Patents

Literature

65results about How to "Reduce the content of particulate matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

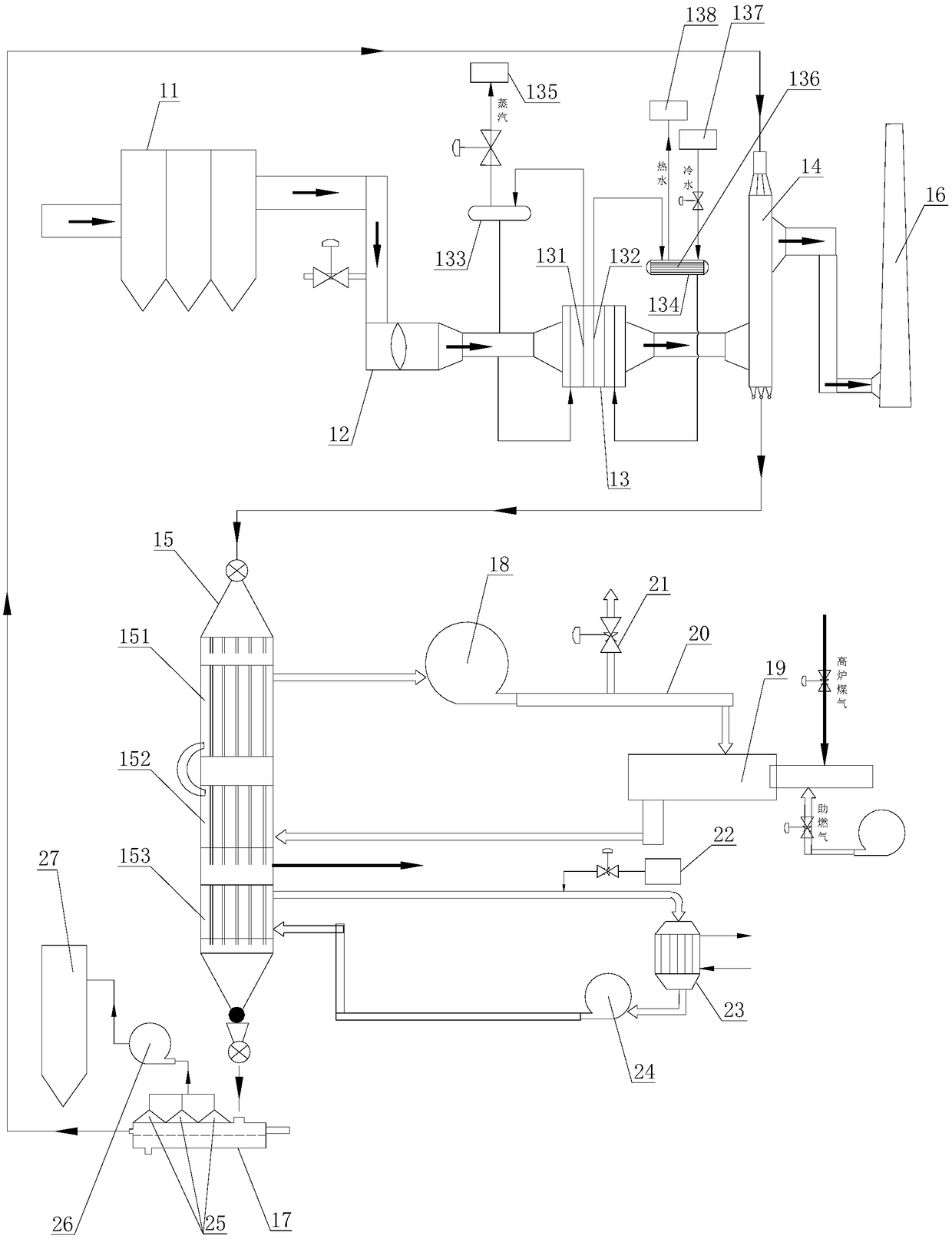

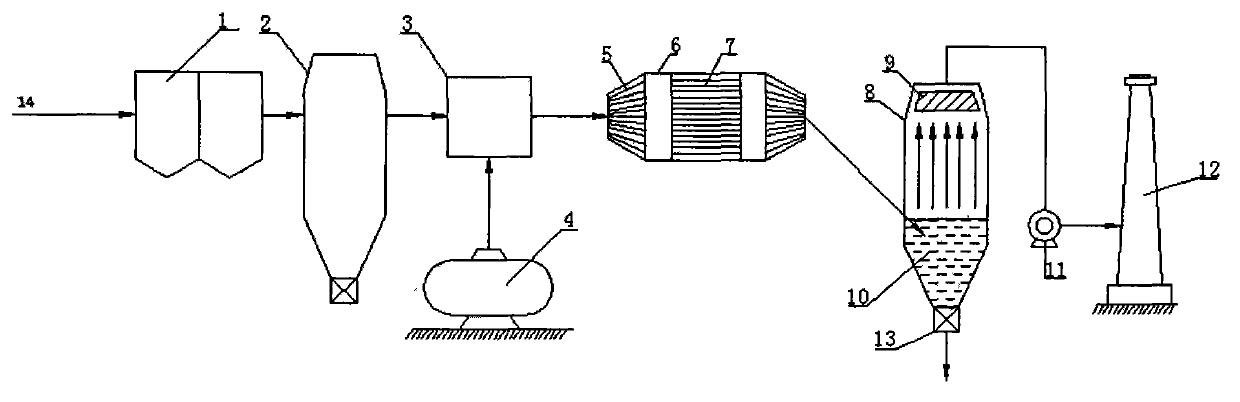

Flue gas desulfurization and denitration system

PendingCN109173570ATower resistance does not riseWill not cause forced production cutsGas treatmentDispersed particle filtrationBaghouseProcess engineering

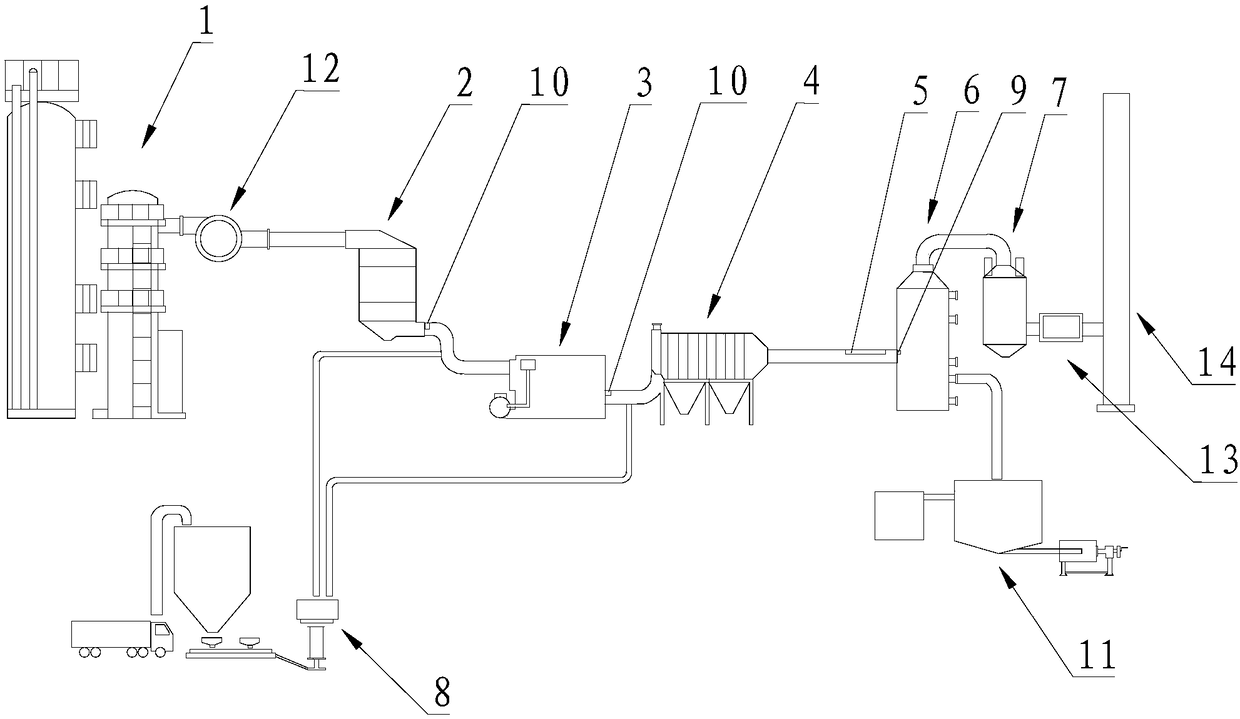

The invention discloses a flue gas desulfurization and denitration system. The system comprises a bag deduster, a booster fan, a waste heat boiler, an adsorption tower and a regeneration tower, the outlet of the bag deduster is communicated with the flue gas inlet of the waste heat boiler through the booster fan, the flue gas outlet of the waste heat boiler is communicated with the flue gas inletof the adsorption tower, the flue gas outlet of the adsorption tower is communicated with the chimney, a material outlet at the bottom of the adsorption tower is communicated with a material inlet atthe top of the regeneration tower, a material outlet at the bottom of the regeneration tower is communicated with a material inlet of a vibrating screen, and the oversize product outlet of the vibrating screen is communicated with a material inlet at the top of the adsorption tower. The system has the advantages of high long-term running stability, high safety, high desulfurization and denitrationefficiency, and realization of safe and ultralow emission of the flue gas.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

Method for refining biologic diesel oil, phospholipid and glycerin by using leftovers of vegetable oil

InactiveCN1958728AShort reaction timeImprove conversion rateOrganic chemistryChemical industryVegetable oilBiodiesel

This invention discloses a method for producing biodiesel oil, phospholipid and glycerol from waste plant oil. The method comprises: (1) extracting the raw material to separate phospholipid, neutral oil and soap; (2) performing interesterification on neutral oil to obtain biodiesel oil and glycerol; (3) acidifying and esterifying the soap to obtain biodiesel oil. The method has such advantages as short reaction time, simple process, high conversion rate of biodiesel oil, low energy consumption, easy recovery of the products, and no pollution. The produced biodiesel oil can satisfy the international DIN V 51.606 standard and China 2# diesel oil standard. The method utilizes waste plant oil to produce biodiesel oil, thus largely reduces the cost and is suitable for mass production.

Owner:HUAZHONG UNIV OF SCI & TECH

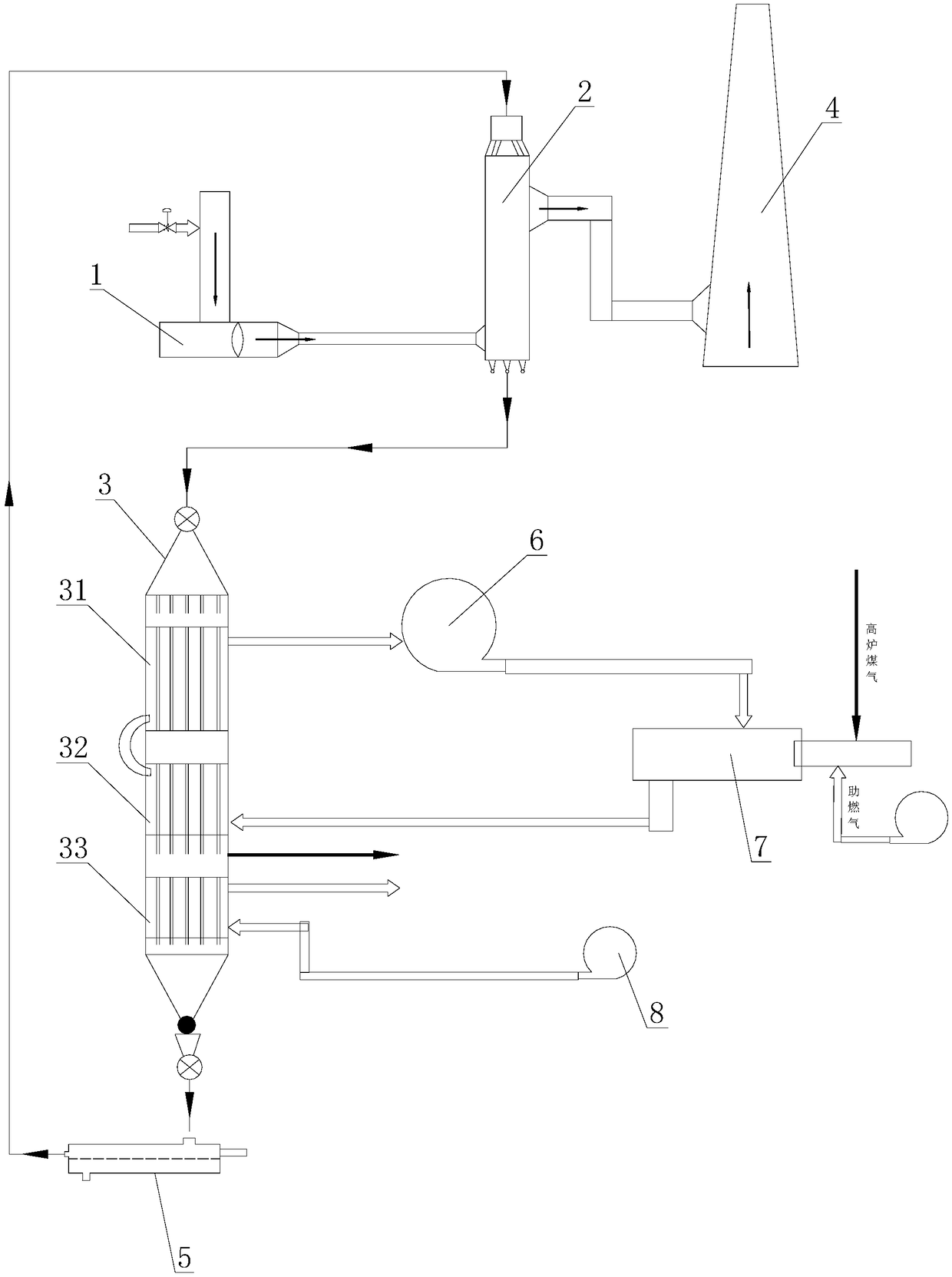

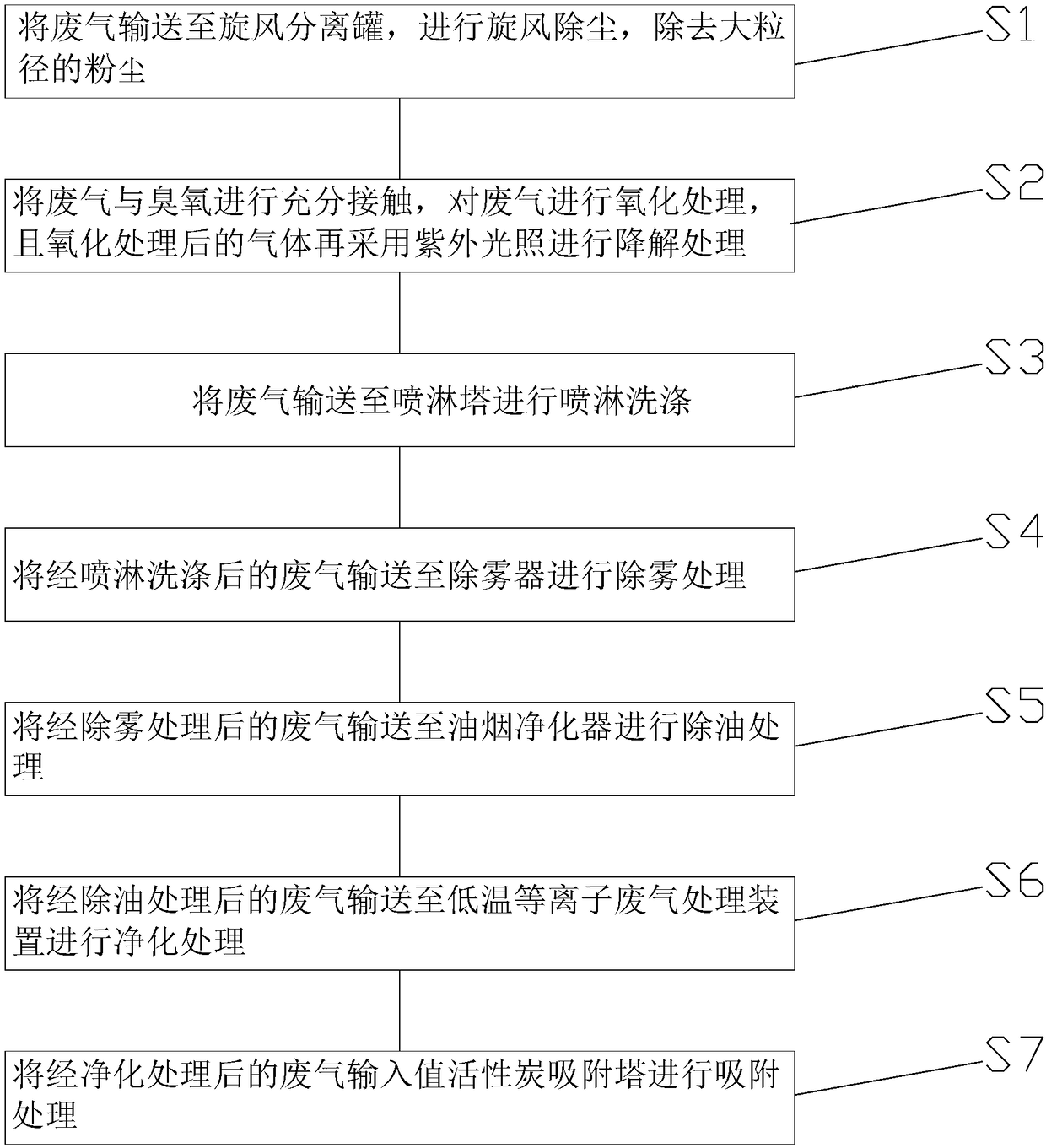

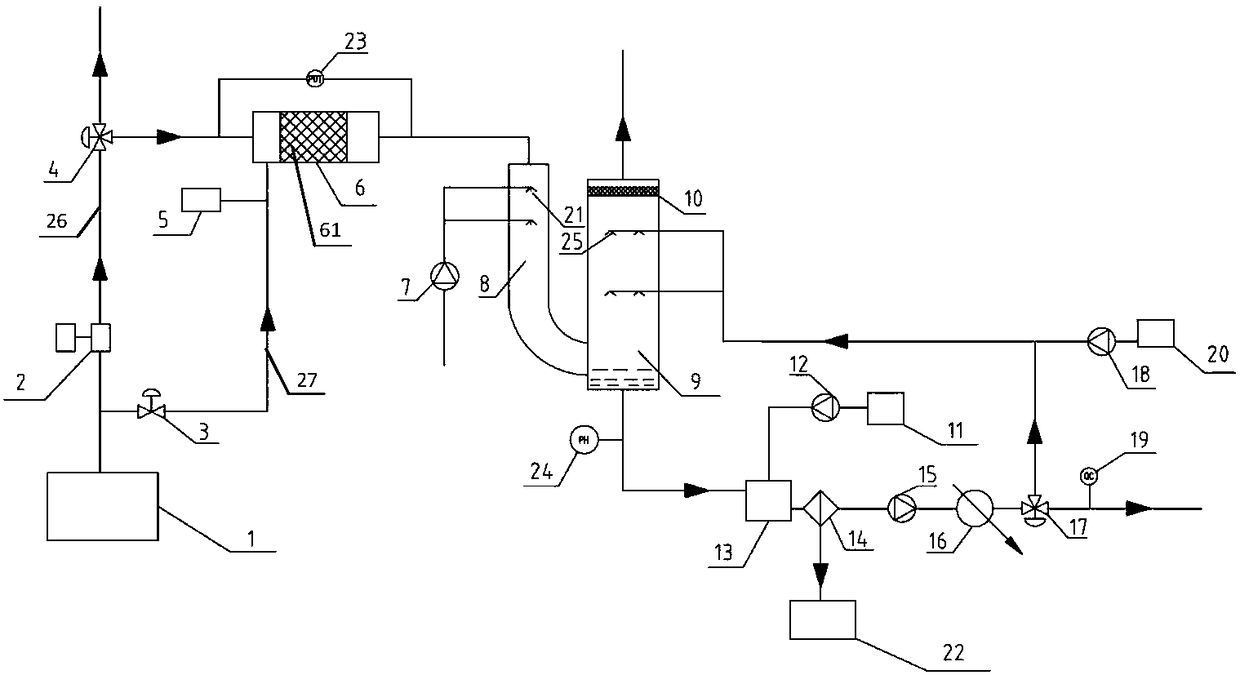

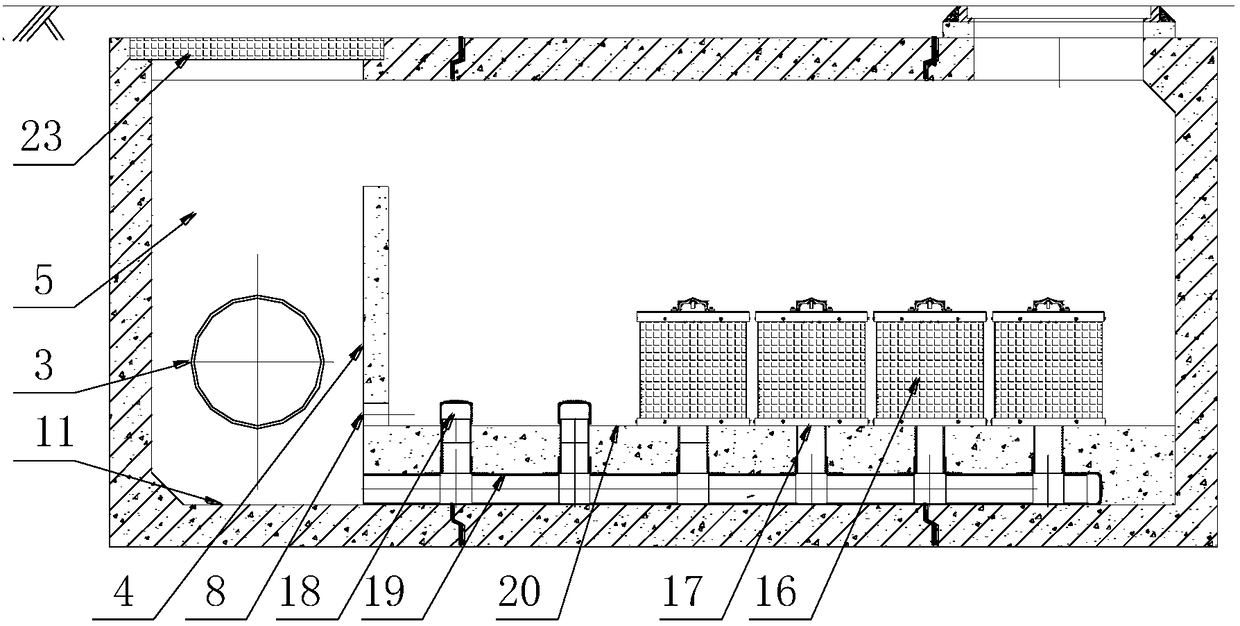

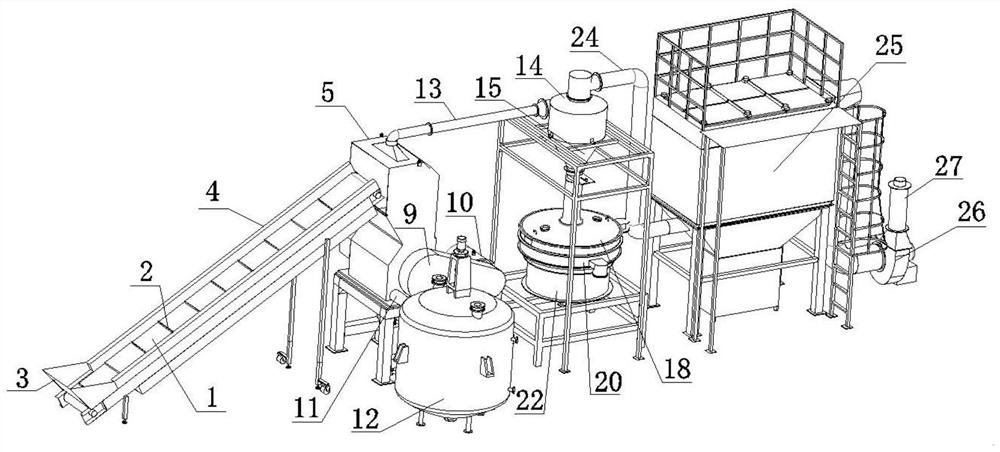

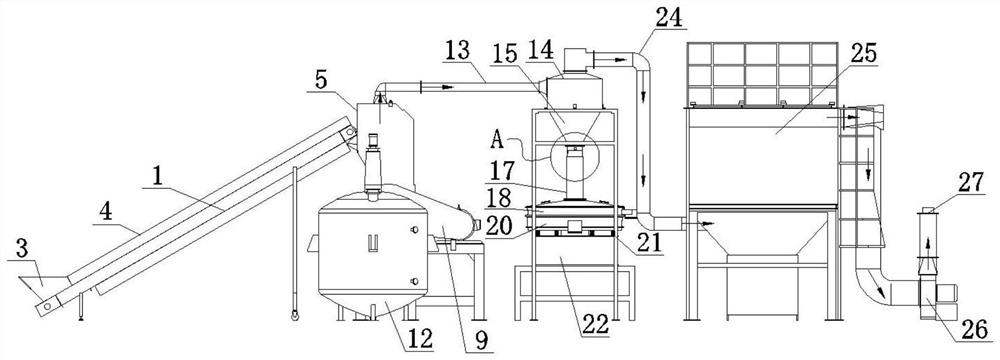

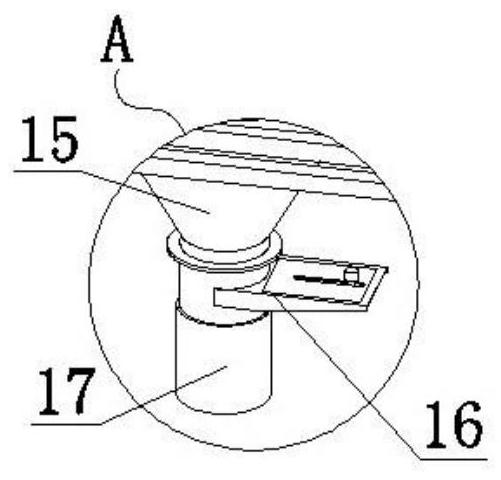

Waste plastic granulation waste gas treatment system and method

InactiveCN108404630AReduce the content of particulate matterEfficient removalCombination devicesActivated carbonParticulates

The invention discloses a waste plastic granulation waste gas treatment method. The waste plastic granulation waste gas treatment method comprises the following steps: delivering waste gas to a spraytower and washing the waste gas in a spraying manner; delivering the waste gas washed in the sprayer manner to a demister and carrying out demisting treatment on the waste gas; delivering the demistedwaste gas to an oil fume purifier and carrying out oil removal treatment on the waste gas; delivering the waste gas subjected to oil removal treatment to a low-temperature plasma waste gas treatmentdevice and carrying out purification treatment on the waste gas; and feeding the purified waste gas into an activated carbon absorption tower and carrying out adsorption treatment. The treatment process is mature, the running cost is low, plastic granulation waste gas can be treated deeply, a multi-layered treatment effect is achieved, residual small-particle water-soluble substances in the wastegas can be removed, organic macromolecules in the waste gas can be split through the low-temperature plasma waste gas treatment device, the particulate matter content of the treated waste gas is low,and the waste gas is degraded into stable and pollution-free compounds to be discharged.

Owner:重庆庚业新材料科技有限公司

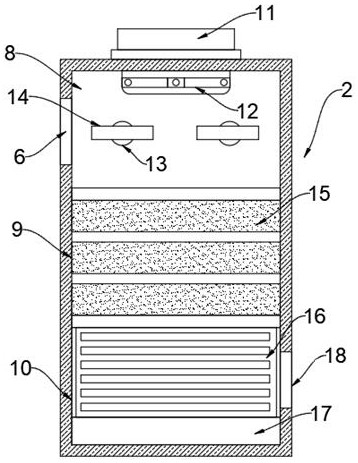

Equipment applied to air sterilization and purification and achievement method thereof

InactiveCN106949555AEffectively blow toImprove disinfection efficiencyGas treatmentDispersed particle filtrationParticulatesProduct gas

The invention discloses equipment applied to air sterilization and purification and an achievement method thereof. The equipment comprises a mounting base. The two sides of the mounting base are both fixedly provided with extension stabilizing plates. The middles of the extension stabilizing plates are fixedly provided with fixing screws. A box is fixedly mounted at the top of the mounting base. The right side of the box is provided with an air inlet located above the mounting base. A suction fan with an air outlet communicating with the air inlet is fixedly mounted on the right side wall of an inner cavity of the box. The left side of the suction fan communicates with an air passing pipeline located in the inner cavity of the box. The left side of the air passing pipeline is fixedly provided with an air passing pipeline sealing mounting block located on the left side wall of the inner cavity of the box. The top of the air passing pipeline communicates with an air outlet pipeline located in the inner cavity of the box. By adoption of the equipment applied to air sterilization and purification, air can be effectively enabled to be blown towards the treatment part, the advantage of high sterilization efficiency is achieved, and particulate matter and peculiar smell in the air can be effectively filtered to enable the air to be more suitable for the human body.

Owner:CHENGDU GUANYU TECH

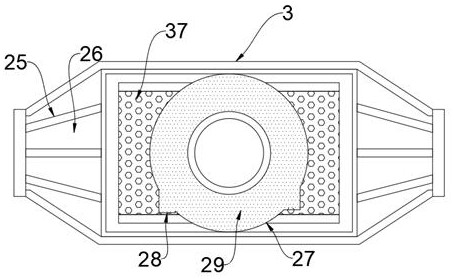

Ship waste gas desulfurization system

ActiveCN108187480AImprove desulfurization efficiencyReduce the content of particulate matterDispersed particle filtrationSpray nozzleEngineering

The invention provides a ship waste gas desulfurization system. The ship waste gas desulfurization system comprises a filtering oxidization device and a washing tower, wherein the filtering oxidization device comprises a waste gas filtering structure provided with an oxidant; a gas inlet of the filtering oxidization device is connected with an exhausting opening of a diesel engine through a firstpipeline; the washing tower is provided with a washing liquid spraying nozzle, a desulfurization waste gas outlet and a washing wastewater outlet; a gas inlet of the washing tower is connected with anexhausting opening of the filtering oxidization device; the washing liquid spraying nozzle is connected with a washing liquid supply system. According to the ship waste gas desulfurization system provided by the invention, the filtering oxidization device is arranged in front of the washing tower, part of particles in waste gas are removed through the filtering oxidization device and SO2 is oxidized into SO3; the desulfurization efficiency of the washing tower can be improved and a wastewater treatment flow is simplified.

Owner:SUNRUI MARINE ENVIRONMENT ENG

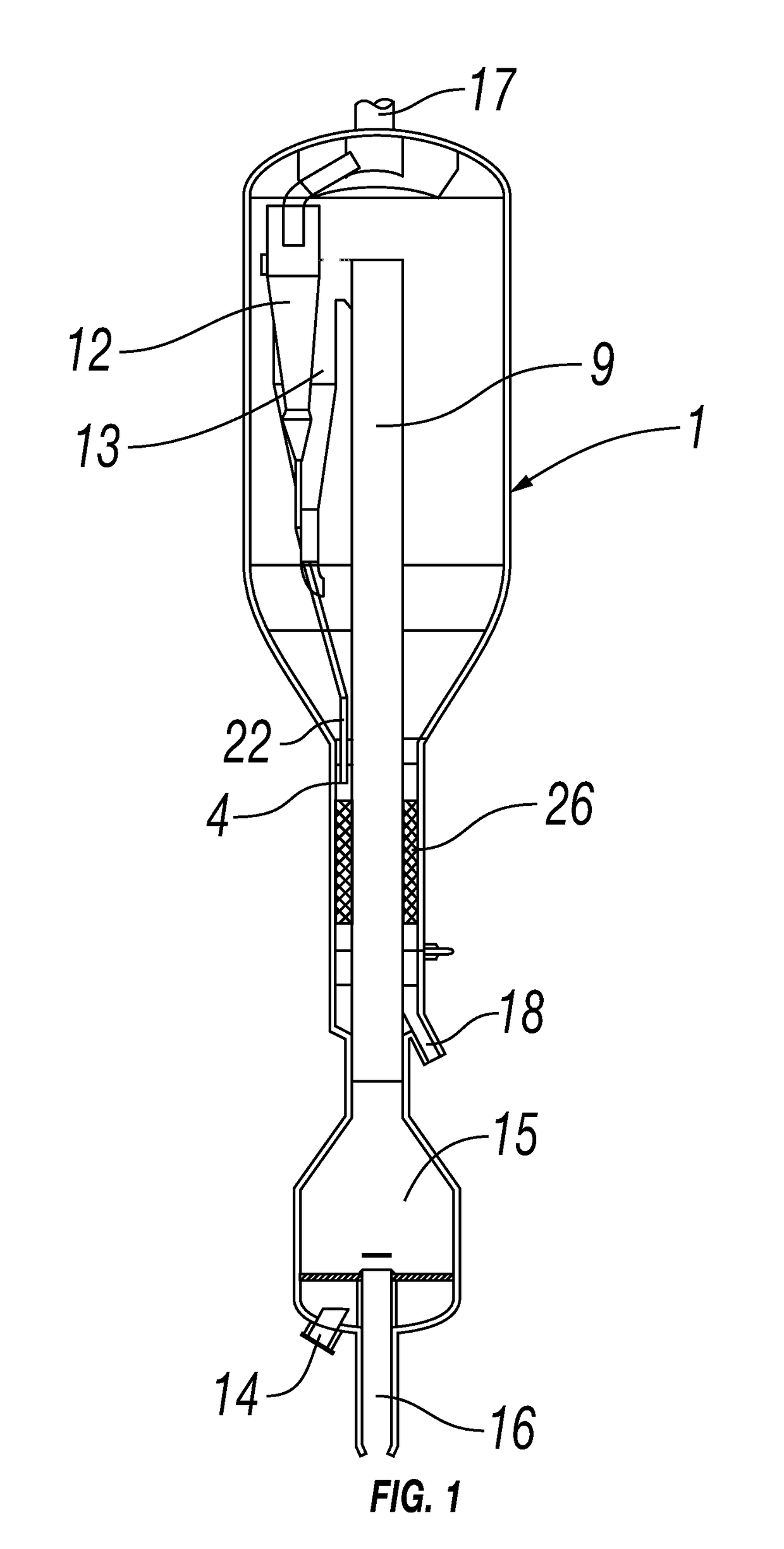

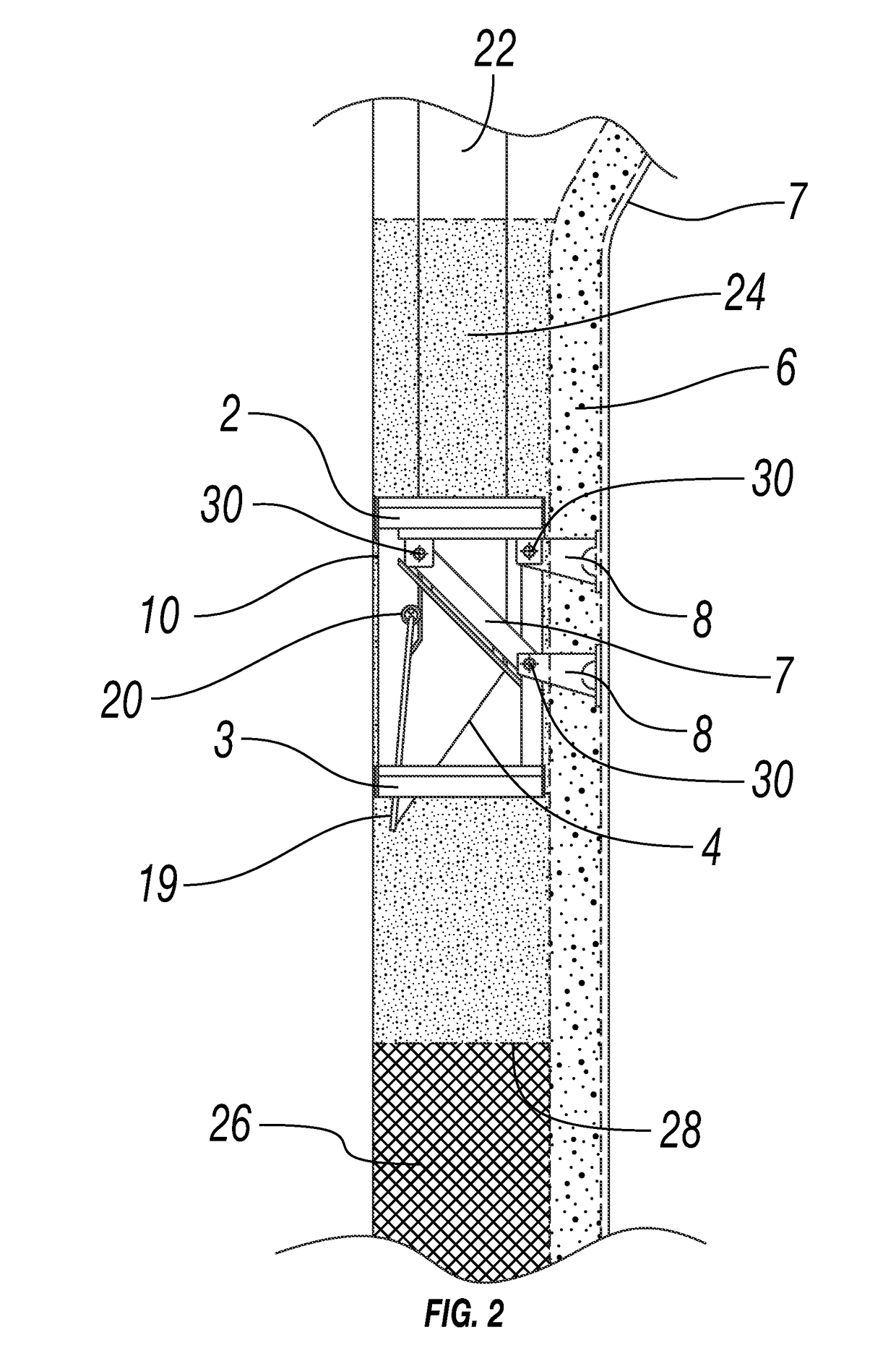

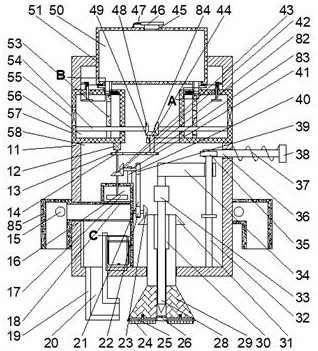

Fluidized Catalyst Stripping Unit for Displacing Entrained Gas From Catalyst Particles

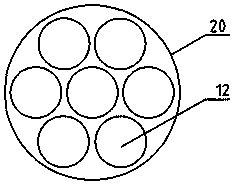

ActiveUS20170151544A1Reduce particulate contentReduce the content of particulate matterCatalytic crackingHydrocarbonsChemistryProduct gas

A fluidized catalyst stripping unit for displacing entrained gas from catalyst particles comprising: a vessel housing a two stage cyclonic separation section which comprises one or more primary cyclonic separation devices and one or more secondary cyclones; a stripping section which comprises internals; and an inlet in fluid communication with a catalytic reactor to feed a particulate-fluid suspension to the two stage cyclonic separation section; wherein each primary cyclonic separation device comprises an internal cylindrical surface to separate a major fraction of the particulates from the suspension and form a vortex of reduced particulate content; a particulate discharge outlet from each secondary cyclone to the stripping section; wherein the particulate discharge outlet of the secondary cyclone is submerged in a catalyst bed located above the stripper internals, and wherein the stripping section comprises one or more bubble breaking grids within the catalyst bed and above the stripping internals is provided.

Owner:DOW GLOBAL TECH LLC

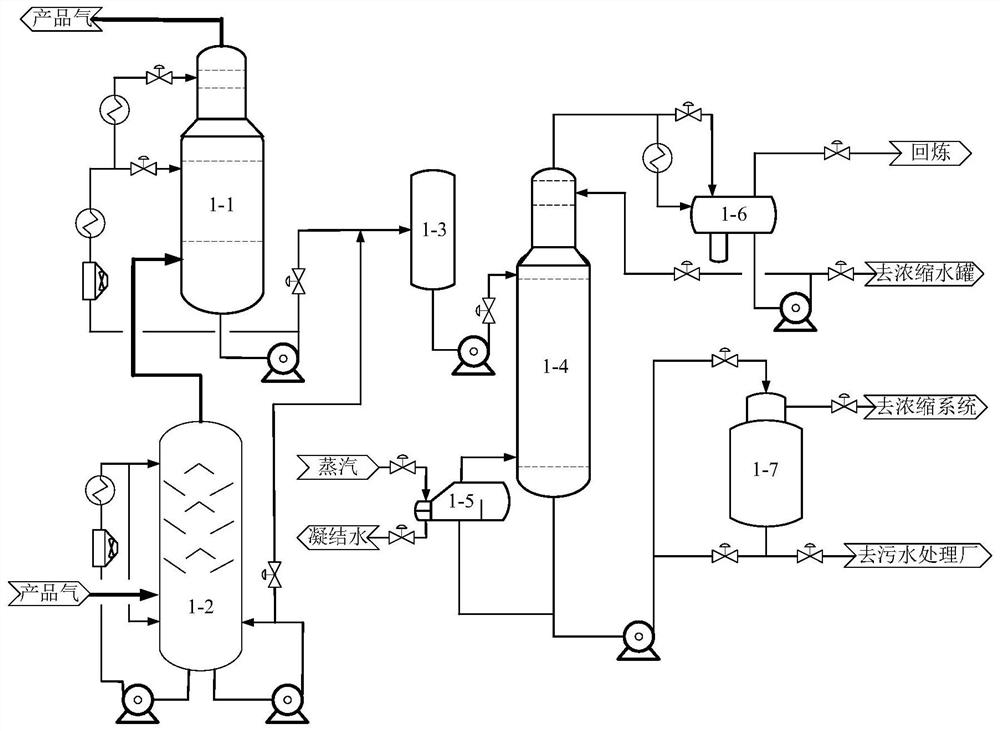

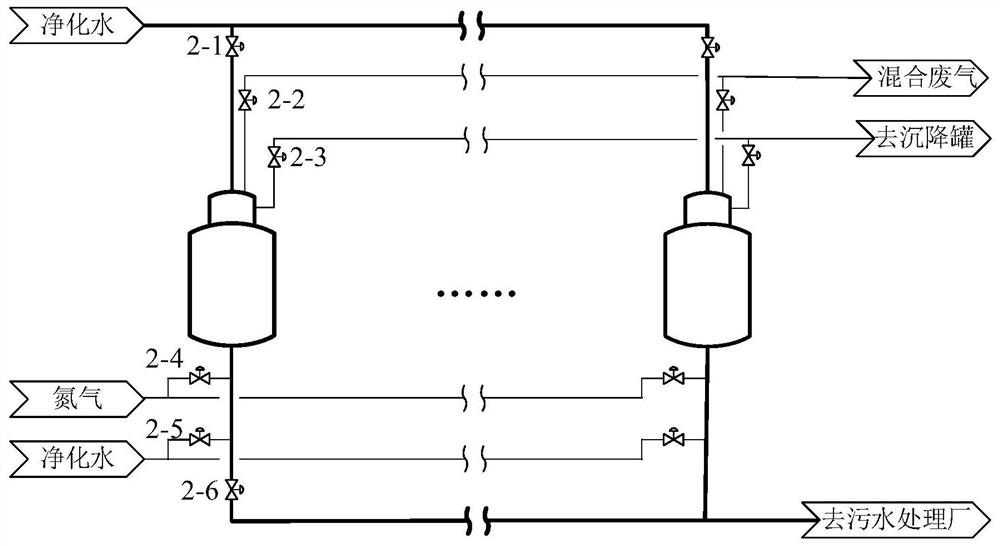

Fluidized bed purification method and device for methanol-to-olefin purified water

PendingCN113045376AMake up for the problem of insufficient separation efficiencyReduce energy consumptionHydrocarbon purification/separationHydrocarbon from oxygen organic compoundsPtru catalystFluidized bed

The invention relates to a fluidized bed purification method and device for methanol-to-olefin purified water. The fluidized bed purification method for the methanol-to-olefin purified water comprises the following steps: (i) feeding product gas to a quench tower for washing and cooling, and washing most of fine catalyst powder entrained in the product gas into quenched water; (ii) feeding the product gas obtained in the step (i) into a water washing tower for washing; (iii) recycling a part of the quenched water obtained in the step (i) and washing water obtained in the step (ii), discharging a part of the quenched water and the washing water into a stripping tower, and conducting stripping to obtain purified water; (iv) further purifying the purified water obtained in the step (iii) through a fluidized bed separator; (v) after the fluidized bed separator continuously runs for a period of time, regenerating a separation medium in the fluidized bed separator through reverse feeding of purified water of the stripping tower; and (vi) further concentrating catalyst slurry concentrated by the fluidized bed separator. The invention also provides the fluidized bed purification device for the methanol-to-olefin purified water.

Owner:EAST CHINA UNIV OF SCI & TECH

Marine fish collagen oligopeptide beverage and preparation method thereof

InactiveCN108719701AGood taste stabilityFor long-term storageNatural extract food ingredientsFood ingredient functionsMarine fishHouttuynia

The invention discloses a marine fish collagen oligopeptide beverage and a preparation method thereof. The marine fish collagen oligopeptide beverage comprises marine fish collagen oligopeptide, a ginseng extractive liquid and a mixed extracted concentrate, wherein 5-10 parts by weight of the ginseng extractive liquid is prepared. The mixed extracted concentrate is prepared from the following rawmaterials in parts by weight: 28-35 parts of black-bone chicken, 8-12 parts of poria cocos, 8-12 parts of Chinese dates, 10-20 parts of longan pulp, 8-14 parts of peach kernels, 8-12 parts of wild jujube kernels, 8-12 parts of lotus seeds, 8-12 parts of Chinese white olives, 8-12 parts of heartleaf houttuynia herb, 9-11 parts of malt, 4-6 parts of orange peel, 4-7 parts of hawthorn fruits, 2-5 parts of dried ginger and 1.5-4.0 parts of licorice. The longan pulp is subjected to at least 90 times of cyclic steaming and sun-drying treatment. The marine fish collagen oligopeptide beverage solves the problem that conventional nourishing beverages are easy to cause excessive internal heat, and the medicinal and edible beverage with the function of enriching blood and beautifying skins is obtained.

Owner:SHENZHEN DASHICHANG BIOTECH CO LTD

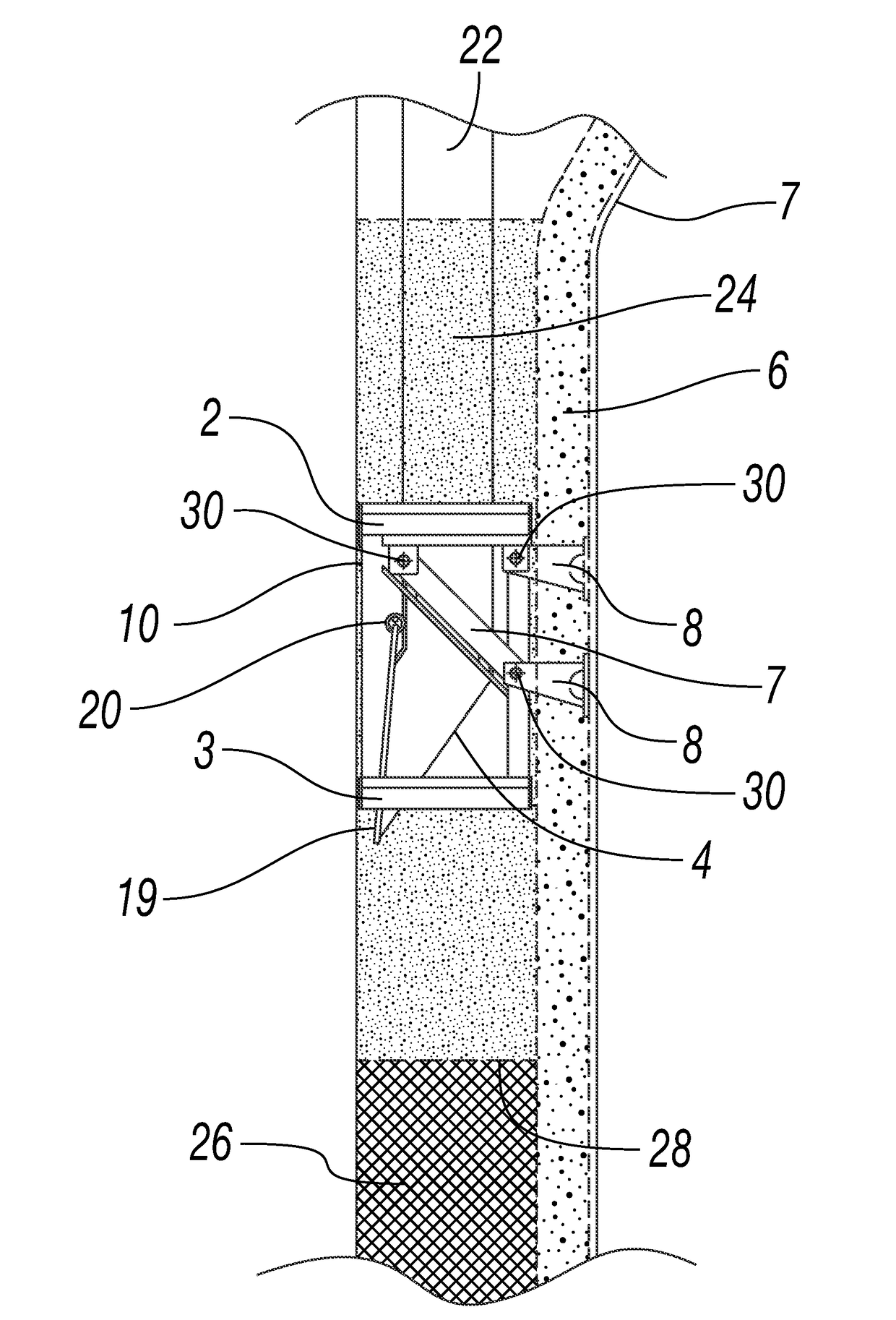

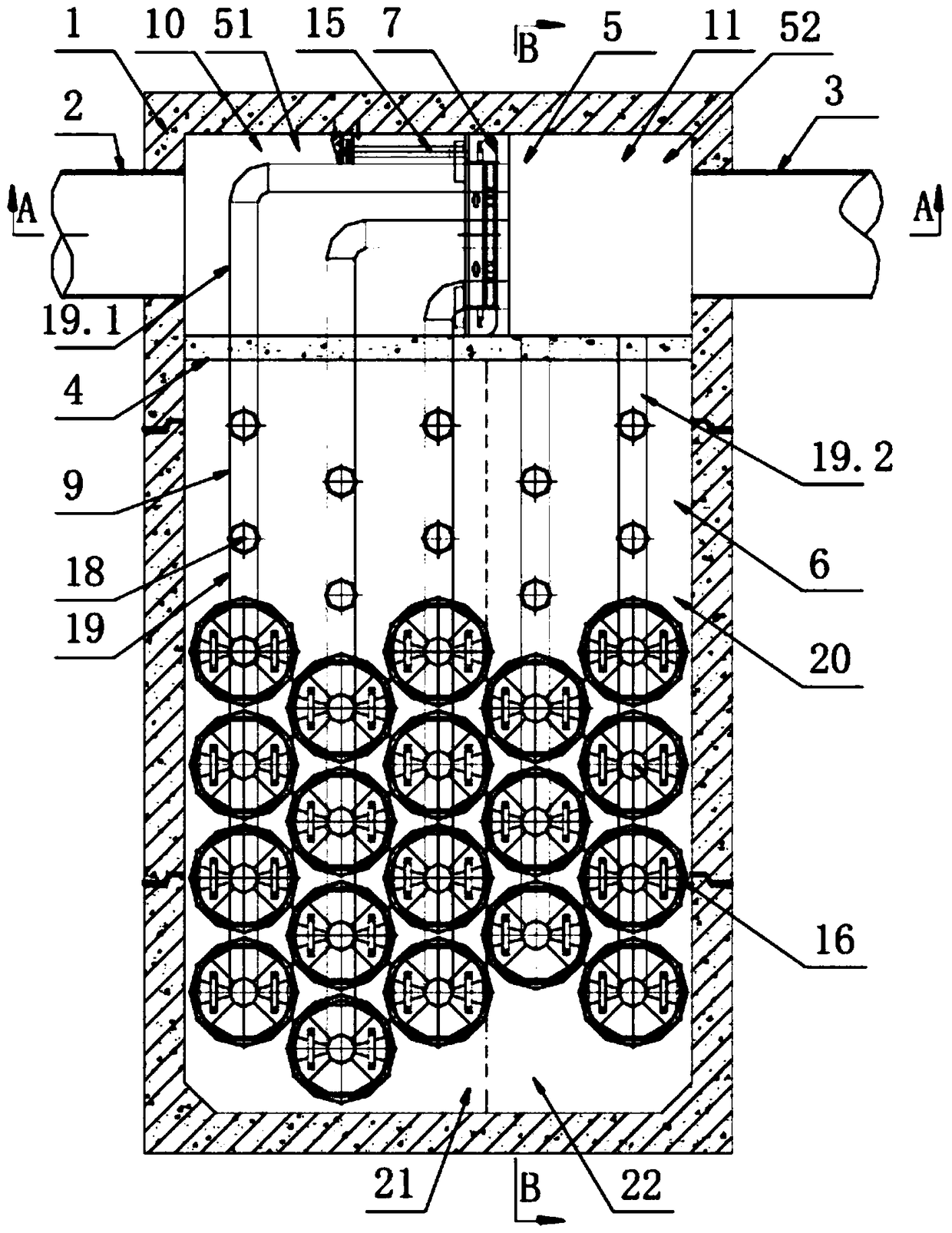

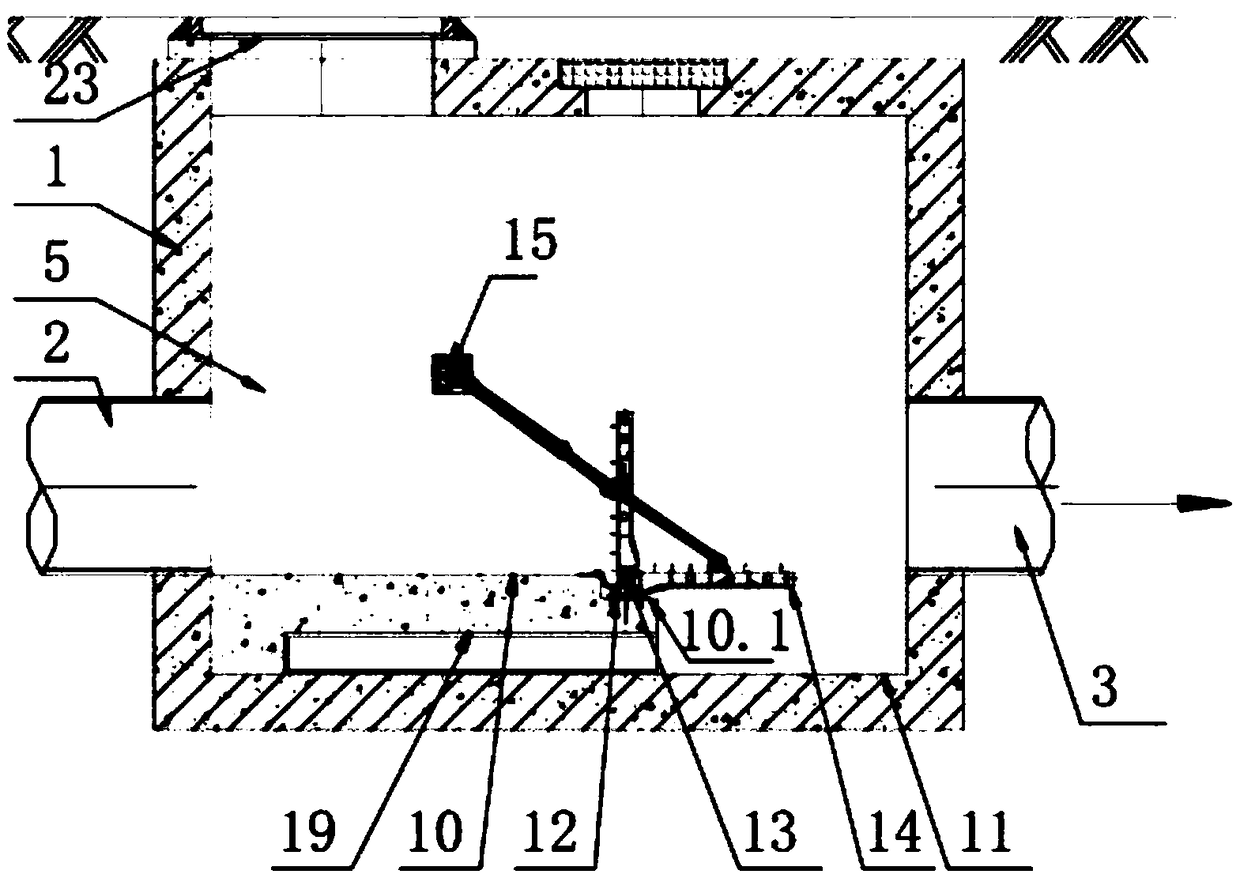

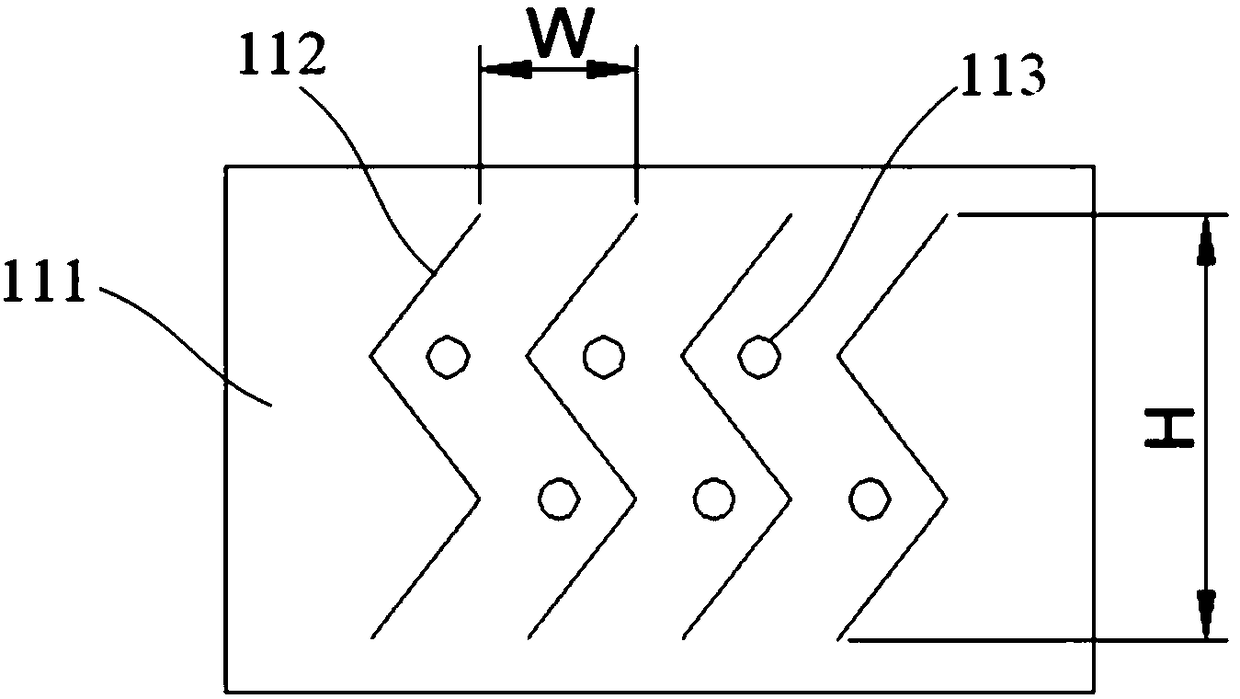

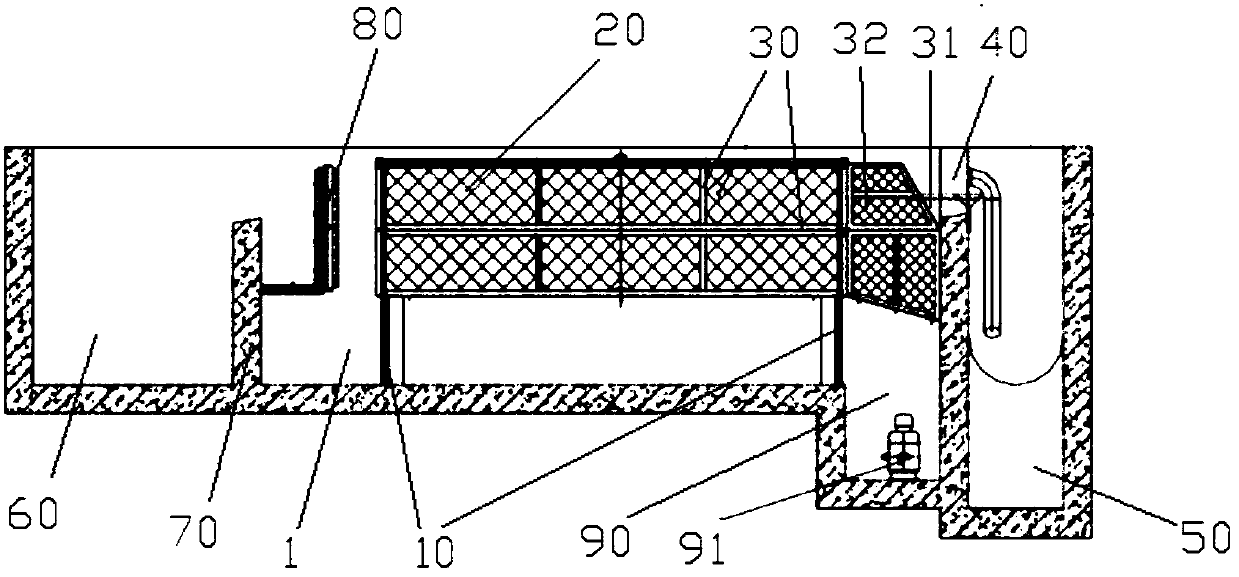

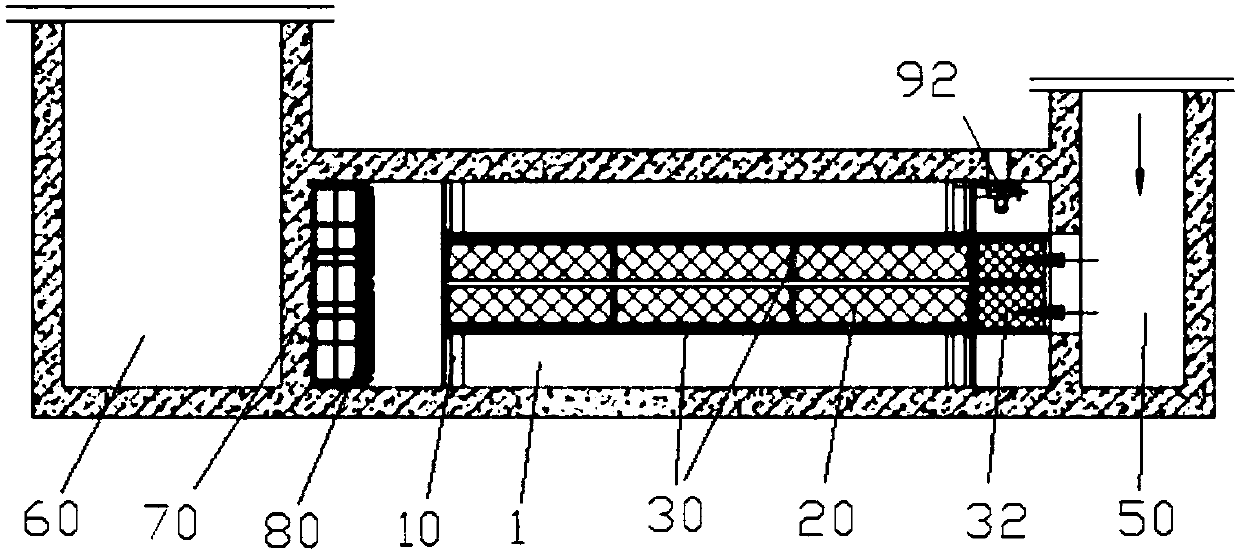

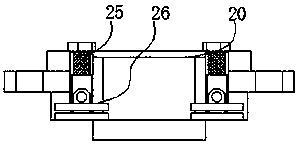

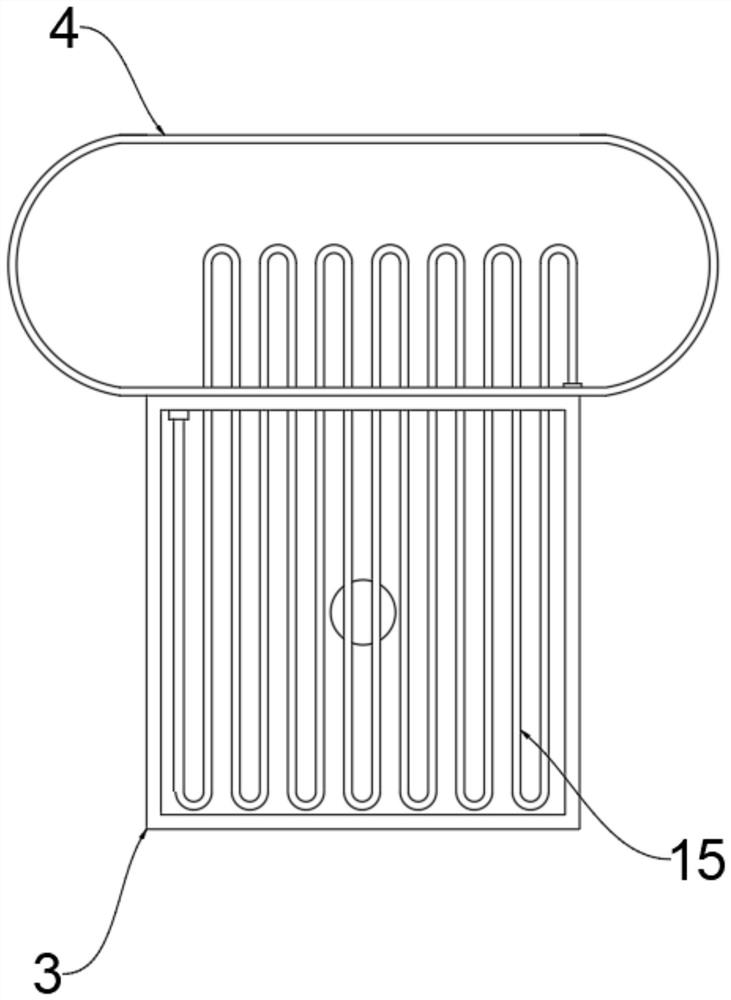

Automatic intercepting filtering pond, and intercepting filtering device, system and method

InactiveCN109364555AEasy to handleAvoid entering the riverFatty/oily/floating substances removal devicesSewerage structuresWater flowEngineering

The invention discloses an automatic intercepting filtering pond, which comprises a pond body (1), a retaining wall (4), an automatic switch, a particle filtering device and a drainage device (9). A water inlet (2) and a water outlet (3) are formed in the pond body (1), the retaining wall (4) is arranged in the pond body (1) and divides the pond body (1) into a water passing corridor (5) and a filtering treating area (6), and the water inlet (2) and the water outlet (3) are located in the side wall, where the water passing corridor (5) is located, of the pond body (1); the automatic switch isarranged in the water passing corridor (5) to control a water flow in the water passing corridor (5) and divides the water passing corridor (5) into a first area (51) and a second area (52), the waterinlet (2) communicates with the first area (51), the water outlet (3) communicates with the second area (52), and the automatic switch comprises a separating wall (12) and one or more automatic switch bodies controlling the communicating state of the first area (51) and the second area (52); and the particle filtering device communicates with the drainage device and is arranged in the filtering treating area (6), wherein a water feeding hole (8) is formed in the part, at the first area (51), of the retaining wall (4) and can communicate with the filtering treating area (6) and the first area(51), and the drainage device (9) can communicate with the filtering treating area (6) and the second area (52).

Owner:WUHAN SHENGYU DRAINING SYST

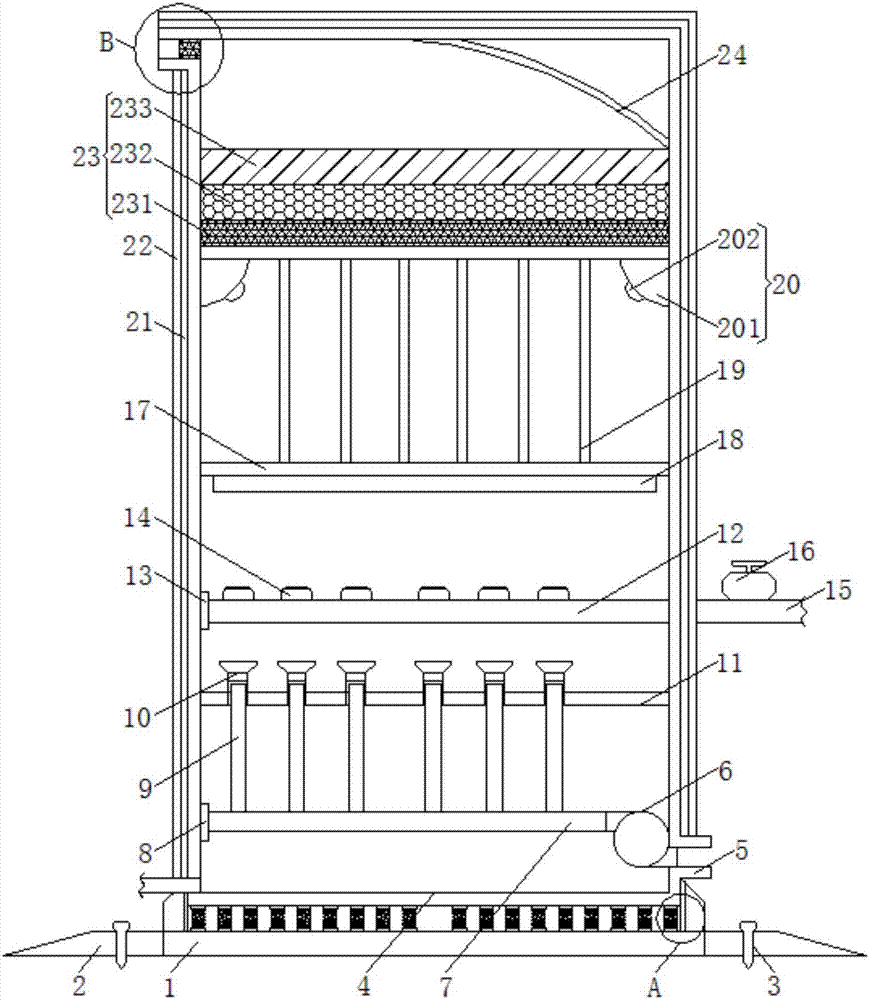

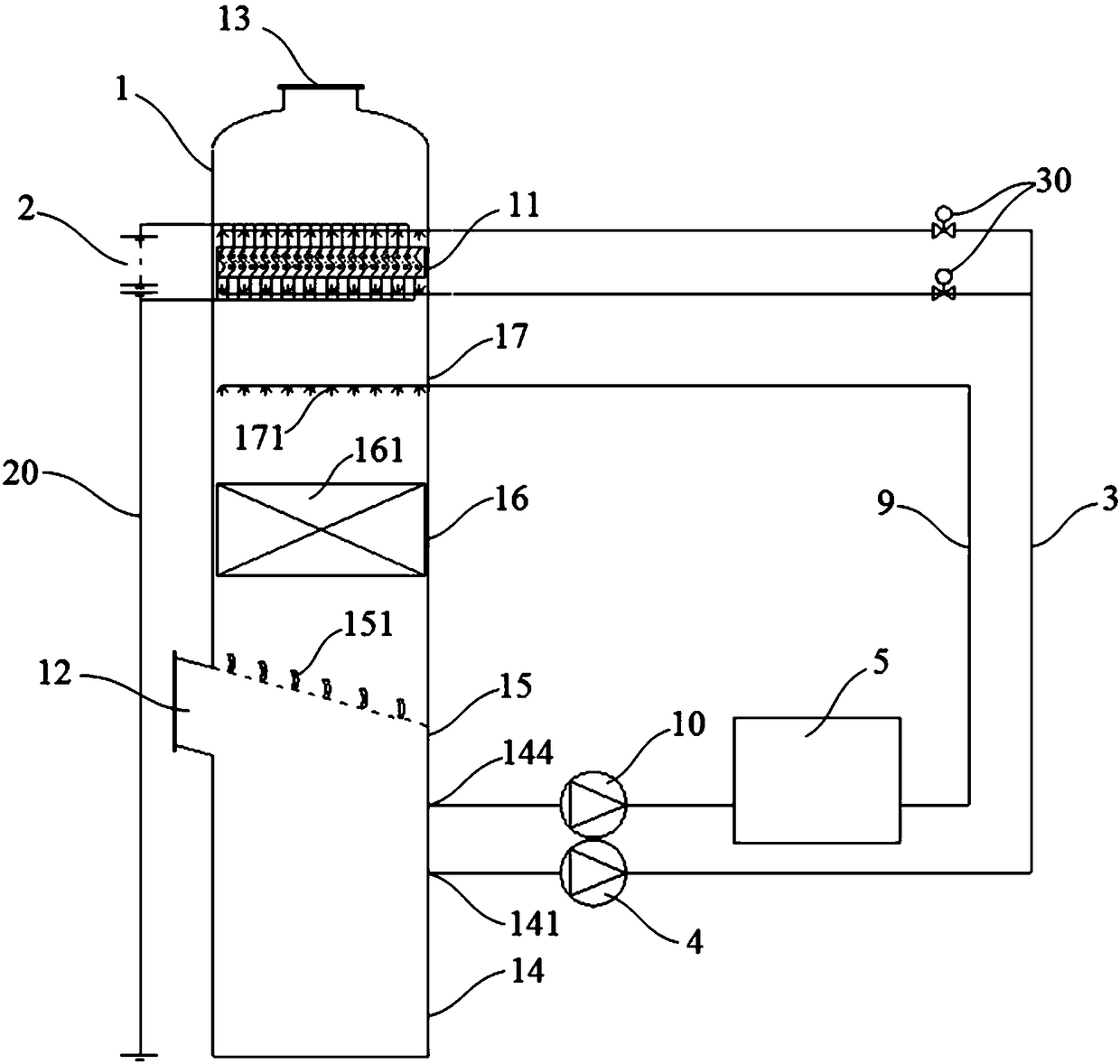

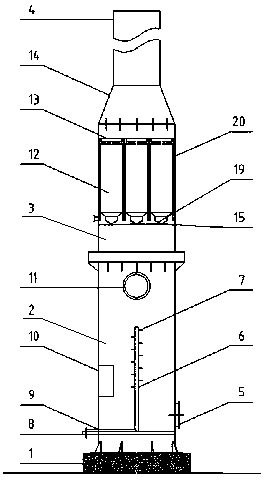

Flue gas purifying and treating apparatus

PendingCN108096966ARandom combinationReduce dustCombination devicesTrickle coolersParticulatesFlue gas

The invention provides a flue gas purifying and treating apparatus. The apparatus comprises a purification tower and a power supply which is positioned at the outer side of the purification tower, thepurification tower is opened with a flue gas inlet and a flue gas outlet, the flue gas inlet is positioned at the lower part of the purification tower, and the flue gas outlet is at the top of the purification tower; the upper part of the purification tower is provided with an ultra-cleaning section, and the ultra-cleaning section comprises a substrate which is positioned in the ultra-cleaning section, multiple anode plates and multiple cathode wires which are fixed on the substrate, multiple cathode wires are uniformly distributed between multiple anode plates, the anode plates and a cathodeof the power supply are connected, the cathode wires and an anode of the power supply are connected; multiple back flushing nozzles are arranged above and / or below the substrate. The flue gas purifying and the treating apparatus is provided with the ultra-cleaning section which is above a spraying section and comprises anode plates and cathode plates, a hygroscopic solution is used for flushing,content of flue gas dust and particles are further reduced before wet type electric precipitation, and at the same time, waste heat of the flue gas is recovered, and purposes of deep purification of flue gas and waste heat recovery are realized.

Owner:HEIMDALLR SHANGHAI ENERGY SAVING TECH

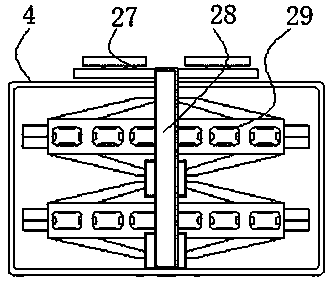

Online treatment system with particle separation and sedimentation device

InactiveCN107596781AAvoid pollutionReduce the content of particulate matterMultistage water/sewage treatmentFiltration circuitsParticulatesWater flow

The invention discloses an online treatment system with a particle separation and sedimentation device. The online treatment system comprises an online treatment tank, wherein a particle separation and sedimentation device is arranged in the online treatment tank and comprises at least two baffle walls, the baffle walls are oppositely arranged at the bottom of the online treatment tank and extendtowards the upper end of the online treatment tank, and a support framework is arranged at the upper ends of the baffle walls; a filter screen is distributed on the support framework to form a semi-closed cavity facing towards one end of the water inlet pipe of the online treatment tank, the semi-closed cavity has an opening and is used for filtering and settling rainwater entering the online treatment tank. According to the online treatment system, the rainwater is pretreated by virtue of the combination of gravity settling and the filter screen, floating objects and greasy dirt in the rainwater are intercepted and are collected into the filter screen, particulate matters in the rainwater are blocked by virtue of the baffle walls and are settled at the bottom of a cavity between the baffles, and finally water flowing out from a water outlet pipe does not contain floating objects, is low in particle content and is relatively clean, so that the pollution of a water body is prevented.

Owner:WUHAN SHENGYU DRAINING SYST

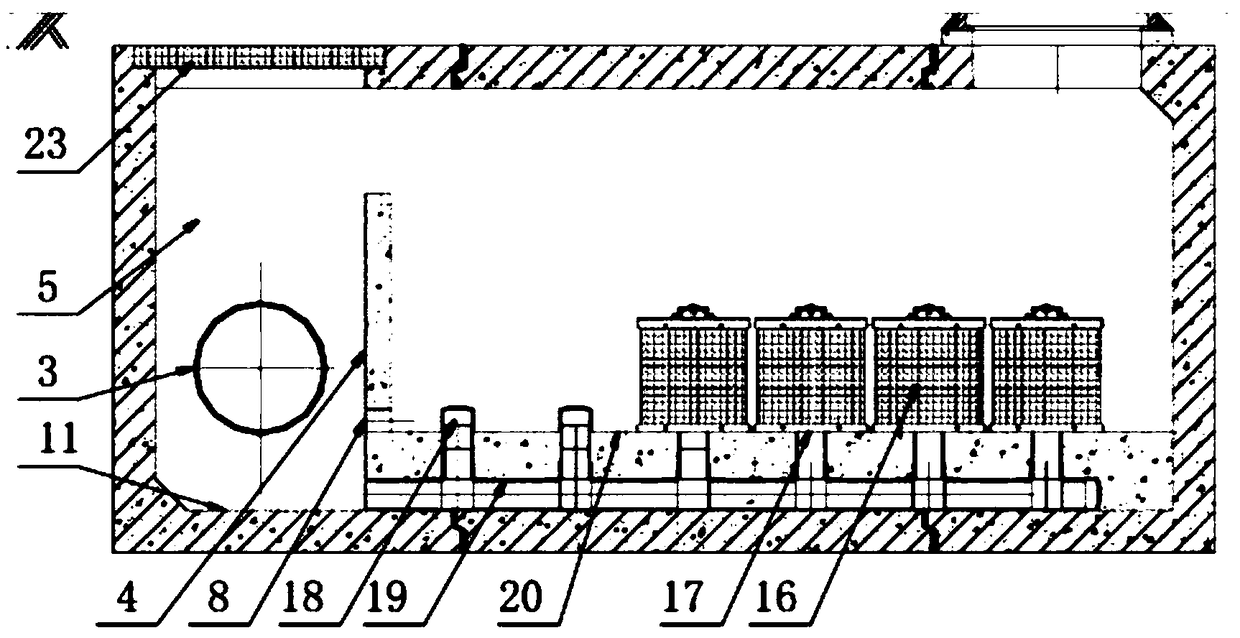

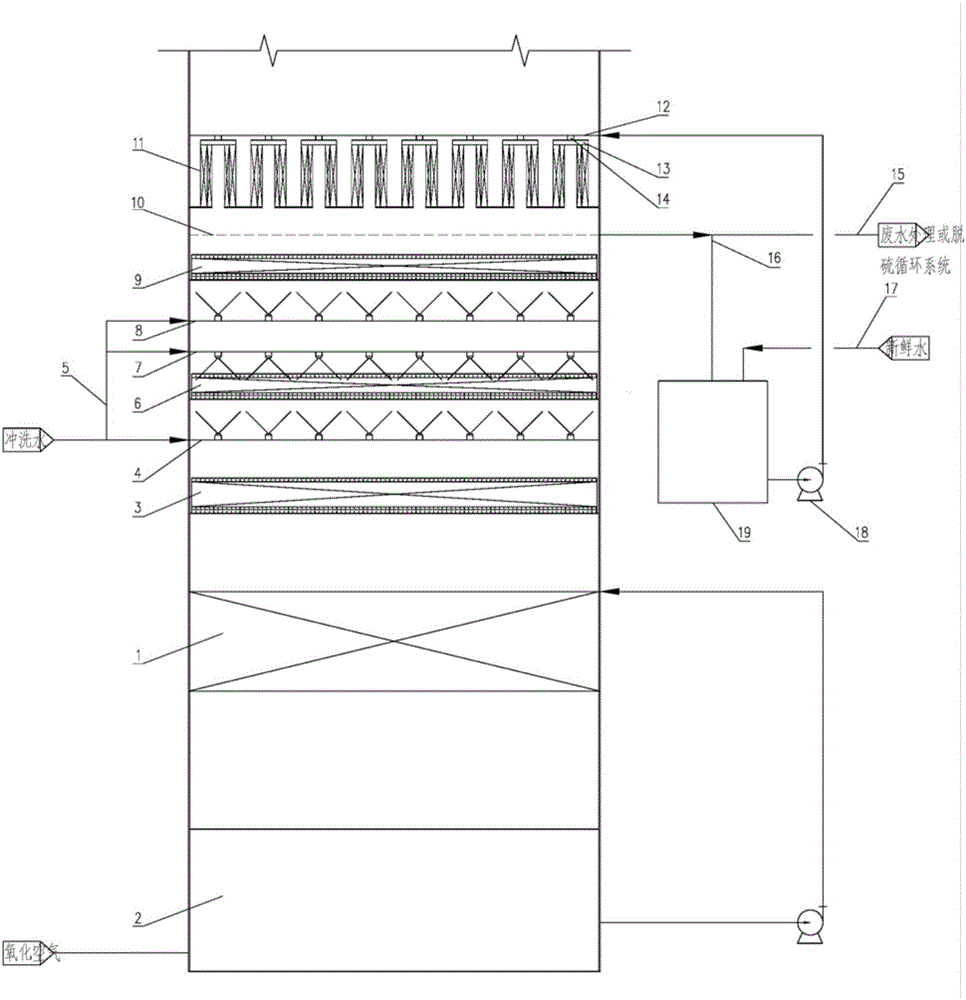

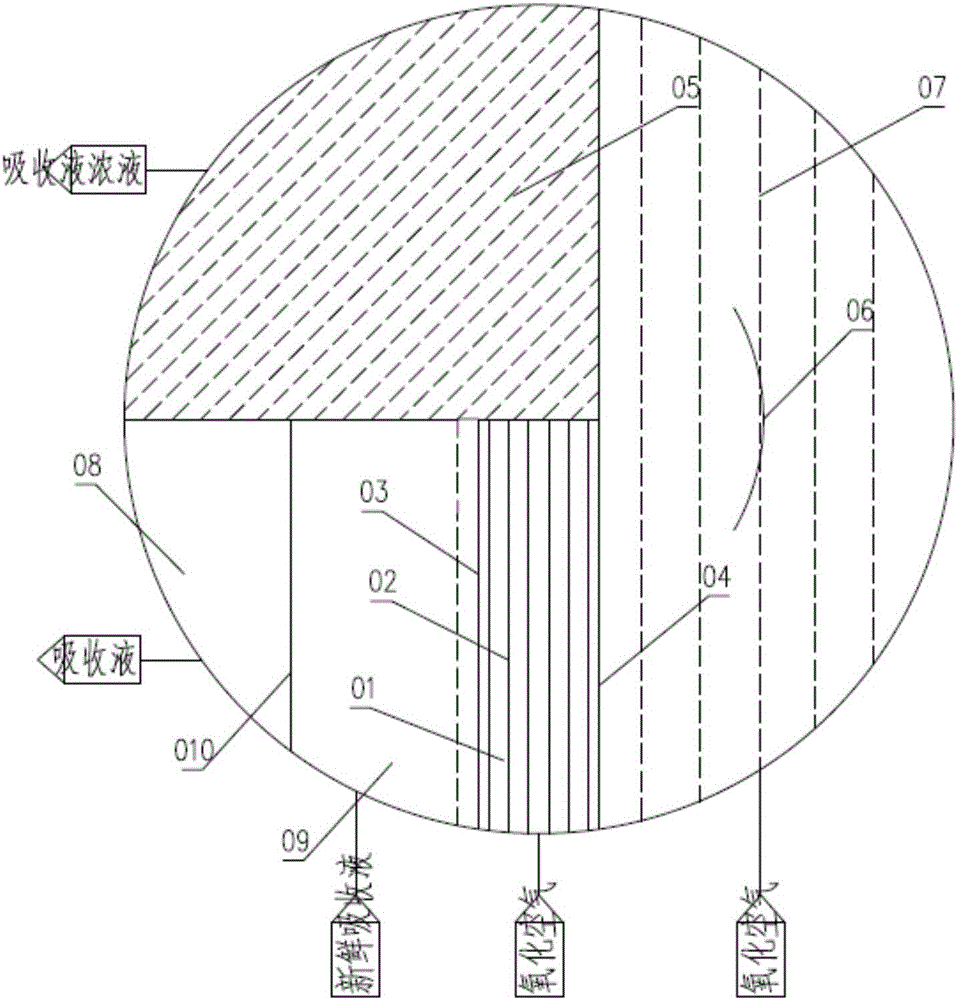

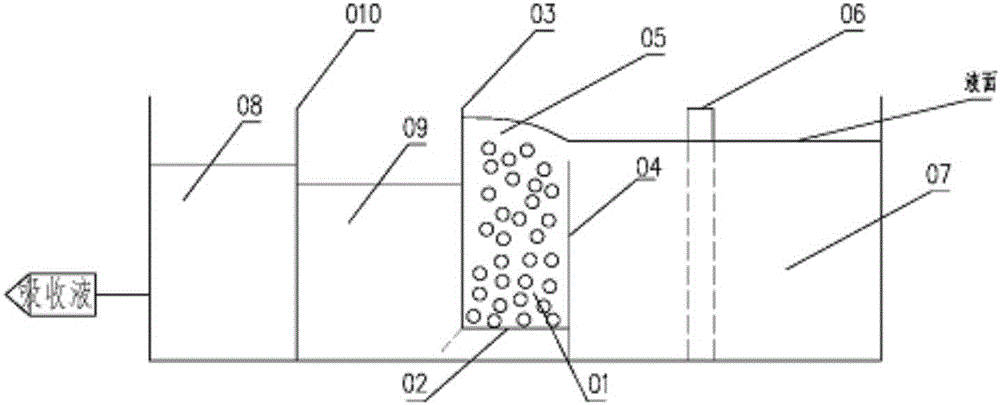

Falling film washing system realizing ultralow emission of coal-fired power plant desulfurated tail gas and technology thereof

ActiveCN105688558AImprove separation efficiency and precisionReduce the content of particulate matterUsing liquid separation agentExhaust gasFluid cell

The invention discloses a falling film washing system realizing ultralow emission of coal-fired power plant desulfurated tail gas and a technology thereof. The washing system comprises an absorbing section, an automatic circulation suction liquid bath, a special plate group demister matched with the absorbing section and a falling film washing section matched with the special plate group demister. The washing technology includes the steps that 1, flue gas enters the absorbing section and then makes contact with an absorbent; 2, most liquid drops with the large particle size and smoke dust in the flue gas are removed by the automatic circulation suction liquid bath to obtain new flue gas, then the flue gas is input into the absorbing section again; 3, the flue gas is conveyed to the special plate group demister through the absorbing section, and liquid drops with the diameter being 10 micrometers or above in the flue gas are removed by the special plate group demister; 4, impurities continue to be removed by the falling film washing section. Top space of an existing desulfuration tower and site space are fully used, separation efficiency and accuracy are improved, and the content of particulate matter in the wet desulfurization tail gas is reduced to the ultralow emission level.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

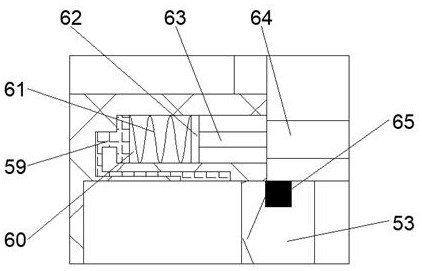

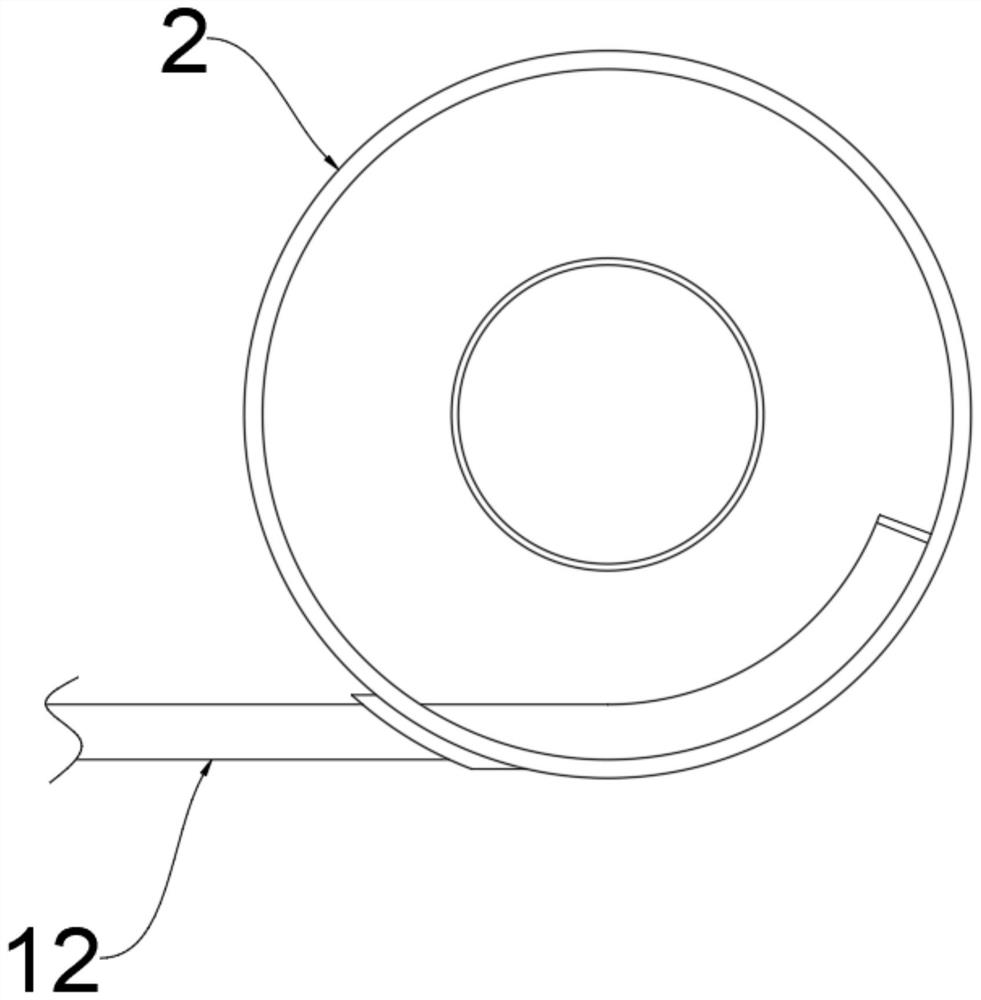

Process decomposition treatment device for medical waste incineration waste gas

ActiveCN113680162AReduce the content of particulate matterAvoid dischargeGas treatmentUsing liquid separation agentFiltrationGlycerol

The invention relates to the technical field of waste treatment, in particular to a process decomposition treatment device for medical waste incineration waste gas. The device comprises a dust removal interlayer, wherein an annular dust settling chamber is arranged on the upper portion of the dust removal interlayer, a deposition space is arranged on the lower portion of the dust removal interlayer, glycerin is arranged in the deposition space, and a spraying system for spraying glycerol downwards from the top of the dust settling chamber is arranged outside the dust removal interlayer. According to the invention, the dust removal interlayer and a neutralization cylinder are arranged to treat dust and acid gas in waste gas, dust particles and metal particles in the waste gas are preliminarily captured in the dust removal interlayer through glycerin with high viscosity so as to reduce the content of particulate matter in the waste gas, meanwhile, dioxin can be absorbed from the waste gas, dioxin is prevented from being discharged, the reliability of continuous filtration can be guaranteed by filtering particulate matter through glycerol, gas enters the neutralization cylinder and then is neutralized through an alkaline solution, and acid gas in waste gas is treated.

Owner:XIAMEN RANNENG ENVIRONMENTAL PROTECTION TECH CO LTD

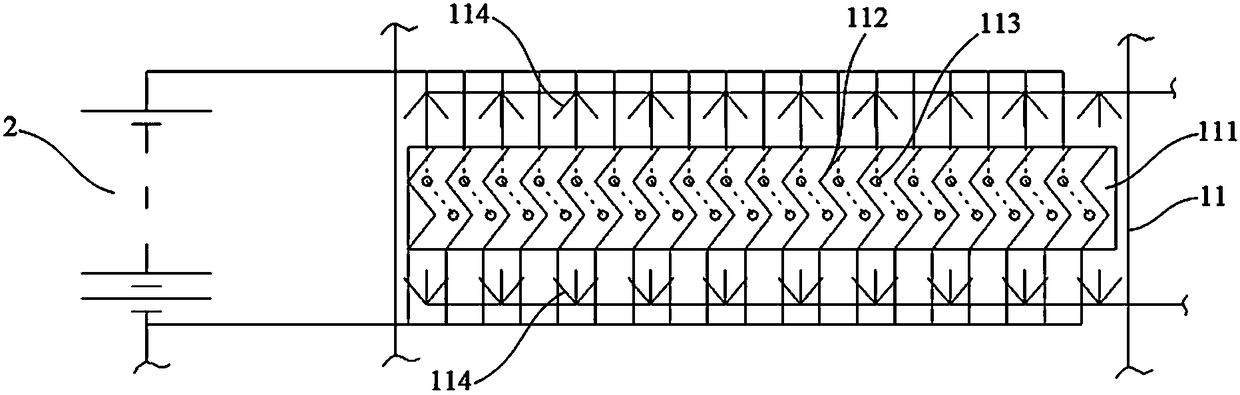

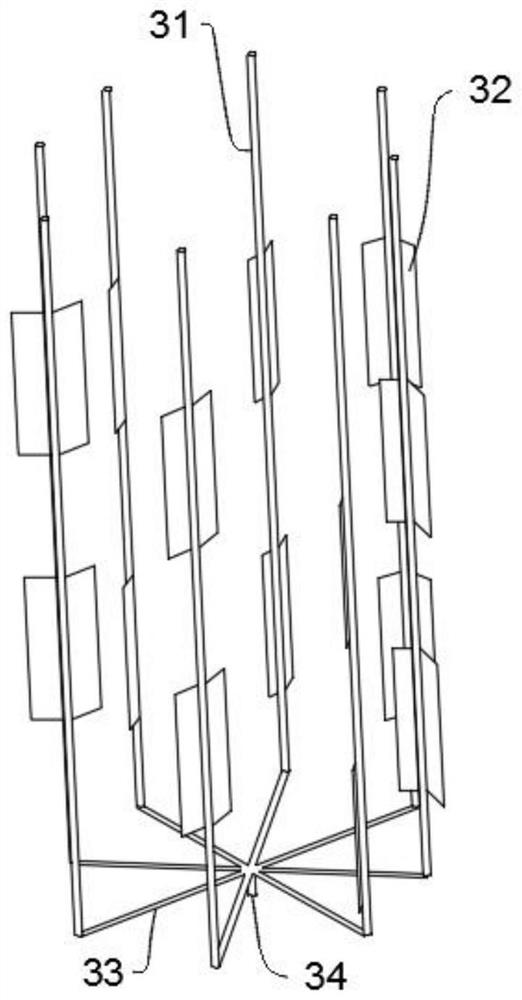

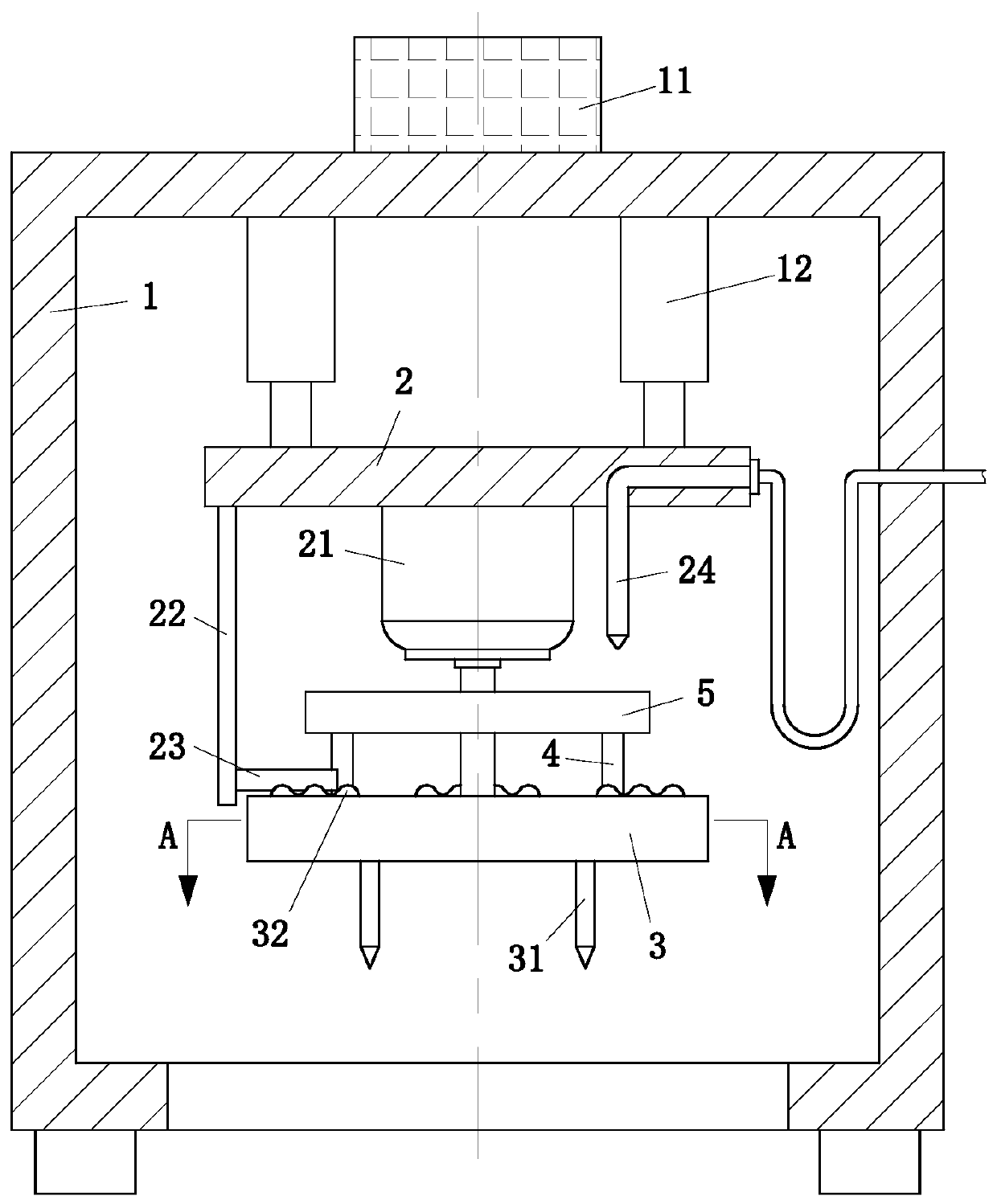

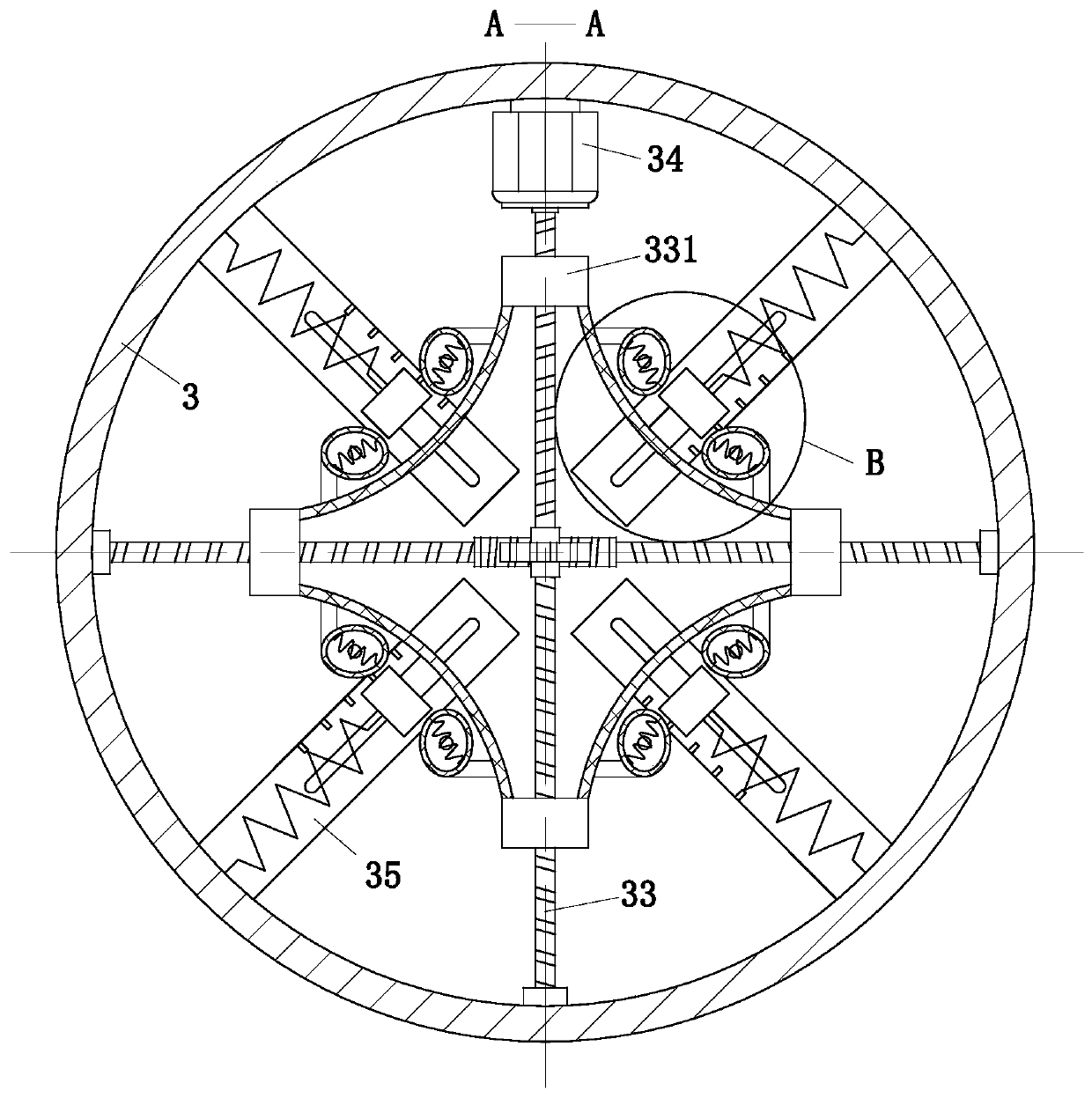

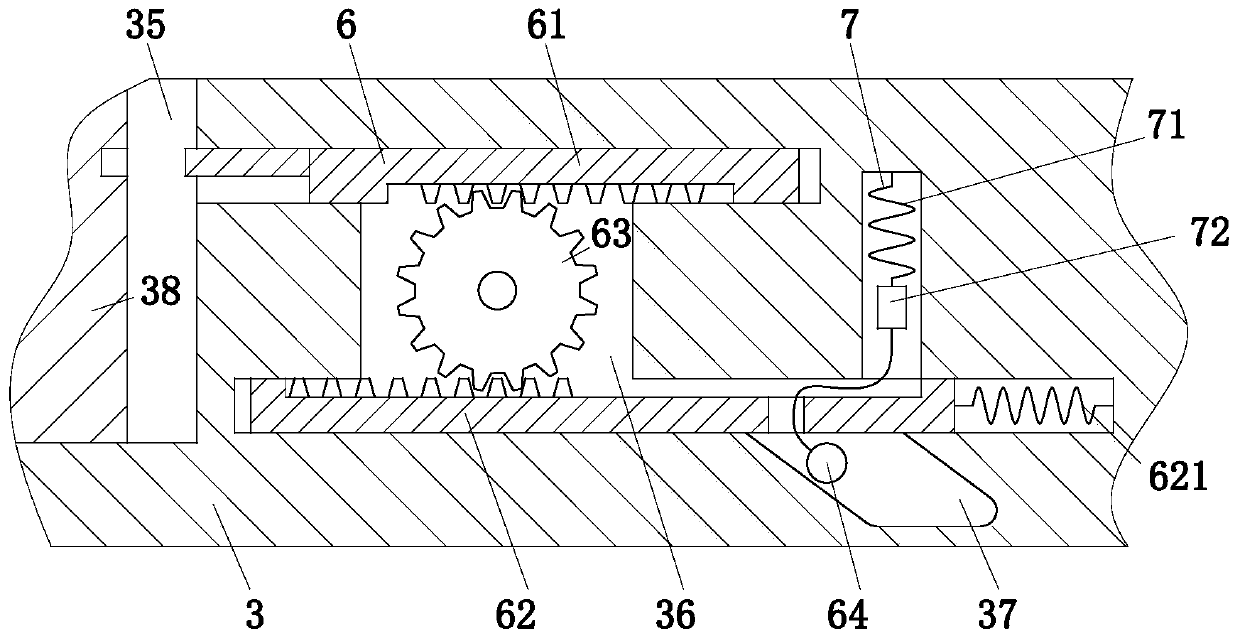

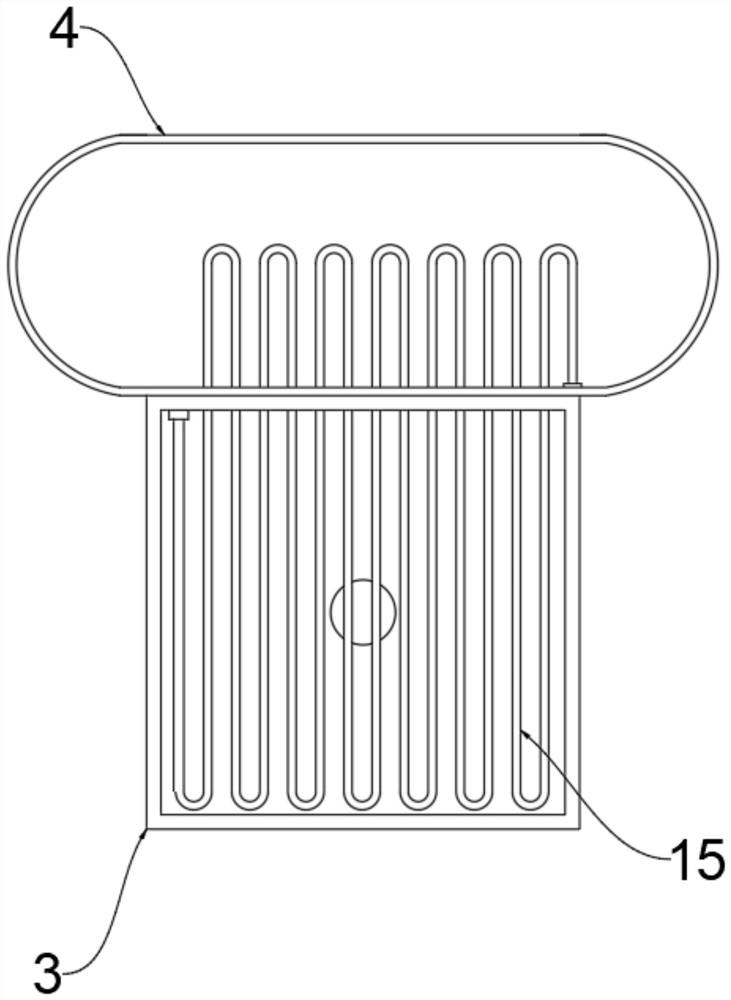

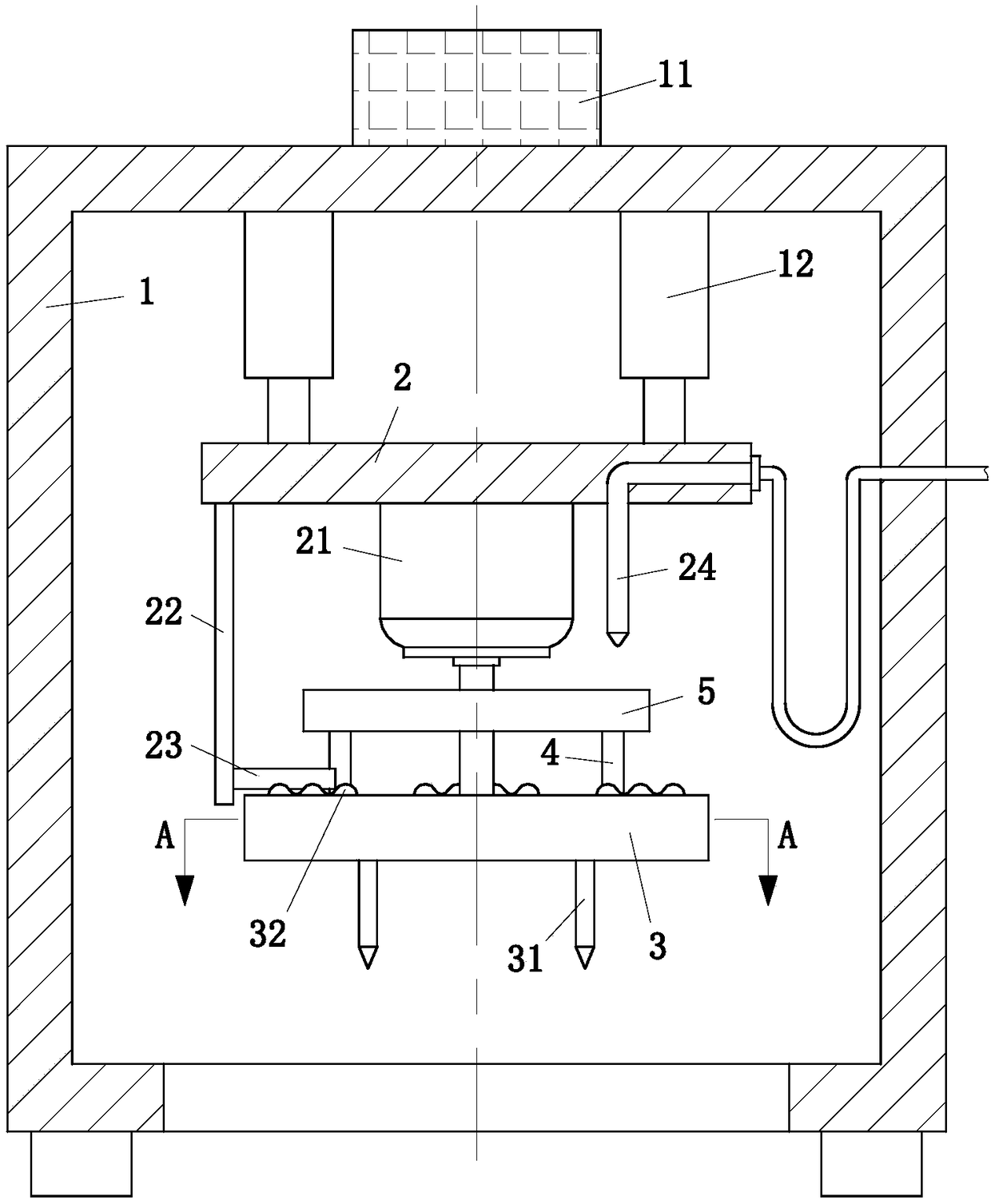

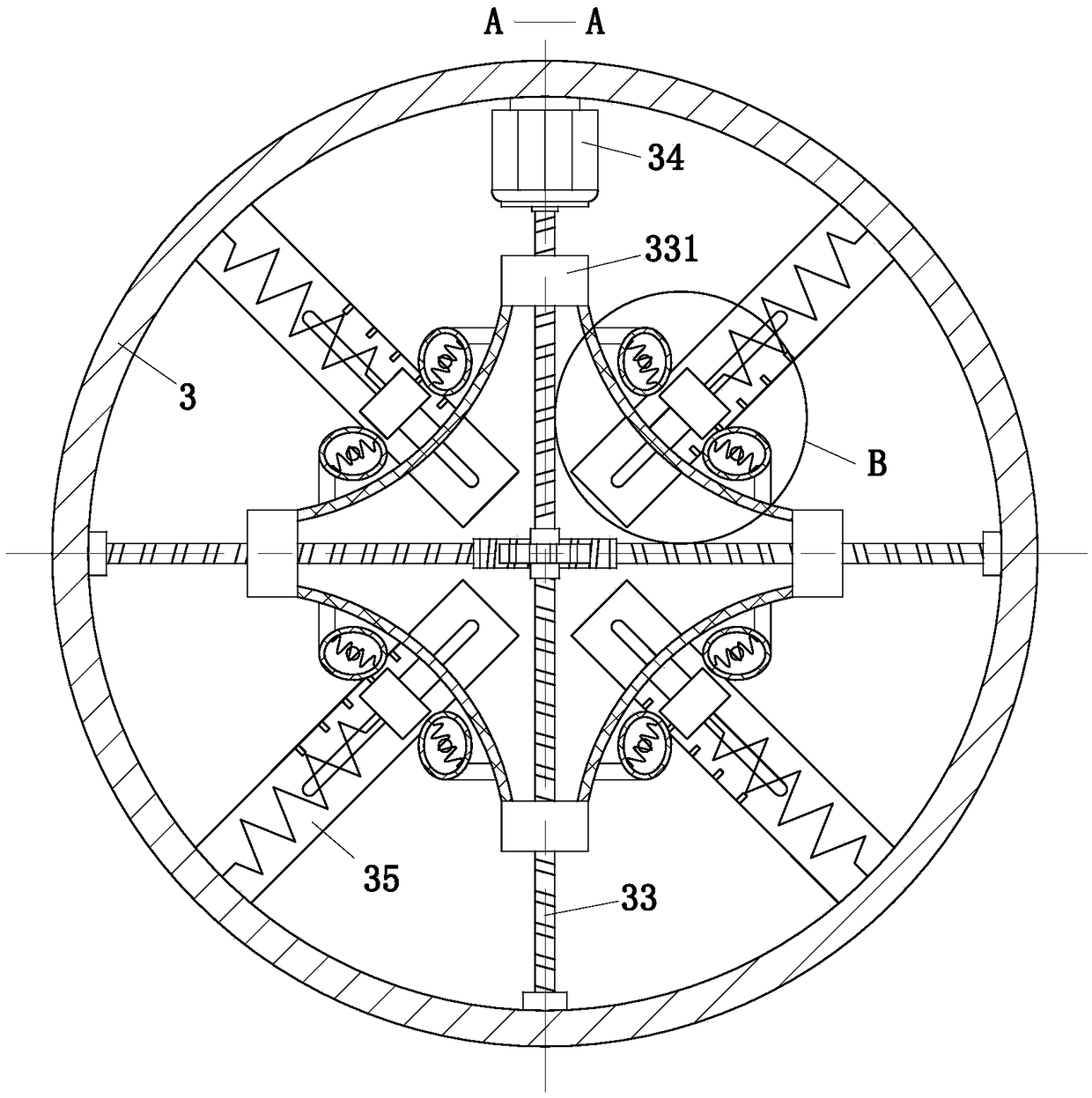

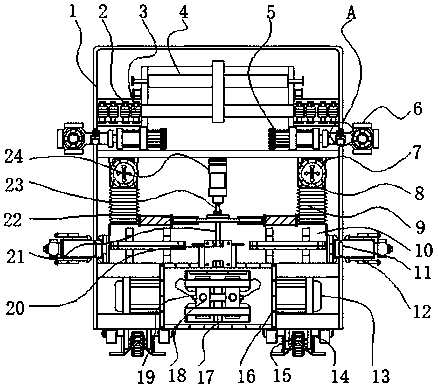

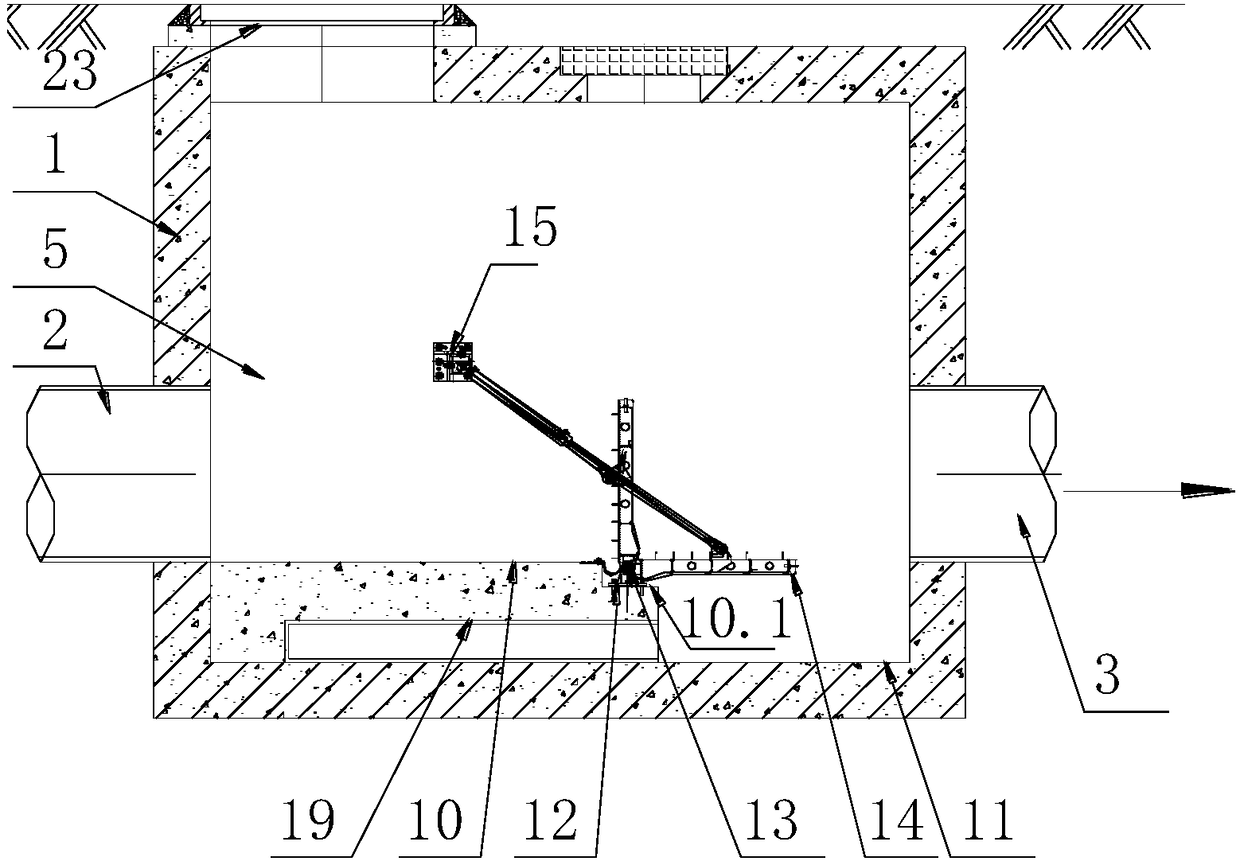

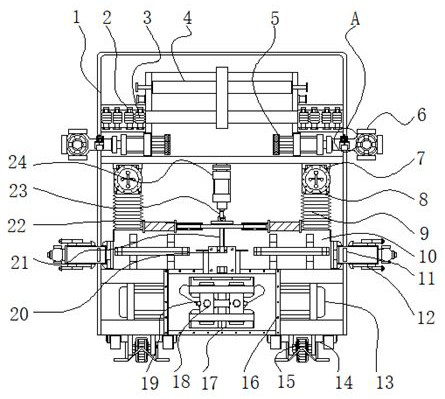

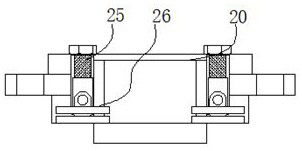

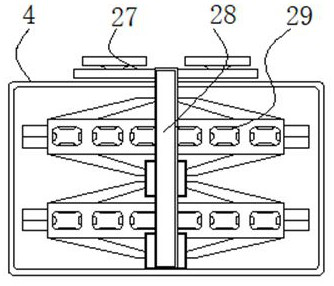

Drilling machine for exploration engineering

ActiveCN109707308AImprove drilling efficiencyEasy to useDrill bitsConstructionsElectric machineArchitectural engineering

The invention belongs to the technical field of drilling machines, and particularly relates to a drilling machine for exploration engineering. The drilling machine comprises a rack, a cutterhead and alocking module; two electric push rods are mounted at the top of the inner side of the rack, and the bottom ends of the two electric push rods are fixedly connected with a motor connecting seat; a first motor is mounted at the bottom of the motor connecting seat and is in transmission connection with the cutterhead through a rotary shaft; the inner side of the cutterhead is rotationally connectedwith two lead screws which are arranged up and down in a cross-shaped mode; a second motor is mounted on the inner side of the cutterhead, and four sets of sliding grooves are formed in the positions, corresponding to the two lead screws, on the cutterhead; the second motor is in transmission connection with the corresponding lead screw; the two ends of the lead screws are provided with connecting blocks correspondingly; the lead screws are used for driving the connecting blocks to move, and an arc-shaped elastic plate is fixedly connected between any two adjacent sets of connecting blocks; and sliding blocks are arranged in the sliding grooves, and the bottom ends of the sliding blocks are fixedly connected with a cutter. Drill holes with different sizes can be drilled, the drilling efficiency is improved effectively, water mist dust removal is utilized, and thus the dust removal efficiency is improved.

Owner:TANGSHAN JINSHI SUPER ABRASIVE

Microparticle sound absorbing atomization device

InactiveCN108721742AReduce stimulationPromote absorptionMedical devicesMedical atomisersEngineeringMicroparticle

The invention discloses a microparticle sound absorbing atomization device. The device comprises a casing, wherein an atomization container user for enabling a liquid to be atomized is arranged in thecasing; an ultrasonic emitter is arranged at the bottom of the atomization container; a sealing cover is arranged at the top of the casing; an exhaust vent is formed in the top of the sealing cover;the exhaust vent is connected with a separator through an exhaust pipe. The device can produce small mist which is convenient for people to absorb, and can reduce the noise and improve the user experience and comfort level by being provided with a sound absorbing device.

Owner:四川大爱科技有限公司

Handheld drillable polishing, dust-removing and dust-falling equipment

InactiveCN112792573AReduce generationReduce the content of particulate matterEdge grinding machinesUsing liquid separation agentParticulatesPolishing

The invention discloses handheld drillable polishing, dust-removing and dust-falling equipment. The handheld drillable polishing, dust-removing and dust-falling equipment comprises a handheld shell, wherein a motor cavity is formed in the handheld shell, four water spraying shells distributed in an annular array mode are fixedly connected to the inner wall of the motor cavity, a motor is fixedly connected to the lower ends of the water spraying shells, and an output shaft is in power connection to the lower end of the motor; and a driving belt wheel is fixedly connected to the periphery of the output shaft, a driven belt wheel is arranged on the right side of the driving belt wheel, a transverse belt is connected between the driven belt wheel and the driving belt wheel, a vertical rotating shaft is fixedly connected to the upper end of the driven belt wheel, and a transverse support is rotationally connected to the periphery of the vertical rotating shaft. According to the equipment, polishing treatment can be performed near a drilled hole while drilling is performed, so that barbs are reduced, the equipment can also be used as a polishing machine, polished dust can be collected, water can be sprayed to perform dust falling on raised dust, the content of particulate matter in air is reduced, and the morbidity of respiratory diseases is reduced.

Owner:深圳市合道信科技有限公司

Engineering system for removing NOx from flue gas in low temperature at rear end of desulfurizing tower

InactiveCN103657409AReduce the content of particulate matterReduce moistureDispersed particle separationAir quality improvementParticulatesChemistry

The invention relates to a system for removing NOx from kiln flue gas under the environment of high humidity (approximate to saturated humidity) and state approximate to normal temperature (40-60 DEG C) state. The system is used for efficiently removing NOx from flue gas with high temperature lower than 60 DEG C after calcium desulfurization, dual-alkali desulfurization and the like, so that SO2 and NOx in the flue gas can be fundamentally separated and absorbed to generate corresponding sulfates and nitrates, and most parts of particulate substances and Hg can be removed. The invention relates to a system for purifying flue gas by means of oxidizing NO in the flue gas through compressed air along the axial flow direction of a flue at the rear end of the existing flue gas desulfurizing tower to generate NO2 and NOx which are absorbed by an absorbent (water, ammonia water, alkali liquor and the like) under the special catalyst condition (low temperature and high humidity). The system provided by the invention can be widely applied to denitrating transformation of the existing desulfurization system.

Owner:张继惟

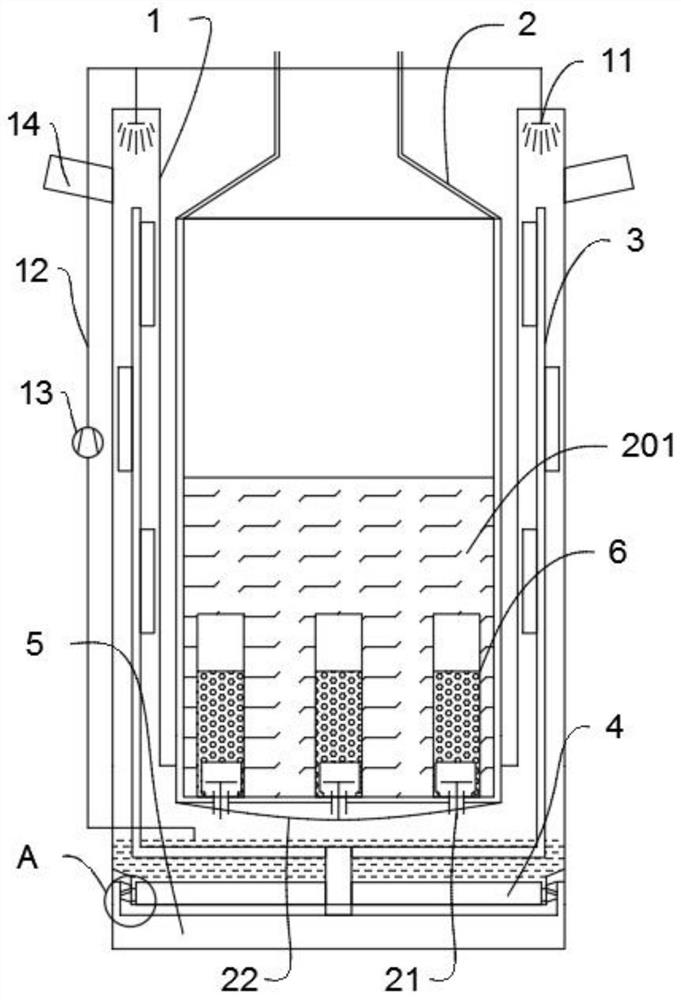

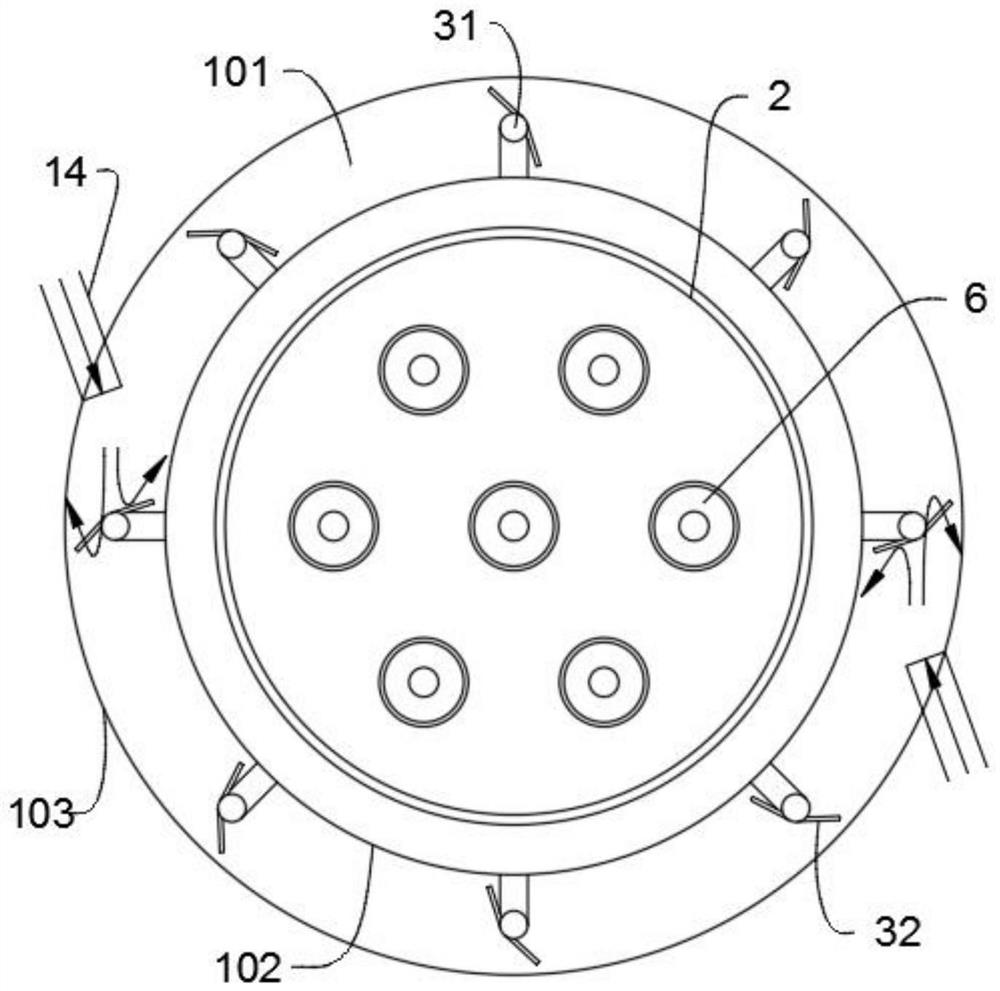

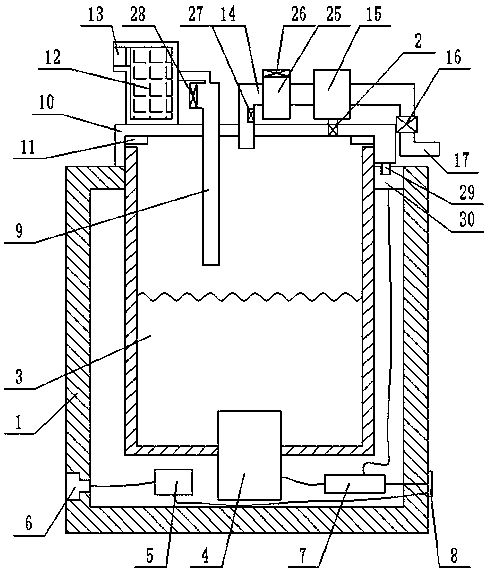

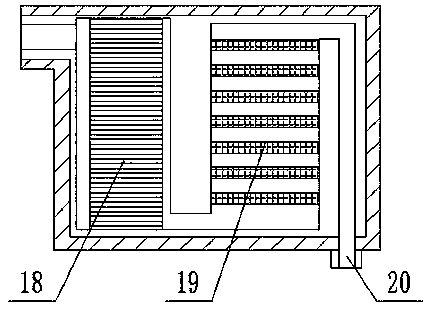

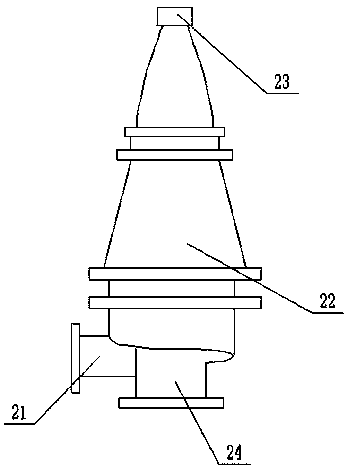

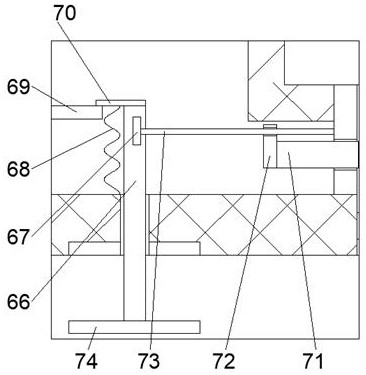

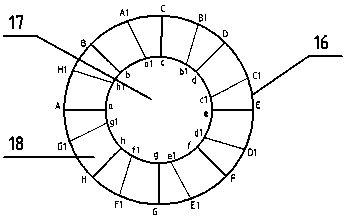

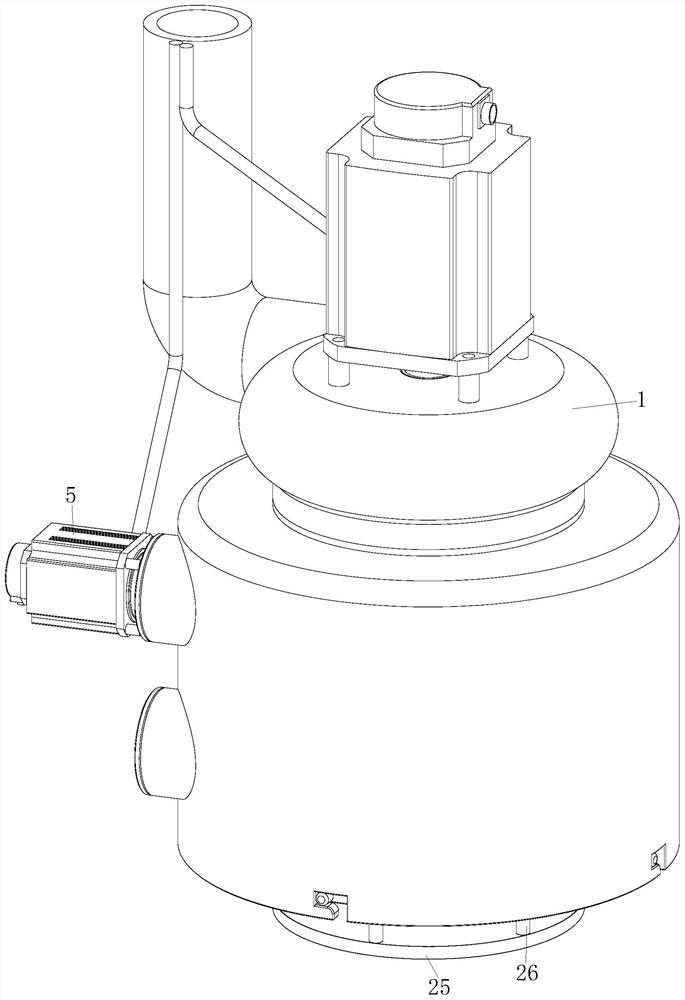

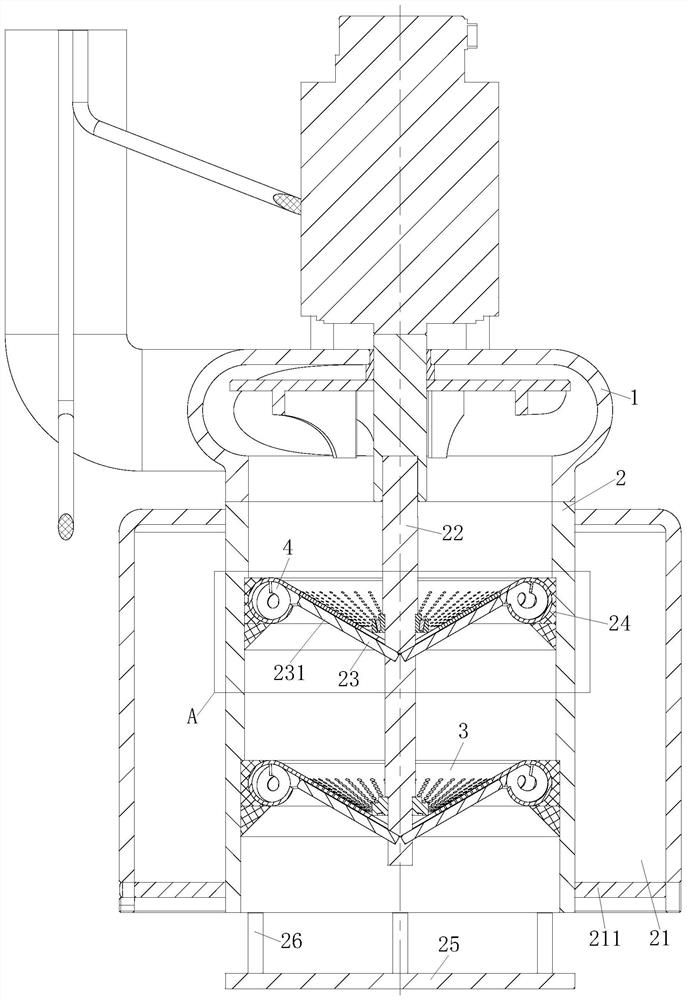

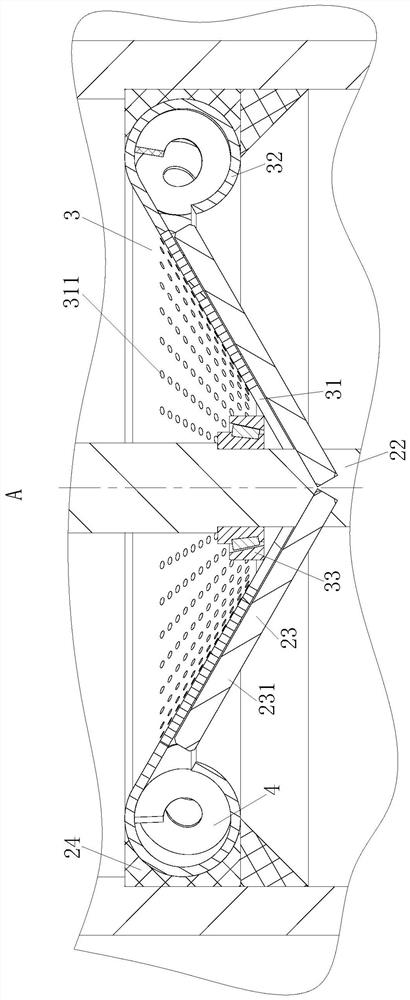

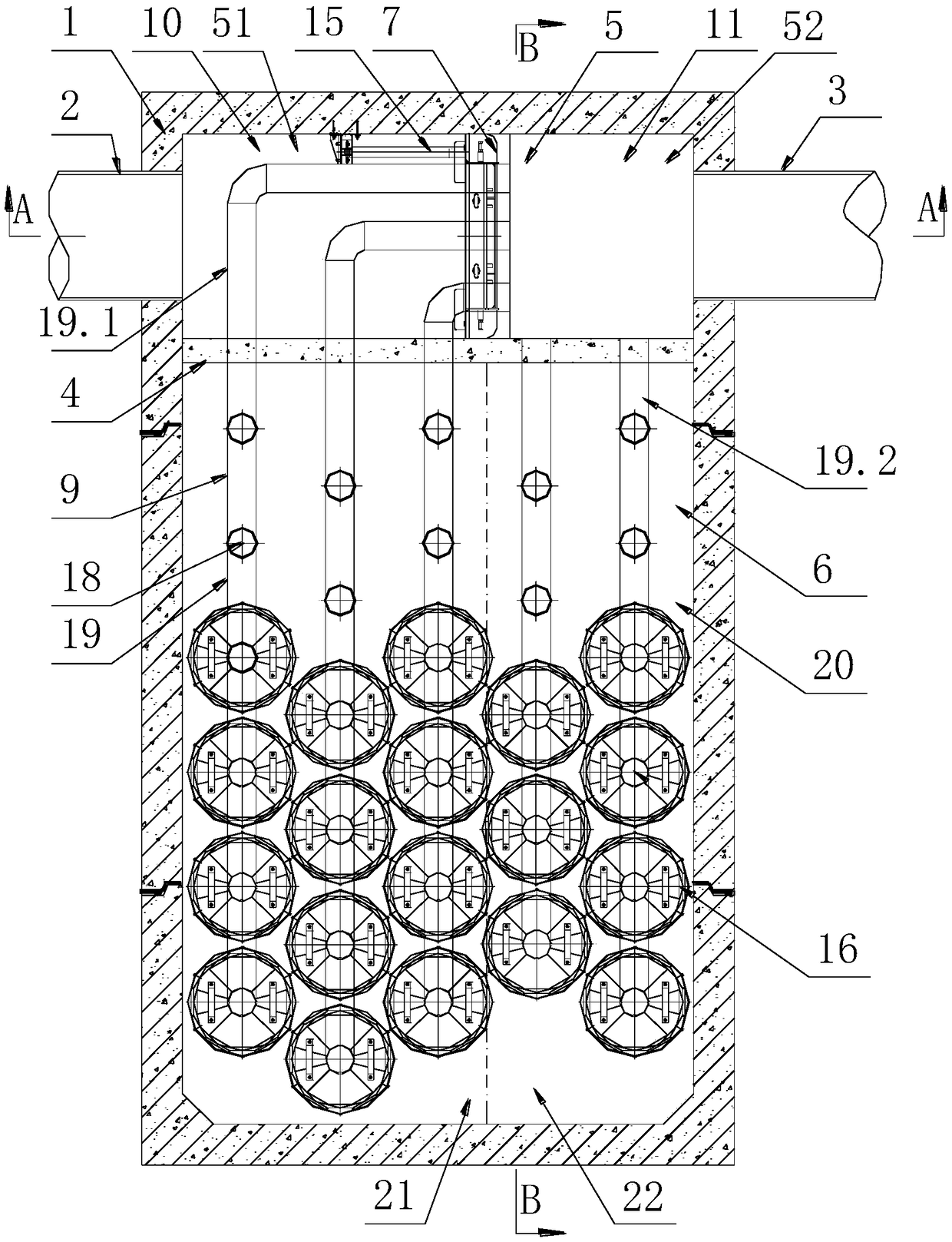

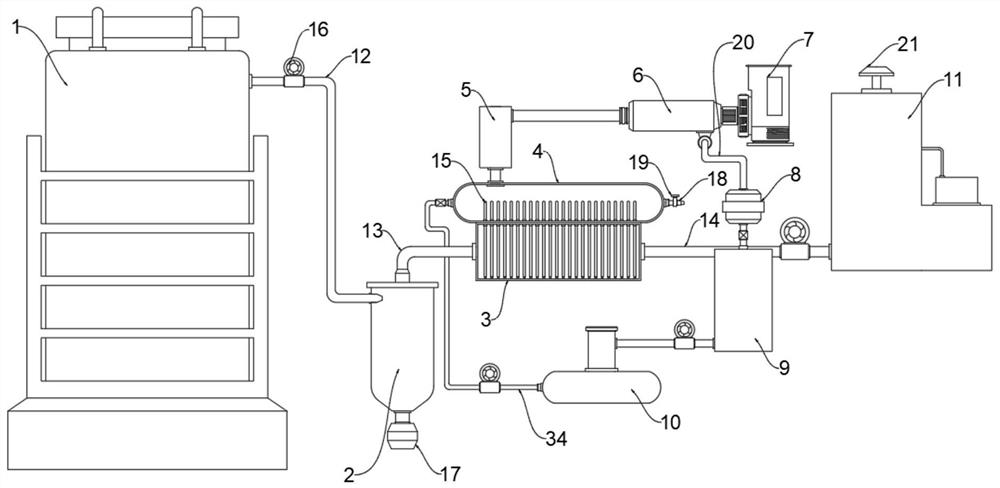

Boiler fume particulate matter purification device and method

The invention discloses a boiler fume particulate matter purification device and method and belongs to the technical field of boiler equipment. The device and method are used for purification of boiler fume. According to the technical scheme, the purification device is composed of an upper tower body and a lower tower body, a central pipe is installed in the lower tower body for sprinkling, partial particles in fume are removed, multiple rotational flow cylinders are installed on the upper tower body, and remaining fume particles are removed. The device has the advantages of being simple in structure, convenient to install, small in size and capable of well adapting to the characteristics of the fume of biomass boilers and is novel equipment for fume purification of existing biomass boilers. The device is an innovation for fume purification treatment of the boilers, a wet dedusting mode is combined with a dry dedusting mode, a gas-phase, liquid-phase and solid-phase adhesion principleand an inertial dedusting principle are utilized, a design mode in which the fume is treated by means of a wet pre-dedusting mode and then treated by means of a rotational flow deep purification dedusting mode is adopted, the content of particulate matter in the fume which is discharged outwards is reduced to a great extent finally, and the problem of emission of pollutants in the fume of the biomass boilers is well solved.

Owner:TANGSHAN IRON & STEEL GROUP +1

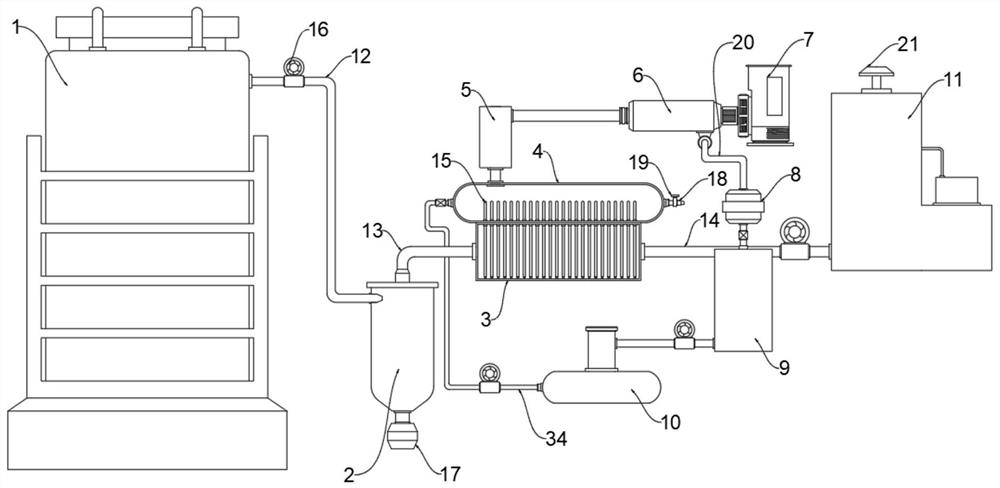

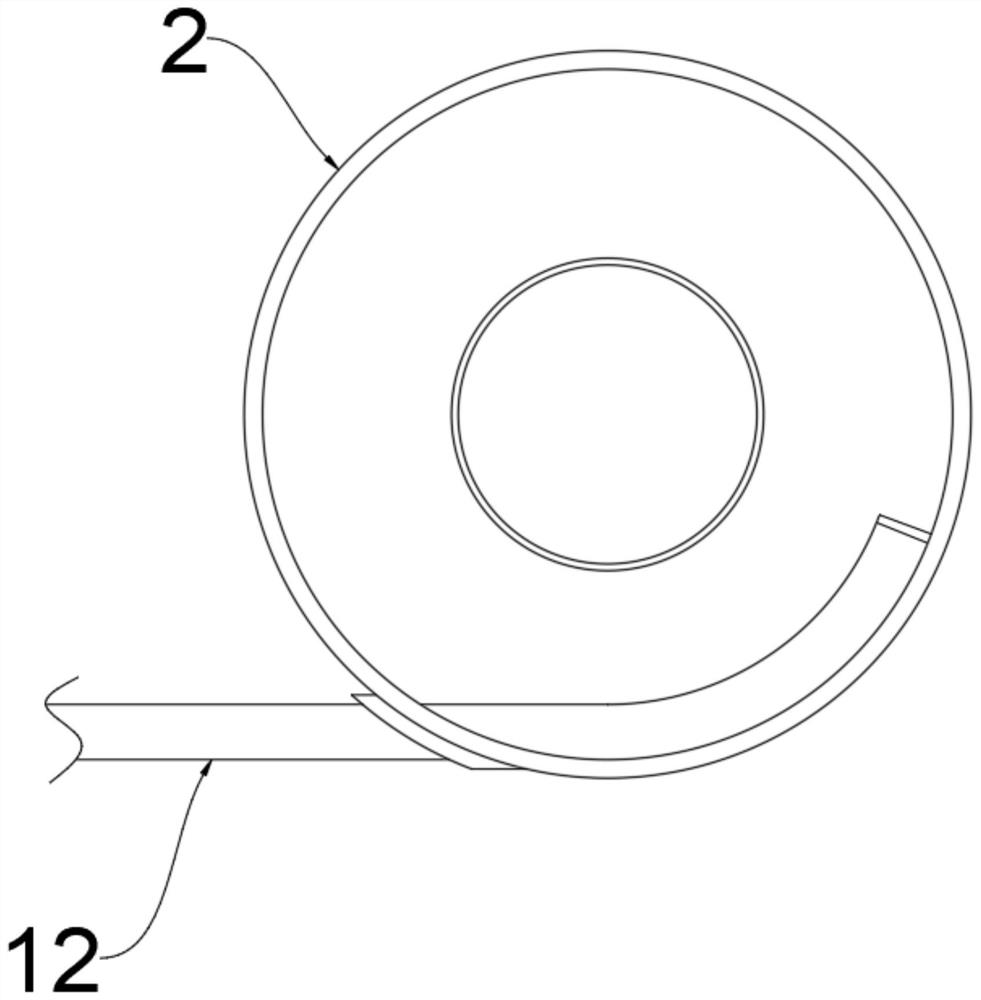

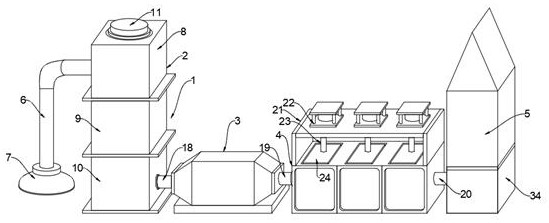

Waste heat recovery system for prebaked anode production, and using method thereof

ActiveCN112066729AIncrease heat absorptionImprove working abilityCombination devicesGas treatmentWater storage tankSuperheater

The invention discloses a waste heat recovery system for prebaked anode production, and a using method thereof, and relates to the technical field of waste heat recovery equipment. The recovery effectis improved on the premise that the existing waste heat recovery is environmentally friendly. A smoke-dust separator is arranged below one side of a pot calciner, and a smoke heat exchange pipeline is arranged above one side of the smoke-dust separator; a steam boiler is fixedly welded at the upper end of the smoke heat exchange pipeline, and heat exchange fins are installed in the smoke heat exchange pipeline, and the upper ends of the heat exchange fins extend into the steam boiler; a superheater header is installed on one side of the upper end of the steam boiler, and a steam turbine is arranged on one side of the superheater header; the superheater header and the steam turbine are fixed through a pipeline hermetically, and a generator is installed at the output end of the steam turbine; a water storage tank is arranged below the generator, and a deaerator is installed on one side of the water storage tank; and a purification tower is arranged on the other side of the water storagetank.

Owner:赤壁长城炭素制品有限公司

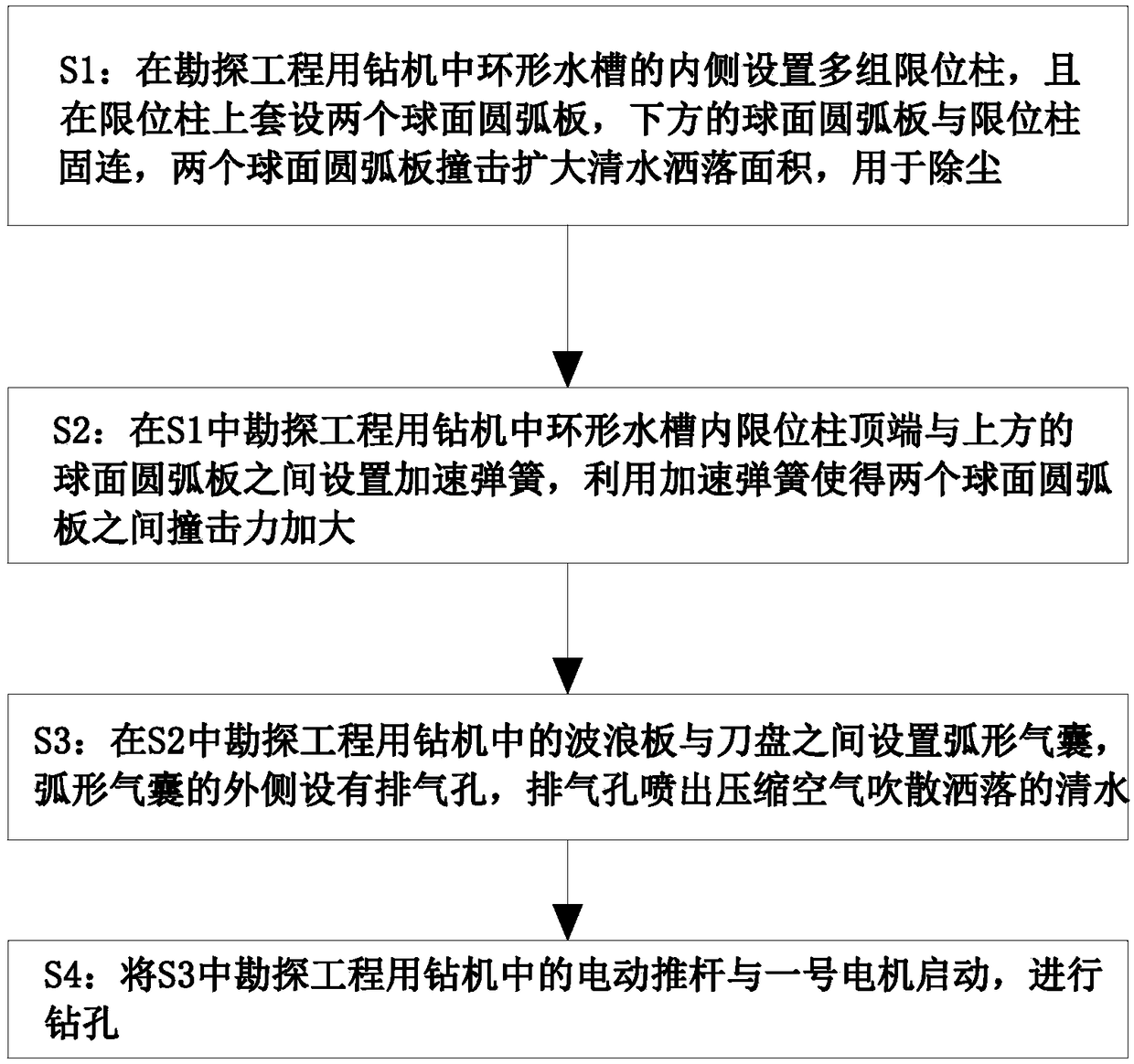

Prospecting borehole drilling method

ActiveCN109488236AExpand the spraying areaImprove dust removal efficiencyEarth drilling toolsDrill bitsPhysical healthWater spray

The invention belongs to the technical field of drilling and particularly relates to a prospecting borehole drilling method, comprising the steps of setting multiple groups of limiting posts in a circular water trough in a prospecting engineering drill rig, and sleeving each limiting post with two spherical arc plates, with the lower spherical arc plate fixedly connected to the limiting post and the two spherical arc plates impacting to enlarge water spraying area for dust removal; setting acceleration springs between the top ends of the limiting posts in the circular water trough of the prospecting engineering drill rig and the spherical arc plates above so that the acceleration springs help enlarge impact force between the spherical arc plates; setting an arc balloon between a wavy plateof the prospecting engineering drill rig and a cutterhead, arranging an exhaust hole in the outer side of the arc balloon, and spraying compressed air from the exhaust hole to blow off sprinkled clear water; starting an electric push bar and a first motor in the prospecting engineering drill rig to perform drilling. The method herein has the advantages that water spraying area is enlarged, dust removal efficiency is effectively improved, and physical health of workers is protected.

Owner:匠桥智谷科技(涡阳)有限公司

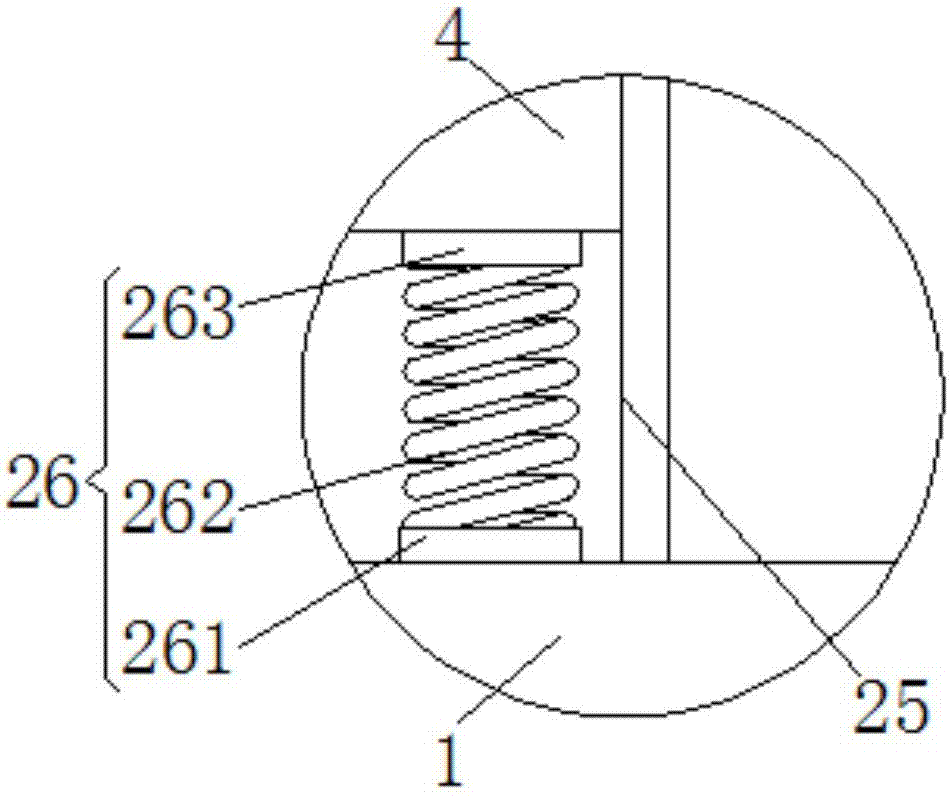

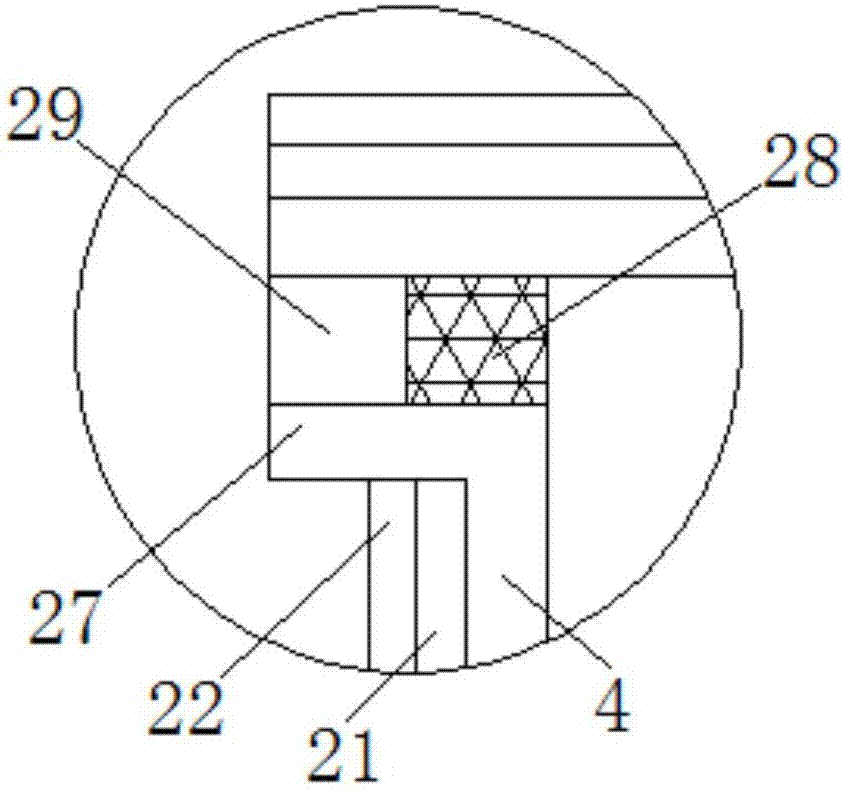

Anti-static floor convenient to install

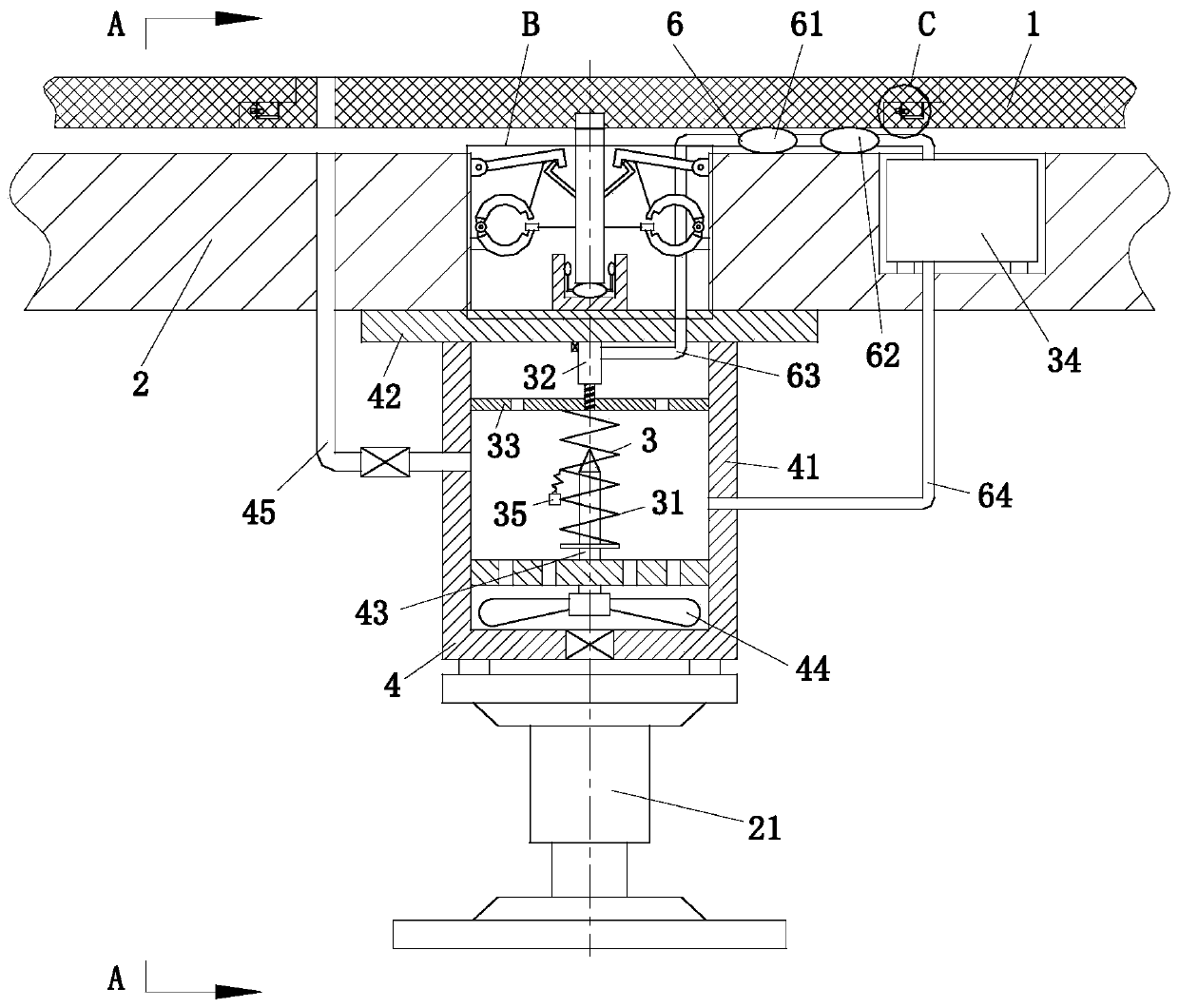

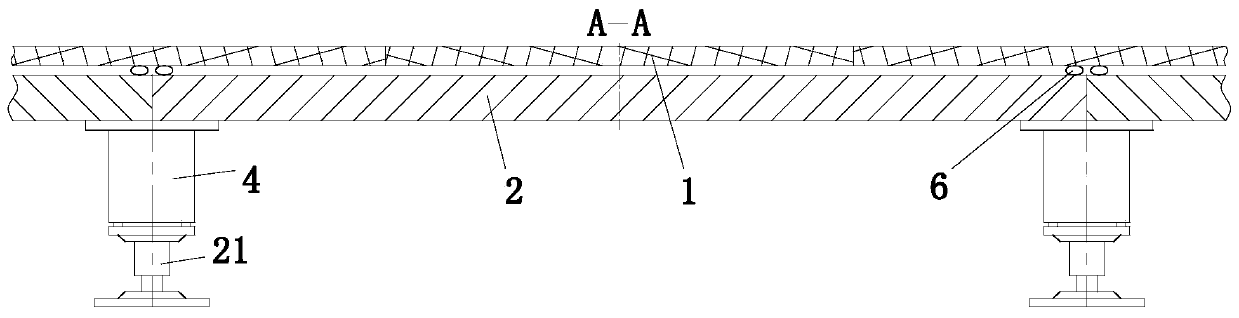

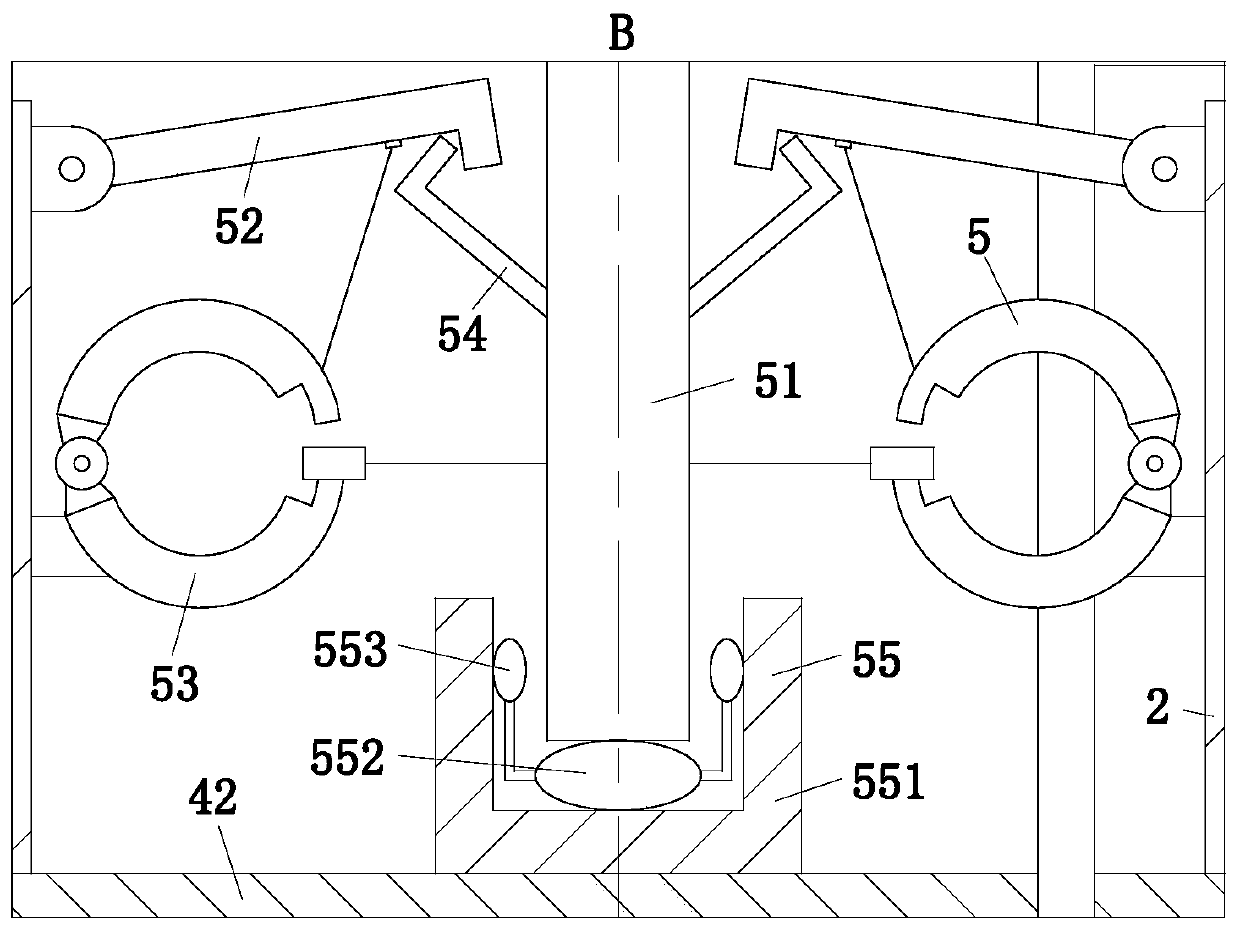

ActiveCN109779200AEasy to installReduce the probability of static electricityFlooring insulationsFalse floorsEngineeringRectangular array

The invention belongs to the technical field of electrostatic prevention, and particularly relates to an anti-static floor convenient to install. The anti-static floor comprises an anti-static floor body, a supporting bottom plate, an adjusting base, a dust removal module, an anti-static module, a fixing module and a controller; the multiple adjusting bases are arranged on the ground in a rectangular array mode; the supporting bottom plate is installed on the adjusting base; the anti-static floor body is arranged at the top of the supporting bottom plate; and a buffer module is arranged between the supporting bottom plate and the anti-static floor body; the controller is arranged at the bottom of the supporting bottom plate; the top of the adjusting base is fixedly connected with the anti-static module; the fixing module is installed at the top of the anti-static module; and the dust removal module is arranged on the inner side of the anti-static module. The electrostatic eliminating device can generate ionized gas, electrostatic eliminating operation is conducted through the ionized gas, the anti-static efficiency is effectively improved, a brush on the inner side of a plastic spring is used for conducting dust removing on a discharging needle, and the dust removing efficiency can be improved.

Owner:浏阳市金穗出口花炮厂(普通合伙)

Fluid catalytic cracking (FCC) flue gas treatment system and FCC flue gas treatment method

PendingCN108187463AReduce the content of particulate matterReduce concentrationCombination devicesGas treatmentFlue gasSulfur trioxide

The invention relates to a fluid catalytic cracking (FCC) flue gas treatment system and an FCC flue gas treatment method. The system comprises a selective catalytic reduction (SCR) reactor, a waste heat boiler, a pre-dust remover, a water mist generator, a wet desulphurization device, a wet electrostatic precipitator, a jet apparatus, a temperature detection device and a sulfur trioxide concentration detection device, wherein a flue gas inlet of the SCR reactor is used for introducing FCC flue gas to be treated; a flue gas outlet of the SCR reactor is communicated with a flue gas inlet of thewaste heat boiler by means of a pipeline, a flue gas outlet of the waste heat boiler is communicated with a flue gas inlet of the pre-dust remover by means of a pipeline, a flue gas outlet of the pre-dust remover is connected with a flue gas inlet of the wet desulphurization device by means of a pipeline, and a flue gas outlet of the wet desulphurization device is communicated with a flue gas inlet of the wet electrostatic precipitator by means of a pipeline; a flue gas outlet of the wet electrostatic precipitator is used for discharging the treated FCC flue gas. The FCC flue gas treatment system and the FCC flue gas treatment method have the advantage of effectively treating colored smoke plume in the FCC flue gas.

Owner:XIAMEN RECH TECH

Filtering and self-collecting type submersible sewage pump

InactiveCN113074118AStable jobEasy to follow upSpecific fluid pumpsPump componentsParticulatesWater flow

The invention belongs to the technical field of pumps, and particularly relates to a filtering and self-collecting type submersible sewage pump which comprises a centrifugal pump, a shell and a filtering part. According to the filtering and self-collecting type submersible sewage pump, the centrifugal pump works, sewage in the shell is sucked into the centrifugal pump through the filtering part, large particles are blocked below by a horn mouth structure, the particles blocked below the horn mouth structure move upwards along the surface of the horn mouth structure under the action of water flow, then the particles enter a collecting structure, and the filtered sewage is discharged by the centrifugal pump, so that the sewage is conveyed; and most of conventional sewage pumps are internally provided with crushing mechanisms, when particles are hard and cannot be crushed or more particles enter, the particles can hinder rotation of an impeller, normal work of the sewage pump is affected, and the submersible sewage pump separates the particles from sewage, so that the situation that rotation of the impeller of the centrifugal pump is hindered by the particles is avoided, then stable work of the centrifugal pump is achieved, and then stable work of the submersible sewage pump is achieved.

Owner:王培娟

Additive for reducing diesel engine PM2.5 emission and application thereof

InactiveCN103224824APromote combustionReduce the content of particulate matterLiquid carbonaceous fuelsFuel additivesChemistryDicarbonate

The present invention relates to an additive for reducing diesel engine PM2.5 emission and an application thereof. The additive is a mixture of a peroxide and an azo compound, wherein the peroxide is a peroxide with a carbon number of 8-24, and is one or a plurality of materials selected from a tert-butyl peroxide, a peroxide organic ester, or a peroxide dicarbonate, and the azo compound is azobisisobutylnitrile, 2,2'-azobis(2,4-dimethyl)valeronitrile or isopropyl azodiformate. The application comprises: adding the additive to a diesel fuel, wherein the additive content is 300-3000 ppm relative to the diesel fuel content. With the present invention, diesel engine PM2.5 emission is significantly reduced; the additive-containing diesel fuel does not produce ash during burning so as not to provide wear for the diesel engine; a good match performance of the peroxide composition and the diesel fuel is provided; the peroxide has a mild reaction temperature; the process is simple; and the product and the diesel fuel are easily mixed so as to provide high practicality.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

High-pressure blowing type runway cleaning device for airport maintenance

ActiveCN110295563AGuaranteed to workReduce noise pollutionRoad cleaningVibration amplitudeEngineering

The invention relates to a high-pressure blowing type runway cleaning device for airport maintenance. The device comprises a main body and a fixed plate; a water tank is mounted at the middle part ofthe inner top end of the main body; the bottom ends of the left and right sides of the water tank are connected with rubber plates; the rubber plates are fixedly connected with the water tank; partition columns are fixed at the bottoms of the rubber plates; the rubber plates are vertical to the partition columns; and water pumps are arranged at the bottom ends of the partition columns. The devicehas the beneficial effects that the distance between the water tank and the main body can be kept through the partition columns between the rubber plates and the water tank, when the machines in the water tank work, the vibration amplitudes of the machines can be reduced through the rubber plates and the partition columns between the water tank and the main body, the water tank can be spaced fromthe main body for a certain distance, the noise of the machines can be isolated so as to reduce the noise pollution of the airports, and the liquid in the water tank can be prevented from leaking ontothe parts of the main body so as to keep the normal work of the cleaning device.

Owner:北京京航安机场工程有限公司

Intercepting filter on-line treatment pool and control method thereof, and rainwater treatment system

InactiveCN108211467AStrong maneuverabilityWide range of applicationsTreatment involving filtrationRunoff/storm water treatmentOnline processingTreatment effect

The invention discloses an intercepting filter on-line treatment pool and a control method thereof, and a rainwater treatment system. The intercepting filter on-line treatment pool comprises a pool body as well as a water inlet and a water outlet which are formed in the pool body, and also comprises a blocking wall arranged in the pool body; the blocking wall partitions the pool body into a waterpassing gallery and a filter treatment area; a particle filtering device and a water discharging device are arranged in the filter treatment area; a water inlet hole is formed in the part, which is positioned on a first area, of the blocking wall; the water inlet hole is used for communicating the filter treatment area and the first area; and the water discharging device is used for communicatingthe filter treatment area and a second area. The intercepting filter on-line treatment pool is simple in structure and convenient to operate; and the on-line treatment pool can deeply filter rainwaterat the early stage of rainfall, can draw off floodwater rapidly when the flow quantity is high, can reduce pollution to a natural water body and can guarantee the rainwater treatment effect of the rainwater treatment system.

Owner:WUHAN SHENGYU DRAINING SYST

Waste lithium ion power battery protection crushing process equipment

PendingCN112958257APrevent deflagration accidentsImprove securityWaste accumulators reclaimingGrain treatmentsPower batteryParticulates

The invention discloses a waste lithium ion power battery protection crushing process equipment. The equipment comprises a conveying belt assembly and a nitrogen tank, and the top end of the conveying belt assembly is arranged at a feeding opening of a crushing machine shell in an attached mode; and a nitrogen pipe connected between the nitrogen tank and the crushing machine shell achieve internal communication of the nitrogen tank and the crushing machine shell, the top of the crushing machine shell is connected with one end of a first conveying pipe in a penetrating mode, the other end of the first conveying pipe is installed on a cyclone dust collector, the lower end of the cyclone dust collector is connected with a storage bin used for collecting particle plates, and an air locking valve is mounted at a port of the storage bin. According to the waste lithium ion power battery protection crushing process equipment, an electrolyte volatile gas treatment structure is arranged inside the equipment, gas atmosphere protection can be conducted on a crushing device, detonation accidents are prevented, safety is better, the equipment can treat particulate matter generated by crushing, the particulate matter content in tail gas is effectively reduced, and the device is more environment-friendly.

Owner:北辰先进循环科技(青岛)有限公司

Aircraft runway high-pressure blowing type cleaning device for airport maintenance

ActiveCN110295563BGuaranteed to workReduce noise pollutionRoad cleaningPlate columnStructural engineering

The invention relates to a high-pressure blowing type cleaning device for airfield runway for airport maintenance, which includes a main body and a fixed plate. A water tank is installed in the middle of the inner top of the main body, and rubber plates are connected to the bottom ends of the left and right sides of the water tank. There is a fixed connection between the board and the water tank, a partition column is fixed at the bottom of the rubber board, and a vertical structure is formed between the rubber board and the partition column, and a water pump is arranged at the bottom of the partition column. The beneficial effects of the present invention are: the distance between the water tank and the main body can be maintained through the partition column between the rubber board and the water tank, and when the machinery in the water tank is working, the rubber board and the partition between the water tank and the main body The plate column can reduce its vibration amplitude, and can keep a certain distance from the main body, and can isolate the mechanical noise, thereby reducing the noise pollution of the airport, and can also prevent the liquid in the water tank from leaking to the parts of the main body , so as to maintain the normal operation of the cleaning equipment.

Owner:北京京航安机场工程有限公司

Printing and packaging ink waste gas collecting and treating device

PendingCN114345064ASpeed up the flowEasy to killCombination devicesDispersed particle filtrationUltraviolet lightsProcess engineering

The invention discloses a printing and packaging ink waste gas collection and treatment device, relates to the technical field of ink waste gas collection and treatment, and aims to solve the problems that existing ink waste gas collection and treatment equipment is incomplete in treatment effect, and particles are difficult to completely irradiate by an irradiation channel during ultraviolet treatment, so that particle residues exist in gas. A printing ink waste gas treatment tower is arranged at one end of the printing ink waste gas treatment mechanism, an ultraviolet treatment box is arranged on one side of the printing ink waste gas treatment tower, a residual impurity filtering box is arranged on one side of the ultraviolet treatment box, and an exhaust mechanism is arranged on one side of the residual impurity filtering box; partition plates are arranged at the two ends of the interior of the ultraviolet treatment box, a partition channel is formed between every two adjacent partition plates, a transparent spiral pipe is arranged in the middle of the interior of the ultraviolet treatment box, and an ultraviolet lamp bead plate is arranged at the rear end of the transparent spiral pipe.

Owner:苏州市大象印刷包装有限公司

A waste heat recovery system for prebaked anode production and its application method

ActiveCN112066729BIncrease heat absorptionImprove working abilityCombination devicesGas treatmentWater storage tankFlue gas

The invention discloses a waste heat recovery system for prebaked anode production and a use method thereof, relates to the technical field of waste heat recovery equipment, and aims to solve the existing problem of how to improve the recovery effect under the premise of waste heat recovery and environmental protection. A soot separator is arranged below one side of the pot calciner, and a flue gas heat exchange pipe is arranged above one side of the soot separator, and a steam boiler is welded and fixed on the upper end of the flue gas heat exchange pipe, and the Heat exchange fins are installed inside the flue gas heat exchange pipe, and the upper end of the heat exchange fins extends to the inside of the steam boiler. An overheating box is installed on one side of the upper end of the steam boiler, and a steam turbine is installed on one side of the overheating box. And the overheating box and the steam turbine are sealed and fixed through pipelines, a generator is installed at the output end of the steam turbine, a water storage tank is arranged under the generator, a deaerator is installed on one side of the water storage tank, and a deaerator is installed on one side of the water storage tank. The other side is provided with a purification tower.

Owner:赤壁长城炭素制品有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com