Fluid catalytic cracking (FCC) flue gas treatment system and FCC flue gas treatment method

A technology of flue gas and flue gas reheater, applied in the field of plume treatment, can solve the problems of high moisture content of waste residue, peeling off of anti-corrosion layer, acid corrosion, etc., achieve high surface area and density, reduce ammonia escape, and strong adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

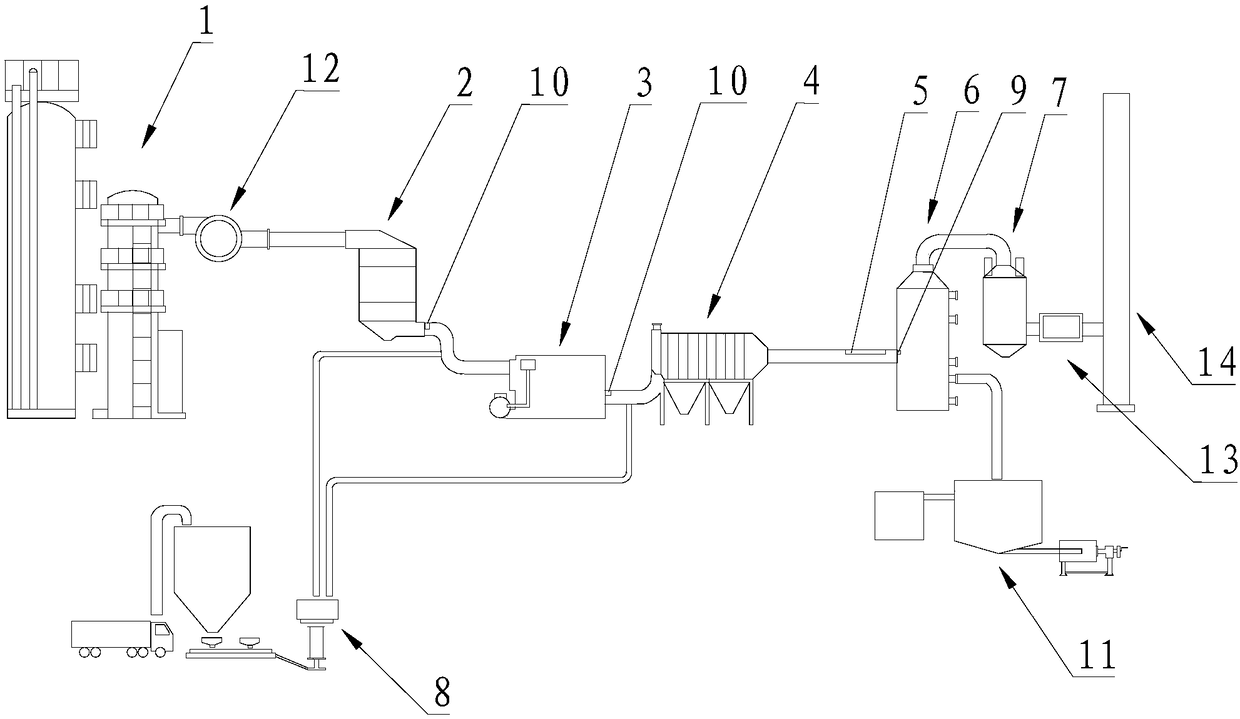

[0072] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0073] The FCC flue gas treatment system of this embodiment includes an SCR reactor 2 (SCR is selective catalytic reduction), a waste heat boiler 3, a pre-dust collector 4, a water mist generating device 5, a wet desulfurization device 6, and a wet electrostatic precipitator. device 7, injection device 8, temperature detection device 9 and sulfur trioxide concentration detection device 10, the smoke inlet of the SCR reactor 2 is used to pass into the FCC flue gas to be treated (discharged from the FCC device 1, FCC is Fluid Catalytic Cracking, that is, catalytic cracking), the smoke outlet of the SCR reactor 2 and the smoke inlet of the waste heat boiler 3, the smoke outlet of the waste heat boiler 3 and the smoke inlet of the pre-dust collector 4, the The smoke outlet of the pre-dust collector 4 is connected to the smoke inlet of the wet desulfurization device 6, and the smoke outlet of the wet des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com