Patents

Literature

36results about How to "Prevent deflagration accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

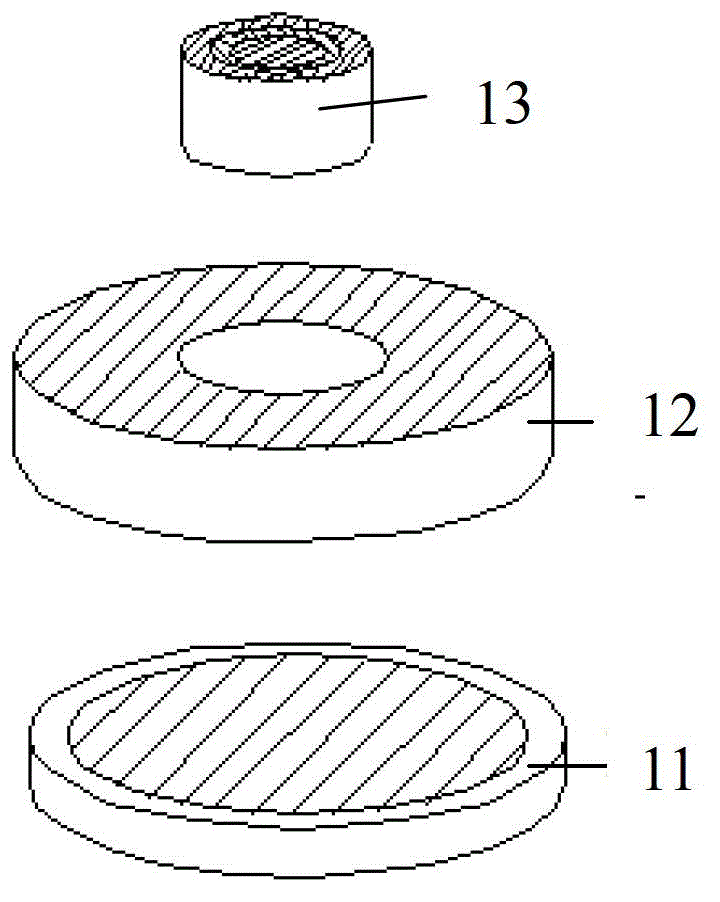

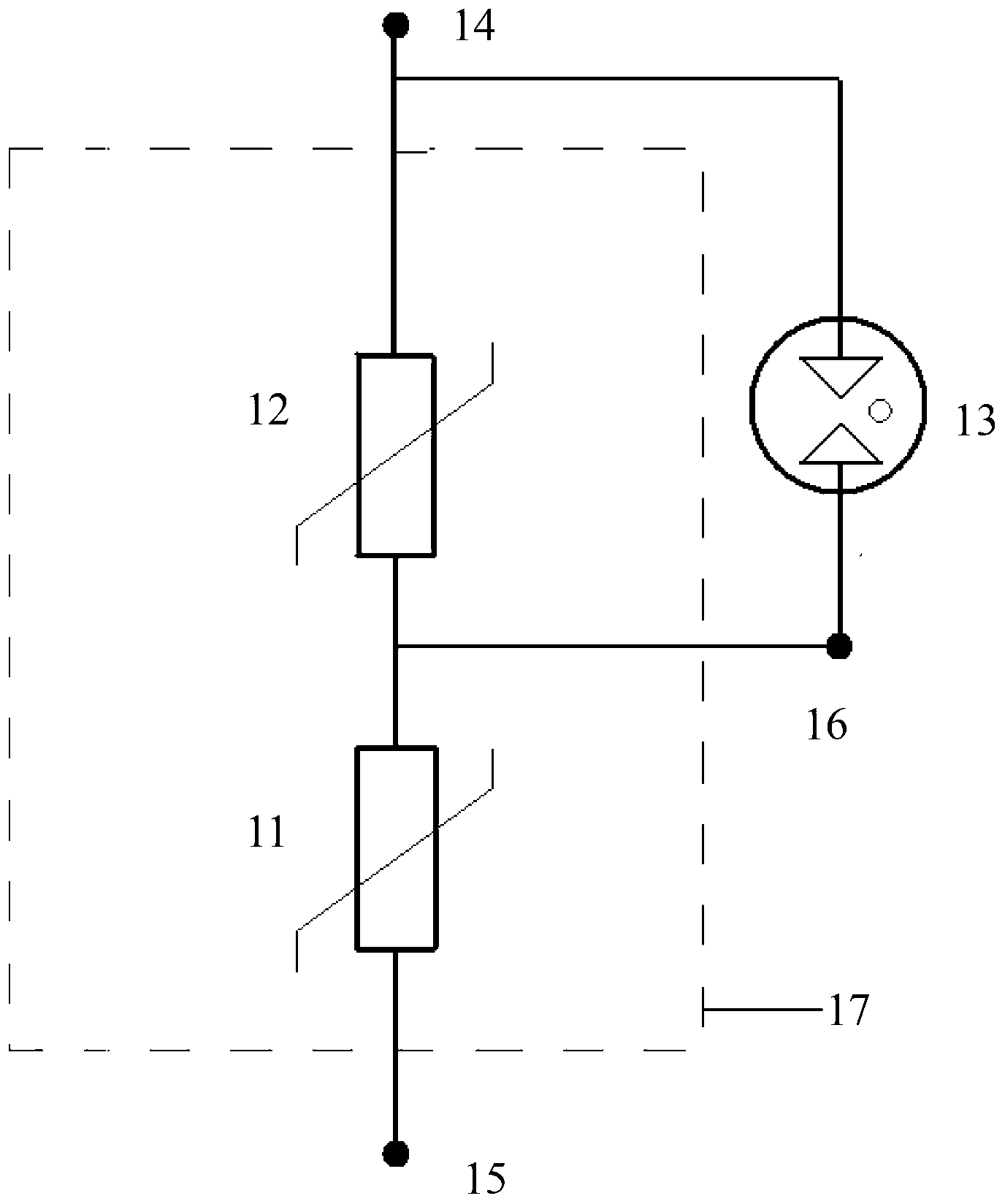

Anti-thunder overvoltage protection device

InactiveCN103346547ANormal work is not affectedCurrent limitEmergency protective arrangements for limiting excess voltage/currentOvervoltageLightning strokes

The invention discloses an anti-thunder overvoltage protection device. The anti-thunder overvoltage protection device comprises a piezoresistor, a positive temperature coefficient thermistor and a gas discharge tube, wherein the positive temperature coefficient thermistor is connected with the gas discharge tube in parallel and then connected with the piezoresistor in series; the positive temperature coefficient thermistor and the piezoresistor form a thermal coupling relationship. The piezoresistor, the positive temperature coefficient thermistor and the gas discharge tube can be packaged into a whole, or the piezoresistor and the positive temperature coefficient thermistor are packaged into a whole, thus a packaged body is formed, and the gas discharge tube is located outside the packaged body. The anti-thunder overvoltage protection device not only can restrain operation overvoltage and fault power frequency overvoltage, but also can have the protection function of a normal voltage-sensitive element when lightning stroke pulse overvoltage occurs.

Owner:SOUTH CHINA UNIV OF TECH +2

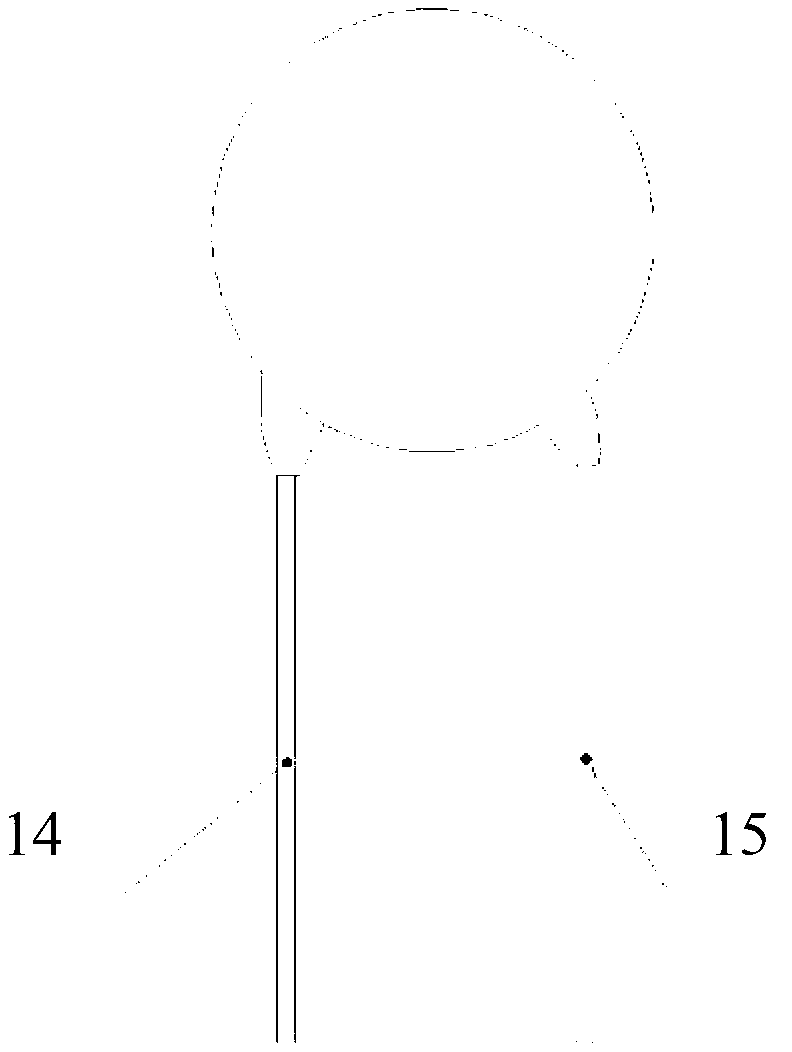

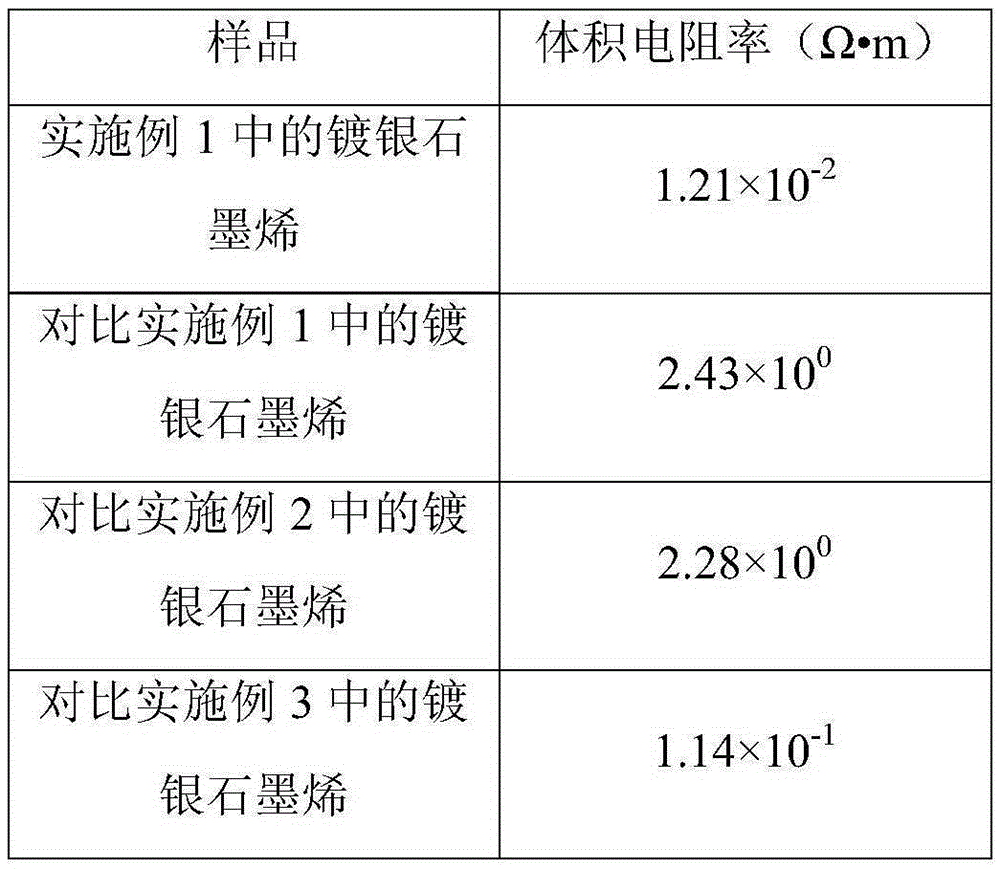

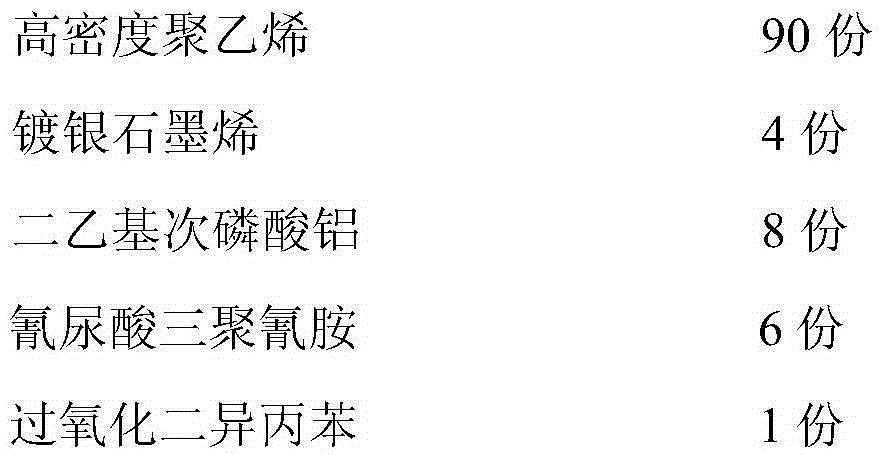

Preparation method of silver-plated graphene, and application of the silver-plated graphene in electric-conductive flame-retarding high-density polyethylene explosion-inhibiting material

The invention belongs to the technical field of flame-retarding and explosion-inhibiting materials and especially relates to a preparation method of an electric-conductive flame-retarding high-density polyethylene / silver-plated graphene composite explosion-inhibiting material. The preparation method includes the steps of purifying graphene, acidifying and silanizing the graphene, preparing a graphene suspension liquid, preparing a silver ammonia solution, and chemically plating silver onto graphene to obtain the graphene of which the surface is chemically plated with silver, and finally performing co-extrusion to the silver-plated graphene with a high-molecular material to obtain the electric-conductive flame-retarding polymer / silver-plated graphene composite explosion-inhibiting material. The material is excellent in electric-conductivity, chemical property, flame-retarding performance and explosion-inhibiting performance. The material overcomes the defects in explosion-inhibiting materials in the prior art.

Owner:CHANGZHOU UNIV +1

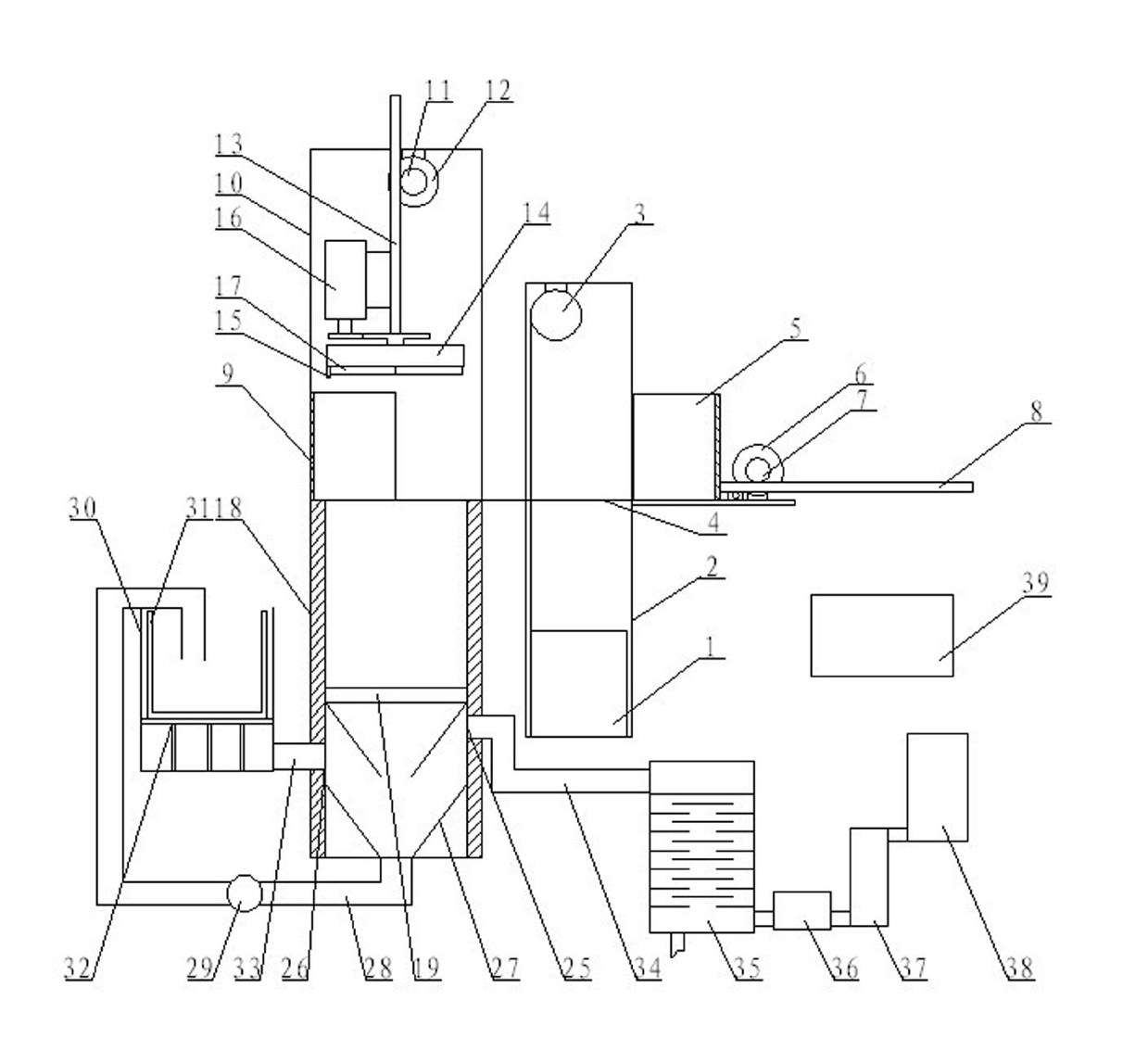

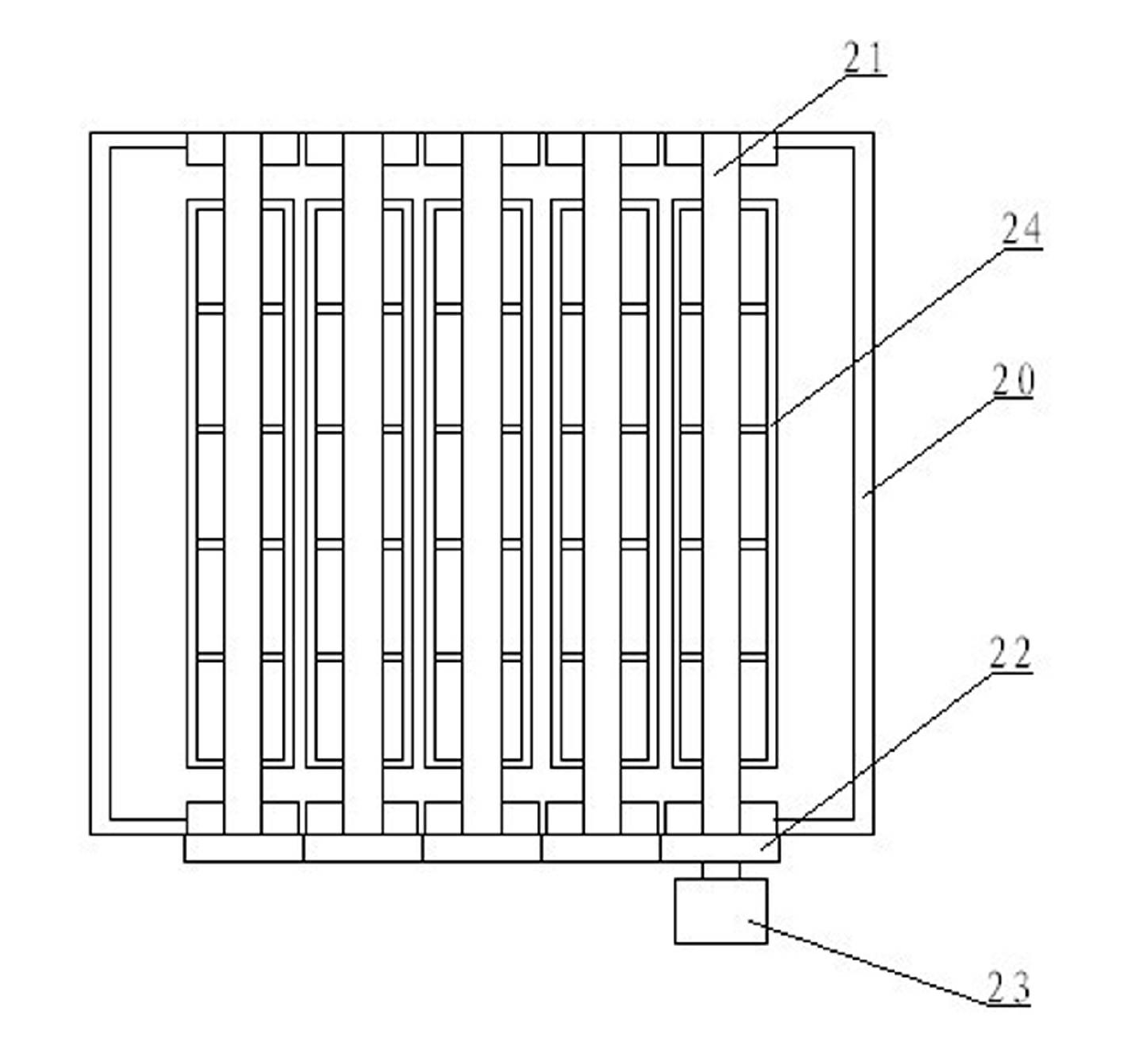

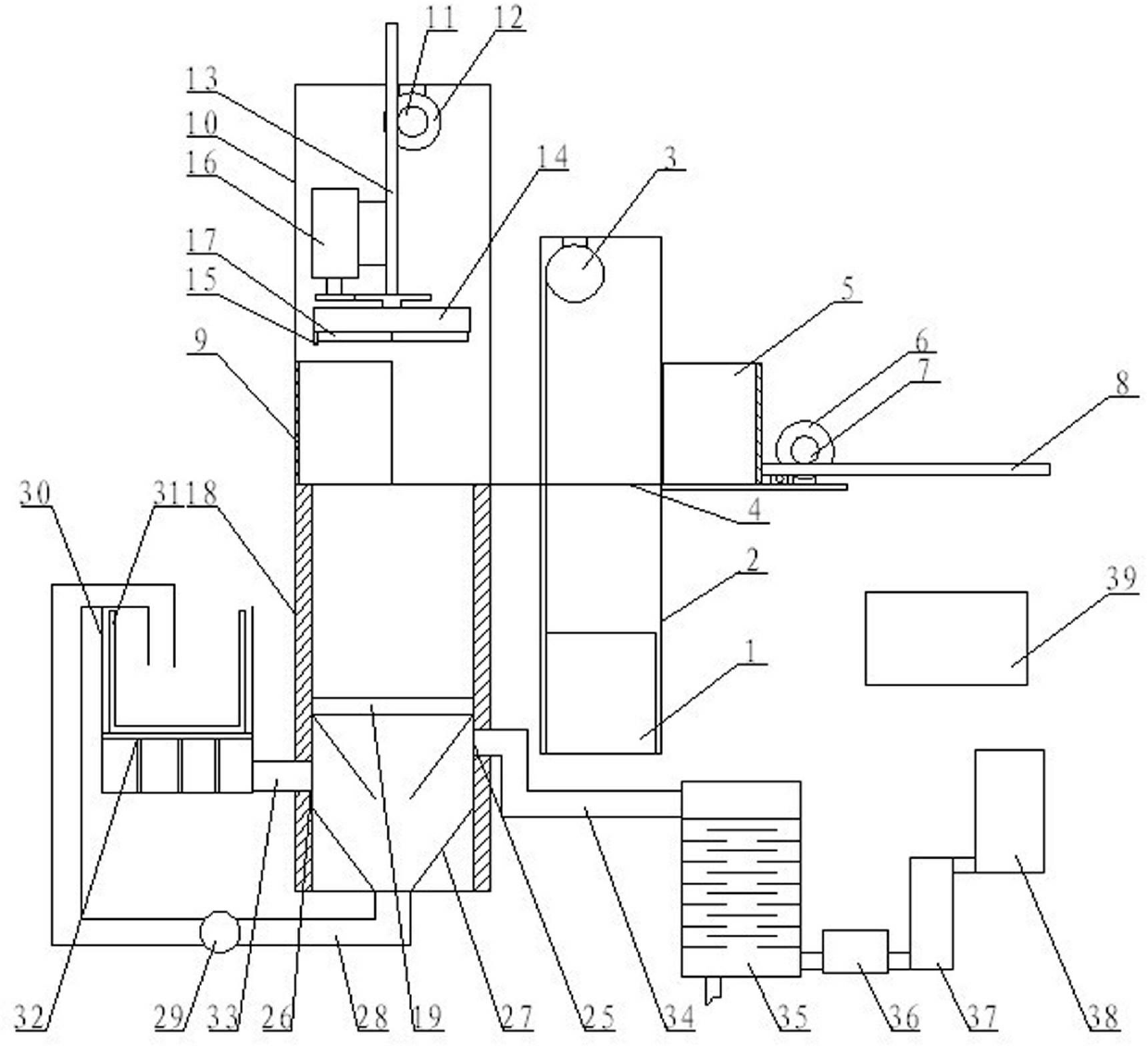

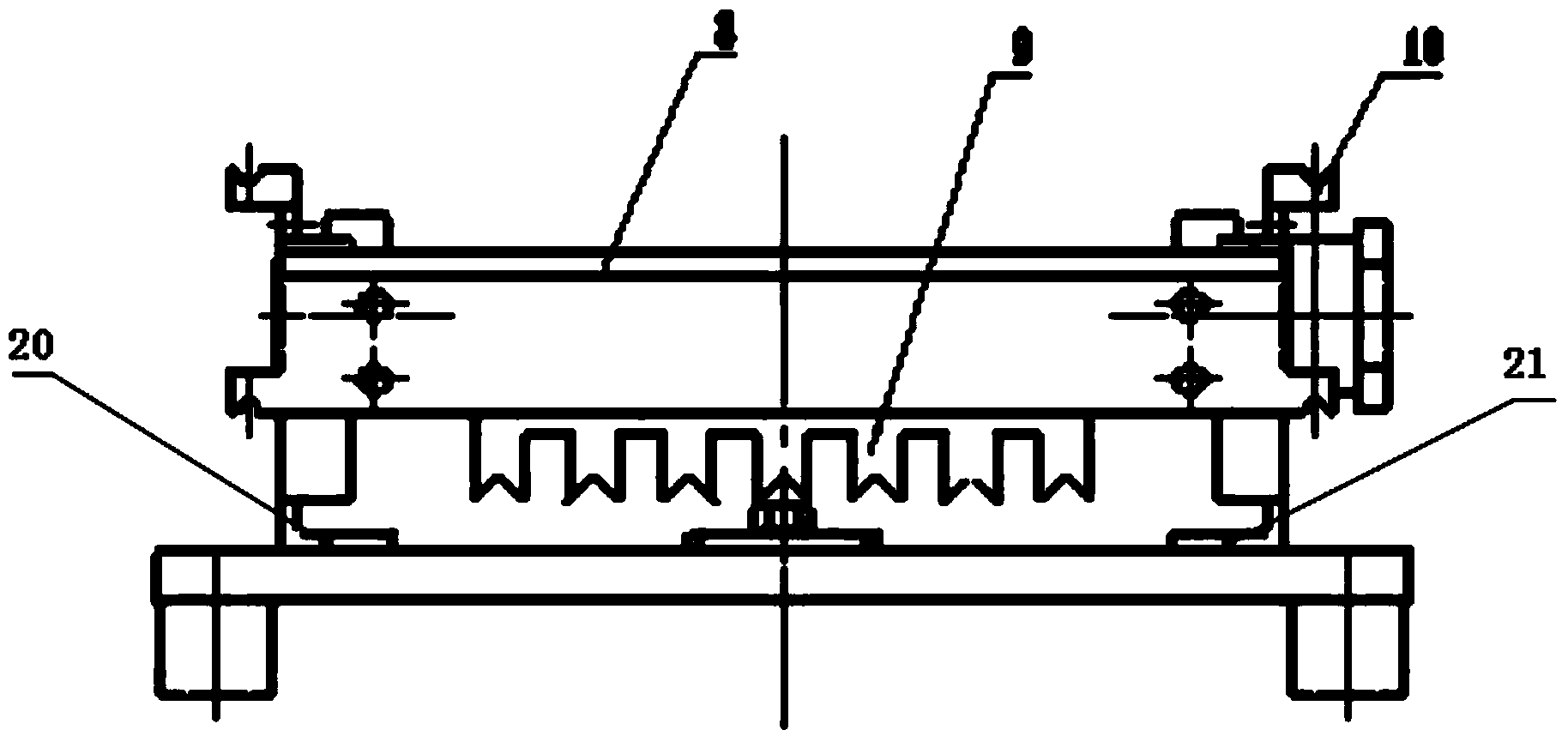

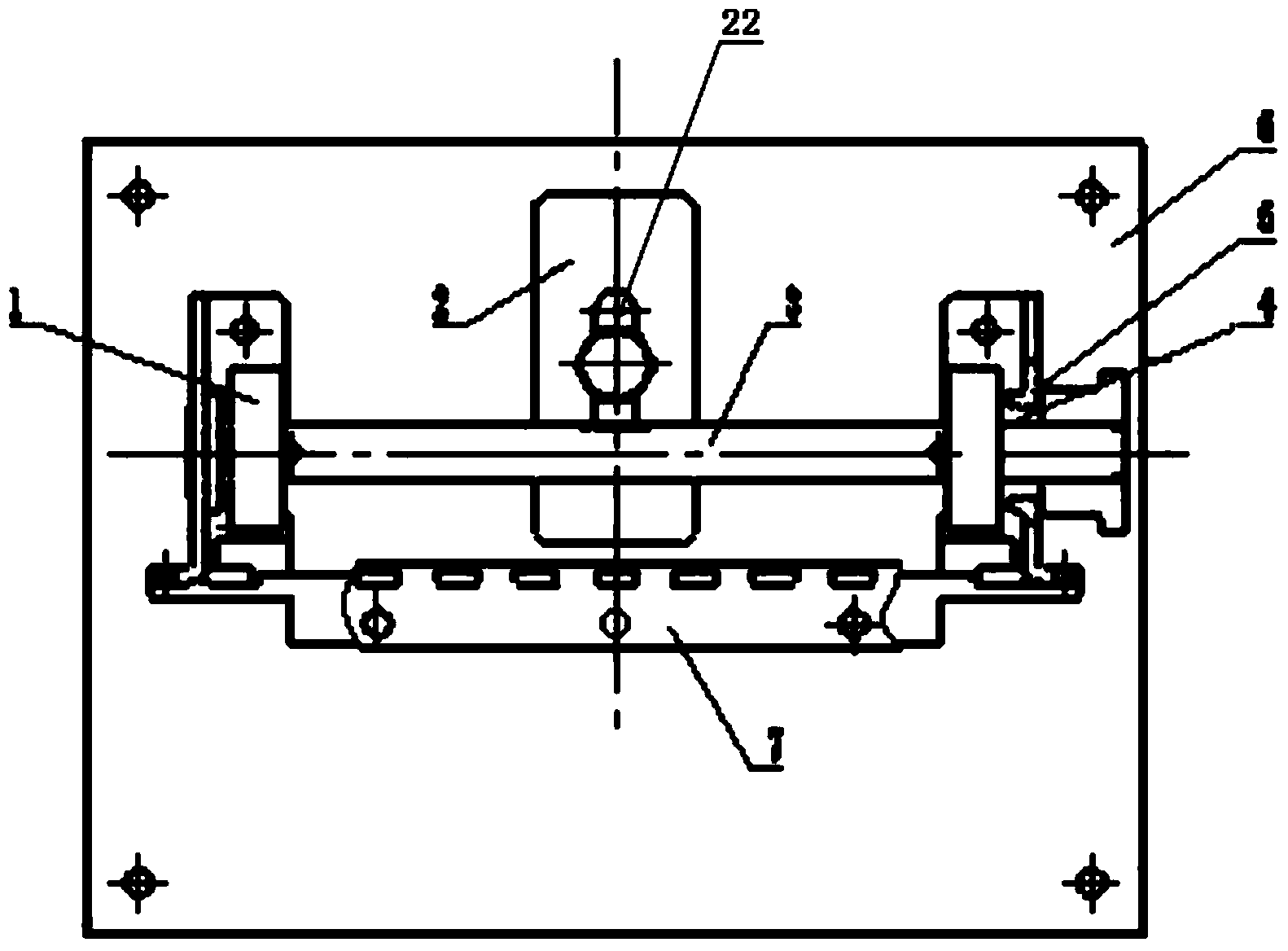

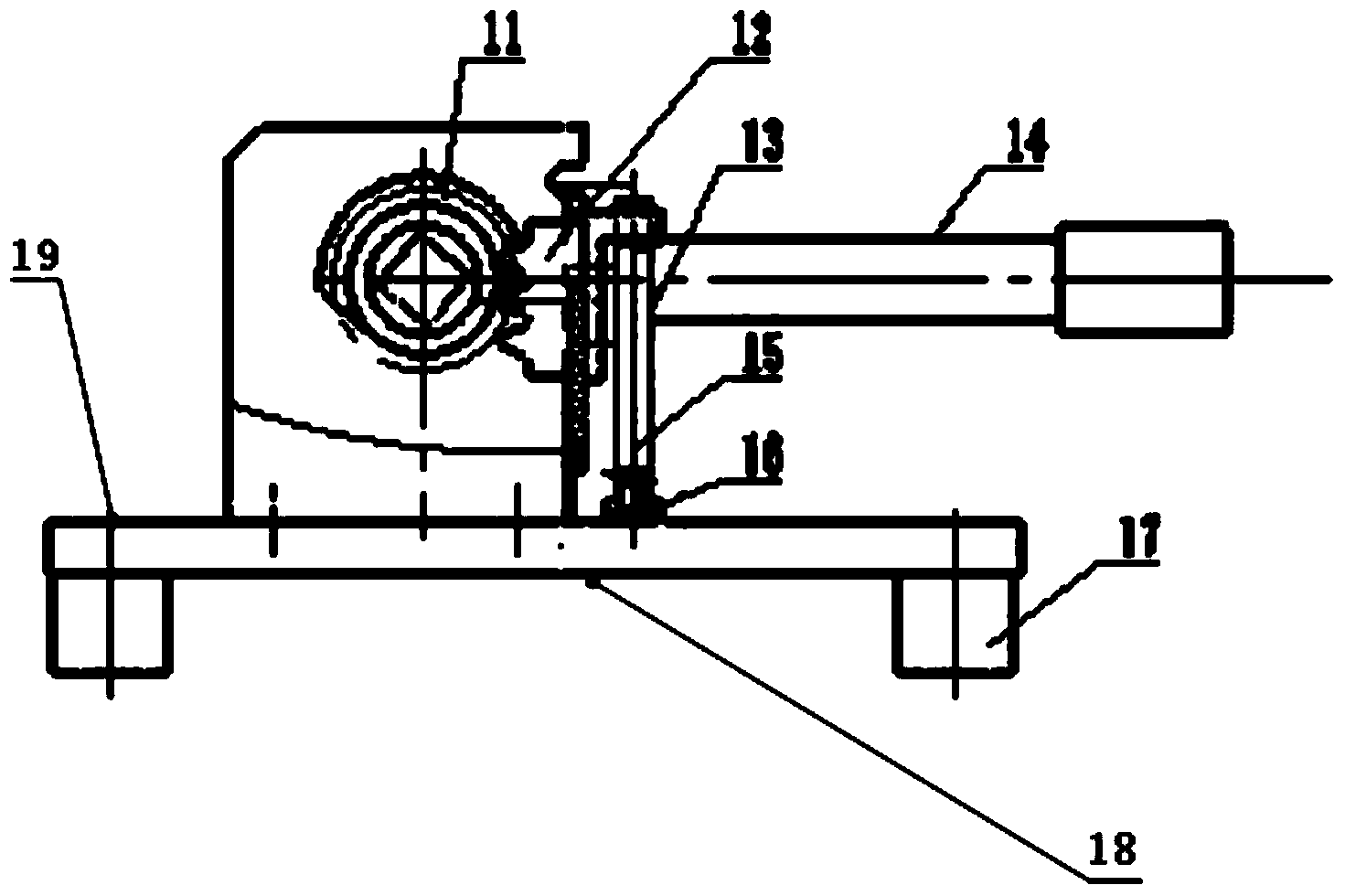

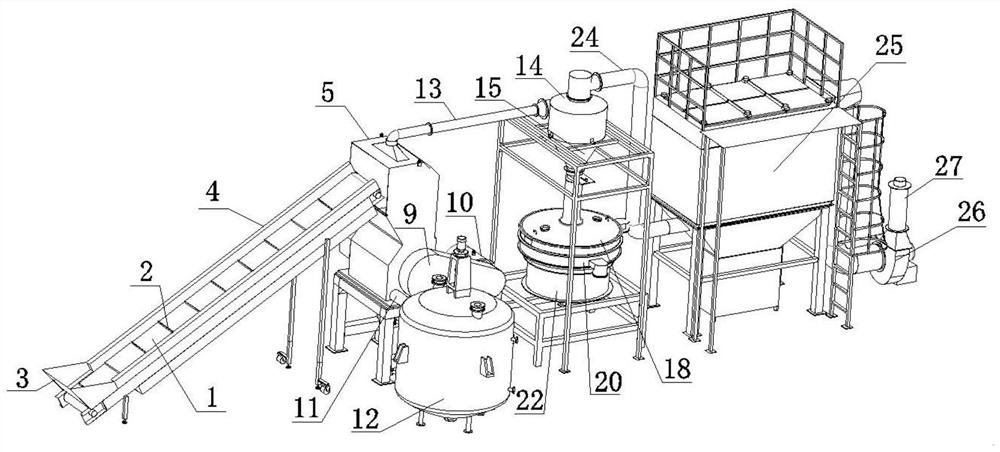

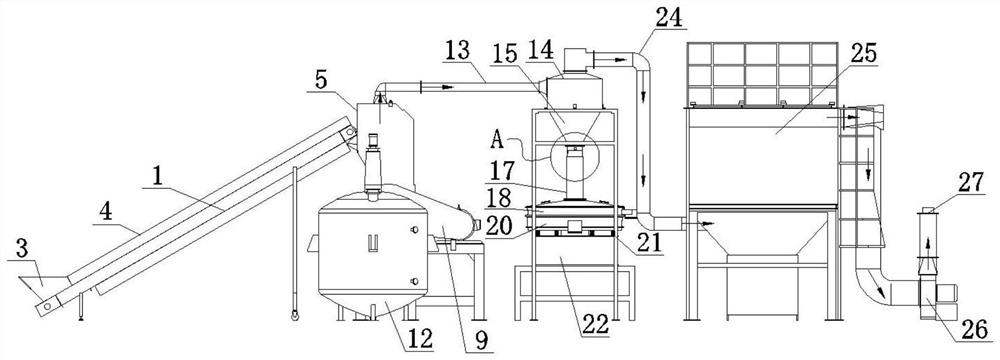

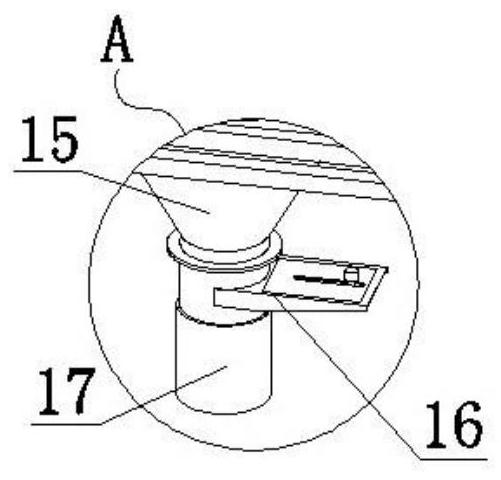

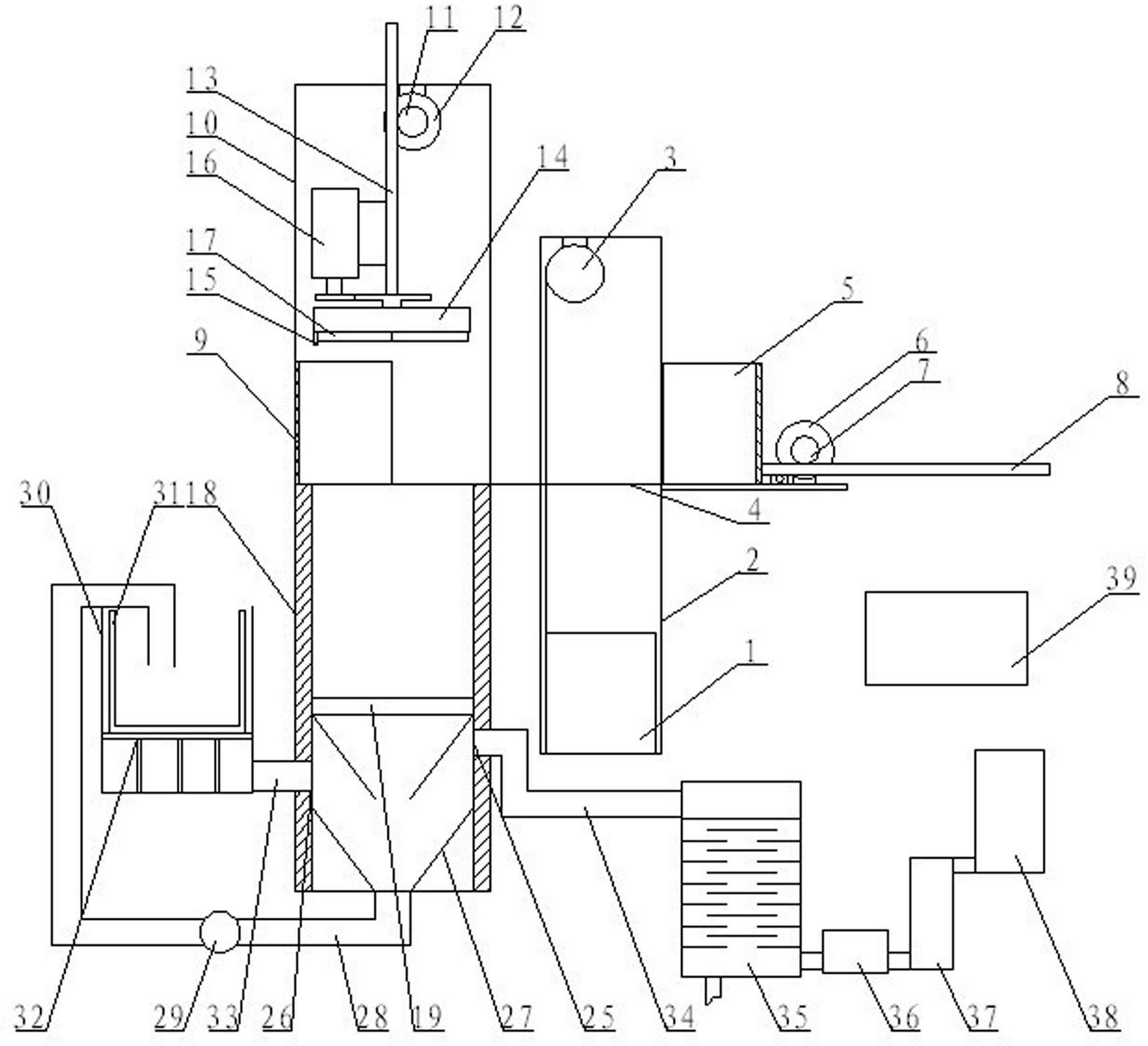

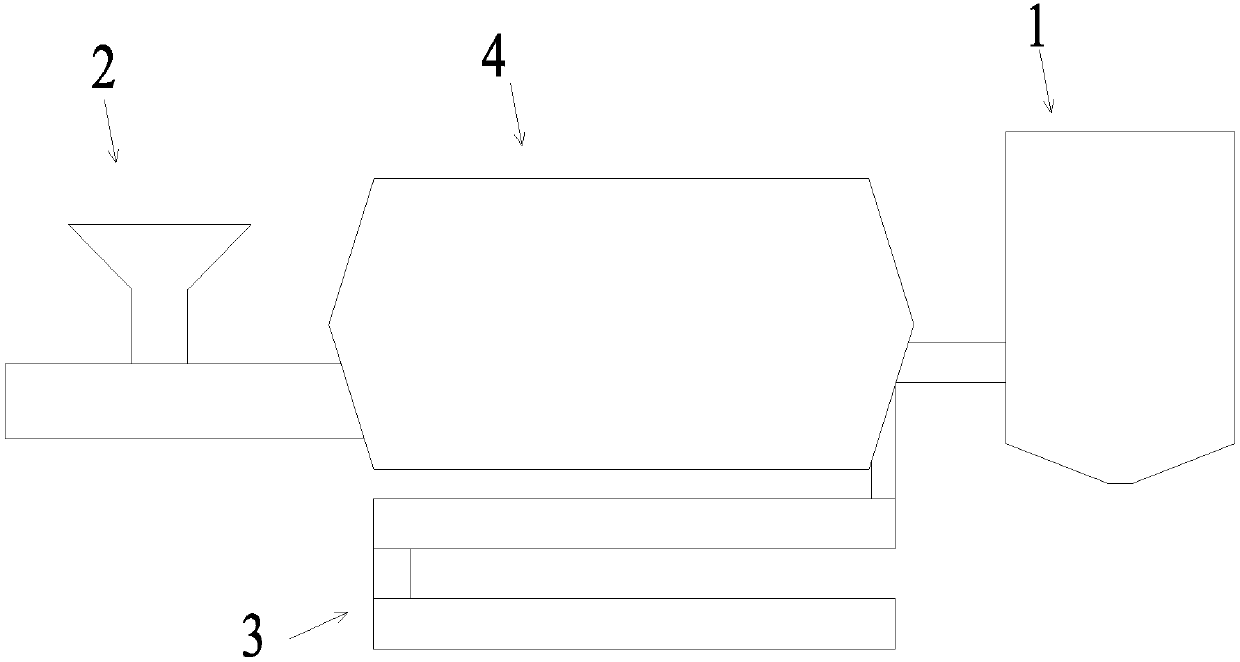

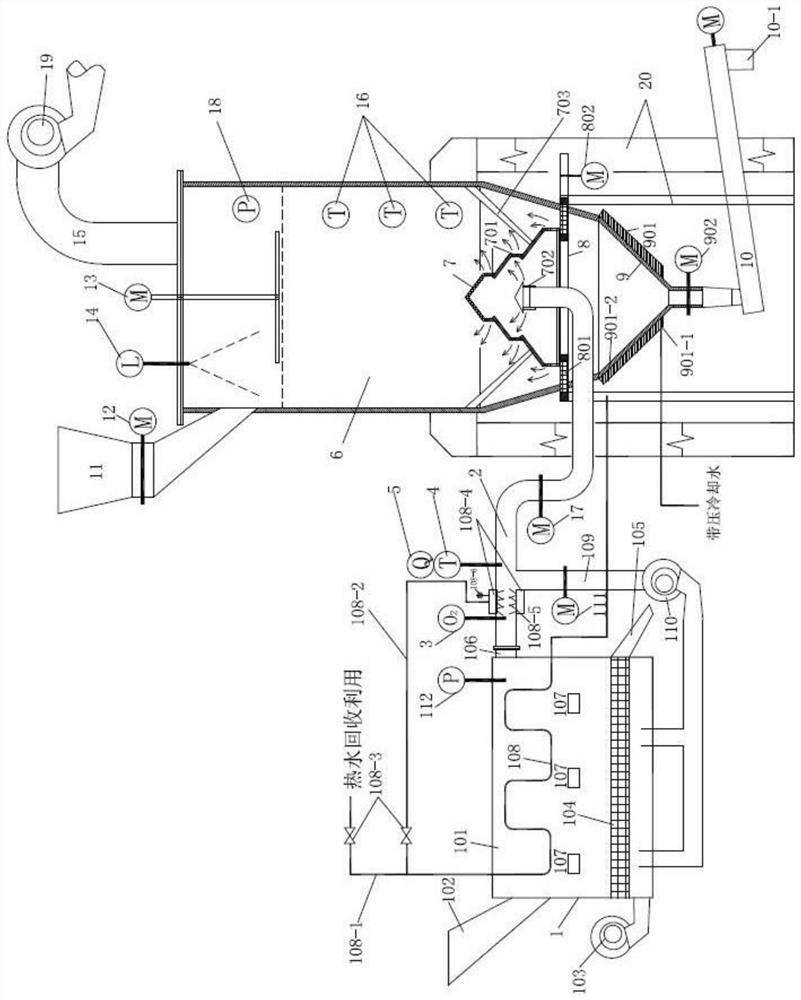

Novel straw direct gasification and poly-cogeneration device and preparation process

InactiveCN102329650AImprove gasification efficiencyUniform densitySpecial form destructive distillationFixed-bed gasificationFiltrationCogeneration

The invention relates to a novel straw direct gasification and poly-cogeneration device and preparation process. The device comprises a gasification furnace, a loading device, a pushing device, a pressing device, a distributing device, a carbon discharging device, a washing device, a fan, a water seal filtration device, a gas storage cabinet and a control cabinet. According to the invention, straw which does not need to be processed is directly fed into the gasification furnace for gasification through the loading, pushing, pressing and distributing devices, thereby effectively controlling straw cogenerated straw carbon and straw gas, matching a carbon shaving grate and the carbon discharging device to collect the straw carbon, carrying out labyrinth spraying and washing and separating the straw gas from straw extract, and filtering and collecting the straw gas in the water seal filtration device. The device has high reliability, good safety, strong practicability, simple gasification process, good gasification effect, high straw utilization ratio and low operation cost.

Owner:顾云江

Ignition boosting methoe for gas boiler

InactiveCN1563804APrevent deflagration accidentsNormal burningAir supply regulationEngineeringProduct gas

The present invention relates to the ignition and pressure lifting method for medium temperature and medium pressure gas burning boiler with coke oven gas as fuel. During ignition, lifting pressure and normal operation, hot blast baffle opening, blower baffle opening, induced draft fan baffle opening, gas regulating door opening and negative hearth pressure in the boiler are set and regulated, so as to control the inflammable gas density inside the boiler during ignition and lifting pressure below the explosion limit and to avoid boiler explosion accident. The ignition and pressure lifting method of the present invention is suitable for all types of gas burning boilers with PLC program controlled ignition system.

Owner:山西焦化股份有限公司

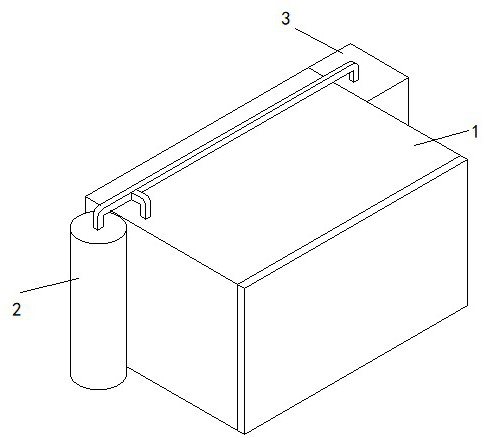

Device for rapidly preparing stability test samples of gunpowder and explosives

ActiveCN104330295AExtended use timeNot easy to producePreparing sample for investigationGunpowderEngineering

The invention discloses a set of device for rapidly preparing stability test samples of gunpowder and explosives, and solves the problems that the stability test samples of the gunpowder and the explosives are low in preparation efficiency, long in consumed time and difficult to collect. The device comprises a knife rest part, a base part and a sample collecting part. According to the device, the samples can be prepared with the specification and size required by testing regulations once in continuous feeding and intermittent shearing stress manners; by virtue of a drawer type sample collector, the spattering of gunpowder particles can be effectively prevented. The device has the beneficial effects that the operation is easy, the time and the labor are saved, the test cycle can be greatly shortened, and the working efficiency is improved.

Owner:XIAN MODERN CHEM RES INST

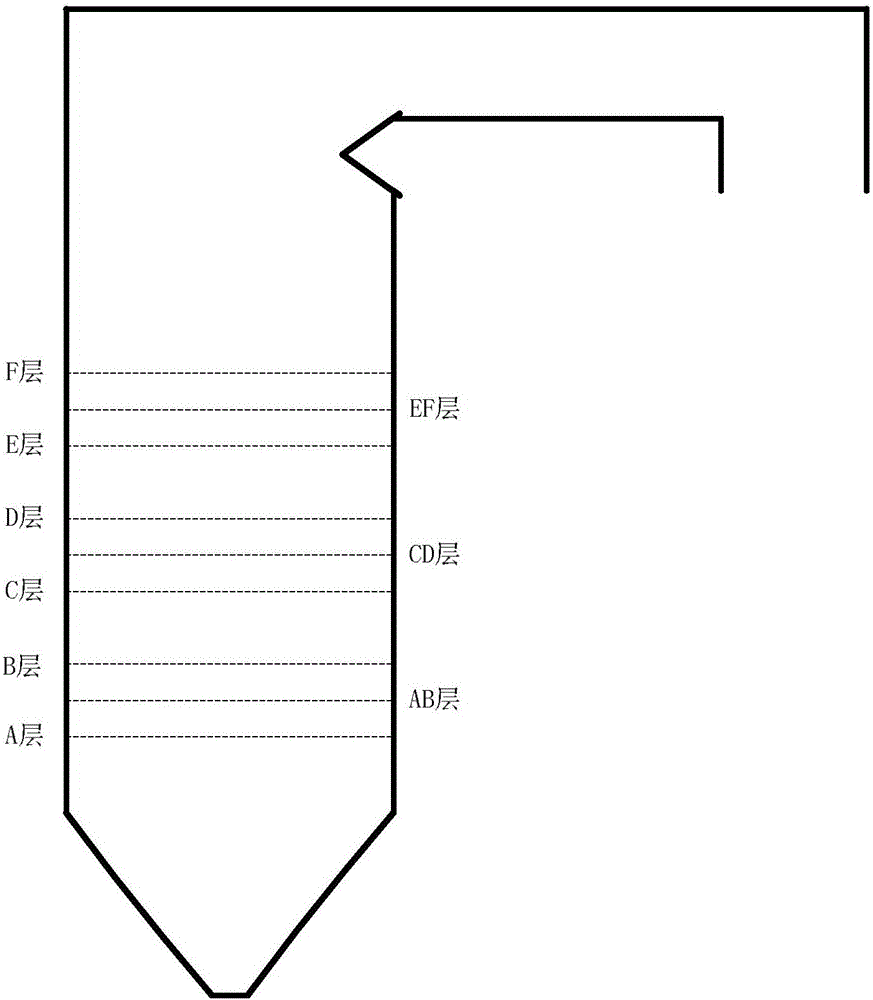

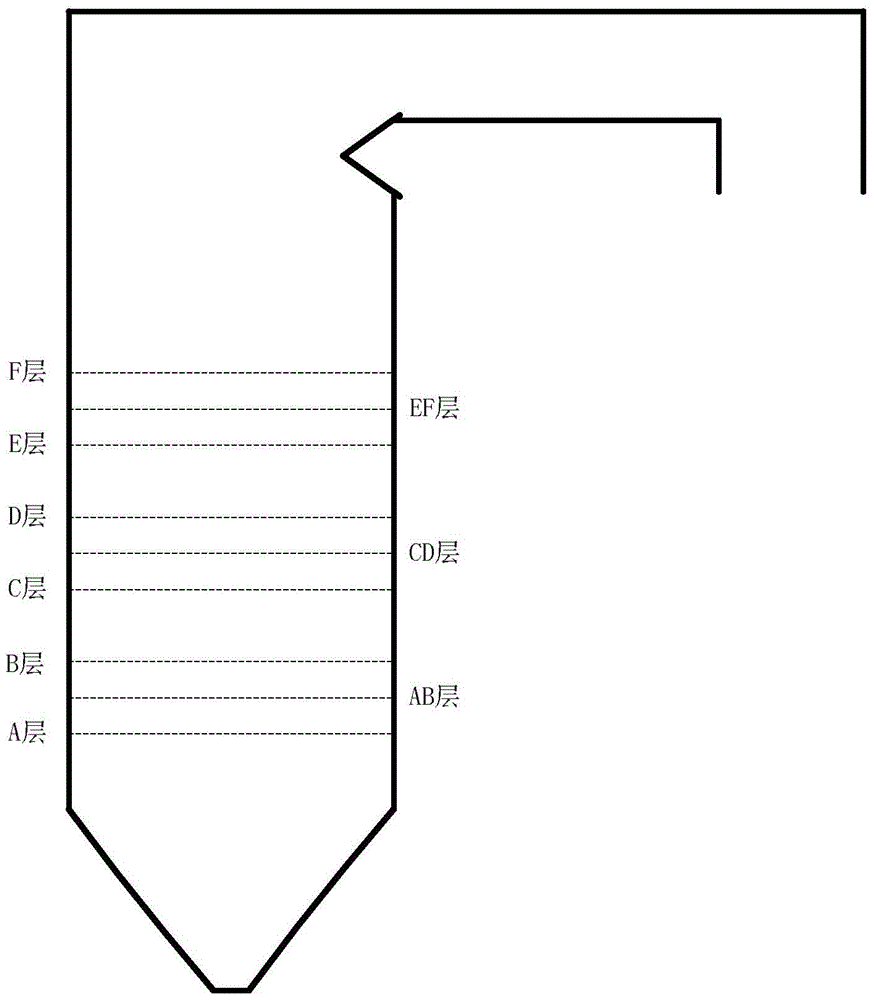

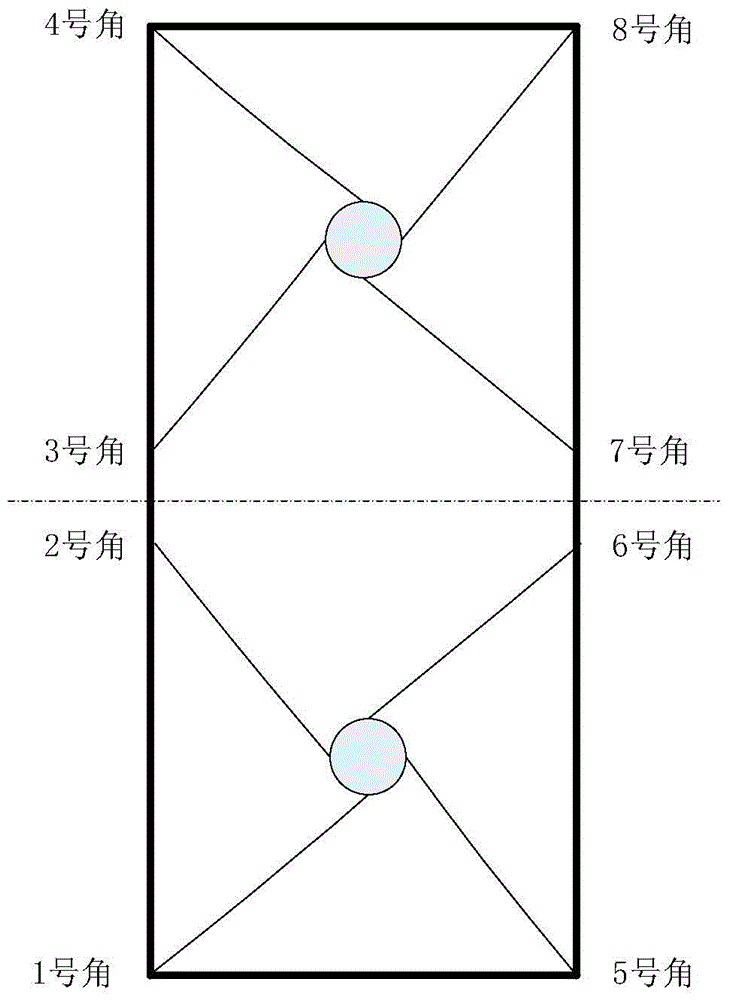

Boiler starting method for preventing oxide skin generation of 1,000 MW octagonal tangent circle boiler and secondary combustion accident of tail flue

The invention discloses a boiler starting method for preventing oxide skin generation of a 1,000 MW octagonal tangent circle boiler and a secondary combustion accident of a tail flue. Boiler warming is carried out before a combustor is put into operation, then, the combustor is put into operation, and the operation of the combustor is adopted according to the following operation principles that all large oil guns in an AB layer and part of large oil guns in a CD layer are put one by one, and when the outlet pressure of a boiler steam-water separator reaches 0.3 MPa, all micro oil guns in an A layer are put, and then a powder manufacturing system of the A layer is put into operation; and at the thermal state flushing and temperature rising and boosting stage, part of or all large oil guns quit one by one according to the pulverized coal combustion situation, and at the load rising stage, powder manufacturing systems are put into operation layer by layer according to the load situation. According to the method, the temperature rising rate of a heating surface of the boiler in the starting process can be controlled, and the good combustion effect of the pulverized coal in a hearth can be guaranteed; and generation of pipe oxide kin of the heating surface of the boiler is effectively prevented, and the purposes of preventing secondary combustion of the tail flue and the detonation accident of the hearth can be achieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

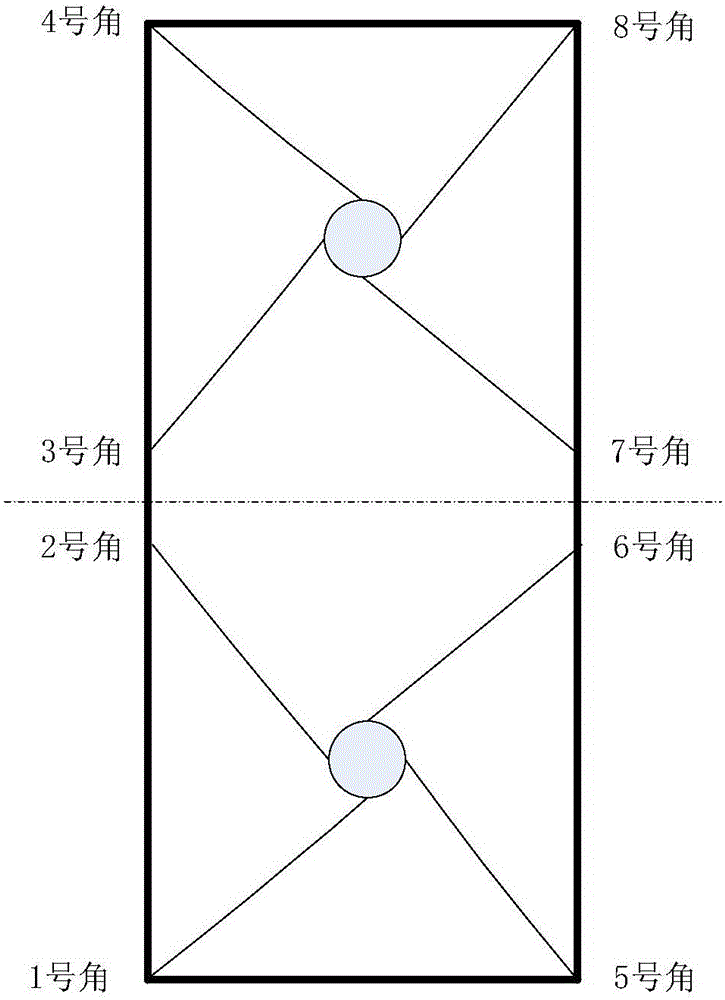

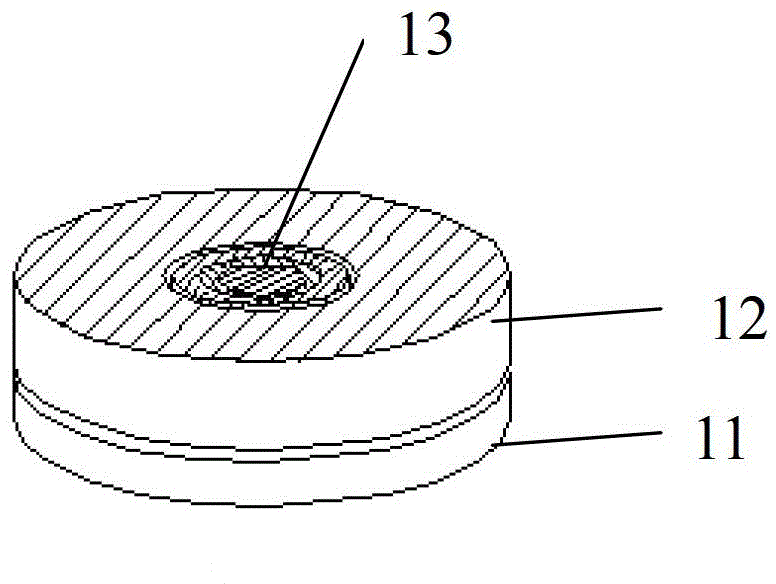

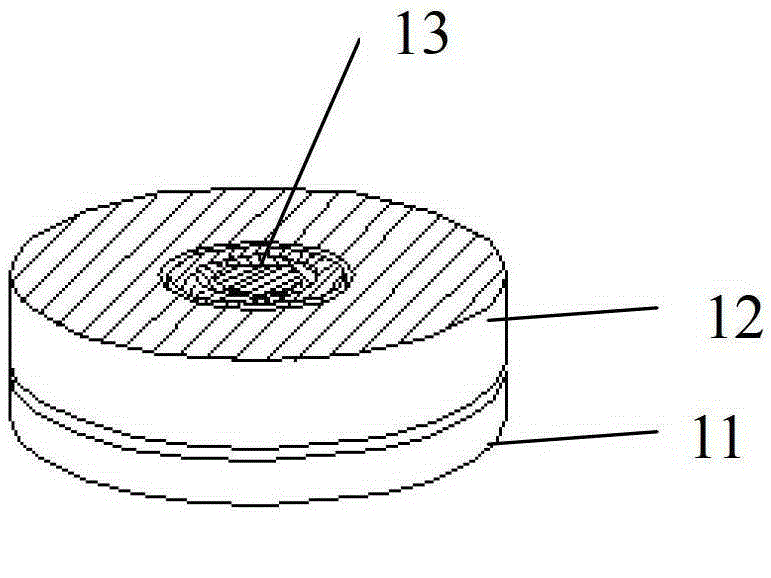

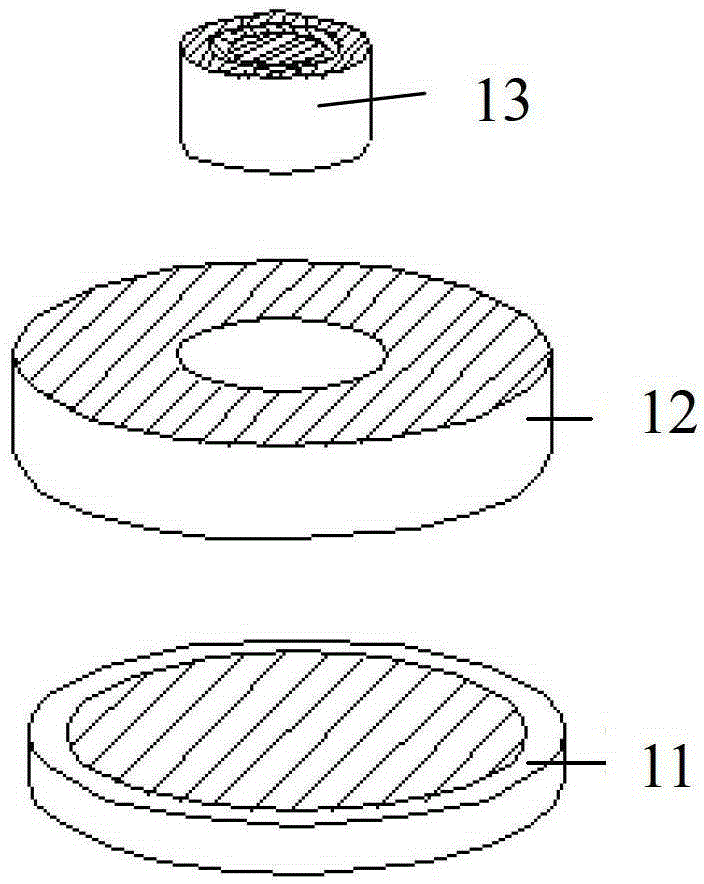

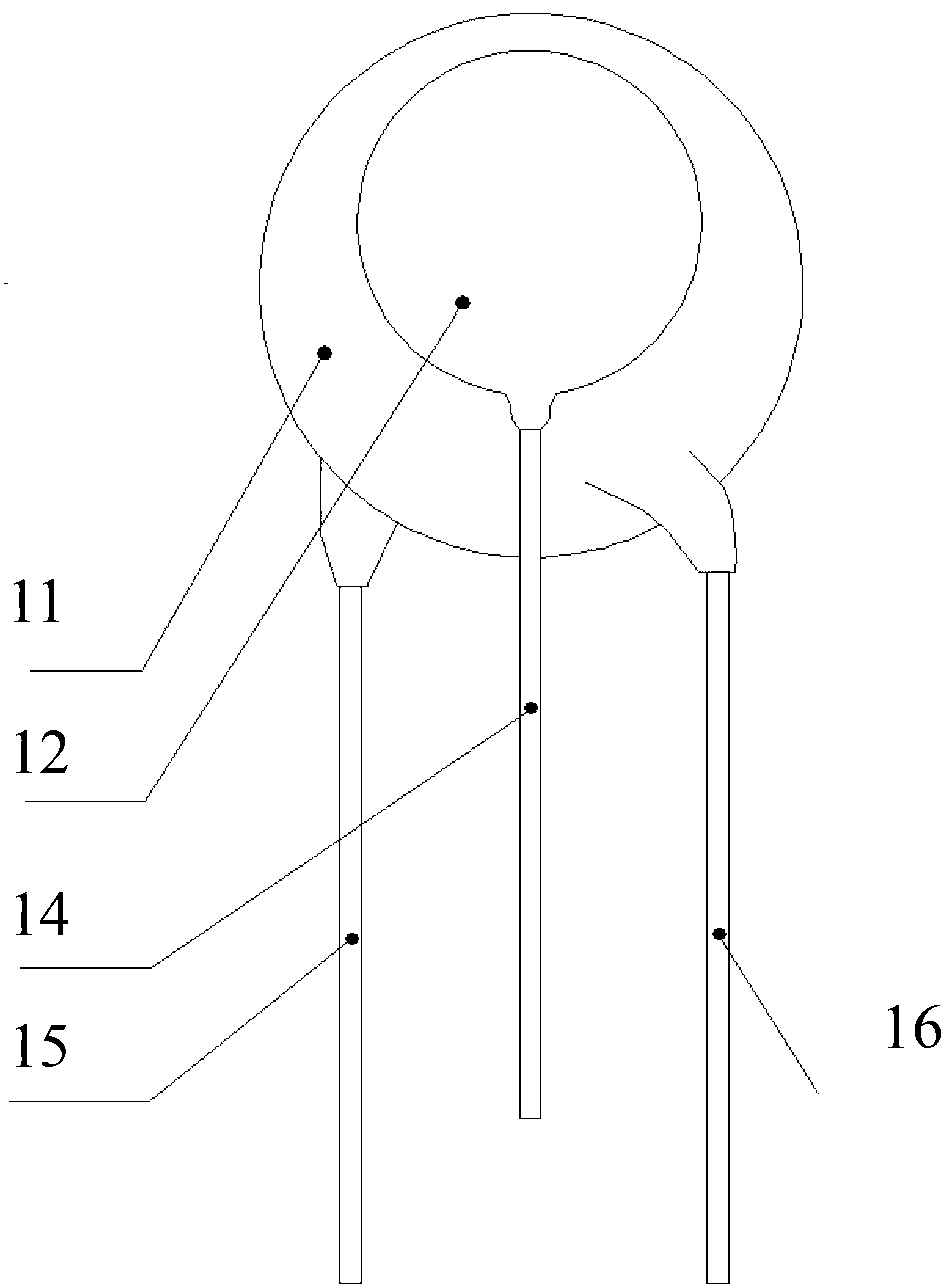

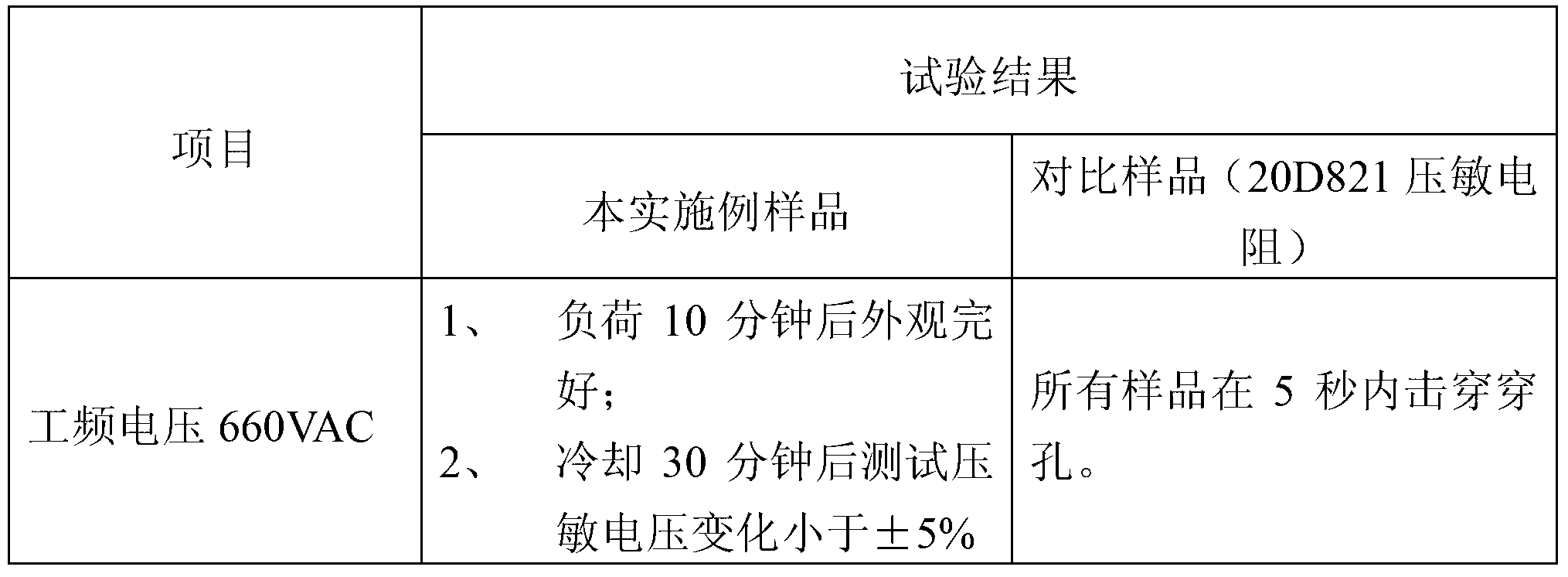

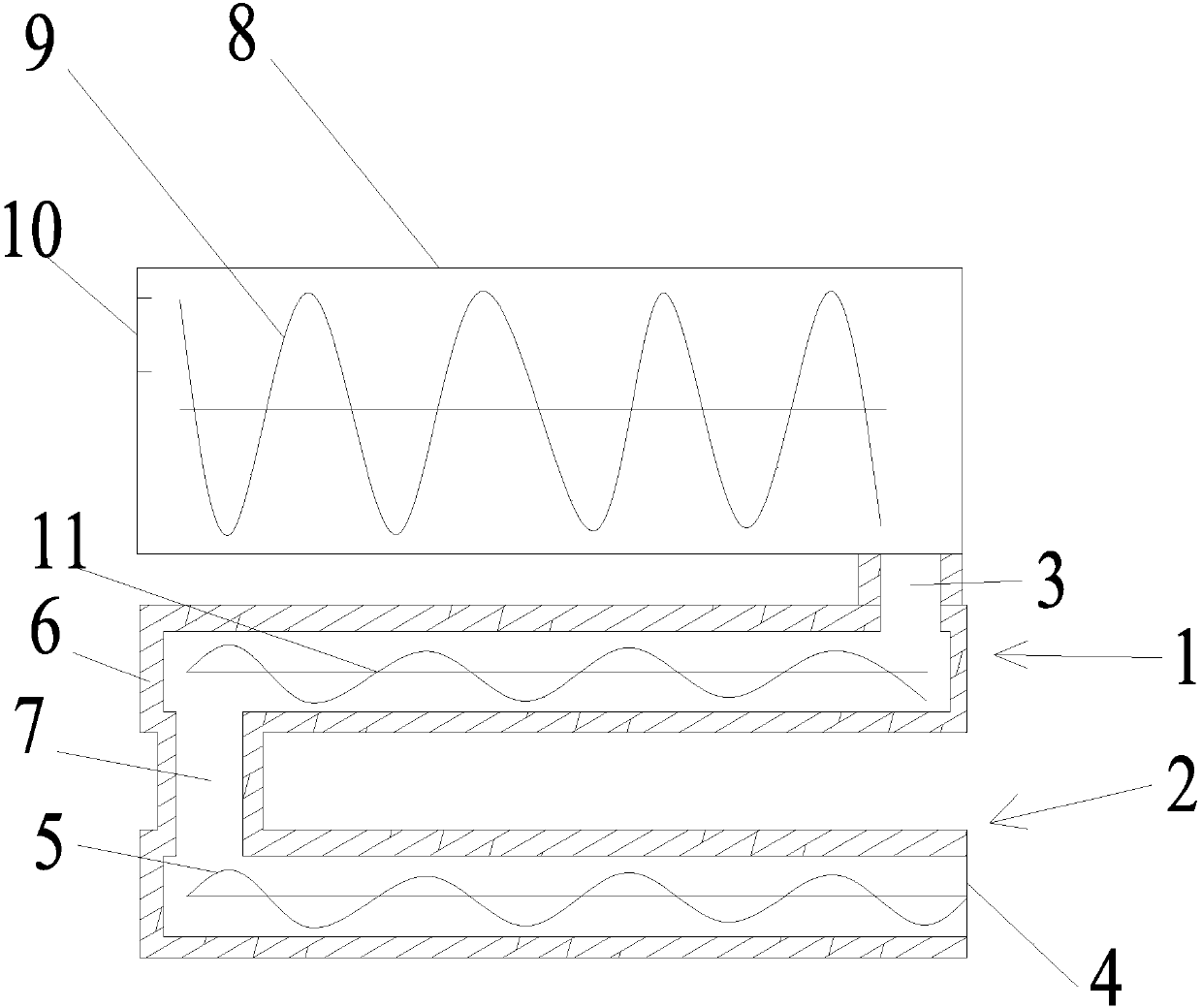

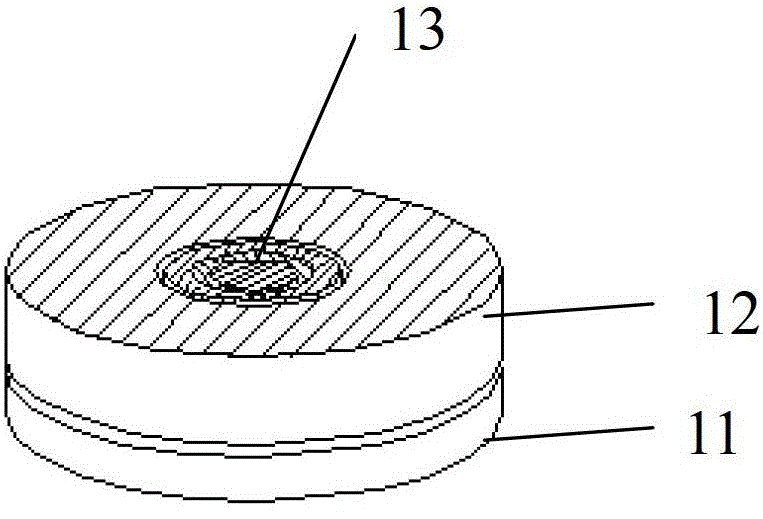

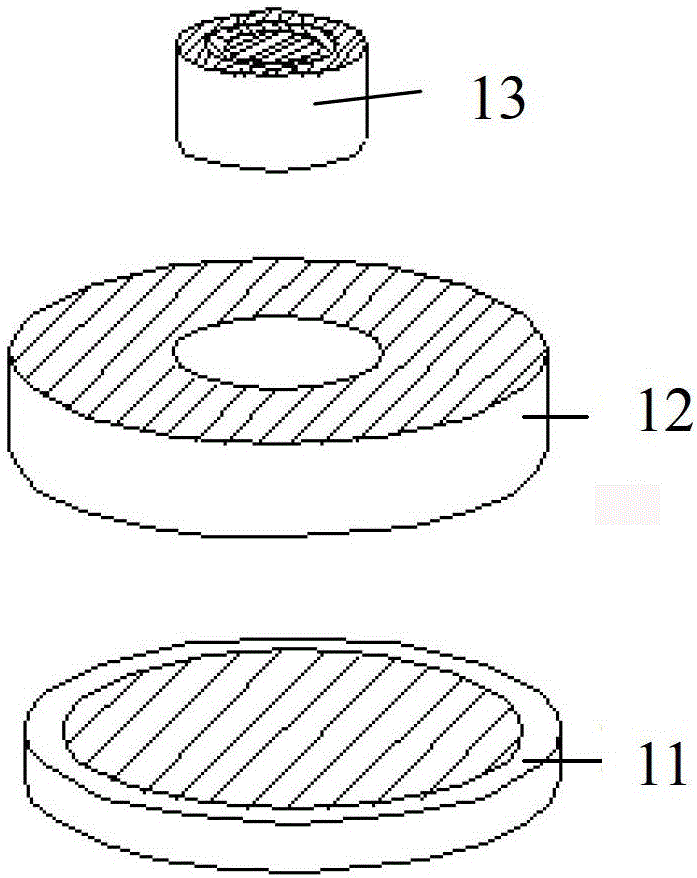

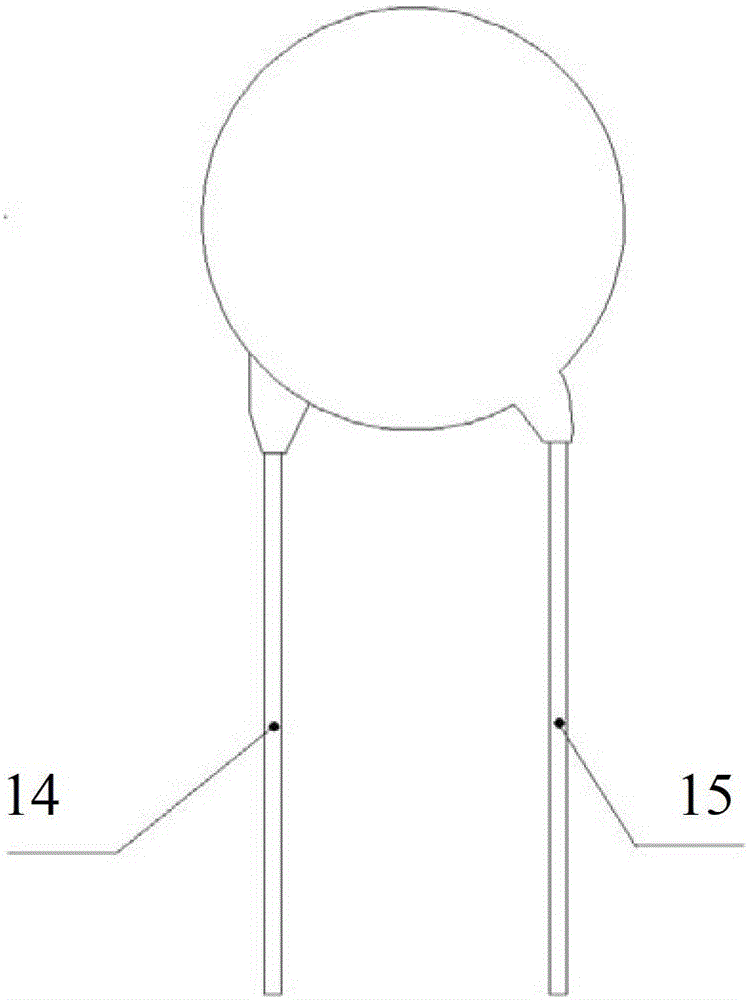

Anti-thunder overvoltage protection component

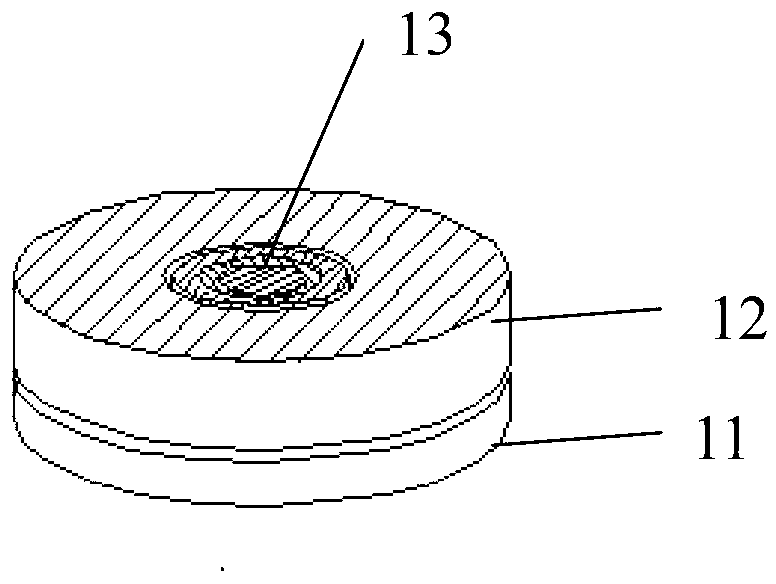

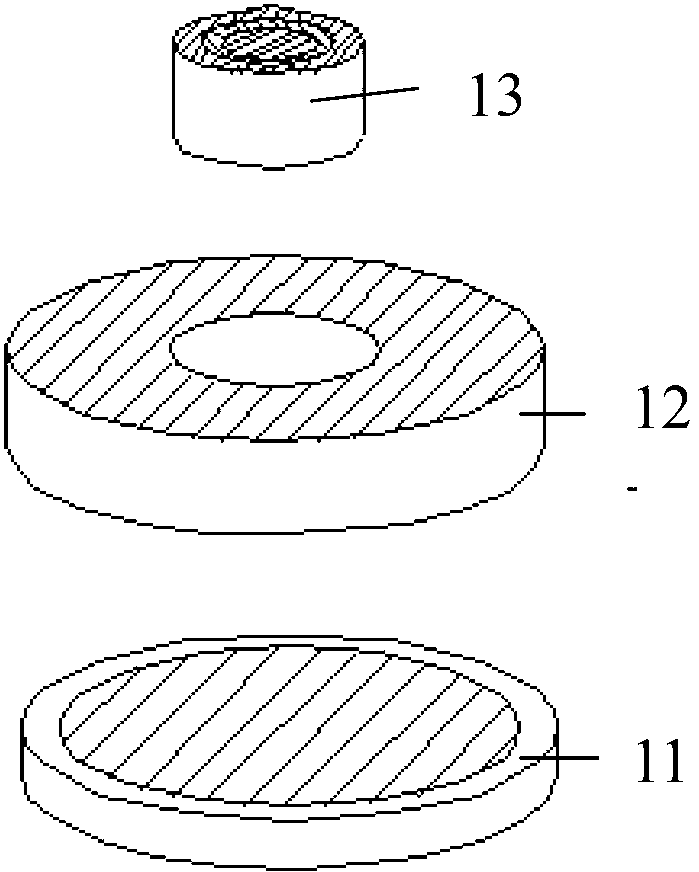

InactiveCN103337848APrevent deflagration accidentsNormal work is not affectedEmergency protective arrangements for limiting excess voltage/currentPressure cellThermistor

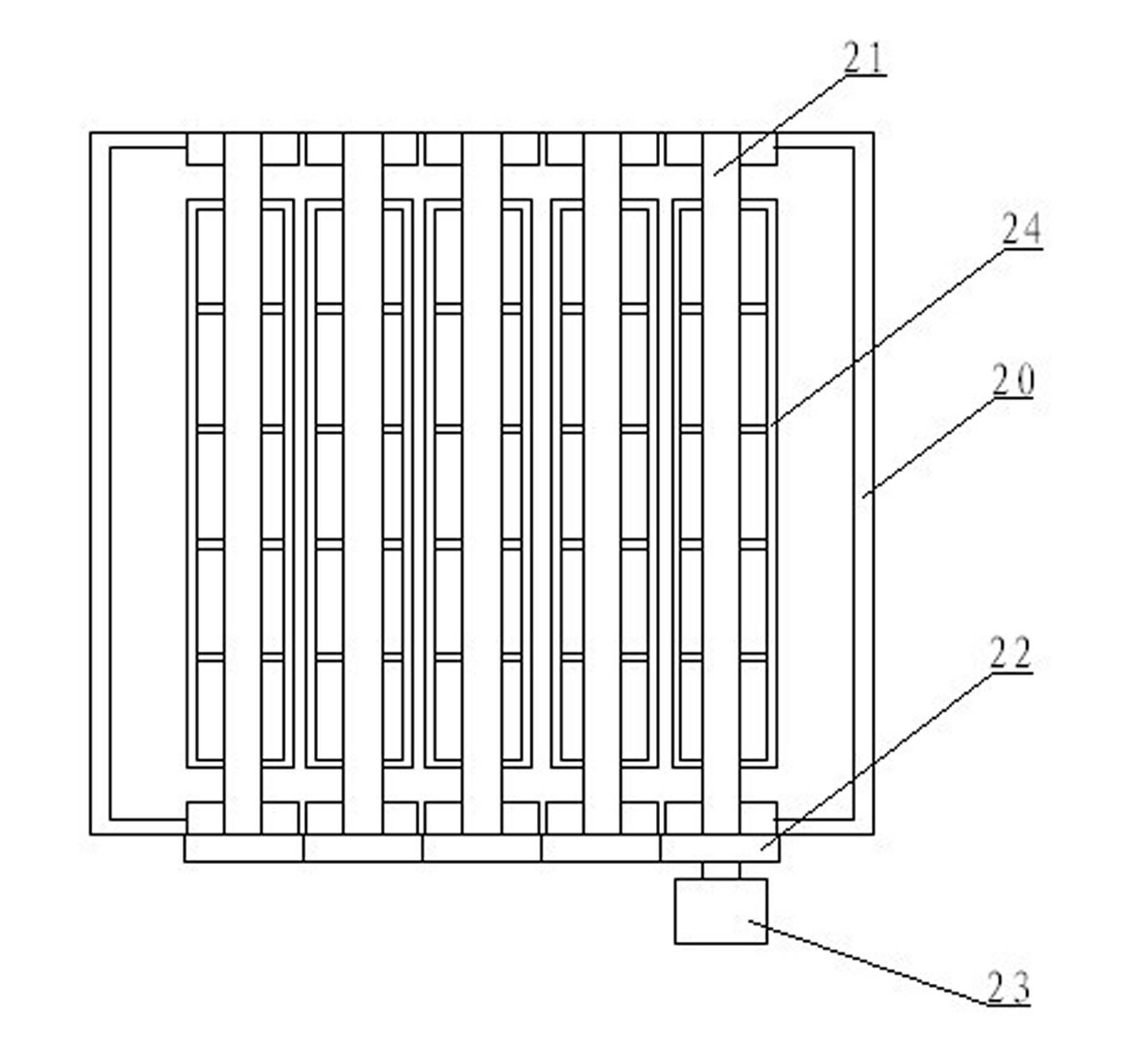

The invention discloses an anti-thunder overvoltage protection component which comprises a piezoresistor disc, a positive temperature coefficient thermistor disc and a gas discharge tube, wherein the piezoresistor disc, the positive temperature coefficient thermistor disc and the gas discharge tube are integratedly packaged; the first common terminal of the positive temperature coefficient thermistor disc and the gas discharge tube is a first leading-out terminal; the second common terminal of the positive temperature coefficient thermistor disc and the gas discharge tube is connected with one end of the piezoresistor disc; the other end of the piezoresistor disc is a second leading-out terminal. The anti-thunder overvoltage protection component can restrain the switching overvoltage and fault power frequency overvoltage, and can play the protective role of a normal pressure cell in case of a thunderstrike pulse overvoltage.

Owner:SOUTH CHINA UNIV OF TECH +2

A lightning protection overvoltage protection device

InactiveCN103346547BNormal work is not affectedCurrent limitEmergency protective arrangements for limiting excess voltage/currentLightning strokesEngineering

The invention discloses an anti-thunder overvoltage protection device. The anti-thunder overvoltage protection device comprises a piezoresistor, a positive temperature coefficient thermistor and a gas discharge tube, wherein the positive temperature coefficient thermistor is connected with the gas discharge tube in parallel and then connected with the piezoresistor in series; the positive temperature coefficient thermistor and the piezoresistor form a thermal coupling relationship. The piezoresistor, the positive temperature coefficient thermistor and the gas discharge tube can be packaged into a whole, or the piezoresistor and the positive temperature coefficient thermistor are packaged into a whole, thus a packaged body is formed, and the gas discharge tube is located outside the packaged body. The anti-thunder overvoltage protection device not only can restrain operation overvoltage and fault power frequency overvoltage, but also can have the protection function of a normal voltage-sensitive element when lightning stroke pulse overvoltage occurs.

Owner:SOUTH CHINA UNIV OF TECH +2

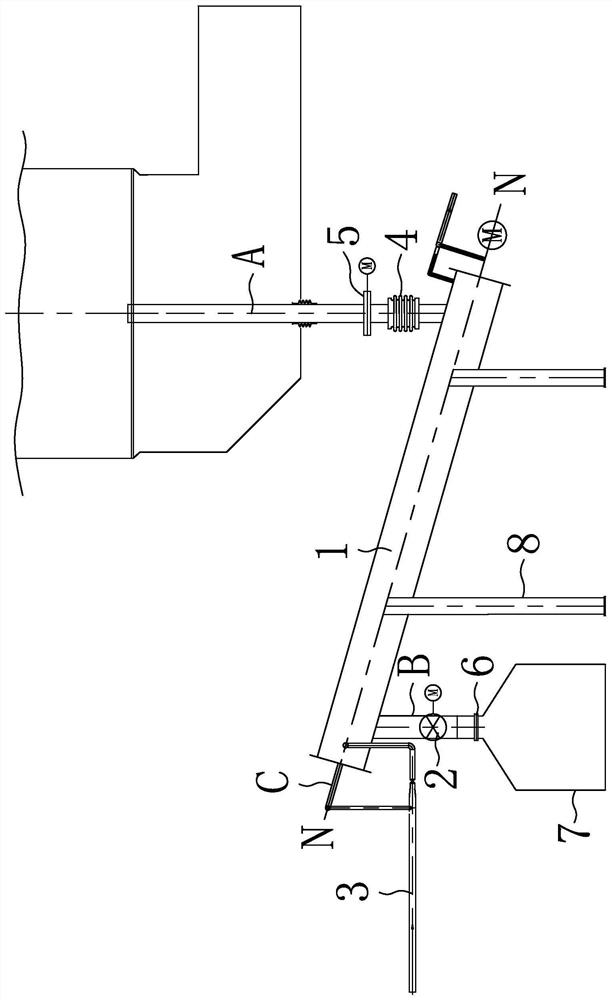

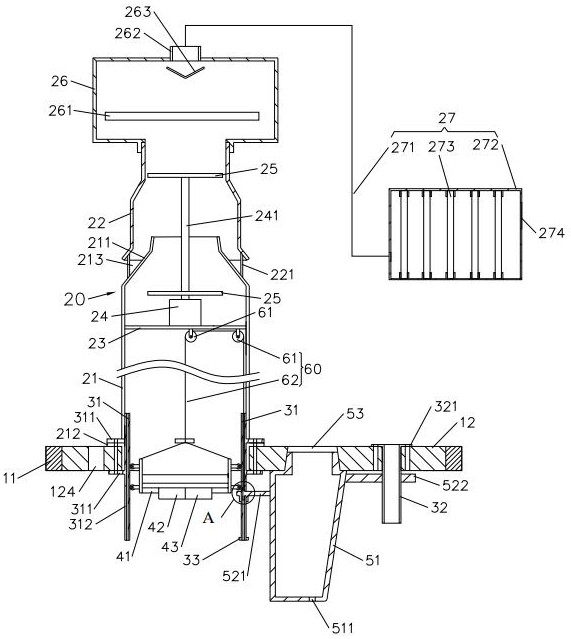

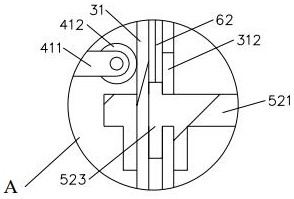

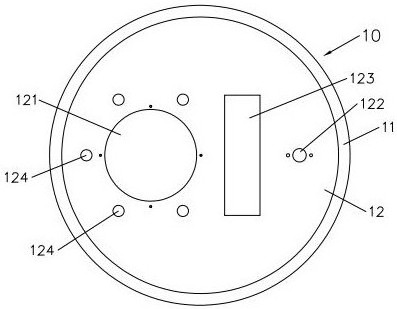

Positive-pressure slag cooling system for biomass fluidized bed gasifier

InactiveCN111996038AAchieve safe dischargePrevent gas leakageLighting and heating apparatusGasification processes detailsFluidized bed gasifierSlag

A positive-pressure slag cooling system for a biomass fluidized bed gasification furnace relates to the field of biomass gasifiers. The slag cooling system solves the problems that an existing slag cooling system only has the slag cooling capacity, the sealing performance cannot be guaranteed, the risk of gas production leakage of a gasifier exists, and harmful gas in ash leaks out. The spiral slag cooler is obliquely arranged; a bracket is arranged below the spiral slag cooler; the spiral slag cooler is connected with the upper end of the bracket; the lower end of the spiral slag cooler is connected with the lower end of a deslagging pipeline of the gasifier; an electric flashboard door is arranged below the deslagging pipeline; the upper end of the spiral slag cooler is connected with the upper end of an ash outlet pipeline; the lower end of the ash outlet pipeline is connected with an ash storage tank; a rotary sealing valve is arranged on the ash outlet pipeline; a manual flashboard door is arranged on the ash outlet pipeline between the rotary sealing valve and the ash storage tank; the cooling water system penetrates through the interior of the spiral ash cooler; and a cooling water pipeline of the cooling water system is in sealing fit with the spiral ash cooler. The system is used for preventing gas generated by the gasifier from leaking and realizing positive-pressureslag cooling.

Owner:HARBIN BOILER

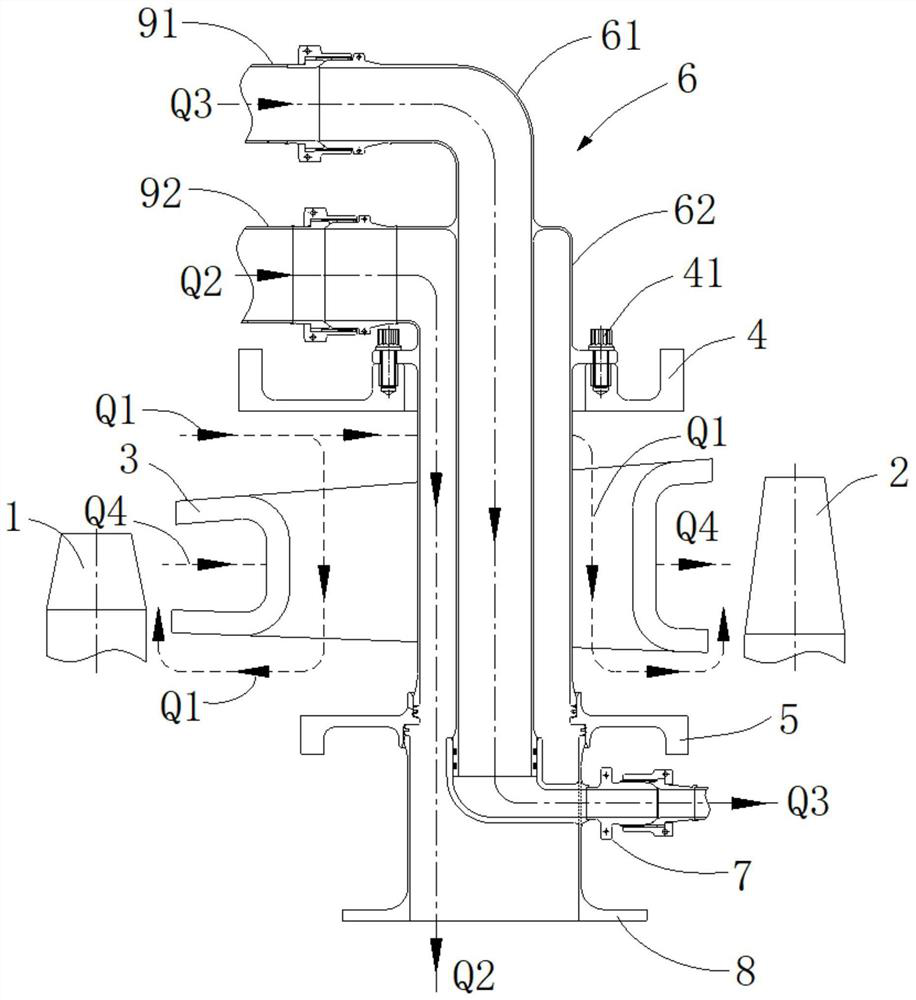

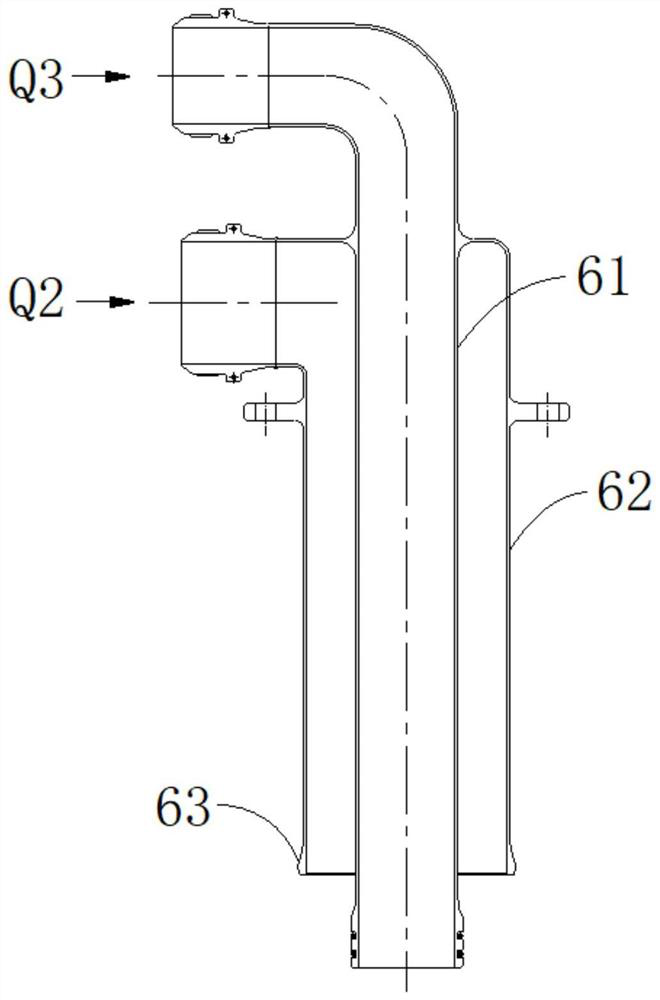

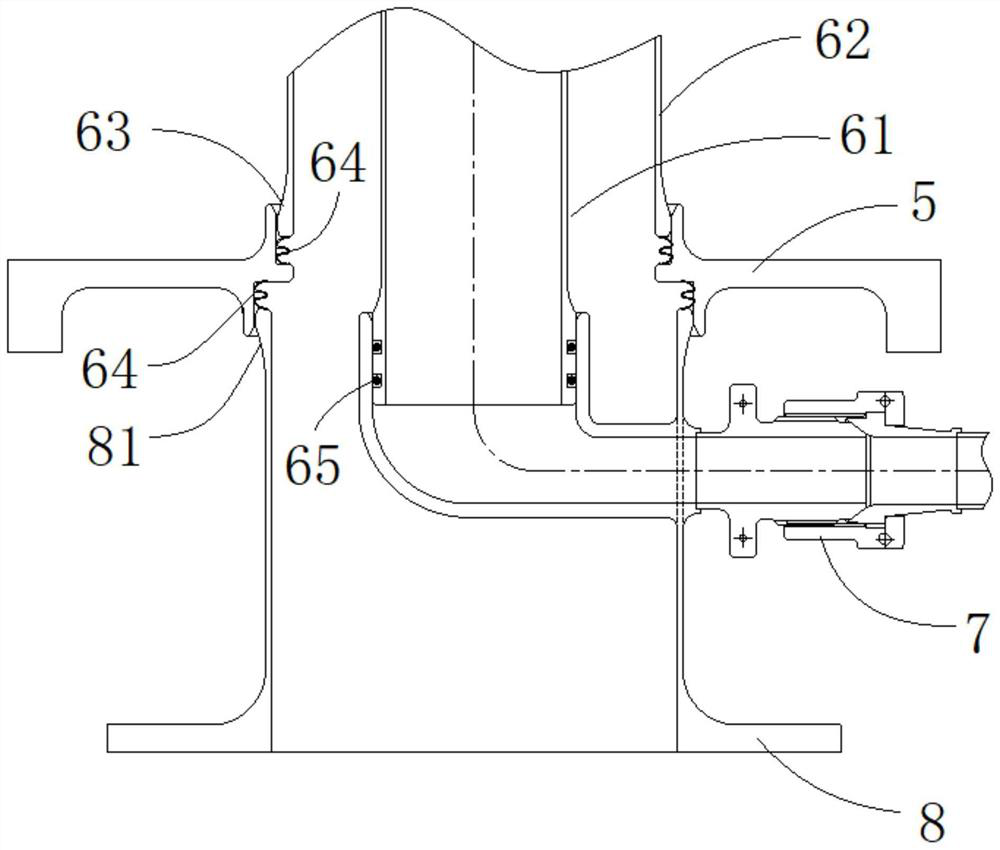

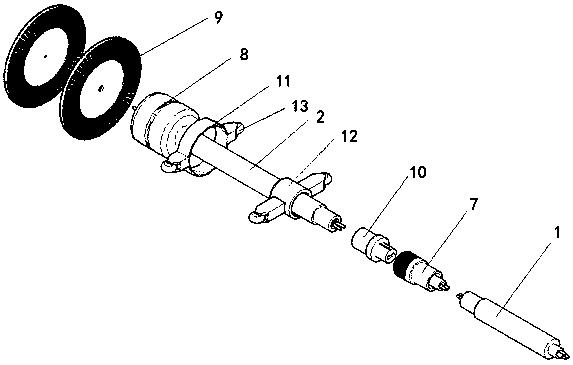

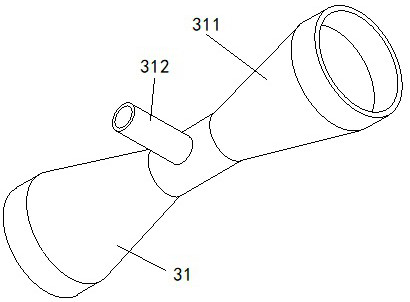

RH vacuum refining explosion preventing device and control method thereof

The invention provides a RH vacuum refining explosion preventing device and a control method thereof. The device comprises a semispherical cover (8), a support frame (7), multiple cylinders, a cylinder reversing valve (96), an electromagnetic reversing valve (85) and an air pipe (83), wherein the semispherical cover (8) adopts a hollow semisphere structure; one end of the air pipe (83) is communicated with the electromagnetic reversing valve (85), and the other end penetrates into a concave surface from a convex surface of the semispherical cover (8); and one end of the cylinder reversing valve (96) is communicated with the cylinders through a pipeline, and the other end drives piston rods of the cylinders to elongate through communicated compressed air. In the control method of the device, the semispherical cover of the hollow semisphere is pushed by the piston rods of the cylinders to lean against a connecting port of a heat bent pipe; and a mode of conveying and filling such inert gases as nitrogen into the heat bent pipe is adopted to dispel and isolate oxygen and coal gas, being preheated and burnt, to stop a deflagration accident in the heat bent pipe so as to improve the safety and the stability of vacuum refining and smelting production.

Owner:LAIWU IRON & STEEL GRP

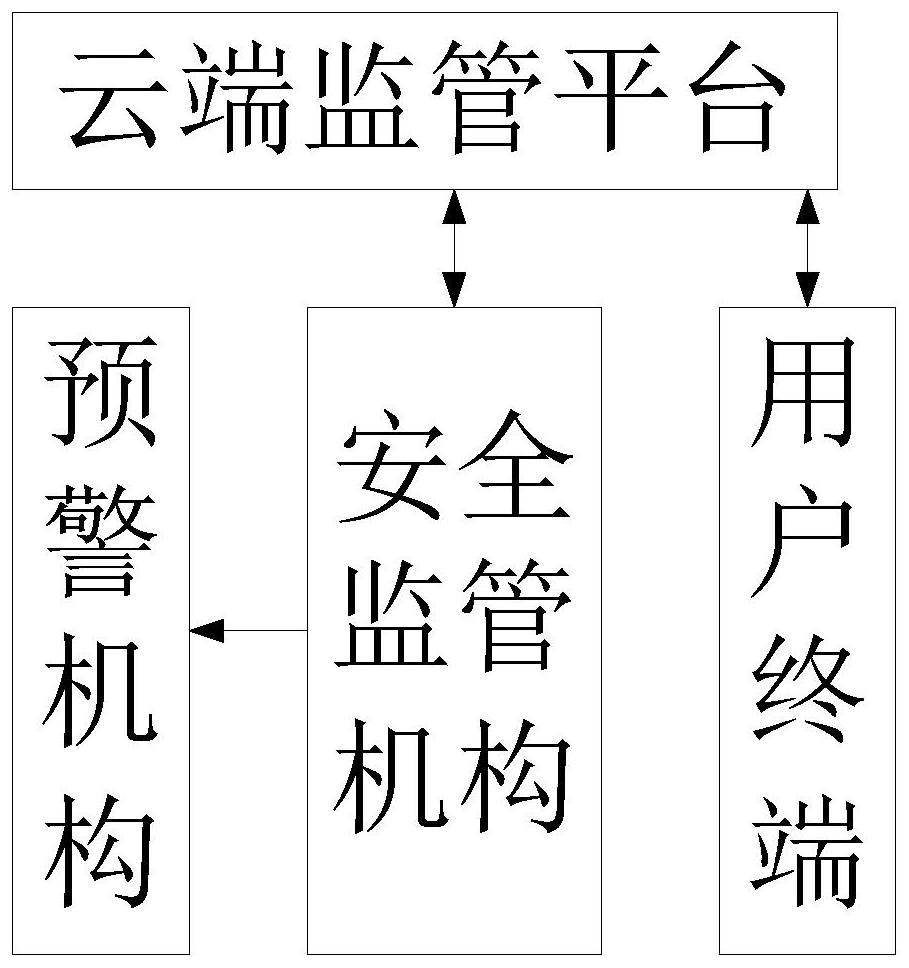

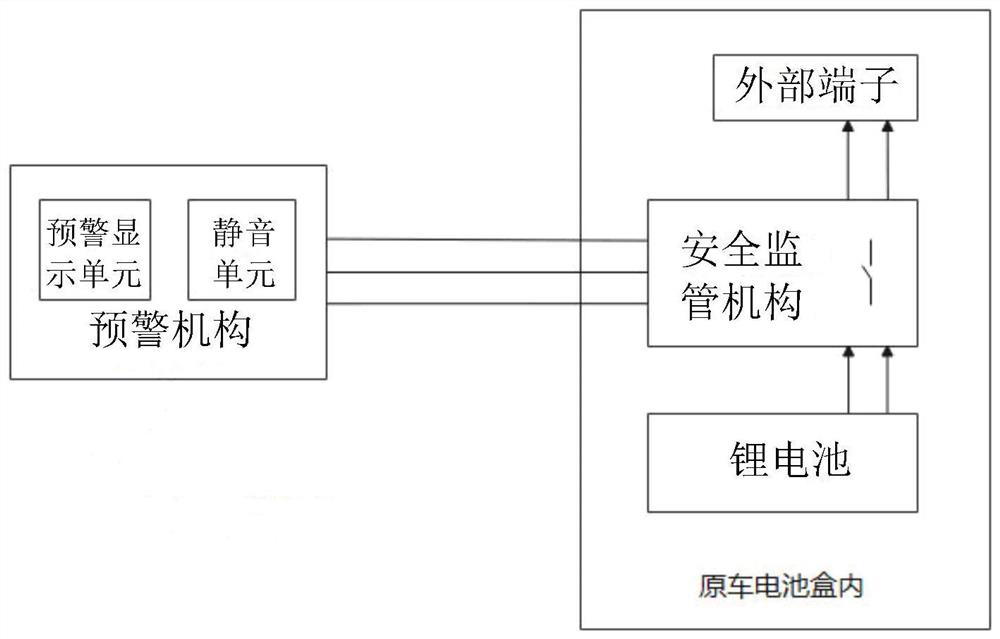

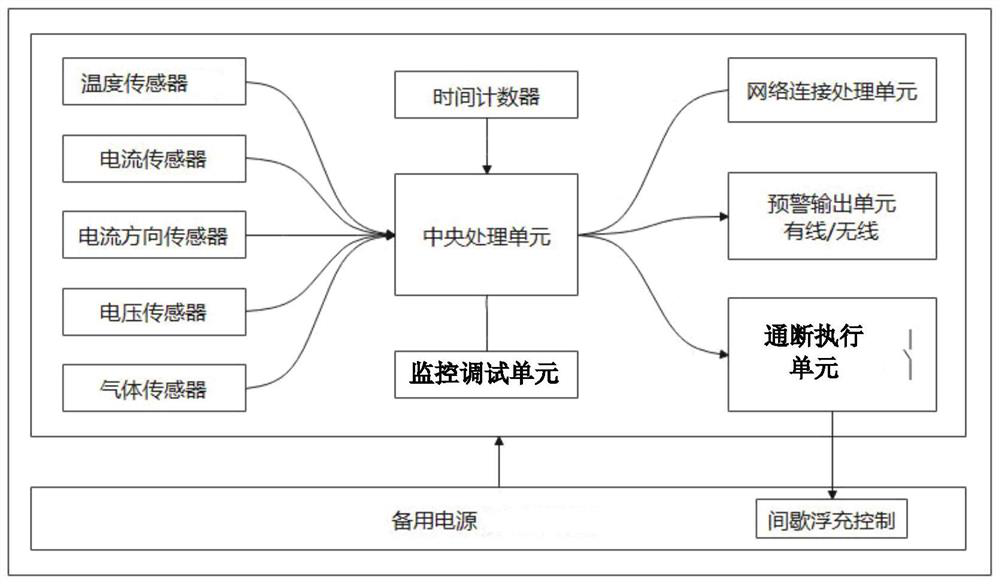

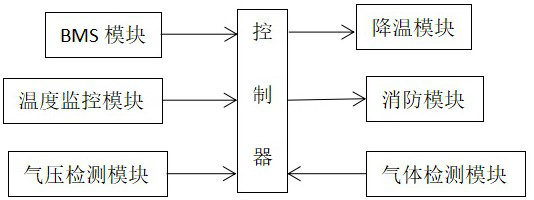

Electric vehicle battery safety supervision and early warning system and supervision and early warning method thereof

ActiveCN113920686ARealize safety supervisionPrevent deflagration accidentsAlarmsSecondary cells servicing/maintenanceEarly warning systemElectrical battery

The invention discloses an electric vehicle battery safety supervision early warning system which comprises a safety supervision mechanism connected between a lithium battery and an external terminal and an early warning mechanism installed on an electric vehicle, wherein the safety supervision mechanism communicates with the early warning mechanism and a cloud early warning platform, and the cloud early warning platform communicates with a user terminal. According to the electric vehicle battery safety supervision early warning system adopting the structure, the current state of the lithium battery is monitored through the safety supervision mechanism installed on the lithium battery, whether charging or discharging can be continued or not is judged, and if the charging or discharging exceeds the safety range, connection of an external circuit is stopped immediately; therefore, lithium battery deflagration accidents caused by continuous charging or discharging are avoided, and a reason data signal for forbidding work is sent to a cloud early warning platform and an early warning mechanism on the electric vehicle, so that safety supervision of the lithium battery is realized.

Owner:闫春林 +1

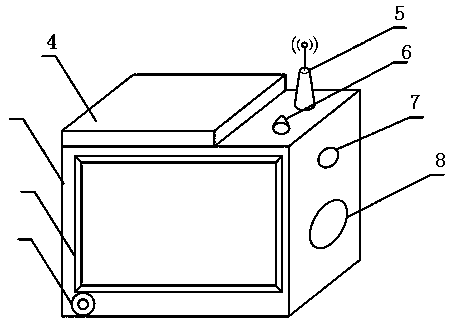

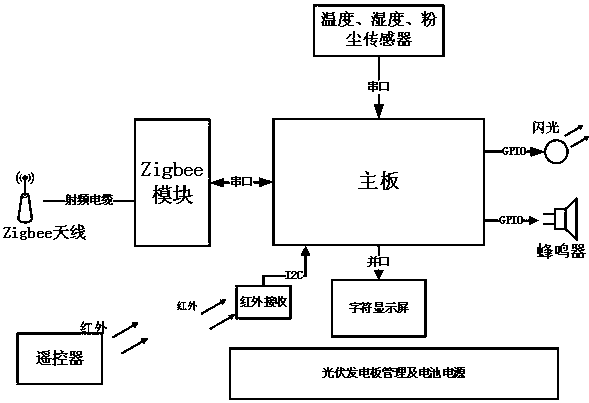

Remote environment monitoring alarm device for grinding and polishing workshops

InactiveCN108288343AMany nodesReliable transmissionBatteries circuit arrangementsElectric powerLiquid-crystal displayRemote control

A remote environment monitoring alarm device for grinding and polishing workshops relates to an alarm device. The device is a remote environment monitoring alarm device for grinding and polishing workshops based on ZigBee and a microprocessor. The device is equipped with a system host and a remote control. The host has a rectangular shell. A liquid crystal display screen is arranged on the front of the host. An infrared receiver is arranged in the lower left corner of the front. A temperature, humidity and dust sensor collected data window is arranged in the upper part of the right side of thehost. A buzzer is arranged in the lower part of the right side of the host. The left side of the top of the host is covered with a solar photovoltaic panel. A burst flashing indicator light is arranged in a position near the display screen on the right side of the top of the host. A ZigBee antenna is arranged in a position away from the display screen on the right side of the top of the host. Theinfrared receiver is connected with the host. The device can remotely collect the temperature, humidity and dust concentration of a grinding and polishing workshop and transmit the collected data through a ZigBee network to a remote monitoring center, has sound and light alarm functions, and is very suitable for upgrading and rebuilding the existing grinding and polishing workshop.

Owner:SHENYANG UNIV

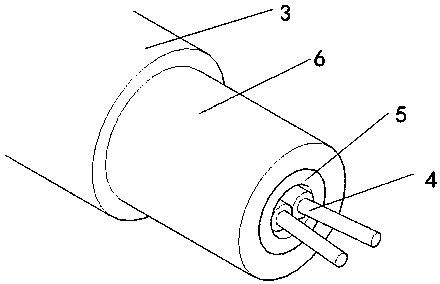

Structure for preventing lubricating oil coking and leakage deflagration at inter-turbine casings

InactiveCN113464282AEliminate overheating and coking problemsPrevent deflagration accidentsGas turbine plantsLeakage preventionTurbineFuel gas

The invention provides a structure for preventing lubricating oil coking and leakage deflagration at inter-turbine casings. The structure comprises a high-pressure turbine, a low-pressure turbine, an inter-turbine outer casing, an inter-turbine inner casing, an isolation type combined pipe joint, a bearing cavity oil supply pipe joint and an outlet flow distribution joint, wherein main runner gas circulates between the high-pressure turbine and the low-pressure turbine; the inter-turbine outer casing and then inter-turbine inner casing are arranged between the high-pressure turbine and the low-pressure turbine, rectification blades are arranged between the high-pressure turbine and the low-pressure turbine, and main runner sealing gas circulates in the rectification blades; the isolation type combined pipe joint penetrates through the rectification blades in a main runner to be connected with the inter-turbine outer casing and the inter-turbine inner casing, the isolation type combined pipe joint is provided with an inner oil supply pipe and an outer sealing gas guide pipe, the inner oil supply pipe is used for circulating lubricating oil, the outer sealing gas guide pipe is used for circulating bearing cavity sealing gas, and the outer sealing gas guide pipe is located on the outer layer of the inner oil supply pipe, and therefore, the bearing cavity sealing gas circulating in the outer sealing gas guide pipe enables the main runner sealing gas in the rectification blades and the lubricating oil in the inner oil supply pipe to form a heat insulation state; and the bearing cavity oil supply pipe joint is connected with the inner oil supply pipe, and the outlet flow distribution joint is connected with the outer sealing gas guide pipe.

Owner:AECC SHENYANG ENGINE RES INST

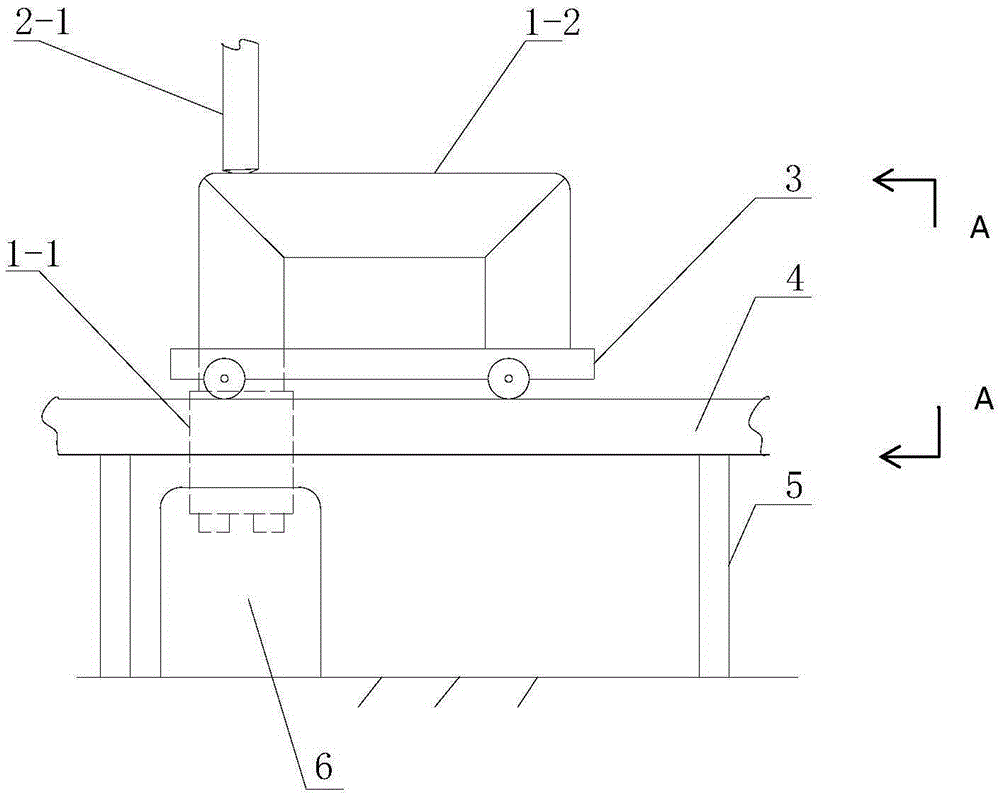

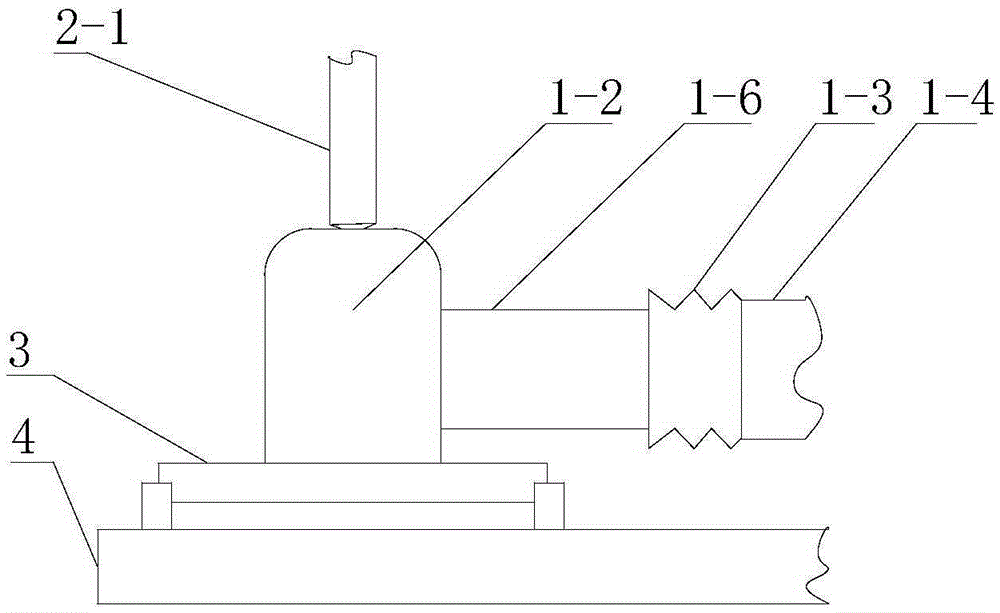

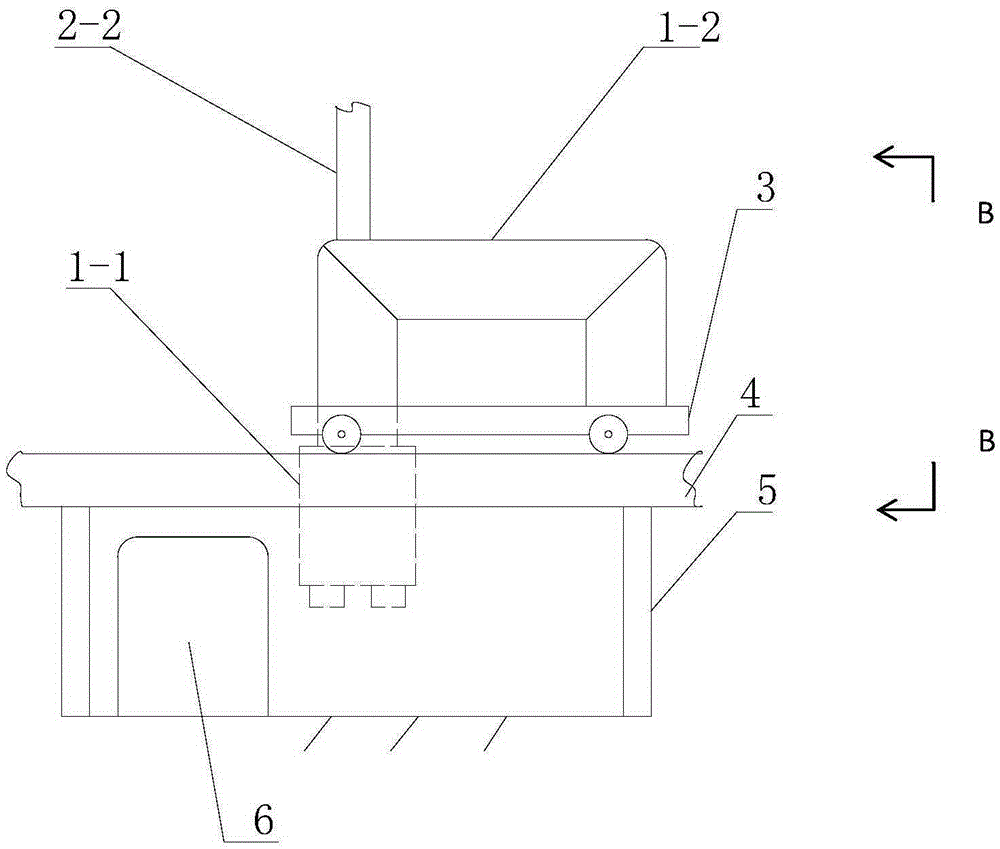

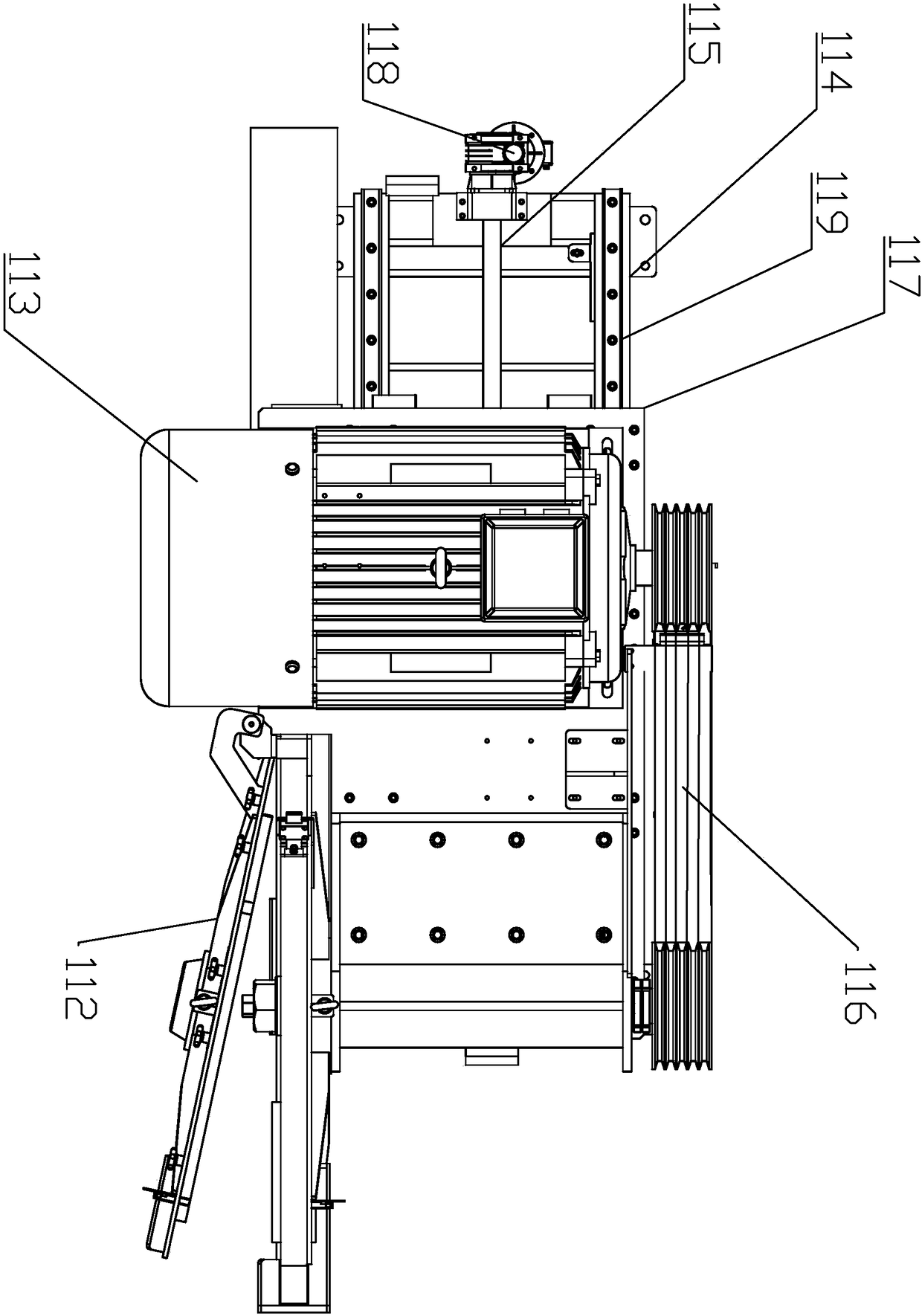

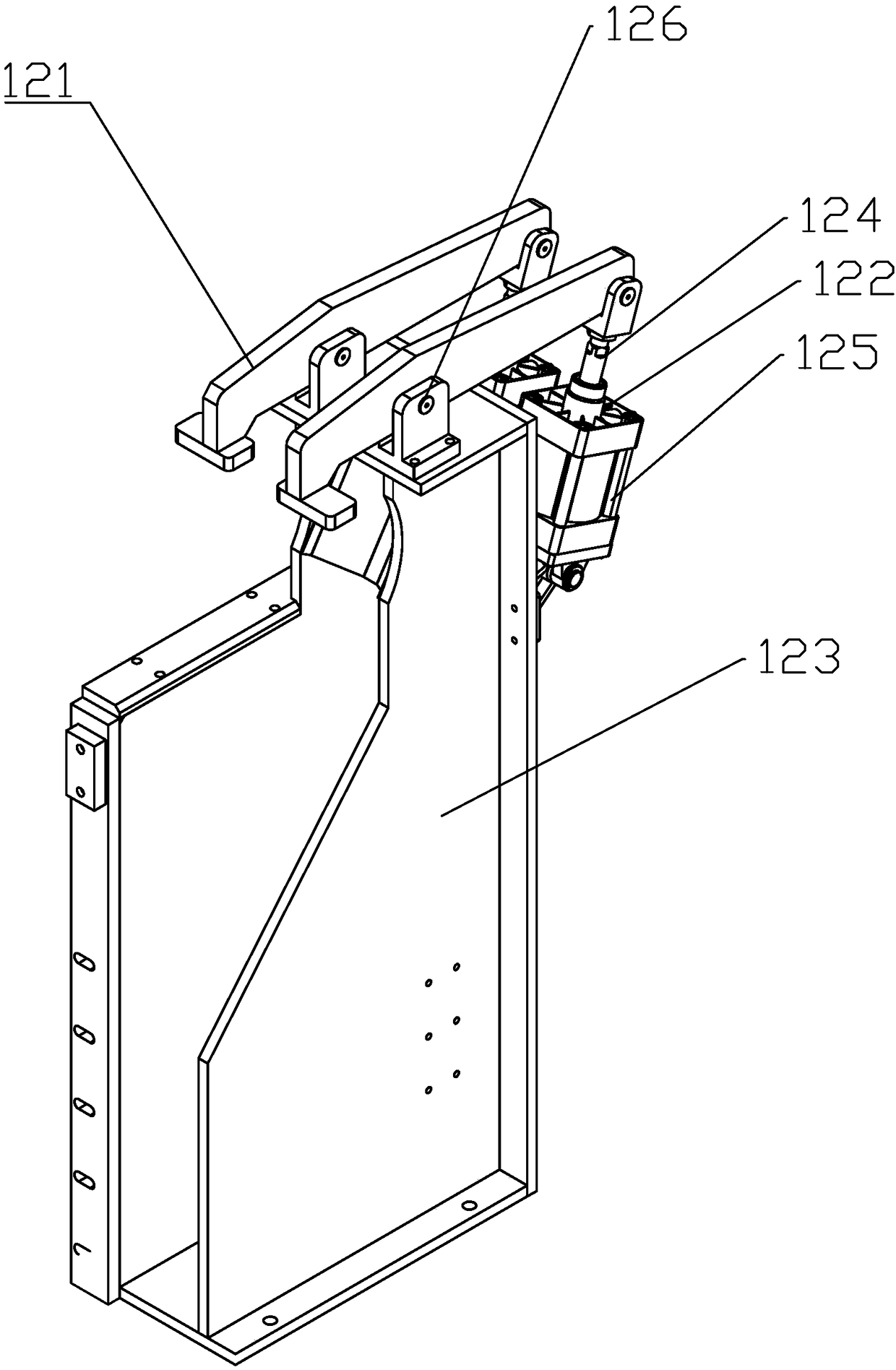

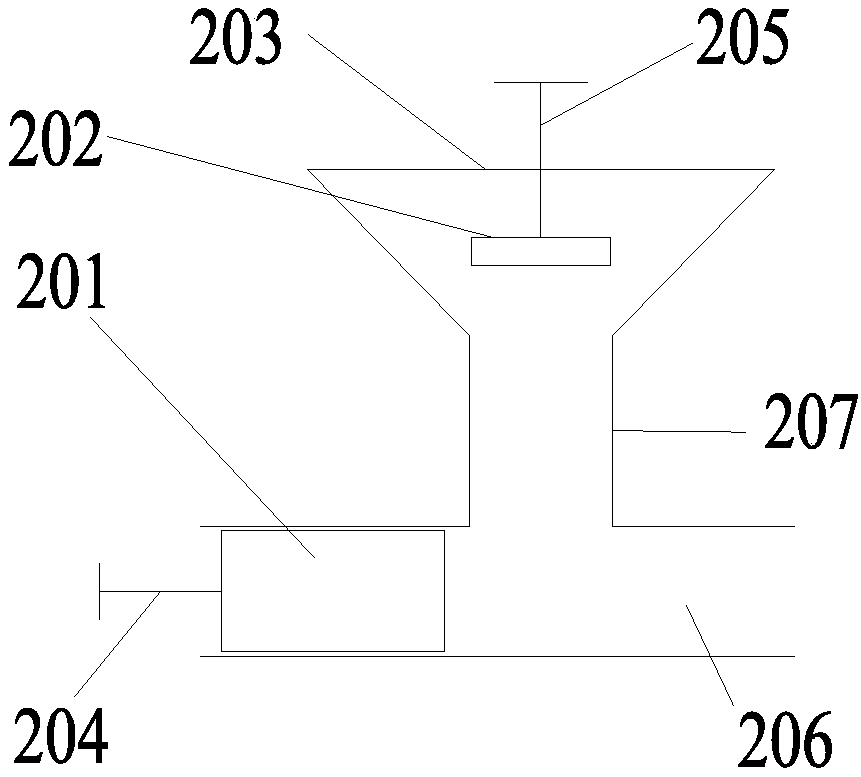

Aluminum-bar hot sawing device

PendingCN108098053APrevent deflagration accidentsStrong pressing forceMetal sawing devicesEngineeringBar pressing

The invention discloses a device and relates to the field of aluminum bar machining, in particular to an aluminum-bar hot sawing device. The aluminum-bar hot sawing device comprises a conveying deviceof an aluminum bar and a hot sawing mechanism; the conveying device of the aluminum bar is connected with the hot sawing mechanism, and the hot sawing mechanism comprises a hot sawing machine and a bar pressing mechanism; the hot sawing machine is provided with a saw blade, and the bar pressing mechanism is arranged in the same direction where the saw blade is placed; the bar pressing mechanism comprises a rocker arm, a bar pressing air cylinder and a pressing seat; and the bar pressing air cylinder comprises a cylinder body and a piston rod, the piston rod is hinged to one end of the rockerarm, the cylinder body is hinged to the pressing seat, a supporting point is arranged between the two ends of the rocker arm, and the supporting point is hinged to the pressing seat. The aluminum-barhot sawing device is safe and stable.

Owner:佛山市南海万格士机械设备有限公司

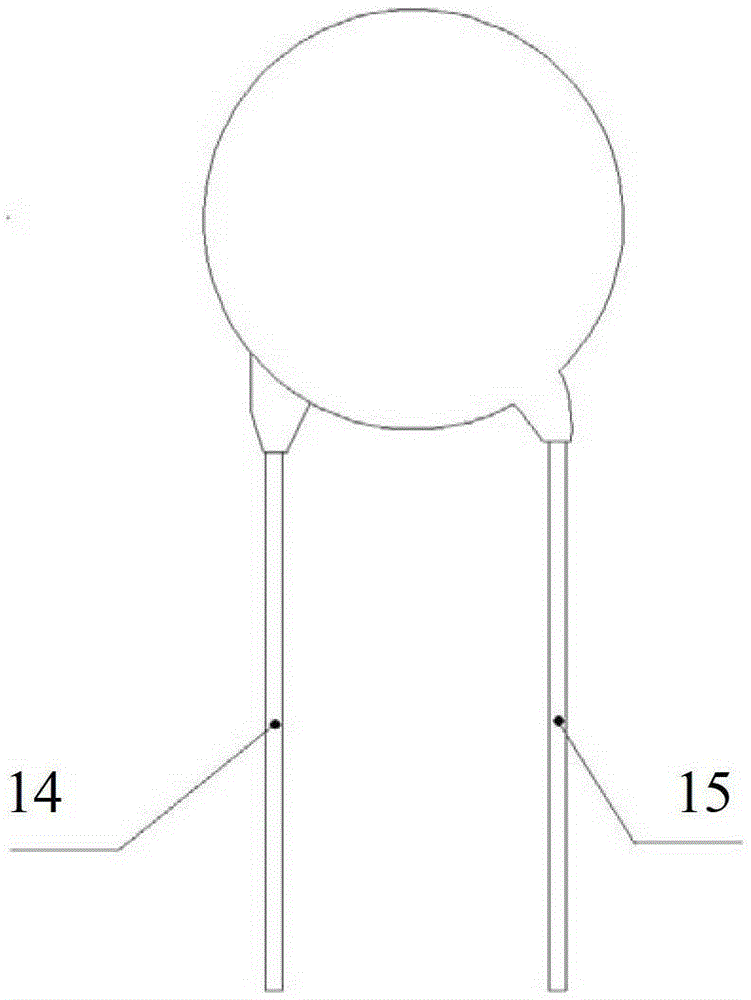

Thunder-prevention overvoltage protection device

InactiveCN103311916ANormal work is not affectedCurrent limitEmergency protective arrangements for limiting excess voltage/currentOvervoltageLightning strokes

The invention discloses a thunder-prevention overvoltage protection device. The thunder-prevention overvoltage protection device comprises a piezoresistor sheet, a positive temperature coefficient thermistor sheet and a gas discharge tube, wherein the piezoresistor sheet and the positive temperature coefficient thermistor sheet are encapsulated integrally to form an encapsulation body. One end of the positive temperature coefficient thermistor sheet is a first leading-out end. The other end of the positive temperature coefficient thermistor sheet is connected with one end of the piezoresistor sheet to form a public end, and the public end serves as a third leading-out end. The other end of the piezoresistor sheet serves as a second leading-out end. The gas discharge tube is located outside the encapsulation body, and two ends of the gas discharge tube are connected with the first leading-out end and the third leading-out end respectively. The thunder-prevention overvoltage protection device can inhabit operation overvoltage and fault power frequency overvoltage and can play a protecting role of a normal voltage-sensitive element when lightning stroke pulse overvoltage occurs.

Owner:SOUTH CHINA UNIV OF TECH +2

Ignition boosting method for gas boiler

InactiveCN1270124CPrevent deflagration accidentsNormal burningAir supply regulationFlammability limitProduct gas

The present invention relates to the ignition and pressure lifting method for medium temperature and medium pressure gas burning boiler with coke oven gas as fuel. During ignition, lifting pressure and normal operation, hot blast baffle opening, blower baffle opening, induced draft fan baffle opening, gas regulating door opening and negative hearth pressure in the boiler are set and regulated, so as to control the inflammable gas density inside the boiler during ignition and lifting pressure below the explosion limit and to avoid boiler explosion accident. The ignition and pressure lifting method of the present invention is suitable for all types of gas burning boilers with PLC program controlled ignition system.

Owner:山西焦化股份有限公司

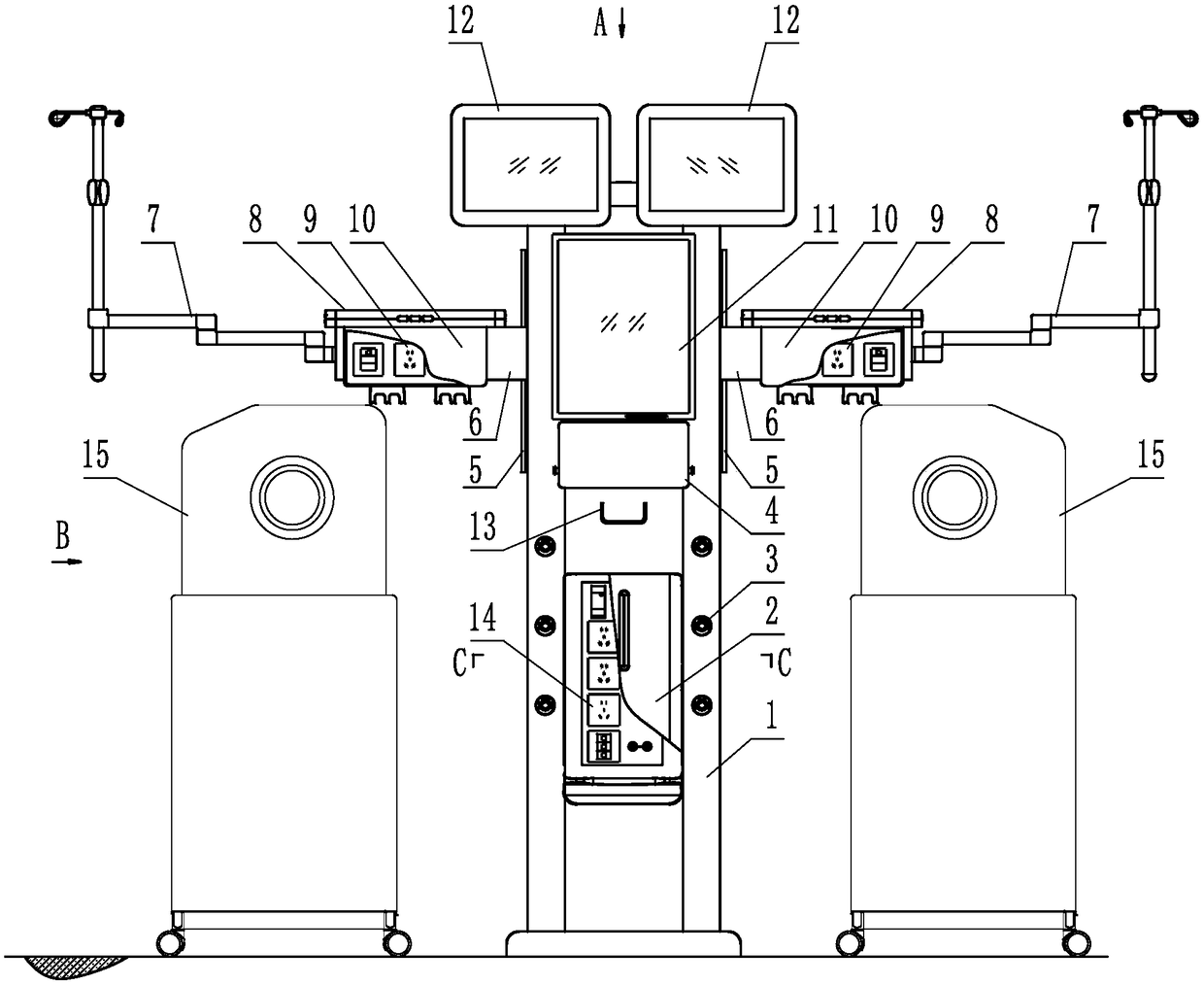

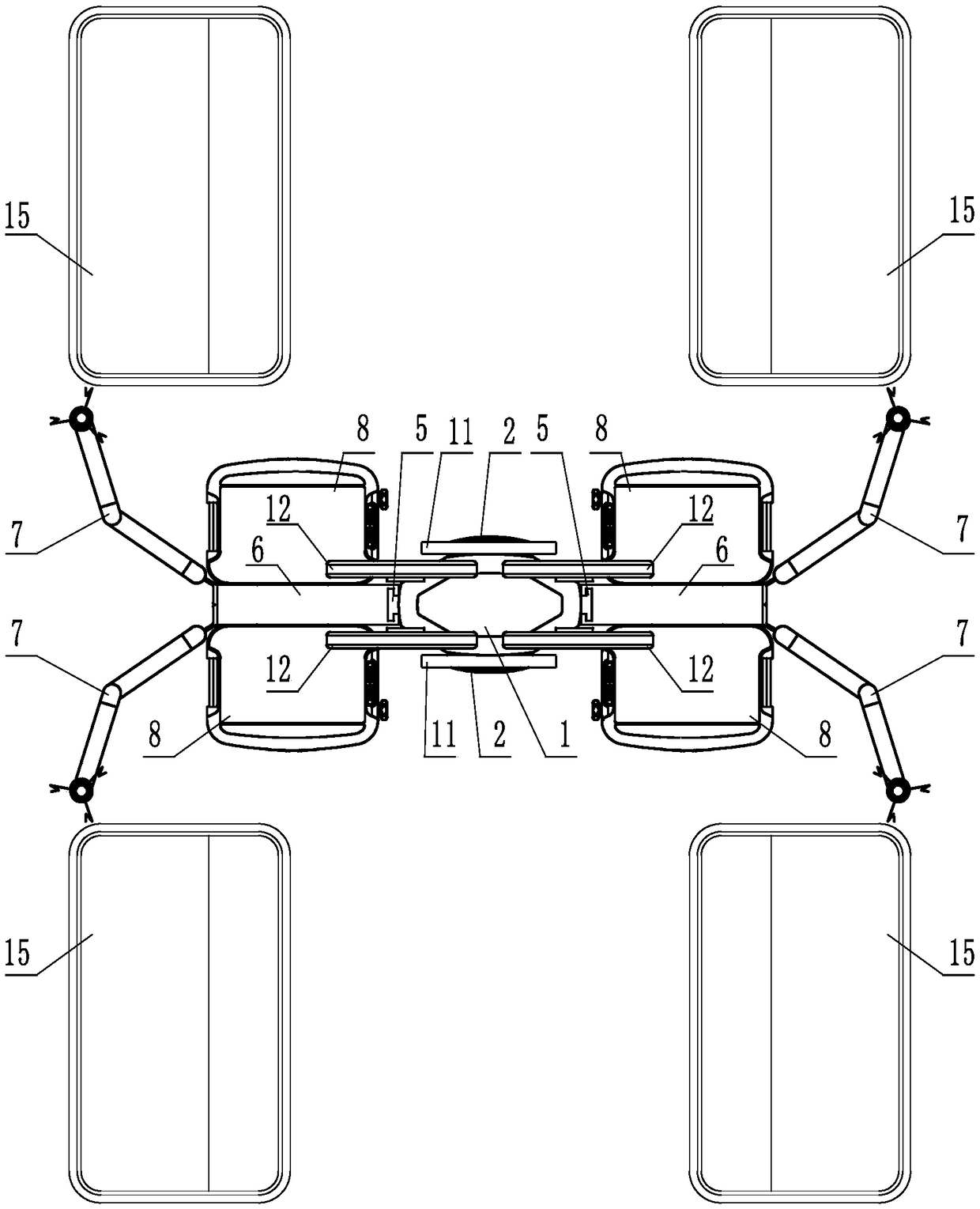

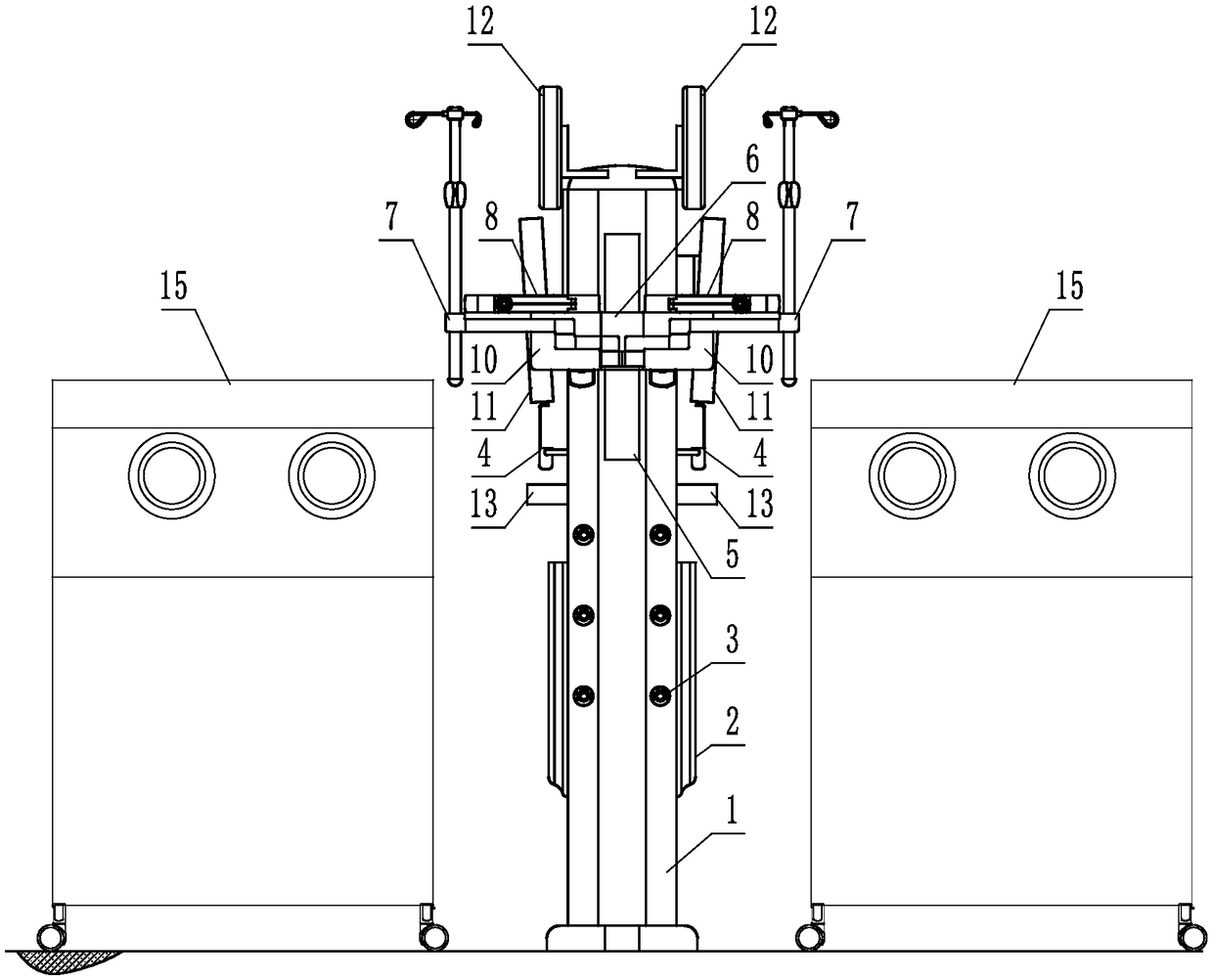

Newborn bedside medical care workstation

PendingCN109431727AProfessional medical careExtended service lifeNursing accommodationMedical transportMedical equipmentWorkstation

The invention discloses a newborn bedside medical care workstation. The newborn bedside medical care workstation is characterized by comprising an equipment vertical column, and medical terminals, medical digital information display devices and concealed strong or weak electrical socket boxes are correspondingly arranged on two opposite lateral sides of the equipment vertical column. The equipmentvertical column is provided with extending arms for connection with an equipment platform and an infusion pump rod device, and the equipment vertical column is provided with a patient basic information display device. The newborn bedside medical care workstation is arranged among a plurality of newborn treatment nursing beds / incubators and connected with the ground or a ceiling and simultaneouslyprovides functions of medical equipment bearing, infusion racks, strong or weak electrical sockets, medical gas connectors, basic information displaying, medical treatment image and medical digital information checking, recording, transmitting, storing and calling for the multiple newborn treatment nursing beds / incubators. The newborn bedside medical care workstation is small in size and compactin structure, each ward can be provided with multiple medical care workstations, and each single medical care station can be used by multiple newborn treatment nursing beds / incubators at the same time.

Owner:HUNAN TAIYANGLONG MEDICAL TECH

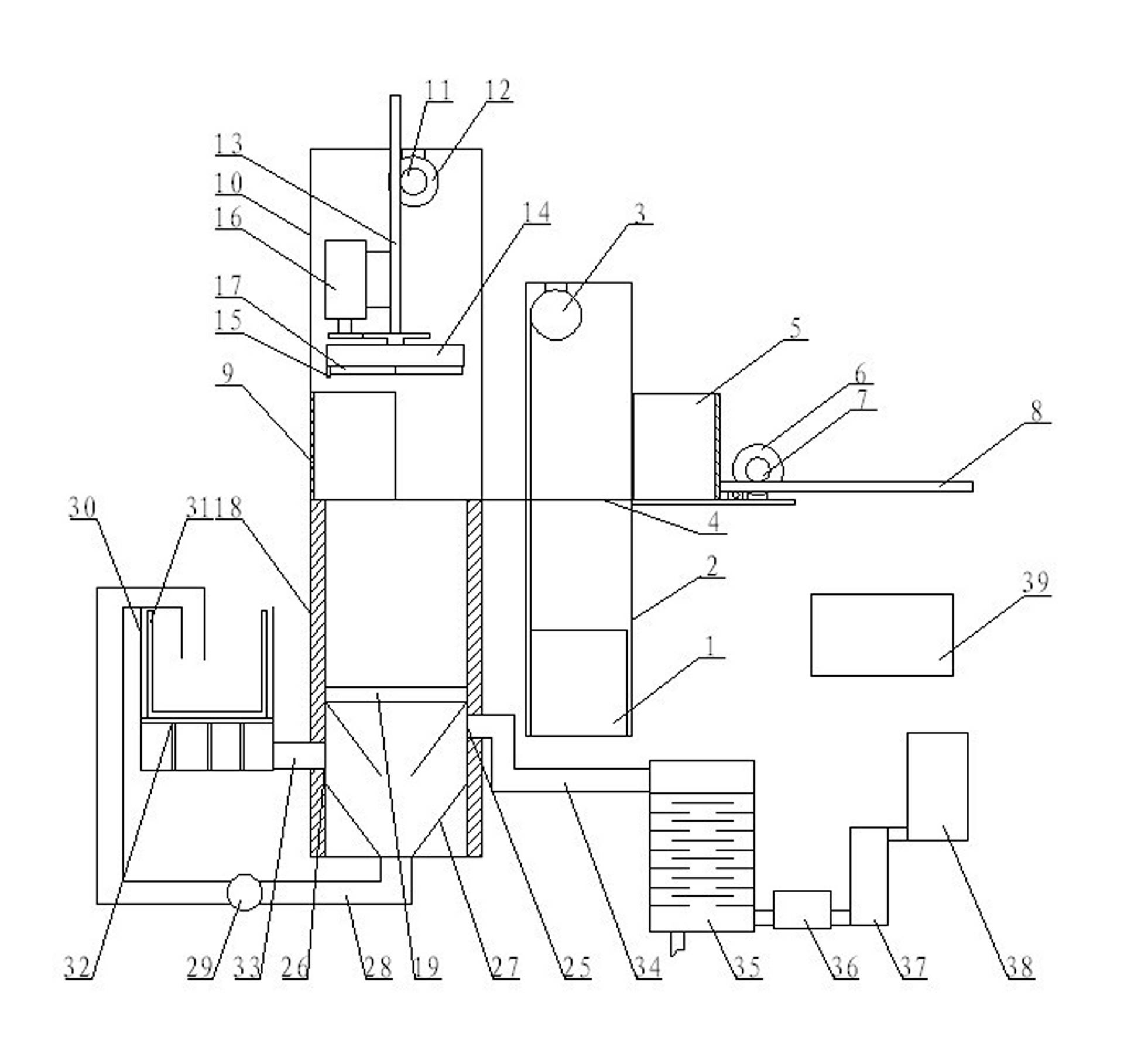

Waste lithium ion power battery protection crushing process equipment

PendingCN112958257APrevent deflagration accidentsImprove securityWaste accumulators reclaimingGrain treatmentsPower batteryParticulates

The invention discloses a waste lithium ion power battery protection crushing process equipment. The equipment comprises a conveying belt assembly and a nitrogen tank, and the top end of the conveying belt assembly is arranged at a feeding opening of a crushing machine shell in an attached mode; and a nitrogen pipe connected between the nitrogen tank and the crushing machine shell achieve internal communication of the nitrogen tank and the crushing machine shell, the top of the crushing machine shell is connected with one end of a first conveying pipe in a penetrating mode, the other end of the first conveying pipe is installed on a cyclone dust collector, the lower end of the cyclone dust collector is connected with a storage bin used for collecting particle plates, and an air locking valve is mounted at a port of the storage bin. According to the waste lithium ion power battery protection crushing process equipment, an electrolyte volatile gas treatment structure is arranged inside the equipment, gas atmosphere protection can be conducted on a crushing device, detonation accidents are prevented, safety is better, the equipment can treat particulate matter generated by crushing, the particulate matter content in tail gas is effectively reduced, and the device is more environment-friendly.

Owner:北辰先进循环科技(青岛)有限公司

Novel straw direct gasification polygeneration preparation process

InactiveCN102329649AConvenient feeding and conveyingUniform densitySpecial form destructive distillationFixed-bed gasificationAgricultural engineeringGas holder

The invention relates to a novel straw direct gasification polygeneration preparation process, comprising a gasification furnace, a feeding device, a material pushing device, a material pressing device, a material homogenizing device, a carbon discharging device, a washing device, a fan, a water seal filtering device, a gas holder and a control cabinet. By virtue of the feeding device, the material pushing device, a material pressing device and a material homogenizing device, straw requiring no processing is directly fed into a gasification furnace to be gasified, the straw is effectively controlled to polygenerate straw carbon and straw gas, a carbon scraping grate and the carbon discharging device are combined to collect the straw carbon, labyrinth type spraying washing is carried out to separate the straw gas and straw extract, the water seal filtering device filters and collects the straw gas, and the device has high reliability, good safety performance, strong practicability, simple gasification process, good gasification effect, high straw utilization rate and low operation cost.

Owner:顾云江

Sewer detection and danger elimination system

ActiveCN113622502AReduce concentrationPrevent deflagration accidentsMeasurement devicesSewerage structuresElectric machineryWater storage tank

The invention discloses a sewer detection and danger elimination system. The sewer detection and danger elimination system comprises a well lid assembly, an exhaust device, a guide device, a detection device, a drainage device, a connecting device and a control device, wherein the well lid assembly comprises an outer frame and a well lid main body arranged on the inner side of the outer frame; the exhaust device comprises a first gas guide cylinder, a second gas guide cylinder, a first bracket, a motor, fan blades, a combustion bin and an absorption assembly; the guide device comprises a guide pipe fitting and a guide cylinder; the detection device comprises a second bracket, an ultrasonic ranging piece and a gas sensor; the drainage device comprises a water storage tank, a bracket assembly and a grating plate; the connecting device comprises a pulley arranged on the first bracket and a pull rope wound on the pulley; and the control device is arranged on the first gas guide cylinder or the second gas guide cylinder and is electrically connected with the motor, an igniter, the ultrasonic ranging piece and the gas sensor. Through the structure, the concentration of combustible gas can be detected, when the concentration exceeds the standard, gas in a sewer and a well can be pumped out, the combustible gas is combusted, toxic and harmful substances in waste gas are absorbed, and the safety is improved.

Owner:深圳市博流测控技术有限公司

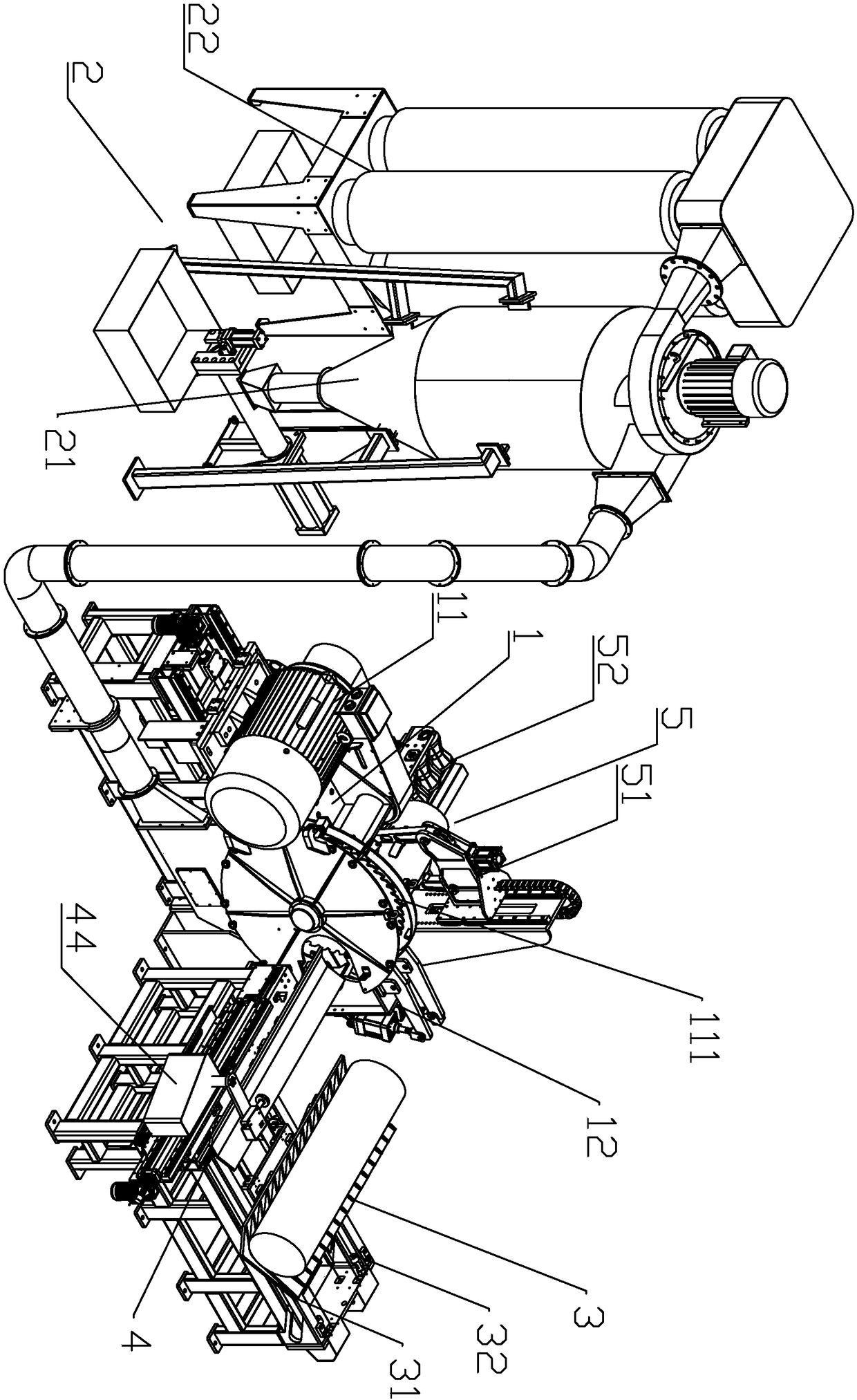

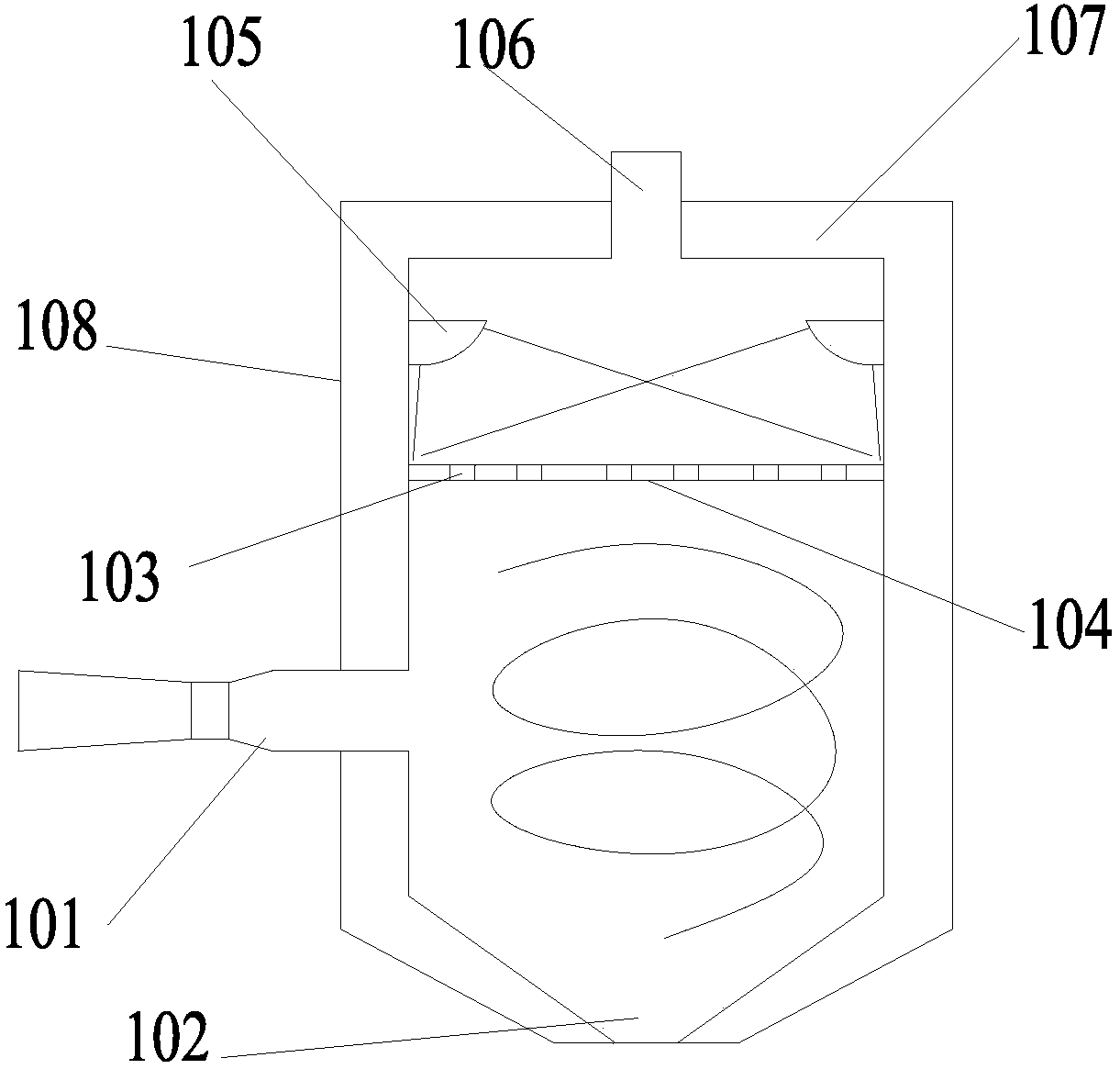

Mobile in-situ treatment apparatus for oil-containing sludge

PendingCN107892458AReduce volumePurification and separation efficiencySludge treatment by pyrolysisByproduct vaporizationSlagProduct gas

The invention relates to mobile in-situ treatment apparatus for oil-containing sludge. The apparatus comprises a natural-gas purification separation device, a material giving device, a material outletdevice, and a pyrolysis device; the pyrolysis device is provided with a material inlet, a slag outlet and a pyrolysis gas outlet, the material inlet is connected with the material giving device, thepyrolysis gas outlet is connected with the natural-gas purification separation device, the slag outlet is connected with the material outlet device, and the pyrolysis device is used to heat and decompose the oil-containing sludge; the material giving device is used to receive the oil-containing sludge and convey the oil-containing sludge into the pyrolysis device; the material outlet device is used to cool high-temperature slag and discharge the cooled slag; and the natural-gas purification separation device is used to separate and purify a pyrolysis gas discharged from the pyrolysis gas outlet, and the obtained natural gas is used for recycling. The mobile in-situ treatment apparatus for the oil-containing sludge provided by the invention can treat the oil-containing sludge in an in-situand environmentally-friendly manner, and changes waste into treasure.

Owner:长春三真实业有限公司

Oil-sludge separation discharging device

PendingCN107902863ALimit refluxPrevent deflagration accidentsWaste water treatment from quariesSludge treatment by pyrolysisOil sludgeWater jacket

The invention relates to an oil-sludge separation discharging device, comprising a first conveying pipeline and a second conveying pipeline, wherein the first conveying pipeline is arranged at a slaghole of a rotary kiln, one end of the first conveying pipeline is connected with the slag hole, and the other end of the first conveying pipeline is connected with a connecting pipeline; the second conveying pipeline is arranged under the first conveying pipeline, one end of the second conveying pipeline is connected with the connecting pipeline, and a discharge hole is formed at the other end ofthe second conveying pipeline; water jackets are respectively arranged at the outer layers of the first conveying pipeline and the second conveying pipeline; the first conveying pipeline is internallyprovided with a first screw conveyer, and the first screw conveyer can be used for conveying dregs falling from the slag hole to the connecting pipeline so as to enable the dregs to fall into the second conveying pipeline; the second conveying pipeline is internally provided with a second screw conveyer, and the second screw conveyer can be used for conveying the dregs falling from the connectingpipeline to the discharge hole so as to discharge the dregs outside. The oil-sludge separation discharging device is arranged at the slag hole of the rotary kiln of an oil-sludge separation device; due to the arrangement of the two stages of conveying pipelines, the air backflow is well limited, and the deflagration accidents are further effectively prevented.

Owner:长春三真实业有限公司

A lightning protection overvoltage protection component

InactiveCN103337848BNormal work is not affectedCurrent limitEmergency protective arrangements for limiting excess voltage/currentPressure cellThermistor

The invention discloses an anti-thunder overvoltage protection component which comprises a piezoresistor disc, a positive temperature coefficient thermistor disc and a gas discharge tube, wherein the piezoresistor disc, the positive temperature coefficient thermistor disc and the gas discharge tube are integratedly packaged; the first common terminal of the positive temperature coefficient thermistor disc and the gas discharge tube is a first leading-out terminal; the second common terminal of the positive temperature coefficient thermistor disc and the gas discharge tube is connected with one end of the piezoresistor disc; the other end of the piezoresistor disc is a second leading-out terminal. The anti-thunder overvoltage protection component can restrain the switching overvoltage and fault power frequency overvoltage, and can play the protective role of a normal pressure cell in case of a thunderstrike pulse overvoltage.

Owner:SOUTH CHINA UNIV OF TECH +2

Biomass gasification hot charcoal co-production system with independent oxidation chamber

PendingCN114540084AHigh-quality gas-carbon cogenerationLow costEnergy inputSolid fuel combustionProcess engineeringFlue gas

The invention provides a biomass gasification hot charcoal co-production system provided with an independent oxidation chamber, and relates to the technical field of biomass comprehensive utilization equipment, the biomass gasification hot charcoal co-production system comprises an oxidation furnace and a gasification furnace which are independently arranged, the oxidation furnace and the gasification furnace are connected through a flue gas pipe, the flue gas pipe is provided with a flue gas pipe valve, and the flue gas pipe valve is connected with the gasification furnace. The flue gas pipe is further connected with one end of a flue gas circulating pipe, the other end of the flue gas circulating pipe is communicated with an oxidation chamber of the oxidation furnace, and the flue gas circulating pipe is provided with a flue gas circulating valve and a flue gas circulating fan; and an oxygen detection device, a temperature sensor and a flow meter are respectively arranged on the flue gas pipe on a pipeline between the flue gas pipe valve and the oxidizing furnace. The oxidation furnace is independently arranged, the oxidation process (combustion) is independently carried out and controlled, the reaction intensity can be easily controlled, the biomass gasification production process can be conveniently and rapidly adjusted and controlled in a wide range by controlling the reaction intensity of the oxidation furnace, and high-quality gas-carbon co-production is achieved.

Owner:江苏嘉林新能源科技有限公司

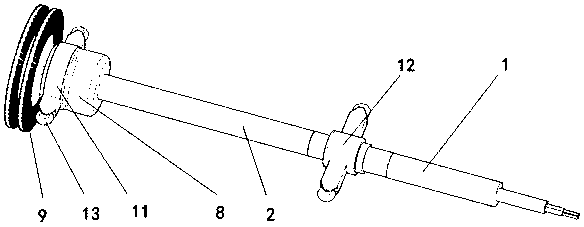

Disassembling-free cleaning device for MOCVD tail pipe

PendingCN111318523APrevent deflagration accidentsImprove securityHollow article cleaningEngineeringBrush

The invention discloses a disassembling-free cleaning device for a MOCVD tail pipe. The disassembling-free cleaning device comprises a front-end cleaning assembly and a tail-end connecting assembly; the front-end cleaning assembly comprises a front-end cable; a cleaning device is fixedly arranged at the end of one side of the front-end cable, and the other end of the front-end cable is connected with the end of a tail-end cable; and the tail-end connecting assembly further comprises a moving device which is fixedly arranged on the peripheral side of the front end cable and used for enabling the whole device to move in the MOCVD tail pipe in the pipeline extending direction. According to the disassembling-free cleaning device for the MOCVD tail pipe, cleaning and maintaining device for thelong tail pipe type MOCVD tail pipe are completed in an electric rotary sweeping mode through a physical brush, the whole device can directly stretch into the MOCVD tail pipe, a pipeline does not needto be frequently detached during periodic maintenance, moreover, deflagration accidents caused by the fact that high-activity particles in the pipeline make contact with air are avoided, and therefore the maintenance safety is improved.

Owner:木昇半导体科技(苏州)有限公司

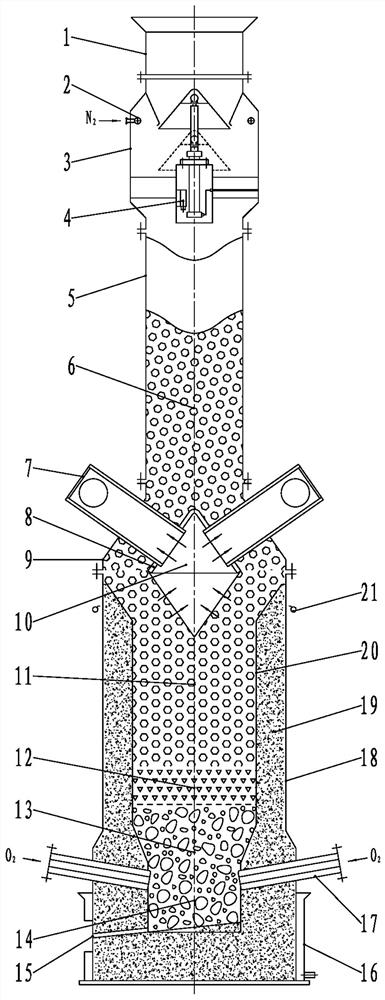

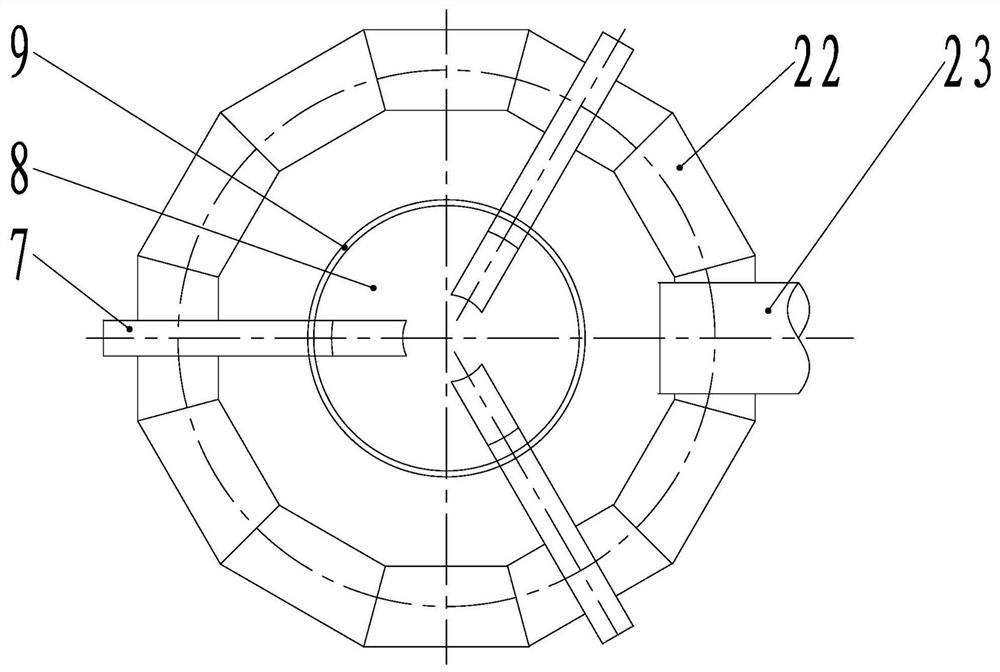

Solid waste and hazardous waste gasification melting furnace with central gas collection

PendingCN111853812ASimple structureReduce manufacturing costIncinerator apparatusThermodynamicsExhaust fumes

The invention discloses a solid waste and hazardous waste gasification melting furnace with central gas collection, and relates to the field of solid waste treatment melting furnaces. The solid wasteand hazardous waste gasification melting furnace comprises a furnace top charging system, a furnace throat central gas collecting device and a furnace body gasifying and melting part, wherein the furnace top charging system is used for feeding materials into the furnace, and comprises a material receiving hopper, a sealing valve and a sealing material barrel, and a nitrogen filling pipe and a material level meter are arranged in the sealing valve; the furnace throat central gas collecting device is used for central gas collection, collecting the furnace gas in the furnace from the middle of the furnace and discharging the gas, and comprises a gas guiding beam, a gas collecting bell and a throat shell body, and the gas collecting bell is fixed to the center of the throat shell body throughthe gas guiding beam; and the furnace body gasifying and melting part comprises a furnace shell, a refractory lining, a furnace hearth and a furnace cylinder, and a tuyere device and a liquid discharging port are arranged on the furnace cylinder. According to the solid waste and hazardous waste gasification melting furnace with central gas collection, a furnace top sealing valve and a nitrogen filling facility are arranged, the charging sealing form is improved, the furnace throat central gas collecting device is arranged, the furnace gas guiding mode is changed, the problems of feeding sealing, furnace air flow and the like are solved, meanwhile the structure is simple, the manufacturing cost is low, and the application range is wide.

Owner:山西正和热电工程有限公司

Boiler start-up method to prevent scale formation and secondary combustion accidents in tail flue of 1000mw octagonal tangential boiler

The invention discloses a boiler starting method for preventing oxide skin generation of a 1,000 MW octagonal tangent circle boiler and a secondary combustion accident of a tail flue. Boiler warming is carried out before a combustor is put into operation, then, the combustor is put into operation, and the operation of the combustor is adopted according to the following operation principles that all large oil guns in an AB layer and part of large oil guns in a CD layer are put one by one, and when the outlet pressure of a boiler steam-water separator reaches 0.3 MPa, all micro oil guns in an A layer are put, and then a powder manufacturing system of the A layer is put into operation; and at the thermal state flushing and temperature rising and boosting stage, part of or all large oil guns quit one by one according to the pulverized coal combustion situation, and at the load rising stage, powder manufacturing systems are put into operation layer by layer according to the load situation. According to the method, the temperature rising rate of a heating surface of the boiler in the starting process can be controlled, and the good combustion effect of the pulverized coal in a hearth can be guaranteed; and generation of pipe oxide kin of the heating surface of the boiler is effectively prevented, and the purposes of preventing secondary combustion of the tail flue and the detonation accident of the hearth can be achieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

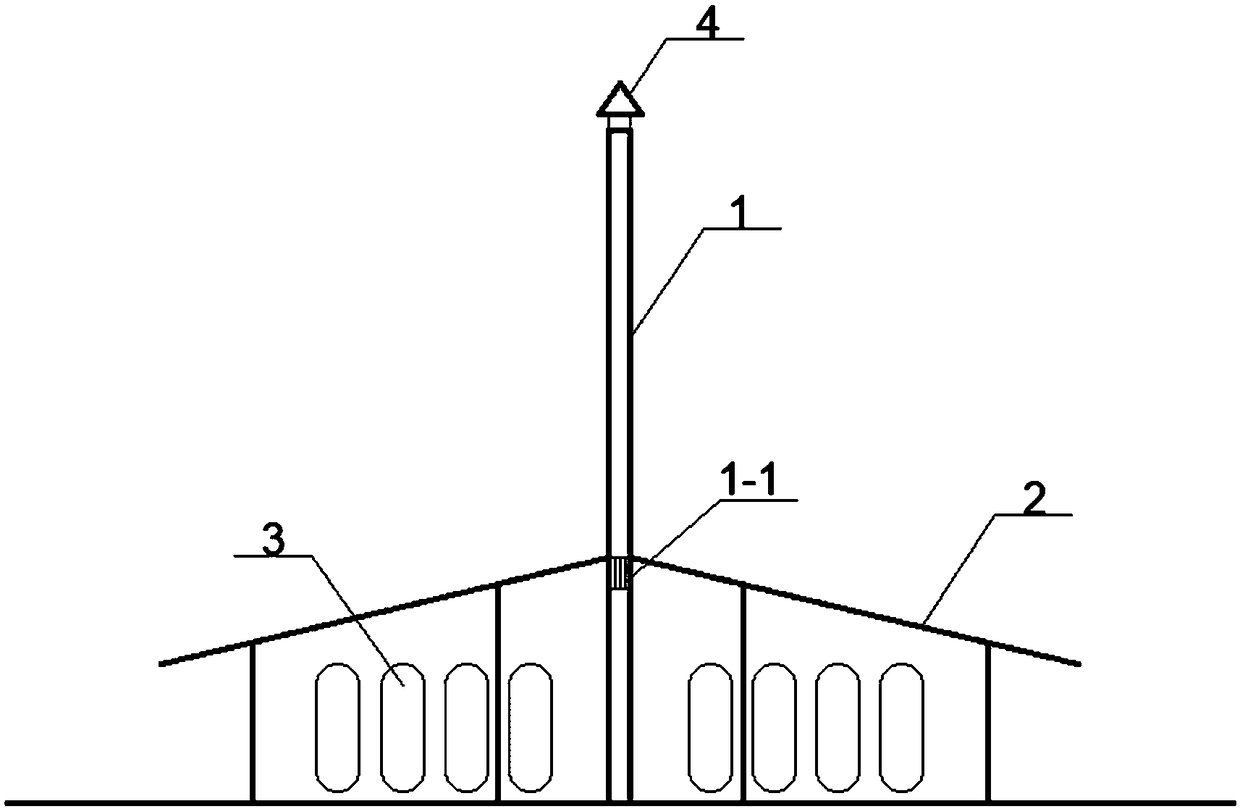

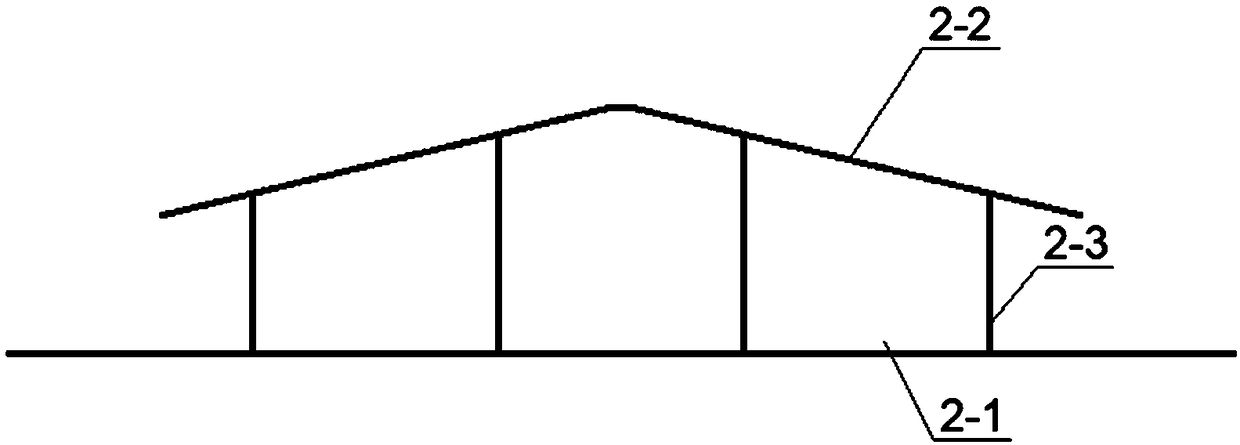

Protective device for high-temperature heat storage system

InactiveCN109443062APromote circulationEasy to breatheHeat storage plantsSafety devices for heat exchange apparatusBoiling pointEngineering

The invention relates to the technical field of energy storage, and provides a protective device for a high-temperature heat storage system. The device comprises a flow guide pipe and a protective shed used for covering the high-temperature heat storage system, the bottom end of the flow guide pipe is fixed on the ground in the protective shed, and the top end of the flow guide pipe extends out ofthe protective shed; and a flow guide port is formed in the flow guide pipe, the flow guide port is located in the top surface, close to the protective shed, of the protective shed, and an air inletis formed in the lower part of the protective shed. According to the device, the structure is simple, and installation is convenient; and the protective device covers the high-temperature heat storagesystem, inherent leakage heat of the high-temperature heat storage system can be used for driving the leaked oil gas to be continuously discharged out of the protective shed through the flow guide pipe, so that the low-boiling-point oil gas gathered near the high-temperature heat storage system is removed in real time, an explosion accident is avoided, the driving part is not needed as well, theservice life is prolonged, and the cost is reduced.

Owner:TSINGHUA UNIV

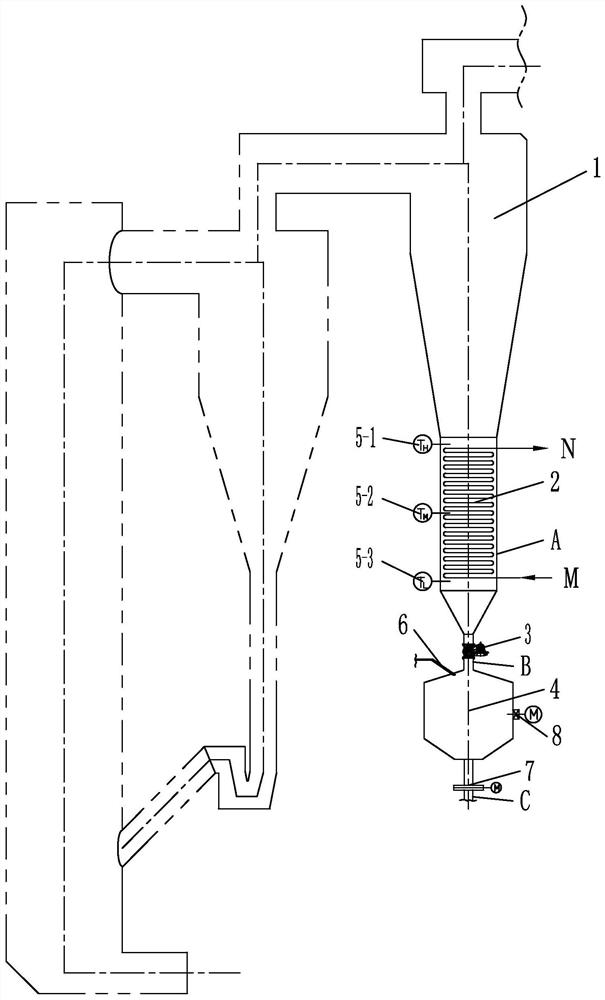

Positive-pressure ash cooling system for biomass fluidized bed gasification furnace

InactiveCN111996037APrevent gas leakagePrevent deflagration accidentsChemical industryGasification processes detailsProcess engineeringFluidized bed gasifier

A positive-pressure ash cooling system for a biomass fluidized bed gasification furnace relates to the field of biomass fluidized bed gasification furnaces. According to the invention, the problem that the fine ash separated by the fine ash separator cannot be directly discharged because the content of the fine ash in the gasified gas of the existing biomass gasification furnace is extremely highand the temperature of the fine ash separated by the fine ash separator is up to 800 DEG C is solved. A vertical pipe is arranged below a fine ash separator; a cooling water heat exchanger is arrangedin the vertical pipe of the fine ash separator; an ash buffer tank is arranged below the fine ash separator, the ash buffer tank is connected with the vertical pipe of the fine ash separator througha connecting pipeline, a rotary sealing valve is arranged on a connecting pipeline between the ash buffer tank and the fine ash separator, an ash discharge pipeline is arranged at an ash discharge port below the ash buffer tank, and an electric flashboard door is arranged on the ash discharge pipeline. The system is used for recovering sensible heat of fine ash, and positive-pressure cold ash is safely discharged.

Owner:HARBIN BOILER

Lithium iron phosphate battery thermal runaway monitoring system based on information fusion

ActiveCN114824537AAvoid spreadingReduce misjudgmentCell temperature controlElectrical testingLithium iron phosphateHeat Avoidance

The invention discloses a lithium iron phosphate battery thermal runaway monitoring system based on information fusion, the position of a battery cell group where a problem battery cell is located is found by monitoring the voltage and current change of the battery cell group, temperature abnormity is found in time by monitoring the temperature and the temperature rise rate of the corresponding battery cell group, and the thermal runaway of the lithium iron phosphate battery is monitored by combining the two modes. The misjudgment condition can be reduced, the problem battery cell group can be found in time, the thermal runaway phenomenon is prevented from being further diffused and spread, and the loss is reduced; in addition, the buffer space is subjected to air exhausting treatment in advance, so that the reaction speed is increased, the requirements for the vacuum degree in the buffer space and the diluting device and the filling degree of inert gas are reduced, combustible gas is exhausted after being diluted, detonation accidents can be avoided, and losses caused by thermal runaway of the battery are reduced.

Owner:深圳市明泰源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com