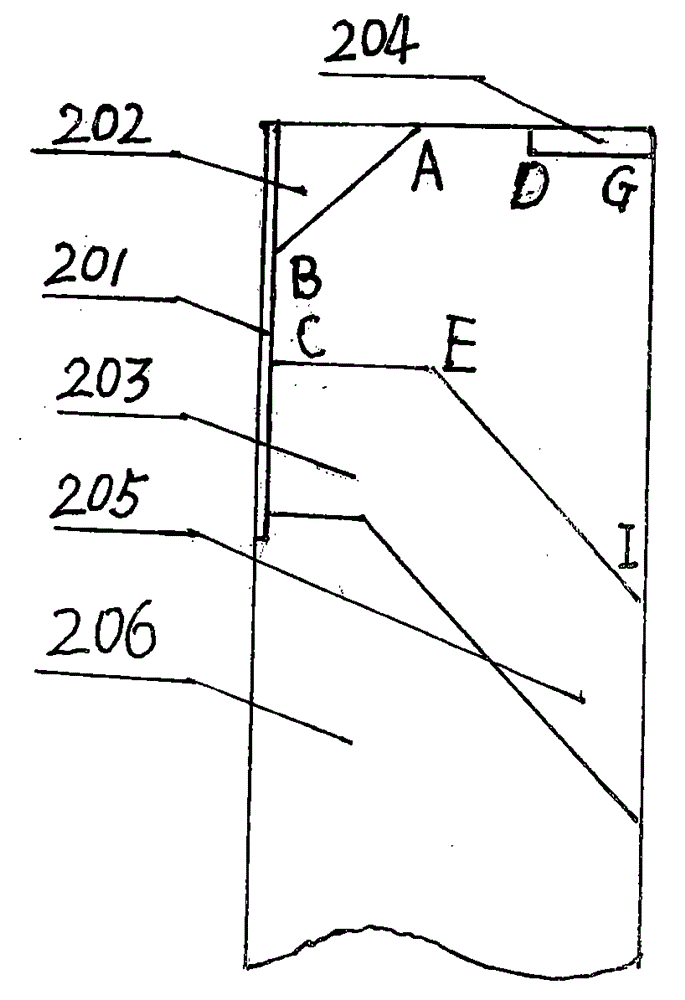

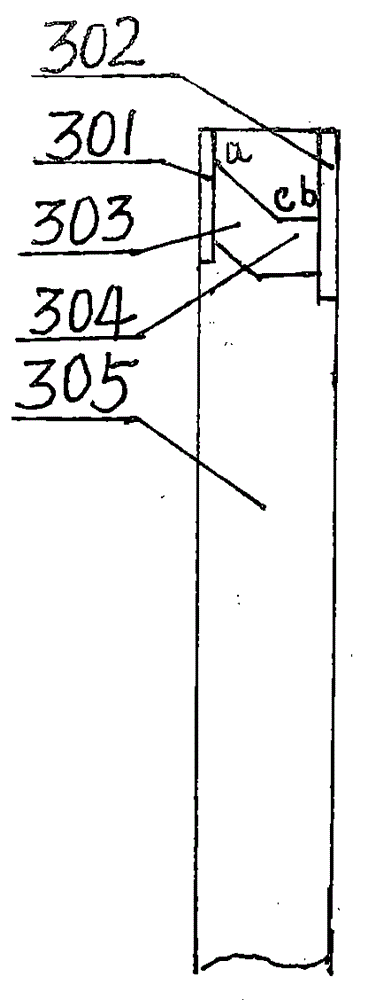

[0086] see Figure 5 , which shows a preferred embodiment of an in-line variable pre-stroke fuel pump and its precisely controlled SCR system of the present invention, including: a variable pre-stroke fuel pump assembly, an SCR system; the variable pre-stroke fuel pump The pump assembly includes: governor assembly, fuel pump assembly, fuel pump pump body, fuel pump camshaft, camshaft bearing, camshaft bearing seat, camshaft bracket, roller body assembly, fuel pump plunger couple , plunger spring, plunger spring upper seat, plunger spring lower seat, fuel pump outlet valve assembly, fuel outlet valve spring, volume reducer, fuel outlet valve tight seat, fuel pump pull rod (or rack), fuel volume adjustment Sleeve, oil volume adjustment ring gear; the SCR system includes: urea pump body, urea pump camshaft, urea pump plunger couple, plunger spring, plunger spring upper seat, plunger spring lower seat, urea pump pull rod , liquid volume adjustment sleeve, liquid volume adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com